SMA to BNC Adapter: 50Ω Straight & Right-Angle Options

Sep 23,2025

Introduction

This image is shown in the document introduction as one of the most common adapter types for connecting precision instruments to field equipment, emphasizing the importance of correct adapter selection to avoid measurement errors and equipment damage.

Verify gender, series, and 50-ohm matching before you buy

This image complements the text explaining the importance of impedance matching. This SMA female connector is a fundamental component of the SMA-to-BNC adapter, ensuring signal integrity in the RF link.

This diagram serves to warn readers that BNC connectors come in both 50 Ohm and 75 Ohm impedance variants. Mixing a 75 Ohm BNC with a 50 Ohm SMA adapter will cause impedance mismatch, leading to signal reflection and measurement errors.

Take TEJTE’s BNC/SMA-KKY feedthrough adapter as an example. Built with a 1/4-36 UNS-2A SMA thread, it maintains a precise 50-ohm path from DC to 6 GHz. Now imagine pairing it with a 75-ohm bnc connector. The two will mate physically, but the electrical mismatch reflects power back into your chain. On a spectrum analyzer trace, that reflection shows up quickly once you pass a few hundred megahertz.

Gender direction matters just as much. Are you moving from SMA male to BNC female, or the reverse? Instruments like analyzers usually carry a sma connector with a female jack, which means you’ll need a male-to-female adapter. Oscilloscopes, on the other hand, expect BNC female jacks, flipping the direction you’ll require.

Field tip: always confirm you’re using a 50 ohm coax connector, not a 75 Ω video-grade type. Many engineers, myself included, keep both sma female to bnc male adapters and sma male to bnc female adapters in the toolbox. Having spares may feel unnecessary—until you’re in the lab late at night and realize the genders don’t line up.

For a deeper look at connector standards and pitfalls, see the RF connector families overview.

Confirm your direction (SMA-M to BNC-F, SMA-F to BNC-M, or reverse)

Direction mistakes are easy to make but costly in time. A SMA-M to BNC-F adapter isn’t interchangeable with a SMA-F to BNC-M, and realizing the mix-up after installation means tearing everything down.

To keep things clear:

This diagram specifies the typical usage direction of an SMA male to BNC female adapter, helping users correctly select the adapter gender based on their equipment interfaces (e.g., instrument port is SMA female, cable end is BNC male).

- A sma male to bnc female adapter is typically used when connecting spectrum analyzers or RF instruments with SMA ports to test cables that terminate in BNC.

This image shows the opposite gender configuration to Figure 4, suitable for scenarios where the device has a BNC female interface that needs to connect to an SMA male cable or port, emphasizing the importance of verifying the connection direction.

- A sma female to bnc male adapter fits the opposite case, such as when your device has a BNC output but the rest of your setup relies on SMA inputs.

It might sound trivial, but many engineers discover they ordered the wrong piece only when they’re already on-site. That’s why checking the datasheet—or simply inspecting the pin and socket before ordering—saves plenty of frustration. Even a flashlight check of the connector face can help avoid errors.

Practical tip: label your adapters. In a dim lab or server room, it’s hard to tell SMA male from female at a glance. A bit of tape or a small marker tag can save you from fumbling and delays.

For more on preventing polarity mistakes, see verify polarity & series before buying.

Choose straight or right-angle (90°) to solve mechanical clearance

Clearance is often the hidden challenge in RF setups. Inside enclosures or along crowded panels, there’s rarely enough room to run a connector straight in without forcing the cable. This is where the choice between straight and right-angle sma to bnc adapters becomes important.

When space allows, a straight adapter is the simplest and cleanest option. But in tight racks or gear mounted flush to a wall, a 90 degree sma to bnc adapter prevents strain on the port and avoids bending cables at dangerous angles. TEJTE’s right-angle models are tested with ≤0.2 dB insertion loss up to 6 GHz, so you gain clearance without compromising performance.

Sometimes you’ll see 45° or 135° adapters as well. These aren’t gimmicks; they solve clearance issues where neither straight nor 90° works. In compact RF boxes, angled adapters can mean the difference between a working build and a failed layout.

