SMA Pigtail Guide: RG174 vs RG316, Loss, Bends & Waterproofing

Sep 26,2025

Should you pick RG174 or RG316 for lower coax attenuation and safer bends?

If you’ve ever opened up a Wi-Fi router or handled an FPV drone, you’ve probably come across both RG174 extension cable and RG316 jumpers. On the surface, they look almost interchangeable: both are 50-ohm coax types, both sit in the 2.5–3 mm size range. Yet once you dig into their specs, the differences show why engineers tend to prefer one over the other in specific contexts.

Here’s how the numbers stack up:

| Parameter | RG174 | RG316 |

|---|---|---|

| Outer diameter | 2.85 mm | 2.50 mm |

| Dielectric | Solid PE | PTFE |

| Min. bend radius | 28 mm | 15 mm |

| Attenuation @ 2.4 GHz | ~1.47 dB/m | ~1.46 dB/m |

| Attenuation @ 5.8 GHz | ~2.0 dB/m (extrap.) | ~2.15 dB/m |

| Operating temp | -20 °C to +70 °C | up to +150 °C |

| Shielding | Bare copper braid | Silver-plated copper braid |

| Weight | ~12 g/m | ~17 g/m |

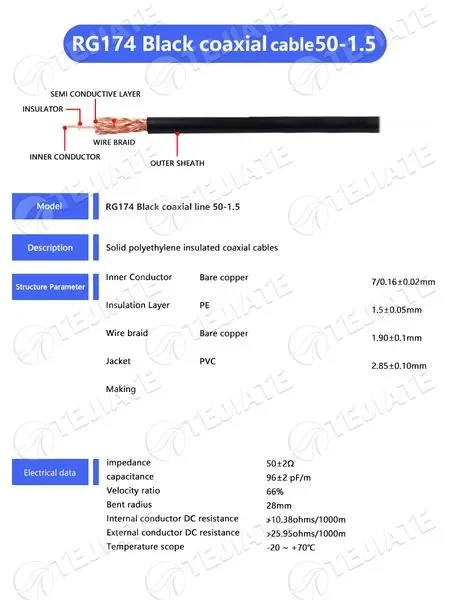

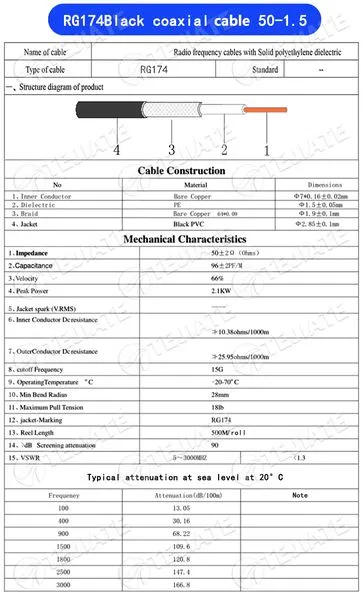

This physical photo shows a common black RG174 cable. Combined with the text, RG174 is lighter and less expensive, with attenuation similar to RG316 at 2.4 GHz and 5.8 GHz. However, its operating temperature range (-20°C to +70°C) and bend radius (28mm) limitations make it more suitable for cost-sensitive, short-distance indoor applications where space is relatively ample.

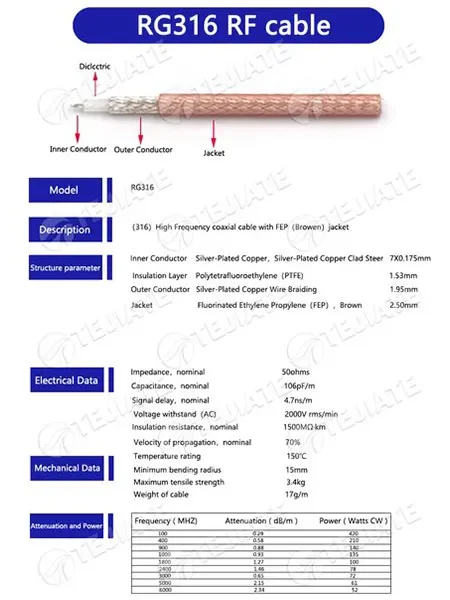

Looking at the table, RG174 is often “good enough” for short indoor jumpers. It’s lighter, cheaper, and maintains a stable VSWR (≤1.3 up to 3 GHz). But when the job demands higher heat resistance, tighter routing, or consistent low loss over a broad frequency range, rg316 coax clearly wins. Thanks to its PTFE insulation and silver-plated braid, it not only bends tighter—just 15 mm radius—but also stays reliable in environments where heat and vibration are constant. That’s why you’ll see it inside aerospace electronics, lab instruments, and military boards.

