SMA to N Adapter Explained: 50Ω Straight & Waterproof Types

Sep 24,2025

Introduction

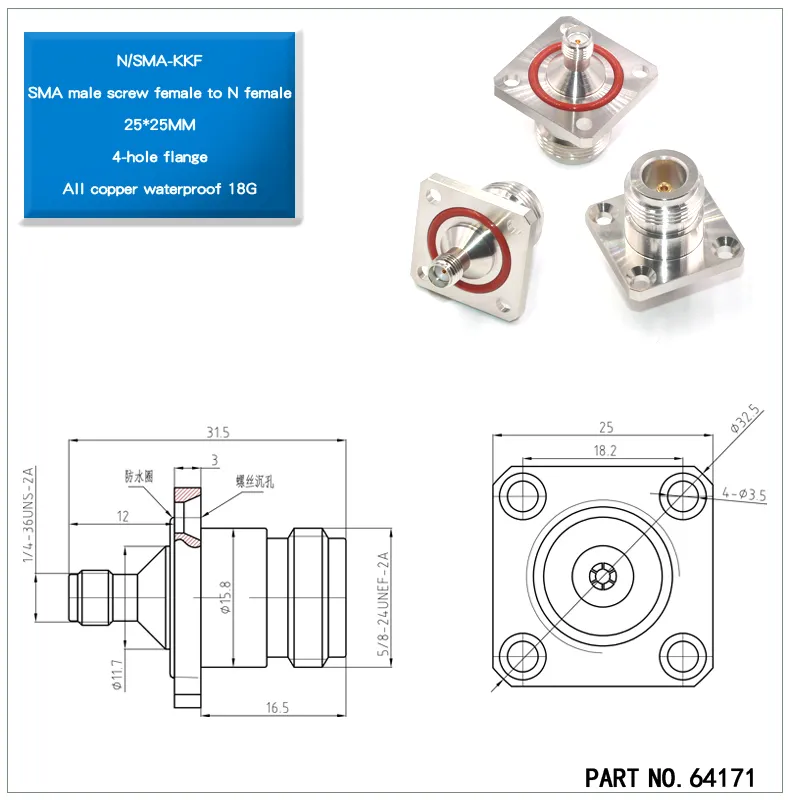

This image is shown in the document introduction as a detailed dimension diagram of a specific TEJTE waterproof SMA-to-N adapter (Part No. 64171). It annotates key dimensions like flange hole spacing and thread specs. Combined with the text, it illustrates the practical factors to consider when selecting an adapter, such as impedance, environmental robustness (e.g., IP rating, temperature range), and mechanical mounting parameters.

Choosing the right SMA to N adapter isn’t as simple as snapping two connectors together. In practice, engineers have to think about impedance, gender direction, and whether the adapter can withstand both mechanical strain and environmental stress. Take TEJTE’s N/SMA-KKF waterproof version as an example—it’s rated for 50 Ω, works from DC–6 GHz, maintains VSWR ≤1.2, and relies on a silicone O-ring to survive outdoors from -45 °C up to +125 °C. These aren’t just numbers on a datasheet. They tell you whether the adapter will hold steady after a storm, or fail just when your gear is needed most.

One small oversight, like forgetting to check sealing or torque specs, can easily turn into costly rework. Many RF engineers learn this early: double-check before drilling that panel cutout or tightening a jack, because once hardware is stressed, the mistake is expensive to undo. A quick review of real parameters often saves hours of frustration later.

Verify direction and impedance before you add to cart

Mixing up impedance is one of the most common mistakes with adapters. SMA connectors are always 50 Ω, but N connectors come in both 50 Ω and 75 Ω. Use the wrong type and reflections creep in, distorting measurements—especially once you push above a few gigahertz. To stay safe, models like TEJTE’s N-K/SMA-K flange type (Part No. 08764) hold to 50 Ω impedance and a DC–6 GHz bandwidth, making them a fit for Wi-Fi, LTE, and other midband systems.

Direction is just as easy to get wrong. Order an adapter with the genders swapped and you’ll be waiting for another delivery instead of testing your circuit. That’s why engineers often keep a printed diagram of common RF connector families at hand, or bookmark resources like the RF connector families overview before submitting a cart. A two-minute check here saves days of delay later.