From personal experience: I’ve seen PCB-mounted SMA jacks ripped clean off because someone forced a straight adapter where it didn’t fit. Spending a few dollars on the right-angle option would have saved an expensive repair and hours of downtime.

For more tips on fitting connectors in cramped layouts, check our guide on solving clearance issues with right-angle vs short pigtail.

Will a short RG316/LMR pigtail outperform a rigid block in loss and stress?

Electrical performance is only half the story. A rigid right-angle block sma to bnc adapter is compact, but it acts like a lever. Every bump, vibration, or accidental tug turns into torque on the port. Over time, that stress can loosen the joint or even crack the connector pad on a PCB.

A short coaxial pigtail, by contrast, absorbs force while still carrying the signal. Consider RG316: it’s highly flexible, supports temperatures up to 150 °C, and has about 1.46 dB/m loss at 2.4 GHz and 2.34 dB/m at 6 GHz. A 0.15 m jumper adds roughly 0.22 dB at 6 GHz—less than the mismatch you might see if a rigid block is paired with the wrong impedance BNC.

Here’s a side-by-side comparison:

| Cable Type | Loss @ 2.4 GHz | Loss @ 6 GHz | Typical Use |

|---|---|---|---|

| RG316 (2.5 mm OD) | 1.46 dB/m | 2.34 dB/m | Flexible, high-temp, test gear |

| RG174 (2.85 mm OD) | ~1.21 dB/m (scaled) | ~1.67 dB/m (scaled) | Low-cost, indoor setups |

| LMR-200 (4.95 mm OD) | ~0.45 dB/m | ~0.9 dB/m | Low-loss, outdoor runs |

From field experience: in portable test kits, I always carry a couple of RG316 jumpers. They add a fraction of a dB but can save delicate front-panel jacks from mechanical damage. That trade-off is almost always worth it.

For more attenuation data across coax options, see our RF coaxial cable guide.

Do you need a bulkhead/panel feedthrough for enclosure pass-throughs?

Whenever your design involves an enclosure—be it a router, base station, or a portable test box—you’ll likely need a bulkhead sma to bnc adapter. These adapters let the connection pass through a panel wall and secure with a nut or flange, creating a stable and repeatable interface.

Take TEJTE’s SMA-KKF flange-mount BNC adapter (Part No. 59685) as an example. It uses a 23.7 mm flange diameter with 12.7 mm hole spacing, making it suitable for most instrument panels. Another option, the SMA-KKY bulkhead type (Part No. 59683), features a 1/4-36 UNS-2A threaded shaft with dual hex nuts, allowing safe mounting on panels up to 3 mm thick.

These dimensions matter. If your panel is thicker than the thread length, the nut won’t seat correctly. If it’s too thin, over-tightening can warp the chassis wall. I’ve seen teams re-drill perfectly good panels simply because they skipped this small check.

Quick advice: measure your panel thickness first, then match it to the bulkhead adapter specs. This five-minute step prevents wasted hardware and frustration.

For more details on feedthrough and flange mounting options, see our panel mount and flange connector guide.

Is an IP-rated SMA-to-BNC adapter necessary outdoors?

Not every project requires waterproofing, but once your setup leaves the lab, conditions change. If you’re mounting antennas on rooftops, running outdoor CPE links, or installing surveillance systems, a waterproof sma to bnc adapter with an O-ring seal is a safer bet. Moisture doesn’t just cause corrosion—it shifts impedance, raises VSWR, and degrades signal quality over time.

TEJTE’s flange and bulkhead models are available with red silicone O-rings, designed to keep out rain and dust. Combined with an IP67-rated enclosure, these adapters prevent water ingress from becoming your weakest link. Stainless-steel housings also offer an edge outdoors, resisting corrosion that quickly tarnishes brass in salty or polluted air.

Indoors, you can keep things simple. A brass gold-plated sma to bnc adapter works perfectly for rack-mounted test gear or lab instruments. But outside, investing a few dollars more in sealing quickly pays off.

