SMA Male Panel Mount Connector Guide: Cutouts, Nuts & IP67 Sealing

Sep 27,2025

Preface

This figure introduces the critical planning phase before selecting and installing an SMA male panel mount connector, highlighting the need to verify cutout size, panel thickness, and the choice between bulkhead and flange types for a proper fit.

When engineers source an SMA male panel mount connector, the challenge isn’t simply finding stock on the shelf. The real work begins when you need to make sure the part actually fits your enclosure—without leaks, spin, or signal loss. That means checking the sma panel cutout diameter, confirming the panel thickness range, and deciding if a single-nut bulkhead is enough or whether a sturdier sma flange connector makes more sense.

Outdoors, things get trickier. An IP-rated waterproof sma bulkhead with the right O-ring compression can make the difference between a reliable system and one that fails after the first rainstorm. It’s one of those details that’s easy to overlook in CAD drawings, but painful to fix once hardware is in the field.

Verify series, gender, and direction before you drill

Depicts an SMA-KKF series connector, emphasizing the necessity of verifying the connector's series, gender (male center pin), and polarity (standard vs. RP-SMA) before drilling the panel to prevent mating errors.

It sounds basic, but mix-ups happen more often than most buyers admit. A sma male bulkhead panel mount connector has an external 1/4-36 UNEF thread with a center pin. If you mistakenly order an RP-SMA version, the polarity flips—the pin becomes a socket, and suddenly your antenna doesn’t mate at all.

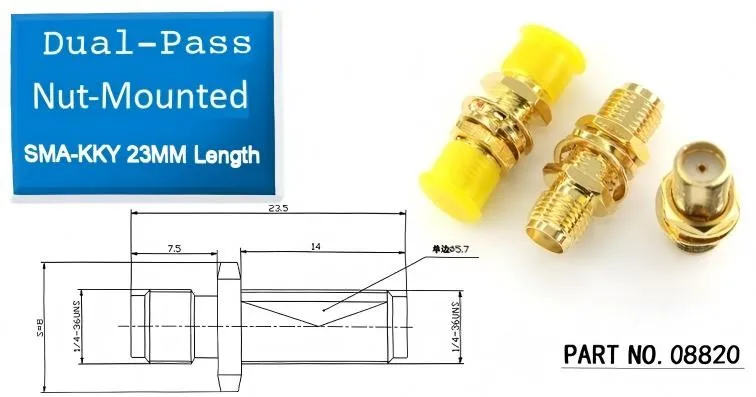

At TEJTE, we provide several options to cover these scenarios. For instance, the SMA-KKY feedthrough offers about 23 mm overall length and can handle up to 500 mating cycles. Meanwhile, the SMA-KKF flange connector, built from brass and rated to 18 GHz, is a sturdier pick when anti-rotation matters. Picking between them depends on your setup: do you need a direct pass-through, or does your enclosure call for a sma male rf coaxial adapter 4 holes panel mount solder post plug jack connector with extra stability?

Avoid RP-SMA mix-ups by checking pin/socket and labeling

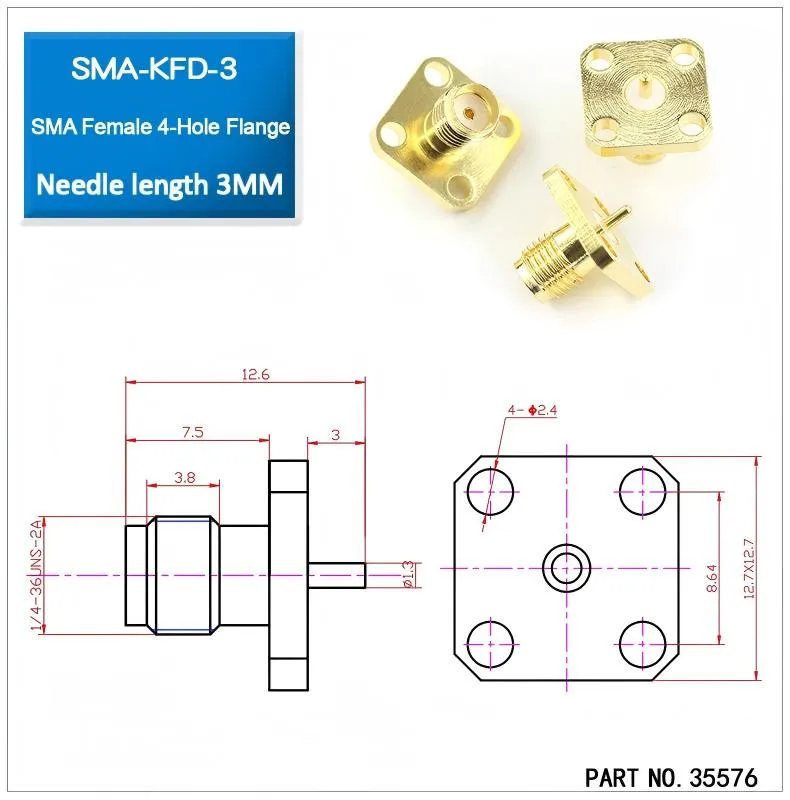

Shows the SMA-KFD-3, a four-hole flange mount connector identified as male due to its center pin, despite having an external thread. It underscores the importance of correctly identifying gender based on the center conductor, not the outer thread.