For enclosure feed-throughs, pairing an sma pigtail built with RG316 and a quality bulkhead connector is often the safer long-term choice. TEJTE’s panel-mount SMA bulkhead options, for example, combine rugged brass housings with gold plating, ensuring both electrical performance and mechanical stability. Using RG174 in the same slot might cut cost upfront, but it’s more likely to fatigue if bent again and again during service.

Practical tip: keep bend radius in mind when routing. RG174 needs about the diameter of a coin (28 mm) to avoid shield damage, while RG316 can weave through a space no larger than your pinky finger (15 mm). Push either cable beyond those limits, and the penalty shows up as extra coax attenuation and eventual shielding cracks.

Should you pick RG174 or RG316 for lower coax attenuation and safer bends?

If you’ve ever opened up a Wi-Fi router or handled an FPV drone, you’ve probably come across both RG174 extension cable and RG316 jumpers. On the surface, they look almost interchangeable: both are 50-ohm coax types, both sit in the 2.5–3 mm size range. Yet once you dig into their specs, the differences show why engineers tend to prefer one over the other in specific contexts.

Here’s how the numbers stack up:

| Parameter | RG174 | RG316 |

|---|---|---|

| Outer diameter | 2.85 mm | 2.50 mm |

| Dielectric | Solid PE | PTFE |

| Min. bend radius | 28 mm | 15 mm |

| Attenuation @ 2.4 GHz | ~1.47 dB/m | ~1.46 dB/m |

| Attenuation @ 5.8 GHz | ~2.0 dB/m (extrap.) | ~2.15 dB/m |

| Operating temp | -20 °C to +70 °C | up to +150 °C |

| Shielding | Bare copper braid | Silver-plated copper braid |

| Weight | ~12 g/m | ~17 g/m |

Looking at the table, RG174 is often “good enough” for short indoor jumpers. It’s lighter, cheaper, and maintains a stable VSWR (≤1.3 up to 3 GHz). But when the job demands higher heat resistance, tighter routing, or consistent low loss over a broad frequency range, RG316 clearly wins. Thanks to its PTFE insulation and silver-plated braid, it not only bends tighter—just 15 mm radius—but also stays reliable in environments where heat and vibration are constant. That’s why you’ll see it inside aerospace electronics, lab instruments, and military boards.

For enclosure feed-throughs, pairing an sma pigtail built with RG316 and a quality bulkhead connector is often the safer long-term choice. TEJTE’s panel-mount SMA bulkhead options, for example, combine rugged brass housings with gold plating, ensuring both electrical performance and mechanical stability. Using RG174 in the same slot might cut cost upfront, but it’s more likely to fatigue if bent again and again during service.

Practical tip: keep bend radius in mind when routing. RG174 needs about the diameter of a coin (28 mm) to avoid shield damage, while RG316 can weave through a space no larger than your pinky finger (15 mm). Push either cable beyond those limits, and the penalty shows up as extra coax attenuation and eventual shielding cracks.

Will a short wifi antenna extension cable beat a rigid adapter chain?

This image appears in the section discussing the use of flexible jumpers instead of rigid adapter chains. The SMA-KWE right-angle bulkhead connector combines silicone O-rings and gold-plated housing, ensuring IP-rated waterproof sealing while maintaining return loss (VSWR) within ≤1.2 (up to 6 GHz). It represents a high-quality hardware solution to space constraints and port stress issues, especially suitable for long-term installations like outdoor Wi-Fi CPE.