Map your path—SMA-M to N-F vs N-F to SMA-M vs N-M to SMA-F

This image complements the text discussion on adapter direction (gender). It visually illustrates the typical application scenario of an N female to SMA male adapter, helping users correctly select the adapter based on their equipment port types (e.g., instrument has N female, cable requires SMA male).

This image shows the opposite gender configuration to Figure 2, suitable when the equipment has an SMA female port that needs to connect to an N male antenna or cable. The document emphasizes that clarifying the connection path direction is a key step to avoid ordering mistakes.

Sketching the connection path is a small step, but it clears up confusion fast. If your board has SMA female ports and the cable ends in an N male, then the fix is an SMA male to N female adapter. Flip it: an N female panel jack linked to an SMA test lead means you’ll need an n female to sma male adapter. And in some instrument setups, the rare N male to SMA female adapter is the one that fits.

The N/SMA-KJ (Part No. 51041) shows how build quality makes this easier. Its gold-plated brass inner conductor with PTFE dielectric keeps loss stable and ensures consistent mating cycles. A quick glance at whether there’s a pin or a hole often tells the story—engineers who check this step almost never order the wrong adapter.

Should you pick straight in-line or a short pigtail to reduce stress?

A rigid block adapter looks neat on paper, but in real hardware it can behave like a crowbar on fragile ports. Take the N/SMA-JK straight adapter (Part No. 51042)—rated DC–18 GHz with VSWR ≤1.2:1—its insertion loss is impressively low, often under 0.15 dB. The problem is mechanical. Every gram of torque is transferred directly into the device port. On a PCB-mounted SMA jack, that stress can eventually crack solder joints or loosen the housing.

This is where a short jumper earns its keep. Ten centimeters of RG316D dual-shield coax adds roughly 0.2 dB loss at 6 GHz (with attenuation of about 2.0 dB/m), but the cable absorbs bending and vibration instead of letting the port take the hit. That small trade-off often prevents a much bigger repair.

Quick comparison from the field:

- Straight block adapter to compact, very low loss (~0.15 dB), best for bench setups where nothing moves.

- RG316D pigtail (10–15 cm) to adds ~0.2–0.3 dB, flexible, protects connectors in racks or outdoor enclosures.

Plenty of engineers have seen the consequences firsthand. I once watched three SMA ports fail in a single rack installation—all due to rigid blocks acting like levers. Swapping in short jumpers solved it immediately. In crowded racks or outdoor gear, that little piece of coax is often the cheapest insurance you can buy.

Do your use cases require an IP-rated adapter for outdoor installs?

Move the setup outdoors, and a plain sma to n adapter won’t last long. Moisture, dust, and even salt fog slowly creep into the connector cavity, raising resistance and throwing off VSWR. That’s why IP-rated adapters exist. Take TEJTE’s N/SMA-KKF waterproof type: it’s rated for 50 Ω, works up to DC–6 GHz, keeps VSWR at ≤1.2, and withstands 1000 V dielectric pressure. Add in a silicone O-ring seal and a -45 °C to +125 °C temperature range, and you have an adapter that shrugs off rain, heat, and cold.

These seals aren’t cosmetic extras—they’re the reason your outdoor radio or camera still works after a winter season. Skip them, and you’ll be chasing corrosion with contact cleaner by spring. More than one field engineer has seen ports ruined because someone tried to save a few dollars on the wrong adapter.

For weather-exposed installs—small cell stations, security cameras, or outdoor IoT hubs—an IP-rated sma to n adapter paired with a panel-mount bulkhead connector is usually the safest bet. Once water makes its way inside a port, no amount of dielectric grease will undo the damage.

Choose the right build—brass gold-plated or stainless for durability

This image corresponds to the discussion in the document about adapter material selection. The diagram aims to help users understand how different materials (e.g., gold-plated brass for regular labs, stainless steel for outdoor/industrial harsh conditions) affect the adapter's durability and suitable application scenarios.

Connector material directly affects how long an sma to n adapter will keep performing. Brass gold-plated contacts are common; they provide excellent conductivity, smooth mating cycles, and stable insertion loss across hundreds of uses. A part like TEJTE’s N/SMA-KJ (Part No. 51041) uses gold-plated brass inner conductors with PTFE insulation, and it’s a reliable choice for everyday lab or bench work.

