50 Ohm Coax Cable for SMA: RG174 vs RG316 vs LMR-200

Sep 25,2025

Introduction

The image introduces how choosing SMA coax involves trade-offs among attenuation, bend radius, and outdoor sealing—helping avoid “cheap now, expensive later.”

Choosing the right 50 ohm coax cable for SMA gear isn’t just about grabbing whatever fits the connector. It’s a balancing act—attenuation, flexibility, outdoor sealing, and connector type all pull in different directions. Some engineers chase the lowest loss at high GHz, while others care more about bending a cable inside a tight router box.

This guide lays out where RG174, RG316, and LMR-200 make sense, when a wifi antenna extension cable is good enough, and how to size both length and bend radius before adding anything to your cart. The goal isn’t to oversell one option, but to help you avoid the common trap of “cheap now, expensive later.” If you’ve ever had to rewire a mast because the jumper couldn’t survive the weather, you already know how costly that mistake can be.

Define your goal—range, bandwidth, flexibility, or outdoor survivability?

Every coax purchase should start with a plain question: what’s the main job? A half-meter jumper inside a PCB housing doesn’t live the same life as a five-meter feeder strapped to a rooftop pole. The sooner you map that reality, the easier it gets to choose the right line.

- Range & bandwidth. For long outdoor links at 5.8 GHz—or even pushing into 18 GHz—the dB per meter is what keeps or kills your link margin.

- Flexibility. In cramped boxes, bend radius is king. RG174 curls down to ~28 mm, while RG316 manages tighter loops at ~15 mm thanks to its PTFE insulation. That difference can be the deciding factor in small IoT boards.

- Outdoor survivability. Rain, sunlight, and vibration punish cables quickly. Unless you use a UV-resistant jacket and an ip rated seal, a “lab-only” jumper can wick moisture into its braid within months.

- Lab use. For instrument jumpers, RG316 often strikes the sweet spot—stable, reasonably low loss, and flexible enough to move around test benches without failing early.

Pro tip: Always leave headroom. Today’s WiFi box may live at 2.4 GHz, but tomorrow’s design might push 5G NR or 6 GHz WiFi. Choosing with that future in mind saves you from tearing down and re-pulling cables later.

Should you pick RG174, RG316, or LMR-200 for minimum loss and safe bending?

The image highlights LMR-200 with foamed dielectric and dual shielding—preferred for rooftop WiFi, GSM/4G/5G small cells where low loss and IP-ready builds matter.

The image shows RG316 as a lab/IoT favorite—stable PTFE dielectric, compact OD, and easy routing in tight enclosures.

The image positions RG174 for short in-box extensions—very flexible, but loss rises quickly at higher GHz and longer runs.

The real decision between RG174, RG316, and LMR-200 comes down to three things: attenuation, size, and how much bending the cable can survive. Engineers sometimes assume “all 50 ohm coax cables are equal,” but the numbers tell a very different story.

Here’s a side-by-side look based on actual datasheets:

| Cable Type | Outer Diameter (mm) | Attenuation @2.4 GHz (dB/m) | Attenuation @5.8 GHz (dB/m) | Min. Bend Radius (mm) | Temp Range | Notes / Typical Use |

|---|---|---|---|---|---|---|

| RG174 | 2.85 | ~1.47 | ~1.67 | ≥28 | -20 ~ +70 ℃ | Small, low-cost, works for short jumpers or tight spaces |

| RG316 | 2.50 | ~1.46 | ~2.15 | ≥15 | -65 ~ +150 ℃ | Flexible, heat-resistant, great for IoT and lab setups |

| LMR-200 | 5.00 | ~0.20 | ~0.35 | ≥25 (static) / 50 (dynamic) | -20 ~ +80 ℃ | Outdoor feeder, very low loss, supports IP67 builds |

From the table, you can see the trade-offs clearly. RG174 extension cable is light and bends like a shoelace, but at 2.5 m on 5.8 GHz, it swallows nearly 4 dB of signal. RG316 doubles the temperature range and improves stability, but it’s still lossy at high GHz. LMR-200, with its foamed dielectric and dual shielding, keeps attenuation down and shielding up—making it the go-to for WiFi access points, GSM/4G repeaters, and 5G small cells.