From practical experience: I’ve seen outdoor Wi-Fi bridges fail in under six months because standard adapters were used. A $6 IP-rated part could have saved hundreds in service costs.

For more advice on outdoor-rated connectors and antennas, see our RF antenna guide.

Match frequency rating and materials for 6/18/26.5 GHz service

This image shows a gold-plated version of the adapter. Combined with the text, this type offers excellent conductivity at a lower cost, making it ideal for rack-mounted test gear or lab instruments indoors.

The diagram shows a stainless steel adapter. According to the document, the stainless steel housing offers better torque stability and thread durability, particularly suitable for high-frequency (e.g., 18GHz or 26.5GHz) applications or situations requiring frequent mating cycles.

This image shows a nickel-plated adapter. The text indicates this is a cost-effective option, but it has higher contact resistance compared to gold-plated versions, making it suitable for applications where extreme precision is not critical.

TEJTE’s SMA/SMP-KJ adapter (Part No. 31437), for instance, maintains ≤1.2 VSWR from DC to 6 GHz, with a safe temperature range of −40 °C to +125 °C. For higher frequencies, stainless steel housings are preferred because they provide torque stability and thread durability, while brass gold-plated adapters offer excellent conductivity at a lower cost. Nickel-plated brass sits in between: economical, but less ideal for high-frequency precision.

Here’s a quick comparison:

| Adapter Material | Typical Finish | Durability | Notes |

|---|---|---|---|

| Brass, gold-plated | Au over Ni | Moderate | High conductivity, budget-friendly |

| Stainless steel | Passivated | High | Rugged threads, long service life |

| Brass, nickel-plated | Ni | Medium | Cost-effective, higher contact resistance |

Practical reminder: using a 6 GHz 50 ohm coax connector in a 26.5 GHz test path doesn’t just reduce accuracy—it may completely hide weak signals you’re trying to measure. Always match the adapter’s frequency rating to your application.

For more connector specification details, see our SMA connector cutouts & thread guide.

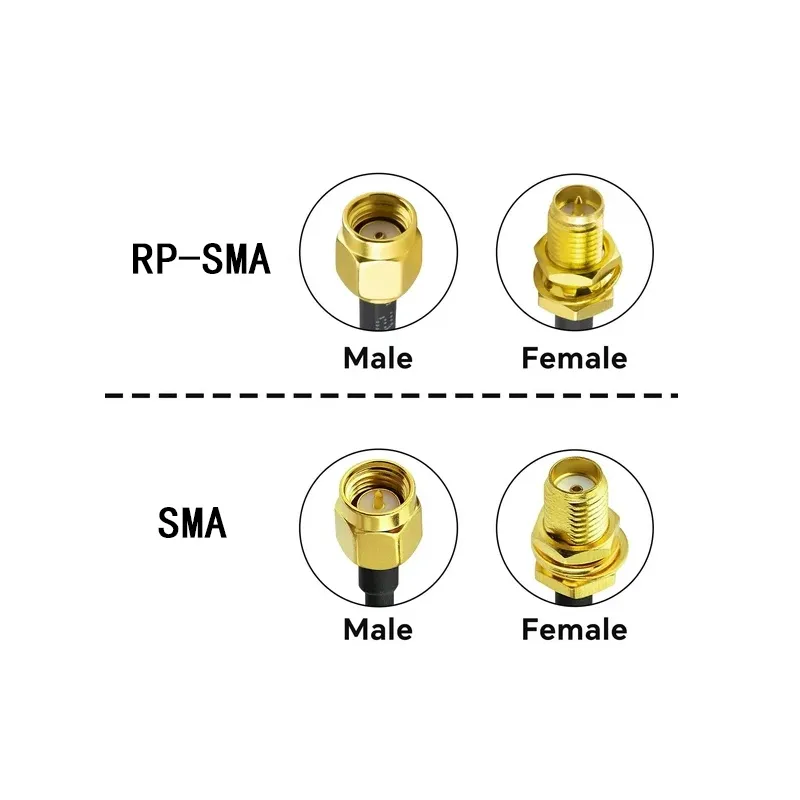

Avoid RP-SMA mix-ups and cross-series pitfalls before checkout

This comparison chart clearly illustrates the fundamental difference in internal pin/socket definitions between RP-SMA and standard SMA, serving to warn readers against mixing them up, which could prevent mating or damage equipment ports.