But in harsh environments—marine gear, outdoor 5G stations, or industrial plants—stainless steel housings usually win. They resist galling, hold torque better under repeated stress, and last longer in salt-spray exposure. One example is the N/SMA-JJ (Part No. 51040), which pairs stainless shells with phosphor bronze contacts. It’s built to keep a stable connection where brass might wear down too quickly.

A quick rule of thumb: if the setup is controlled and indoors, brass gold-plated saves cost without compromising performance. If corrosion, vibration, or frequent torque cycles are in play, stainless is the safer bet. More than one technician has regretted skipping stainless on outdoor installs after finding green corrosion in less than a year. For more context on repeated connector cycling, check TEJTE’s RF adapter cable selection—those assemblies often face the same durability trade-offs.

Match frequency rating for 6/18/26.5 GHz—how much headroom is wise?

Not every sma to n adapter is built for the same frequency range. Entry-level versions—like the N/SMA-KKF waterproof type—cover DC–6 GHz with VSWR ≤1.2, which makes them perfect for Wi-Fi, LTE, and other sub-6 GHz systems. Higher-grade models such as N/SMA-JK (Part No. 51042) or N/SMA-JJ (Part No. 51044) extend operation to DC–18 GHz, holding performance steady across much of the microwave spectrum. Specialized lab units go even further, rated up to 26.5 GHz for instrumentation work.

Does that mean you should always choose the highest rating? Not necessarily. A 26.5 GHz adapter on a 2.4 GHz Wi-Fi link works fine, but it’s overkill in both cost and precision. Most engineers aim for a 1.5×–2× headroom margin. If your project operates at 5.8 GHz, then an 18 GHz-rated adapter offers plenty of overhead without the premium price tag.

That said, some labs keep a stock of DC–18 GHz or DC–26.5 GHz adapters for flexibility. Having them on hand avoids last-minute shortages when a project unexpectedly shifts to higher frequencies. If you’re planning mixed RF and microwave work, building margin into your inventory is often cheaper than urgent reorders. For broader frequency planning—including how cables interact with adapters—see TEJTE’s Understanding RF Cables guide.

Pick the correct gender set without a bench rework

Few things stall a project faster than ordering the wrong connector gender. With an n to sma adapter, you need to know which side is male, which side is female, and how they mate with your existing gear. It sounds simple, but in busy labs it’s one of the top mistakes.

Here’s a quick breakdown:

- An n female to sma male adapter is common on rack-mounted instruments with N female ports that need to link to SMA test leads.

- An sma male to n female adapter is often used with antennas or cables where the SMA plug must meet an N female bulkhead.

- The less common case—an N male to SMA female adapter—still matters in certain test setups, especially when bridging between measurement gear and compact modules.

TEJTE’s catalog reflects all three. Both the N/SMA-KJ (Part No. 51041) and N/SMA-JK (Part No. 51042) specify 50 Ω impedance, support up to DC–18 GHz, and maintain VSWR ≤1.2, but their gender orientation is opposite. That single detail determines whether your cable clicks in or not. Many engineers keep a simple sketch of port genders taped to the lab bench—it’s faster than searching through paperwork. For more detail on port drawings and thread standards, check TEJTE’s SMA Connector Dimensions guide.

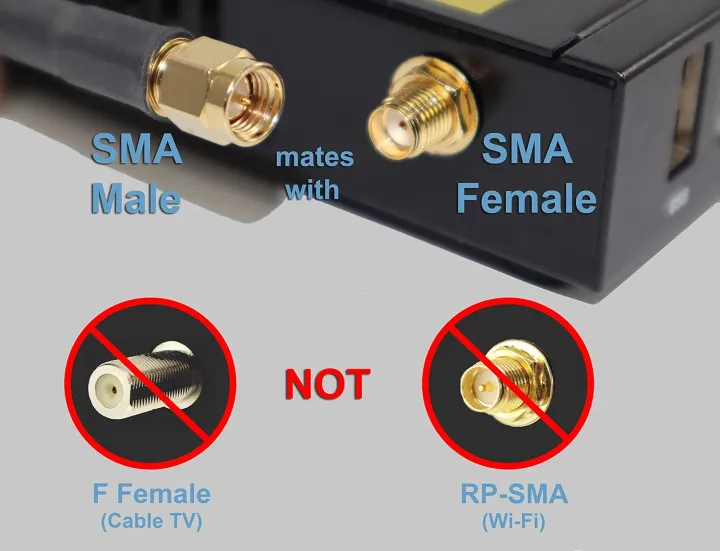

Avoid RP-SMA confusion at router and IoT ports

This chart clearly compares the polarity differences between standard SMA and RP-SMA, also noting their distinction from F-type (CATV) connectors. Combined with the text, it serves to warn readers to confirm whether a port is standard SMA or RP-SMA when connecting Wi-Fi routers or IoT devices, to avoid mating failures due to reversed polarity.