It’s tempting, especially in a test bench setup, to stack rigid SMA adapters just to reach a port. At first glance, it feels quick and harmless. In reality, though, each adapter introduces about 0.1 dB of insertion loss and a surprising amount of mechanical leverage on the port itself. Put three in a row and you’ve already added 0.3 dB—not catastrophic, but at 5.8 GHz that little bit can tip your link budget and cause unstable video feeds. Worse still, the extra stress often cracks solder joints on fragile PCB-mounted SMA jacks.

A short wifi antenna extension cable or sma extension cable is a far better solution. Take a 15 cm RG316 pigtail as an example: it carries less than 0.15 dB of loss up to 6 GHz and is rated for more than 500 mating cycles. That one flexible lead can do the work of three rigid couplers while reducing strain on the board. In practice, installers often notice fewer returns and far fewer “mystery failures” when they use a pigtail instead of building an adapter tower.

Outdoor setups raise the stakes further. Without an IP rated bulkhead gland, rain or condensation can creep in and corrode brass threads. TEJTE’s SMA-KWE right-angle bulkhead connectors combine silicone O-rings with gold-plated housings, ensuring both watertight sealing and return loss within spec (VSWR ≤1.2 up to 6 GHz). That small choice often separates a reliable long-term Wi-Fi CPE installation from one that fails in its first rainy season.

Rule of thumb: whenever you find yourself reaching for multiple rigid couplers, stop and ask whether a short wifi antenna extension cable could handle the job with less loss and less risk. Nine times out of ten, the flexible option is the smarter call.

Related reading: Use an sma extension cable when rigid adapters add stress

Do your enclosures require an ip rated gland or bulkhead to stay dry?

This image shows the practical installation scenario of the SMA-KWE bulkhead connector. Combined with the discussion about the need for IP-rated protection in outdoor installations, it visually demonstrates how to build a reliable outdoor RF interface that can resist rain, condensation, and pulling forces through high-quality bulkhead connectors, drip loops, and strain relief measures.

Field deployments often reveal what lab tests can’t. Even the best sma pigtail won’t last long if moisture sneaks into the connector. Once water finds its way to the brass threads or center contact, corrosion starts quickly, and performance degrades—sometimes within weeks.

That’s where IP rated bulkhead glands and O-ring seals come in. Take TEJTE’s SMA-KWE bulkhead connectors as an example: they use silicone rubber 6146 O-rings, gold-plated brass housings, and are rated for insertion loss ≤0.15 dB up to 6 GHz. On top of that, they endure more than 500 mating cycles and can withstand 1000 V rms. Installed through a standard 6.5 mm panel cutout, the O-ring compresses evenly, sealing out rain and condensation while keeping impedance stable.

It’s not just about the connector itself. Best practice also means routing the cable with a drip loop outside the enclosure, so gravity helps water fall away instead of running inside. Adding a strain-relief clamp prevents tugging forces from stressing the bulkhead seal. These small details—IP sealing, drip loops, and tension relief—often decide whether your outdoor Wi-Fi gateway or IoT box runs for years or fails after the first storm.

If you’re debating whether your design needs an ip rated bulkhead pass-through, ask yourself: will this gear live outdoors, in basements, or anywhere condensation can form? If the answer is yes, then sealing is non-negotiable. Skipping it may save a dollar today, but corroded SMA threads and unstable VSWR will cost you more in replacements tomorrow.

Related reading: Plan ip rated pass-throughs

How do you map ports and genders to avoid RP-SMA and U.FL mix-ups?

Connector mix-ups happen more often than people like to admit. At first glance, a wifi antenna extension cable with an SMA female looks nearly identical to one with RP-SMA. The body is the same hex shape, the threads match, yet the polarity is reversed—so the connectors don’t mate. The result? A brand-new antenna that simply won’t connect.

Here’s a quick reference to keep handy:

- SMA male → outer thread + center pin

- SMA female → outer hex + center socket

- RP-SMA male → outer thread + center socket

- RP-SMA female → outer hex + center pin

- U.FL / IPEX → ultra-mini press-fit used in laptops, Wi-Fi cards, and FPV drones

A common case is the Intel 8265 wireless card. It expects a U.FL to RP-SMA pigtail. If you mistakenly order a standard sma pigtail, the gender and polarity won’t line up, leaving you with an unusable cable. This is why checking both the mechanical interface and polarity before purchase is critical.