One of the most common errors engineers make is mixing up a standard sma to bnc adapter with an rp-sma to bnc adapter. At a glance they look almost identical, but the pin and socket orientation is reversed. If your Wi-Fi router uses an RP-SMA jack, a normal SMA plug simply won’t fit—no matter how much you twist it.

The best defense is to check both the thread type and the center conductor before ordering. TEJTE’s catalog separates SMA and RP-SMA clearly, so you can avoid last-minute surprises.

Cross-series transitions can be another trap. It’s tempting to connect SMA into UHF, N-type, or TNC with whatever adapter looks right, but the mismatch can introduce reflections and high VSWR. In these cases, a coaxial cable adapter—for example, a short RG316 jumper with SMA and BNC ends—is the safer path. It adds minimal loss while protecting the port from mechanical stress.

From field lessons: I once saw a junior engineer force an RP-SMA into an SMA jack and then spend hours troubleshooting “mystery” signal loss. A two-second visual check would have solved the problem.

For more on identifying gender and polarity issues, see our guide on verifying polarity & series before buying.

Calculate mismatch, clearance, and torque before you order

Choosing a sma to bnc adapter isn’t guesswork—you can run simple checks before buying. By calculating mismatch, clearance, and torque, you’ll know whether an adapter or a short jumper makes more sense for your setup. That’s the idea behind the SMA to BNC Fit & Mismatch Planner.

Inputs worth checking:

- Direction: SMA-M to BNC-F or SMA-F to BNC-M

- Angle: Straight, Right-Angle, 45°, 135°

- Impedance: Z_SMA = 50 Ω, Z_BNC = 50 or 75 Ω

- Frequency: 2.4, 5.8, 18, 26.5 GHz

- Insertion Loss: adapter typically 0.15–0.2 dB

- Coaxial alternatives:

- RG316: 1.46 dB/m @ 2.4 GHz; 2.34 dB/m @ 6 GHz

- RG174: ~13 dB/100 m @ 100 MHz, scaling up to ~167 dB/100 m @ 3 GHz

- LMR-200: ~0.45 dB/m @ 2.4 GHz, ~0.9 dB/m @ 6 GHz

- Torque: SMA threads rated at 0.56–0.79 N·m

Formulas in play:

- Mismatch Loss = −10·log10(1 − Γ²), where Γ = |(Z_BNC − Z_SMA)/(Z_BNC + Z_SMA)|

- Lever Arm Moment M ≈ (Mass × 9.81 × Protrusion)/1000 N·m

Example:

At 6 GHz, a 0.15 m RG316 jumper adds about 0.22 dB. A rigid adapter block might show 0.2 dB insertion loss plus ~0.3 dB mismatch if used with a 75 Ω BNC. The jumper wins in both loss and mechanical safety.

Quick lesson learned: don’t ignore clearance. If an adapter sticks out 25 mm but your chassis clearance is only 20 mm, you’ll be reaching for the drill. A five-minute check with calipers can save you an afternoon of frustration.

For more attenuation references, see our RF coaxial cable guide.

Install and torque the adapter without detuning your port

Even the highest-grade sma to bnc adapter won’t perform as intended if it’s installed incorrectly. SMA threads are small and delicate—overtighten them and you risk stripping the plating or cracking the PCB pad underneath. Leave them too loose and vibration can shift the joint, detuning your signal chain.

The correct approach is straightforward. Start threading by hand to avoid cross-threading. Once it’s finger-tight, finish with a torque wrench set to 0.56–0.79 N·m. This range secures the joint without crushing the interface. Stainless steel adapters are more forgiving under repeated tightening, while brass gold-plated models conduct extremely well but can deform if forced past their limit.

A quick field story: I once watched a colleague grab pliers to “make sure it was tight.” The connector held for a few hours, then failed catastrophically. A $40 torque wrench would have saved us both the downtime and the repair bill.