Routers and IoT hardware add an extra twist: many of them don’t use standard SMA, but RP-SMA connectors. The thread looks the same, yet the pin and socket are reversed. That’s when you’ll need an rp-sma to n adapter, not a regular sma to n adapter. Order the wrong one and you’ll discover the connectors simply won’t mate, even though the threads engage.

A quick tip: hold the connector against the light. An SMA male has a center pin, while an RP-SMA male has a hollow center. For the female side, the rule flips. This five-second check prevents hours of frustration later. Many field engineers keep a reference pair—one SMA and one RP-SMA—just to avoid guessing under pressure.

When extending router antennas, or bridging IoT hubs to outdoor N-type cables, the correct rp-sma to n adapter ensures compatibility while maintaining 50 Ω impedance. TEJTE’s SMA/N series includes both indoor and IP-rated outdoor versions, covering DC–6 GHz for Wi-Fi bands and DC–18 GHz for lab use. For a deeper look at how small connector changes affect whole networks, the RJ45 vs RJ11 connector guide offers a useful comparison—different interface standards can create very similar headaches.

Size your panel and torque to prevent detuning

Even with the right sma to n adapter, the installation details decide whether performance holds steady. SMA connectors are smaller and more delicate than N connectors, so torque matters. The sweet spot is 0.56–0.79 N·m (5–7 in-lb) on the SMA side. Push harder and you risk cracking the PCB solder or detuning the jack; apply too little and the return loss climbs because of poor contact.

Panel clearance is just as important. A bulkhead adapter like the N/SMA-KKF waterproof type extends roughly 25 mm beyond the panel surface, with flange holes spaced at 18.3 mm. If nearby heatsinks or housings don’t allow that space, the adapter may collide or create a lever effect once cables are attached. That mechanical stress shows up later as intermittent faults.

Installers who plan ahead often print mechanical drawings and check cutouts before drilling. It’s a small step that saves rework and replacement costs. For more structured guidance, TEJTE’s SMA Bulkhead Connector guide explains how to balance cutout size, sealing, and torque so the adapter survives both electrically and mechanically.

Calculate mismatch, clearance, and loss before you order

This image is a physical photo of a specific TEJTE adapter model (N/SMA-JJ, Part No. 51044). The text indicates this model uses a stainless steel housing, designed to meet higher demands for durability and corrosion resistance in harsh environments, typically used in outdoor 5G stations, industrial settings, etc.

Dropping an sma to n adapter into a parts list without checking the math can create headaches later. Even though most TEJTE adapters, like the N/SMA-JJ (Part No. 51044), are built for 50 Ω impedance and hold VSWR around 1.2:1 up to 18 GHz, not every system is that clean. Some devices still run on 75 Ω N connectors, and mixing 50 with 75 Ω introduces mismatch. The loss isn’t dramatic—about 0.18 dB—but in lab-grade setups that margin can distort power readings.

Mechanical clearance adds another layer. A bulkhead adapter such as the N/SMA-KKF waterproof type protrudes nearly 25 mm past the panel, with flanges at 18.3 mm spacing. If your chassis doesn’t allow for that, the connector may collide with nearby components. Add the cable’s weight, and you get a lever-arm effect that stresses the port far more than expected.

For many engineers, this is where a short jumper solves the puzzle. A 10 cm length of RG316D dual-shield introduces only ~0.2 dB loss at 6 GHz (attenuation ~2.0 dB/m), yet it relieves strain and clears tight enclosures. It’s a small penalty in insertion loss that can prevent a costly PCB repair.

If you want a deeper dive into coax losses and impedance planning, TEJTE’s RF Coaxial Cable Guide lays out attenuation tables and practical examples. Running these numbers before you place the order often means your adapters fit both electrically and mechanically the first time.