The good news is that most of these mistakes can be avoided by double-checking diagrams in datasheets. TEJTE’s SMA male/female connector guides show pin and socket orientation clearly, making it easy to confirm before you click “buy.”

Practical tip: don’t rely on product photos alone. Even experienced installers have ordered the wrong RP-SMA parts because the hex body looked identical to SMA. A thirty-second check against the datasheet can save days of delay and unnecessary returns.

Can you keep loss within budget at 2.4/5.8 GHz with your target length?

Every RF design comes with a link budget—the small cushion between what your transmitter can deliver and what your receiver needs. A poorly chosen cable can eat that margin quickly, especially at Wi-Fi and FPV frequencies. This is where knowing the coax attenuation numbers for RG174 and rg316 coax pays off.

Let’s put real figures on the table.

- RG174: ~1.47 dB/m at 2.4 GHz, ~2.0 dB/m at 5.8 GHz

- RG316 coax: ~1.46 dB/m at 2.4 GHz, ~2.15 dB/m at 5.8 GHz

- Connector insertion loss: ≈0.1 dB per SMA end

Now imagine a 1 m rg174 extension cable with two SMA ends:

- Cable loss = 1.47 dB

- Connector loss = 0.2 dB

- Total ≈ 1.67 dB

If your system allows 2 dB at 2.4 GHz, that’s fine. But stretch the run to 2 m and you’re looking at ~3.3 dB—already pushing many Wi-Fi radios past their comfort zone. At 5.8 GHz, the losses climb even faster, which is why shorter sma pigtails or an upgrade to rg316 coax are common choices.

Here’s a quick reference table for comparison:

| Length | RG174 @2.4 GHz | RG174 @5.8 GHz | RG316 @2.4 GHz | RG316 @5.8 GHz |

|---|---|---|---|---|

| 0.5 m | ~0.74 dB | ~1.0 dB | ~0.73 dB | ~1.1 dB |

| 1.0 m | ~1.47 dB | ~2.0 dB | ~1.46 dB | ~2.15 dB |

| 2.0 m | ~2.94 dB | ~4.0 dB | ~2.92 dB | ~4.3 dB |

| Input Field | Meaning |

|---|---|

| Freq_GHz | 2.4 / 5.8 |

| Cable_Family | RG174 / RG316 |

| Alpha(f) | Attenuation (dB/m) from datasheet |

| L (m) | Intended length |

| Conn_Loss_per_end | ~0.1 dB |

| OD (mm) | 2.85 mm (RG174), 2.50 mm (RG316) |

| Min Bend Factor | 5–10×OD |

| Loss_Budget_dB | Your acceptable max loss |

| Outdoor | Yes/No (for IP-rated sealing check) |

Equations:

- Cable loss = Alpha(f) × L

- Total loss ≈ Cable loss + 2 × Conn_Loss_per_end

- Pass_loss = (Total ≤ Loss_Budget_dB)

- Min_Bend_Radius ≈ Min_Bend_Factor × OD

Design tip: If Pass_loss fails, shorten the run or move from RG174 to rg316 coax. If bend radius fails, reroute the cable. If Outdoor_Pass fails, add an IP rated bulkhead. Planning with these numbers upfront saves both RF margin and field headaches.

Related reading: Compare coax attenuation and bend radius

Install and torque the SMA side without detuning the PCB jack

It’s easy to think of SMA connectors as rugged, but PCB-mounted jacks can be surprisingly delicate. Over-tighten the nut on an sma pigtail, and you risk twisting the jack right off the board. Leave it too loose, and you’ll see micro-movement that shows up as intermittent VSWR spikes. The solution is to start with finger tightening, then finish with a torque wrench set between 0.45 and 0.56 N·m, the range recommended by RF industry standards.