Never rely on visual guesses alone. In SMA terminology, “male” or “female” refers to the center conductor, not the outer shell. That’s why a part like the SMA-KFD-3 four-hole flange still counts as male, even though it has an external thread—it carries the pin.

A simple but effective habit is labeling bags or bins as soon as connectors arrive. Write “SMA” or “RP-SMA” plus “male” or “female” clearly on the package. It sounds old-school, but it prevents the all-too-common scenario of grabbing the wrong flange or bulkhead during final assembly.

How big should your sma panel cutout be and what panel thickness will fit?

The SMA thread spec is 1/4-36 UNEF, which translates to a major diameter close to 6.35 mm. In practice, your sma panel cutout should be slightly larger—around 6.4–6.5 mm—to allow the connector body to slide in without scraping off plating. Drill too tight and you’ll fight to seat the part; drill too loose and the washer won’t bite, leaving a sloppy fit.

Equally important is the panel thickness. From TEJTE’s datasheets:

- Standard bulkhead SMA connectors such as the SMA-KKY (and the waterproof variant) handle panels between 1.5–3.2 mm, thanks to a thread length of about 6.8 mm.

- When the wall is thicker, extended bulkheads or a sma flange connector like SMA-KKF spread the load with screws, bypassing the nut’s limitation.

| Parameter | Typical Value | TEJTE Example (SMA-KKY) |

|---|---|---|

| Thread type | 1/4-36 UNEF | 1/4-36 UNEF |

| Recommended cutout | 6.4–6.5 mm | 6.5 mm |

| Panel thickness range | 1.5–3.2 mm | 1.5–3.0 mm |

| Nut size (across flats) | 5/16" (~8 mm) | 8 mm hex nut |

| Seal option | O-ring, IP67 | Silicone rubber 6146 |

Check wrench clearance around the sma nut and nearby heat-sinks

Choose bulkhead vs flange—when does an sma flange connector win?

Provides a detailed dimensional diagram of the SMA-KFD-3 flange connector, including its 12.7x12.7 mm footprint, four Ø2.4 mm mounting holes, and thread specification. This visual aid is crucial for ensuring proper fit and anti-rotation capability in the panel design.

Both sma bulkhead connectors and sma flange connectors are designed for panel mounting, but they behave very differently once installed. A single-nut bulkhead is fast and compact: drill the hole, slide the connector in, add the washer and nut, and you’re done. For quick builds or small enclosures with only one or two ports, this method often works fine.

But torque repeatability and anti-rotation change the story. A 4-hole sma flange connector spreads the load over screws, keeping the body from twisting when cables are connected and disconnected repeatedly. In systems exposed to vibration or handled by multiple technicians, that extra rigidity makes a visible difference.

Take the SMA-KFD-3 flange mount as an example. It uses an external thread, four Ø2.4 mm mounting holes, and a 12.7 × 12.7 mm footprint. Rated up to 18 GHz, it provides a stable anchor that resists spin, even when installers over-tighten cables.

For side-by-side comparisons of panel mount sma connectors and flange styles, check TEJTE’s RF Connector Guide.

Compare with sma male rf coaxial adapter 4 holes panel mount solder post plug jack connector

Do outdoor installs require ip rated or waterproof sma bulkhead?

If your equipment is installed indoors, a standard sma male bulkhead panel mount connector is usually enough. But the moment it goes outdoors—on a smart meter, an IoT gateway, or a 5G small cell—you’ll want an IP-rated waterproof sma bulkhead. Without sealing, even a light drizzle can creep past the nut and into the enclosure, damaging electronics.

TEJTE’s SMA-KKY waterproof series uses a silicone O-ring (material 6146) sized for 15–30% compression. When torqued correctly, this delivers an IP67 seal, capable of handling rain or temporary immersion. But the O-ring alone is not the whole story. Long-term exposure to UV, salt fog, and freeze-thaw cycles can still compromise a seal if the wrong materials are chosen.

| Outdoor Factor | Risk if ignored | Mitigation with SMA bulkhead |

|---|---|---|

| UV exposure | O-ring cracking | UV-stable silicone gasket |

| Salt fog (IEC 60068) | Brass patina, corrosion | Stainless waterproof SMA bulkhead |

| Freeze-thaw cycles | Panel warping, leaks | Proper torque + flexible O-ring |

| Pressure wash | Water bypasses nut stack | Flange-mount SMA with IP67 sealing |

Pick materials—brass gold-plated vs stainless for corrosion control

This figure likely presents a table or diagram summarizing key outdoor environmental factors (UV, salt fog, freeze-thaw, pressure washing) that impact connector longevity, along with recommended mitigation strategies such as using UV-stable O-rings or stainless steel bodies for corrosive environments.