If you want to dig deeper into how connector choices also change performance, take a look at our RF Connector Guide. It explains why the wrong SMA termination can undo the advantage of even the best coax.

Will an RG174 extension cable be “good enough” at 2.4/5.8 GHz?

It’s a common question: can you rely on a simple RG174 extension cable for WiFi or IoT projects? On paper, it looks attractive—OD just 2.85 mm, bends down to 28 mm, and the price is low. But once you check the attenuation numbers, the trade-off becomes obvious.

From TEJTE’s test data:

- At 2.4 GHz, RG174 drops about ~1.47 dB per meter.

- At 5.8 GHz, loss climbs to ~1.67 dB per meter.

- Add two SMA connections (≈0.2–0.3 dB), and a 2 m run costs nearly 3.5 dB in total.

What does that mean in practice? If you’re just linking a router to a nearby antenna, you may never notice the difference. But if the same cable is feeding a drone’s FPV transmitter or an outdoor AP stretched to its range limit, that extra 3 dB could be the difference between a clean link and random dropouts.

For short runs—under 1 m—RG174 is still perfectly serviceable. Many installers use it inside enclosures where flexibility matters more than squeezing every last dB. Once you cross that length, though, it’s smarter to step up. RG316, with its PTFE dielectric and -65~150 ℃ rating, balances flexibility and stability; while LMR-200, with only ~0.35 dB/m loss at 5.8 GHz, is the clear winner for longer feeds.

We cover this trade-off in more depth in our SMA Extension Cable Guide, where you can see how cable type and length interact with link margin.

Will a wifi antenna extension cable hurt 5 GHz performance on short runs?

Grabbing a wifi antenna extension cable is often the fastest way to move an antenna away from metal housings or tight enclosures. The question most people ask: does that short extension ruin performance at 5 GHz?

For runs under a meter, the impact is usually small. Even RG174, with ~1.67 dB/m attenuation at 5.8 GHz, will cost you less than 1 dB over that distance. In a typical WiFi router or IoT gateway with 15–20 dB fade margin, that extra loss barely dents performance.

Stretch the cable beyond 2 m, though, and things shift quickly. At 5.8 GHz:

- RG174 adds roughly 3.5 dB of loss.

- RG316 climbs even higher, around 4.3 dB.

- LMR-200, by contrast, still stays under 1 dB at the same length.

This is why professional outdoor installers prefer LMR-200 jumpers with IP67 bulkhead seals. They balance low loss with weather resistance, making them suitable for rooftop WiFi, GSM, or 5G antennas. Indoors, where cables are short and flexibility matters more, a simple RG174 pigtail often does the job without issue.

For field installers: if your jobsite is less than a meter of extension and protected from weather, you’ll rarely regret using RG174. But if it’s a permanent outdoor run, stepping up to LMR-200 saves you a lot of future headaches. More details on sealing and outdoor practices are in our SMA to N Adapter Weatherproof Guide.

Size the length to meet your loss budget before you add to cart

The image emphasizes doing the math—e.g., at 5.8 GHz a 2 m run of RG174 approaches ~3.5 dB with connectors—so longer outdoor links should step up to LMR-200.

Buying any 50 ohm coax cable without thinking about length is like swiping a credit card without checking your balance—you’ll pay for it later. Each meter of coax “spends” part of your system’s link margin. Once that budget runs out, no antenna gain or amplifier can save the signal.