Why does torque matter so much? Inside the connector, the PTFE dielectric is designed for a precise geometry. Excessive force can warp that dielectric, shifting impedance and introducing extra coax attenuation. Too little torque, on the other hand, lets vibration loosen the thread, which often explains mysterious “signal fading” in field gear.

TEJTE’s bulkhead SMA connectors are built for resilience—rated at ≤0.15 dB insertion loss up to 6 GHz, tested to 1000 V rms withstand voltage, and surviving 500+ mating cycles. But those specs hold true only when you respect installation practice. Add a simple strain-relief clamp and maintain the minimum bend radius (≥28 mm for RG174, ≥15 mm for RG316), and the assembly can serve for years without drama.

Field note: installers often overtighten out of fear the nut will back off. A dab of thread-locking compound is a better safeguard than brute force, and it avoids detuning the jack.

Related reading: Solve tight spaces without extra loss

Troubleshoot field issues—kinks, VSWR spikes, or water ingress?

Even with careful planning, failures still show up in the field. A cable that looked fine on the bench can behave very differently once it’s routed through a tight enclosure or exposed to weather. Knowing the common failure points helps you act fast instead of guessing.

- Kinks and crushed shielding → Once the braid is deformed, the 50 Ω impedance is gone. The result is extra loss and reflections. In practice, a damaged sma pigtail isn’t worth salvaging—replace it rather than trying to “straighten it out.”

- VSWR spikes → Often traced back to loose or overtightened connectors. Overtorque can compress the PTFE dielectric and detune the jack. The quick fix is to re-seat the connector and torque it within spec.

- Water ingress → Moisture creeping past the seal quickly corrodes brass contacts. That’s why an ip rated bulkhead with a silicone O-ring and an outdoor drip loop are must-haves for routers or IoT gateways. Once corrosion sets in, no amount of cleaning restores stable return loss.

- Connector wear → Gold plating thins after hundreds of insertions. Most SMA designs, including TEJTE’s, are rated for ~500 cycles. Past that, contact resistance climbs, and performance becomes unpredictable.

One practical trick: keep a spare wifi antenna extension cable or short rg174 extension cable in your kit. Swapping it in takes seconds and instantly tells you if the problem lies in the cable assembly or the device port. This approach often saves hours of probing with test gear.

For deeper troubleshooting, TEJTE’s RF connector families overview explains how VSWR, shielding, and insertion loss interact—knowledge that comes in handy when diagnosing subtle failures in telecom, industrial, or IoT deployments.

Can you DIY or repair a U.FL-to-SMA sma pigtail safely?

This image appears in the section discussing avoiding confusion between RP-SMA and U.FL. U.FL is an ultra-miniature press-fit interface commonly used inside space-constrained devices. This schematic helps users identify the U.FL interface and understand the importance of correctly selecting a U.FL to SMA (or RP-SMA) pigtail to avoid connection failures due to interface mismatch.

Field technicians often ask whether a broken sma pigtail can be patched instead of replaced. The answer depends on which end has failed. On the SMA side, minor repairs are possible. A loose pin can sometimes be re-crimped or re-soldered, especially if you’ve got access to proper tools. Adding a layer of heat-shrink tubing around the joint also helps relieve strain, which is particularly useful in FPV drones where vibration is constant.

The U.FL side, however, is a different story. U.FL connectors are tiny press-fit types, designed for only about 30 mating cycles. Once their spring fingers lose tension, no amount of solder or bending will restore proper contact. If the U.FL end is damaged, the only reliable fix is full replacement. Trying to repair it often leads to unstable VSWR or intermittent connections that show up only under load.

There are niche cases where direct solder is an option. For example, some FPV pilots solder the coax directly onto a Mach 2 VTX board when they don’t have a replacement handy. It works—but only if you’re using a temperature-controlled iron and understand PTFE’s limits. Overheating melts the dielectric, shifting impedance and raising coax attenuation. Unless you’ve got steady hands and experience, it’s a risky move.

From a professional standpoint, stocking a few spare assemblies is smarter. TEJTE’s RG316-based pigtails, rated for ≤0.15 dB insertion loss at 6 GHz and built with gold-plated brass, are reliable drop-in replacements. They’re also IP67-ready when paired with bulkhead O-rings, making them suitable for both indoor and outdoor use.