- Brass gold-plated: Offers low insertion loss (≤0.15 dB @ 6 GHz), excellent conductivity, and is cost-effective. Ideal for telecom racks or mixed indoor-outdoor environments.

- Stainless SMA connectors: Slightly higher insertion loss, but they shine in coastal or marine settings where corrosion eats through brass quickly.

The takeaway? Match the connector material to the environment, not just the RF spec. If you’re designing for long-term outdoor reliability, stainless plus an ip rated sealing stack is hard to beat.

Reduce strain—should you choose an lmr100 sma male panel mount connector with a short pigtail?

Illustrates an SMA male bulkhead connector with a short, flexible LMR100 coaxial cable (pigtail) pre-attached. This design is ideal for cramped enclosures, as it simplifies routing, minimizes sharp bends, and absorbs mechanical strain that could otherwise damage the PCB or connector solder joints.

A straight feedthrough bulkhead looks neat on drawings, but in a cramped enclosure it can be a stress point. Every sharp bend in the coax increases return loss and reduces service life. That’s why many engineers prefer using an LMR100 sma male panel mount connector with a short pigtail. The flexible jumper takes the mechanical strain, leaving the panel connection stable.

TEJTE’s catalog includes LMR-100 coax connector sma male bulkhead panel mount options rated up to 6 GHz, with PE insulation and about 500 mating cycles. The 2.8 mm outer diameter makes the cable small enough for IoT boxes and embedded devices, yet it maintains a bend radius of around 12 mm—far safer than trying to kink a rigid feedthrough against the panel wall.

Real-world note: I’ve seen PCB-mounted feedthroughs rip pads clean off when someone pulled a cable sideways. A 10 cm LMR-100 jumper would have absorbed that force, sparing the board and saving a lot of repair work.

When comparing:

- Straight feedthrough bulkhead SMA → shorter signal path, but rigid and unforgiving.

- LMR-100 pigtail panel mount SMA → adds flexibility, reduces strain, and makes service easier if you need to swap cables.

For a deeper comparison between coax types, see TEJTE’s SMA Pigtail Guide: RG174 vs RG316, Loss, Bends & Waterproofing.

Prevent detuning—what torque is safe on the SMA nut?

Even a well-chosen sma male panel mount connector can fail if the nut is over- or under-tightened. The safe zone is narrow: about 0.45–0.56 N·m (4–5 in-lb). Below this, the O-ring may not compress enough to seal; above it, the panel can bow or the PTFE dielectric may crack. Either way, you’ll see performance drift, especially above 3 GHz.

Lab data from TEJTE confirms the risk. The SMA-KKY bulkhead lasted over 500 tightening cycles when torque stayed in spec. But once installers exceeded the range, failures came quickly—loose seals, fractured insulators, and a visible rise in VSWR.

If your panel design doesn’t leave enough room for a wrench, a sma flange connector can be the safer choice. It avoids the risk of over-torque by locking the connector body with screws instead of depending on nut compression alone. For more sizing and clearance details, see TEJTE’s SMA Connector Dimensions: Cutouts & Thread.

Calculate cutout, stack height, and seal compression before you buy

Guesswork has no place in enclosure design. Before drilling, you should verify the sma panel cutout, confirm thread engagement, and check that the O-ring compression falls into range. A quick calculation prevents surprises later—like a nut that bottoms out before sealing or a gasket that gets crushed flat.

Here’s a simplified Panel-Mount SMA Male Fit & Sealing Planner, based on TEJTE’s bulkhead specs.

| Input / Field | Value Example |

|---|---|

| Thread spec (fixed) | 1/4-36 UNEF |

| Panel thickness t | 2.0 mm |

| Cutout diameter D_hole | 6.5 mm |

| Connector thread length L | 6.8 mm (SMA-KKY) |

| Nut + washer thickness | 3.5 mm |

| O-ring free height H_o | 1.0 mm (silicone 6146) |

| Target compression c | 20 % (0.2 mm) |

| Wrench clearance C_min | 8 mm hex + 1 mm margin |

| Torque target T | 0.5 N·m |

Checks performed:

- O-ring compression: 1.0 × 20% = 0.2 mm → within the 15–30% range

- Thread engagement: 6.8 – (2.0 + 3.5 + 0.2) = 1.1 mm → enough for ≥2–3 threads

- Cutout fit: 6.5 mm hole vs 6.35 mm thread major diameter → pass

- Clearance: 8 mm nut with 1 mm spacing margin → pass

Result: The connector seals properly and leaves enough headroom for torqueing.