From the real attenuation data you provided:

- RG174: ~1.47 dB/m @2.4 GHz, ~1.67 dB/m @5.8 GHz

- RG316: ~1.46 dB/m @2.4 GHz, ~2.15 dB/m @5.8 GHz

- LMR-200: ~0.20 dB/m @2.4 GHz, ~0.35 dB/m @5.8 GHz

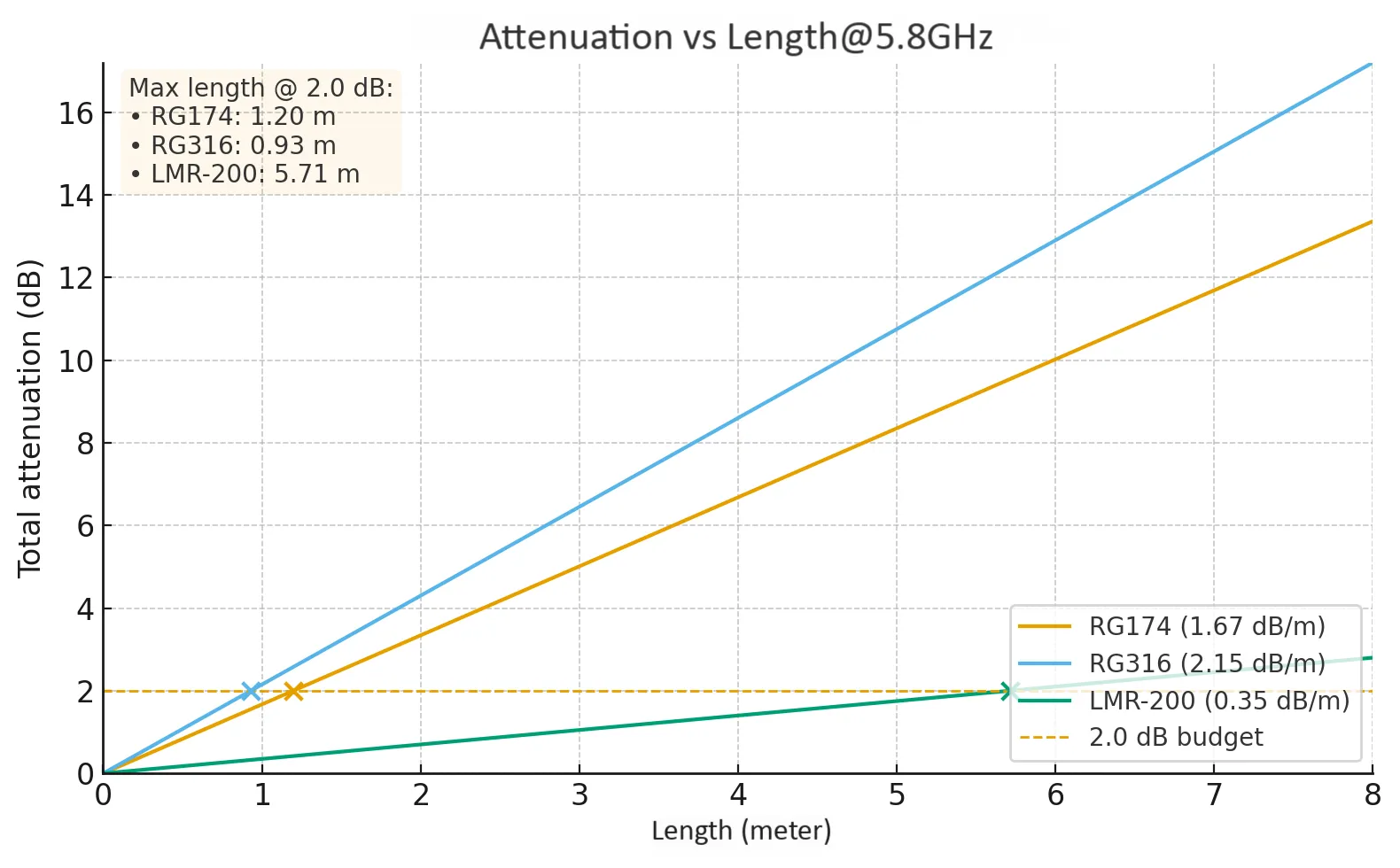

Now let’s do the math with a 2 dB loss budget:

- RG174 → only ~1.2 m at 5.8 GHz before you blow the budget.

- RG316 → even shorter, about 0.9 m.