Practical note: a DIY patch might get you through a test session, but for production equipment—routers, medical devices, or military radios—replacement is always the safer call.

Related reading: Choose the right sma pigtail

Frequently Asked Questions

How long can a 2.4/5.8 GHz SMA pigtail be before loss becomes a problem?

At 2.4 GHz, RG174 loses roughly 1.47 dB per meter, while RG316 is similar but holds up better to heat and tighter bends. Once you go beyond 2 m, total loss—including ~0.2 dB from connectors—reaches around 3 dB. At 5.8 GHz, the same length burns nearly double the margin. For Wi-Fi or FPV gear, try to keep pigtails under 1 m unless you upgrade to a lower-loss family. See compare coax attenuation and bend radius for more examples.

Is RG316 a meaningful upgrade over RG174 for short internal jumpers?

Yes. For runs under 1 m, the attenuation difference is small. But RG316’s PTFE dielectric and 150 ℃ rating make it more durable, especially in hot enclosures or near power circuits. That’s why aerospace and lab gear specify RG316 even when a basic rg174 extension cable could technically work.

Do I need an ip rated bulkhead if the enclosure already has a sealed feed-through?

If the feed-through is compression-tested, you might get away without one. But real-world installs see condensation, cable tugging, and vibration. An IP rated bulkhead with a silicone O-ring adds redundancy and peace of mind. TEJTE’s SMA bulkhead connectors are designed exactly for this.

What’s a safe minimum bend radius for RG174 vs RG316 inside tight enclosures?

RG174 should stay above 28 mm, roughly the size of a coin. RG316 bends tighter at about 15 mm, similar to your pinky finger. Push either cable tighter than spec, and you’ll see rising coax attenuation and premature braid fatigue.

Can I repair a U.FL-to-SMA pigtail in the field, or should I replace it outright?

The SMA side can sometimes be re-crimped or reinforced with heat-shrink. But the U.FL side is rated for just 30 insertions. Once worn, it’s done. For mission-critical gear, replacement is the professional call. Keeping a few spares avoids downtime.

Will a short wifi antenna extension cable outperform a rigid adapter stack on the bench?

Absolutely. Each rigid adapter adds ~0.1 dB of loss and extra stress. A wifi antenna extension cable or short sma extension cable replaces multiple couplers with less loss and less risk to PCB jacks. See use an sma extension cable when rigid adapters add stress.

How do I avoid RP-SMA vs SMA polarity mistakes when ordering replacement pigtails?

Check the center: SMA male = pin, SMA female = socket; RP-SMA reverses it. Many Wi-Fi cards (like the Intel 8265) use RP-SMA. Double-check datasheets or refer to SMA male/female connector guides.

Wrapping Up: Choosing the Right SMA Pigtail

This image appears in the conclusion section of the document, showing a physical TEJTE SMA pigtail (SMA-J) and its key dimensions. Serving as a visual summary, it emphasizes that when selecting a pigtail, in addition to cable type (RG174/RG316) and connectors (IP rating, gender), the specific physical dimensions (like length) are also crucial to ensure proper installation and routing inside equipment or chassis.

Selecting the right sma pigtail isn’t about guessing—it’s about mapping system needs to real specs. If your priority is low coax attenuation, RG316 offers safer margins at high frequencies and in hotter environments. If cost and light weight are higher on your list, a short rg174 extension cable often gets the job done. And for outdoor gear, never skimp on ip rated bulkheads—they’re the difference between stable long-term installs and corroded threads after one rainy season.

In practice, engineers juggle three factors: loss, bend radius, and environment. TEJTE’s lineup—from bulkhead connectors to custom-cut pigtails between 0.08 m and 2 m—covers these trade-offs directly. With real numbers in hand, you’ll avoid mismatched adapters, unstable VSWR, and wasted link margin.

Bottom line: plan ahead. Respect bend specs, keep losses in budget, and think about where water might sneak in. Do that, and your assemblies will perform consistently across Wi-Fi routers, FPV drones, industrial boards, and even outdoor 5G gear.

Explore more:

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.