Install in the right order and re-check return loss after tightening

Even the best n to sma adapter won’t save you if it’s installed carelessly. The rule most RF engineers repeat is simple: hand-start, torque, verify. Always begin threading by hand to avoid cross-threading, then tighten with a torque wrench. On the SMA side, the sweet spot is 0.56–0.79 N·m (5–7 in-lb). Anything higher risks cracking solder joints or detuning the jack, while going too light can raise return loss.

Verification matters just as much. Once tightened, measure return loss or VSWR again. A quality adapter like TEJTE’s N/SMA-JK (Part No. 51042, DC–18 GHz) should still show VSWR ≤1.2:1 after proper tightening. If the value drifts upward, it usually means torque was misapplied or mechanical strain is pulling on the port. One easy safeguard: never twist the coax while tightening—always let the wrench turn the nut.

I’ve personally seen a $10 sma to n adapter prevent damage to a $5,000 analyzer, purely because the installer followed this sequence. A little discipline pays off quickly. For more detailed torque practices and connector handling advice, check TEJTE’s SMA Adapter Guide.

FAQs

This image appears in the FAQ section, schematically illustrating the recommendation to perform electrical performance verification (e.g., VSWR measurement) after adapter installation. The document emphasizes that even with a high-quality adapter, improper installation (e.g., incorrect torque) can degrade performance, making post-installation verification a critical step for ensuring measurement accuracy.

Look closely at the port. An SMA female has outer threads with a socket, while an SMA male has a center pin. Match that against the N side and you’ll know if it’s an sma male to n female adapter or an n female to sma male adapter you need. Many engineers keep a quick reference chart handy—resources like the RF connector families overview make it easier to double-check before ordering.

Is a short RG316 pigtail usually lower risk than a rigid SMA-to-N block on crowded panels?

In most cases, yes. A rigid sma to n adapter block has lower loss (~0.15 dB), but it also acts like a lever on the port. A 10 cm RG316D dual-shield jumper adds ~0.2 dB loss at 6 GHz, yet it prevents broken jacks. That trade-off is often worth it. If you need to compare coax jumper options, TEJTE’s adapter cable range shows several choices engineers rely on in dense racks.

When is an IP-rated SMA-to-N adapter mandatory for outdoor radios and cameras?

Anytime the connector sits directly in weather. A waterproof unit like TEJTE’s N/SMA-KKF is rated 50 Ω, DC–6 GHz, VSWR ≤1.2, and sealed with a silicone O-ring. It also withstands 1000 V dielectric strength and operates between -45 °C and +125 °C. Without these protections, ports corrode fast. For enclosure planning tips, see the SMA bulkhead connector guide.

Does brass gold-plated measure differently from stainless at 5.8 GHz vs 18 GHz?

Electrically, insertion loss is nearly the same—usually ≤0.3 dB. The difference is durability. Brass with gold plating, like the N/SMA-KJ (Part No. 51041), ensures smooth mating in labs. Stainless, as in the N/SMA-JJ (Part No. 51040), resists salt fog and repeated torque cycles. If the environment is humid or outdoors, stainless pays off in fewer replacements.

What torque should I apply on the SMA side to avoid detuning a PCB-mounted jack?

Stick to 0.56–0.79 N·m (5–7 in-lb). Over-tightening risks cracking solder joints; under-tightening raises VSWR. If you’re unsure, torque guidance in TEJTE’s SMA connector dimensions guide is worth reviewing. It’s a small step that keeps measurements reliable.

Will a 50 to 75 Ω SMA-to-N mismatch noticeably skew my power readings?

Yes. Mixing a 50 Ω SMA port with a 75 Ω N connector adds about 0.18 dB mismatch loss. That may not ruin a casual link, but in lab tests it distorts power readings and efficiency numbers. For planning signal budgets, the RF coaxial cable guide includes attenuation data to help compare options.

Can I keep a DC–26.5 GHz adapter on a 2.4 GHz link for future-proofing, or is that overkill?

It works fine, but you may not need it. An 18 GHz-rated sma to n adapter already covers most Wi-Fi, LTE, and microwave bands with room to spare. Still, many labs stock 26.5 GHz parts so they’re ready for unexpected high-frequency jobs. If your team often shifts between IoT and microwave work, keeping a few high-spec adapters avoids emergency orders later.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.