- LMR-200 → stretches much farther, up to ~5.5 m at 5.8 GHz.

That comparison makes the decision obvious. If you’re just running a short jumper inside an enclosure, RG174 or RG316 will work fine. But once your design needs more than 2 m, only LMR-200 gives you enough breathing room.

Field tip: Always add connector losses into the math (0.1–0.2 dB per SMA pair). Many engineers forget this and end up chasing “mystery dB” in the field. To make planning easier, check our RF Coaxial Cable Guide where we break down formulas and show how to back-calculate maximum length before ordering.

Do you need an ip rated outdoor build with strain relief and seals?

Once a 50 ohm coax cable leaves the bench and heads outdoors, the environment starts fighting back. Sunlight hardens PVC jackets, rain finds its way into connectors, and temperature swings stress the dielectric. If the assembly isn’t ip rated, failure is only a matter of time.

A reliable outdoor jumper usually includes:

- O-rings or silicone rubber seals around SMA or N-type bulkheads (TEJTE’s O-type seals are tested to 1000 V rms).

- Boots or heat-shrink sleeves to absorb strain at the connector transition.

- Drip loops that guide water away instead of letting it pool at the feed-through.

- UV-resistant jackets such as polyethylene (PE), which last longer than standard PVC under constant sun.

Take LMR-200 as an example: foamed PE dielectric, tinned copper braid, and black PVC/PE jackets make it far more suitable for WiFi, GSM, or 5G rooftop runs than RG174, which is limited to -20 ~ +70 ℃ and has weaker moisture resistance.

Installers often share the same rule of thumb: if it looks overbuilt for the weather, it’s probably just right. Skimping on sealing may save a few dollars today, but replacing a flooded cable or corroded SMA port can cost far more. For detailed practices, see our SMA to N Adapter Weatherproof Guide.

Choose ends that fit—go with an sma pigtail, bulkhead, or in-line coupler

Cable choice is only half the equation; the connector style you pick can make or break the build. An sma pigtail is often the best solution when routing between a PCB and an enclosure wall. Its PTFE dielectric and gold-plated contacts keep insertion loss low—typically under 0.15 dB up to 6 GHz—while still giving you the flexibility that rigid adapters can’t.

- Bulkhead SMA. Perfect for passing through panels or enclosures. TEJTE offers variants with tooth lengths of 8.5 mm or 17 mm, so you can match wall thickness without stripping threads.

- In-line coupler. A quick way to extend an existing jumper without rerouting. While it adds ~0.1–0.2 dB, it’s practical in lab setups where space isn’t tight.

- Custom pigtails. When your enclosure layout demands exact lengths or right-angle options (90° or 135°), ordering a tailored sma pigtail prevents sharp bends that raise VSWR.

Real-world reliability matters here. TEJTE’s bulkhead SMA connectors are tested for ≥500 mating cycles, 335 V rms withstand, and inner conductor resistance ≤5 mΩ. Numbers aside, this means you won’t have to worry about a feedthrough wearing out before the cable does.

A simple tip from installers: think about serviceability. A well-placed bulkhead lets you swap antennas in minutes, while a poorly chosen coupler could add hours to future maintenance. For more connector selection guidance, check our RF Adapter Cable product line.

Avoid mismatch—confirm 50 Ω from radio to antenna, including jumpers

One silent killer of RF performance is impedance mismatch. A chain that mixes 50 Ω and 75 Ω cables may look fine at a glance, but electrically it’s a troublemaker. Reflections creep in, VSWR climbs, and suddenly your “good” 50 ohm coax cable doesn’t behave the way you expected.

To stay safe:

- Verify every piece in the chain is 50 Ω—from the radio, through jumpers, to the antenna feed.

- Always factor in 0.1–0.2 dB per SMA connection when calculating your total coax attenuation.

- Watch out for SMA vs RP-SMA confusion; they may screw together, but they won’t match electrically.