Installer’s note: If engagement comes out ≤0, or compression falls under 15%, don’t force it. Switch to a longer-thread version or a waterproof sma bulkhead flange. It’s far easier to redesign at this stage than to fix leaks in the field.

For more on pre-drill planning, see TEJTE’s SMA Panel Mount Connector: Cutouts & Nuts.

Install in the right order and verify VSWR after assembly

Even the best panel mount sma connectors can fail if installed out of sequence. The order matters, and rushing often leads to leaks, cross-threading, or unexpected RF mismatch.

Here’s the recommended process most RF technicians follow:

- Drill & deburr the sma panel cutout to the correct 6.4–6.5 mm size. A rough hole edge can chew into the plating and weaken sealing.

- Insert the connector with the O-ring in place. Never forget the gasket—it’s what makes a waterproof sma bulkhead hold up outdoors.

- Seat the washer and carefully hand-thread the sma nut. Hand-starting prevents cross-thread damage to the fine 1/4-36 UNEF screw.

- Torque to spec (0.45–0.56 N·m) using an 8 mm wrench. Don’t overdo it; bowing the panel leads to leaks later.

- Continuity check: ensure inner conductor ≤5 mΩ, outer ≤2 mΩ. This catches poor contact before RF testing.

- Seal check: look for ~20% O-ring compression. If it looks flattened, you’ve gone too far.

- RF sweep: confirm VSWR ≤1.2 up to 6 GHz (or ≤1.1 for semi-rigid builds). A ripple here is a sign of over-torque or misalignment.

Pro installer tip: Don’t skip the RF sweep. A connector may “look fine” but still detune the circuit if the nut is overtightened or the O-ring is crushed unevenly. A five-minute check can save you from hours of troubleshooting down the line.

For more detailed step-by-step methods, see TEJTE’s How to Use Crimp Connectors Guide, which also explains sealing and torque checks relevant to RF assemblies.

Wrap-up: avoid rework by planning your SMA male panel mount connector

Selecting the right sma male panel mount connector isn’t just about ordering part numbers. Success depends on careful planning: making sure the sma panel cutout is correct, verifying the panel thickness, choosing between bulkhead and sma flange connectors, and confirming whether an ip rated waterproof sma bulkhead is required for outdoor use.

Bulkheads are compact and quick to install. Flange types prevent spin and spread mechanical load. Add O-rings, proper torque on the sma nut, and a quick VSWR sweep, and you’ll have a connector that lasts years in the field. Skipping those steps often leads to re-drilled panels, stripped threads, or unexpected detuning.

For a broader overview of connector types, see TEJTE’s RF Connector Guide. If you’re sourcing parts today, our RF Connector Catalog lists stock and customization options with full datasheets.

FAQ

Q1. What hole diameter and panel thickness are typical for an SMA male panel mount connector?

Most designs use a 6.4–6.5 mm cutout with panels between 1.5–3.2 mm. Extended-thread bulkheads or sma flange connectors can handle thicker walls. See SMA Connector Dimensions: Cutouts & Thread for detailed specs.

Q2. When should I pick a 4-hole flange over a single-nut bulkhead on thin enclosures?

On thin or vibration-prone panels, the sma flange connector spreads load across screws, preventing spin. Single-nut bulkheads are faster but less robust.

Q3. Do I need an ip rated waterproof sma bulkhead if the cabinet door is gasketed?

Yes. A gasketed door won’t protect the panel holes themselves. Each sma male bulkhead panel mount connector should have its own O-ring seal compressed 15–30% to reach IP67.

Q4. Which wrench size and torque range are safe for the sma nut without detuning?

Use an 8 mm wrench and stay within 0.45–0.56 N·m. Too loose and the seal fails; too tight and the dielectric may crack. See Panel Mount Connector Cutouts & Sealing Guide.

Q5. Is an LMR100 sma male panel mount connector with a short pigtail preferable in cramped builds?

Yes. A lmr-100 coax connector sma male bulkhead panel mount absorbs strain in tight spaces and protects PCB traces. For details, check SMA Pigtail Guide.

Q6. How much O-ring compression should I target to reach IP67 without panel bowing?

Aim for 15–30% compression. Below 15% risks leaks; above 30% risks bowing. TEJTE’s waterproof series is sized for this range.

Q7. Will brass gold-plated hardware resist corrosion outdoors or should I use stainless?

Brass gold-plated performs well indoors and in most telecom racks. In coastal or marine sites, stainless waterproof sma bulkheads last longer under salt fog.

Q8. How many mating cycles can an SMA male panel mount connector survive?

Most bulkheads are rated around 500 cycles. Using gold-plated brass helps maintain stable VSWR across those cycles.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.