After installation, run a quick return loss or VSWR sweep if the adapter is part of a measurement setup. Even slight misalignment can alter readings above a few gigahertz. Many engineers who test daily keep a compact torque wrench in their travel kits—it’s cheap insurance for consistent results.

For detailed connector handling techniques, see our guide on SMA male connectors and PCB mounting.

When should you choose a right-angle bulkhead instead of straight + pigtail?

Designers often face this choice: do you mount a right-angle bulkhead sma to bnc adapter, or pair a straight bulkhead with a short jumper cable? Both work, but the right pick depends on space, torque, and sealing.

If panel clearance is tight, a 90° bulkhead adapter is usually the cleaner option. It reduces protrusion, keeps wiring compact, and simplifies enclosure layouts. TEJTE’s flange-mount bulkhead designs even include O-rings for IP sealing, making them well-suited to outdoor or ruggedized equipment.

On the other hand, if the application involves frequent vibration or handling, a straight bulkhead plus a 0.1 m RG316 coaxial cable adapter distributes stress more evenly. The jumper absorbs the movement instead of letting torque act directly on the SMA threads. This approach is common in field-deployed gear or portable test kits where connectors see daily strain.

Practical takeaway: use a right-angle bulkhead when clearance and sealing are critical, but rely on straight + pigtail when mechanical reliability matters most.

For further design insights, check our panel mount and flange connector guide.

FAQs

Engineers often raise the same questions before ordering a sma to bnc adapter. Here are the answers drawn from both specs and hands-on experience:

Will a 50-to-75-ohm mismatch distort my scope readings?

Yes. Above 1 GHz the mismatch becomes noticeable, showing up as reflected power and measurement error. Stick to 50 Ω BNC for RF; 75 Ω is fine for video distribution but not precision RF testing.

When should I pick a right-angle instead of straight?

Use a 90 degree sma to bnc adapter when clearance is limited, such as inside crowded racks. For fragile ports, a straight adapter paired with a short RG316 jumper is safer.

Is a short RG316 safer than a rigid block?

Usually yes. At 6 GHz, a 0.15 m RG316 adds only ~0.22 dB, but it protects the SMA port from bending forces. This trade-off is often worth it in portable or high-vibration setups.

Do stainless-steel adapters impact VSWR compared with brass gold-plated?

Performance is similar, but stainless threads last longer and maintain torque better. Brass is excellent for conductivity but wears faster under repeated tightening.

What torque should I apply on SMA threads?

Finger-tight first, then finish with a torque wrench at 0.56–0.79 N·m. More than that risks damage.

Do I need IP-rated adapters outdoors?

Yes—unless your enclosure already seals around the connector. For outdoor CPE, antennas, or cameras, always use O-ring sealed or IP-rated adapters.

For deeper background on connector standards and related topics, see the RF connector families overview.

Conclusion

A sma to bnc adapter may look like the simplest piece in your RF toolkit, but choosing the wrong type can cause ripple effects far beyond a loose fit. Impedance mismatches, gender confusion, or ignoring torque and sealing can all compromise accuracy—or worse, damage expensive equipment.

The best approach is systematic:

- Verify connector gender and impedance before ordering.

- Match the geometry—straight, right-angle, or jumper—to your space constraints.

- Check frequency rating and material; don’t expect a 6 GHz adapter to hold up at 26.5 GHz.

- Install carefully with the right torque, and use IP-rated options when the environment demands it.

From experience: many engineers only learn the hard way that saving a few dollars on the wrong adapter can cost hundreds in retests or repairs. Taking a few minutes to plan saves both time and budget.

TEJTE offers a complete range—from panel bulkhead SMA-to-BNC adapters to IP67-rated outdoor versions—so you can match the right solution to your application. Explore our RF adapter product line or check related resources like the SMA right-angle guide for more design tips.

In RF work, small details make a big difference. Choose carefully, install correctly, and your adapters will keep your measurements honest—whether you’re in the lab, the field, or scaling up a deployment.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.