A practical note: TEJTE’s SMA connectors are tested to deliver return loss better than 21 dB (VSWR ≤1.1:1) straight through 6 GHz. That level of matching keeps LTE and 5G systems stable under load. By contrast, slipping in a 75 Ω TV patch cable can drag that return loss into the danger zone, sometimes without you realizing until field tests fail.

Installer’s tip: if you’re ever unsure about a cable’s impedance, don’t guess—check the datasheet or sweep it on a handheld VNA. The five minutes you spend there can save you hours of troubleshooting later. For a broader look at connector families and their impedance traps, see our RF Connector Guide.

Calculate attenuation, bend radius, and power headroom before routing

The image shows a 50-ohm coaxial cable used with SMA connectors. In this guide, cable selection balances three factors: loss over length, bend routing inside enclosures, and outdoor readiness. Flexible RG-series cables suit tight builds, while low-loss feeder types are preferred for longer or outdoor runs.

The smartest way to choose a 50 ohm coax cable isn’t to guess—it’s to calculate. Every datasheet lists attenuation, bend radius, and power handling. Put those numbers together, and you’ll know right away whether RG174, RG316, or LMR-200 fits your project.

Here’s a condensed snapshot from TEJTE’s data (20 ℃, sea level):

| Checkpoint | Recommended Value / Action | Why it matters |

|---|---|---|

| Direction | SMA-M to TNC-F / TNC-M to SMA-F | Avoids gender mismatch |

| Impedance | 50 Ω to 50 Ω preferred | Prevents reflections |

| Mismatch loss | ~0.2 dB if 50 Ω to 75 Ω @ 2.4 GHz | Skews test accuracy |

| Insertion loss | <0.2 dB @ 2.4 GHz (TEJTE flange) | Keeps efficiency high |

| Clearance | 30.5 mm protrusion | Check panel space |

| Torque | 0.45–0.56 N·m (brass) | Protects SMA port |

| Outdoor use | IP67 with O-rings | Blocks moisture & corrosion |

Now apply the planner before you order:

- IL_cable = Alpha(f) × L

- IL_total ≈ IL_cable + 2 × Conn_Loss (0.1 dB each)

- Pass_loss = IL_total ≤ Loss_Budget_dB

- Min_Bend_Radius = OD × factor (5–10×)

Example: For a 3 m run at 5.8 GHz with ≤2 dB loss:

- RG174 → 3 × 1.67 = 5.0 dB → fails.

- RG316 → 3 × 2.15 = 6.5 dB → fails.

- LMR-200 → 3 × 0.35 = 1.05 dB → passes.

Installer tip: Don’t forget dynamic vs static bend radius. A coax bent safely on the bench might still fail after weeks of vibration in the field. That’s why rooftop crews often jump straight to LMR-200 or thicker cables like LMR-400. For more formulas and ready-to-use calculators, check our RF Coaxial Cable Guide.

Install and torque connectors without detuning the SMA port

Even the best 50 ohm coax cable will underperform if the connectors are mishandled. SMA ports are precise, threaded, and surprisingly easy to damage. TEJTE’s specs show insertion loss ≤0.15 dB up to 6 GHz and ≥500 mating cycles—but those numbers only hold if you install and torque the connectors correctly.

Here’s what seasoned engineers stick to:

- Hand-start every thread. Cross-threading happens fast, and once the SMA port is stripped, there’s no easy fix.

- Torque to spec (≈8 in-lbs). Too tight, and you risk cracking the PTFE dielectric; too loose, and micro-gaps raise VSWR.

- Strain-relieve the cable. Use a clamp or zip tie to keep tension off the SMA body. Without relief, the coax acts like a lever arm that can tear the connector loose.

- Re-check VSWR after install. A quick sweep confirms nothing shifted. Skipping this step is how hidden faults sneak into production.

Field tip: A small SMA torque wrench costs far less than a damaged instrument port. Many labs keep one on every bench for that reason. For more practical connector handling details, check our SMA Connector Dimensions & Thread Guide.

When should you choose an sma extension cable instead of an adapter chain?

The image illustrates that stacking several M-F/angle/bulkhead adapters adds ~0.1–0.2 dB each and mechanical stress; a single matched SMA extension keeps loss and strain under control.

It’s tempting to build a signal path from a handful of adapters—SMA male to female, a right-angle elbow, maybe a bulkhead. On paper, it works. In reality, every adapter adds ~0.1–0.2 dB of loss and puts extra stress on the mating port. Over time, that stress can do more damage than the dB loss itself.

A single sma extension cable often solves the problem. Flexible, length-matched, and with insertion loss under control, it replaces multiple rigid adapters with one clean jumper. On a 5.8 GHz drone link, for example, swapping three adapters (≈0.5 dB combined) for a 20 cm RG316 extension not only halved the loss but also spared the SMA port from cracking under vibration.

Rule of thumb:

- Two adapters or fewer → usually fine.

- Three or more → switch to a proper extension cable.

Engineers who ignore this end up with broken PCB-mounted connectors or puzzling loss that doesn’t match the math. If you’re looking for deeper comparisons between short jumpers and adapter stacks, see our SMA Extension Cable Length & Loss Guide.

FAQ

How long can I run RG174 at 5.8 GHz before loss kills my link margin?

At 5.8 GHz, RG174 averages ~1.67 dB/m attenuation. Add two SMA ends, and a safe limit is about 1.2–1.5 m before you exceed a 2 dB budget. Anything longer risks dropped packets or unstable video links. For outdoor feeders, most installers jump to LMR-200, which holds loss below 1.1 dB over 3 m. You can see planning tools in our RF Coaxial Cable Guide.

Is RG316 a drop-in upgrade over RG174, or should I jump to LMR-200 instead?

RG316 does improve thermal stability (rated -65~150 ℃) and offers tighter bend radius (15 mm vs 28 mm), but its loss isn’t dramatically better. At 5.8 GHz, it’s even higher than RG174. For short IoT jumpers, it’s fine. For anything beyond 2 m, LMR-200 is the safer long-term choice. A full breakdown is in our RG316 Coaxial Cable Guide.

Will a short wifi antenna extension cable work as well as a rigid SMA adapter chain?

Yes. For runs under 1 m, a wifi antenna extension cable usually performs better than stacking rigid adapters. Each adapter adds ~0.1–0.2 dB and mechanical stress, while a single jumper keeps loss and strain down. For outdoor runs, pair the extension with an IP67-rated bulkhead. More comparisons are in our SMA Extension Cable Length & Loss Guide.

What’s a safe minimum bend radius for these cables inside crowded enclosures?

Follow the 5–10× outer diameter rule:

- RG174 → ≥28 mm

- RG316 → ≥15 mm

- LMR-200 → ≥25 mm (static) / ≥50 mm (dynamic)

Bend tighter than that, and you’ll risk pinching the dielectric and raising VSWR. If your layout forces sharp turns, consider a right-angle adapter—our SMA Right Angle Adapter Guide covers those cases.

Do I need an ip rated jumper outdoors if my antenna feed-through is already sealed?

Yes. Even with a sealed bulkhead, moisture can wick into unprotected PVC jackets. An ip rated 50 ohm coax cable with O-rings and UV-stable PE jackets resists both water and sunlight. It’s the difference between a stable link and corrosion inside the braid. Outdoor sealing practices are detailed in our SMA to N Adapter Weatherproof Guide.

How much connector loss should I budget per SMA end in casual lab setups?

Plan for ~0.1–0.15 dB per mated pair. That aligns with TEJTE’s own SMA spec (≤0.15 dB @6 GHz). While the number looks small, three or four connectors can eat half a dB fast. Always fold this into your coax attenuation budget. For more lab-specific advice, see our SMA Connector Dimensions & Thread Guide.

When is a custom sma pigtail worth it compared with buying off-the-shelf lengths?

Custom sma pigtails pay off whenever you need exact lengths or special angles to avoid sharp bends. They reduce stress on board-mounted connectors and keep VSWR low. OEMs often request them for enclosures where space is tight. For tailored builds, check our RF Adapter Cable category to see available options.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.