SMA Panel Mount Connector Guide: Bulkhead, Flange & Waterproof

Sep 26,2025

Introduction

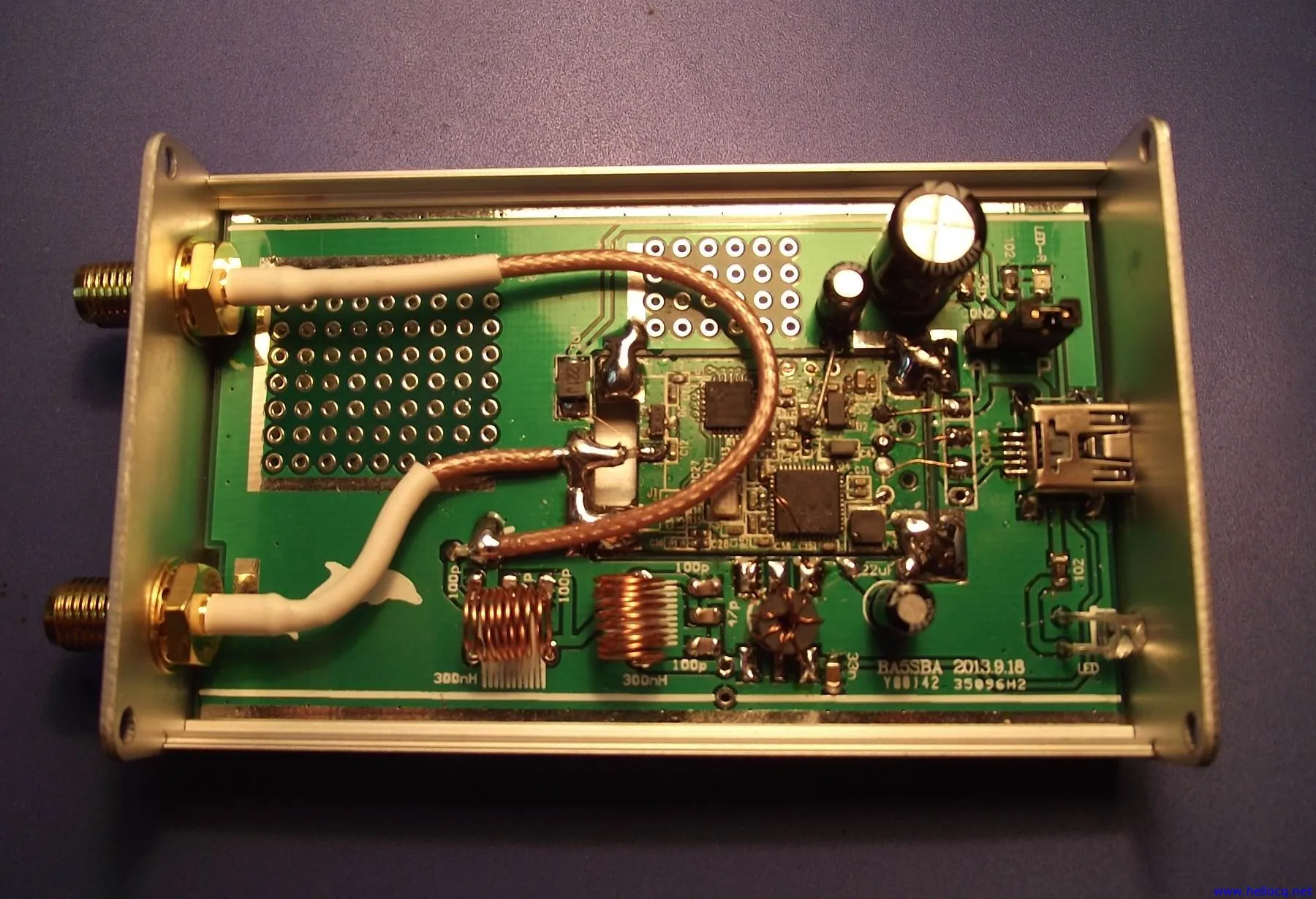

This diagram highlights the initial planning steps for selecting a panel mount SMA connector, such as choosing between a bulkhead or flange style and ensuring the correct fit for the enclosure to prevent sealing or vibration issues.

Before ordering a panel mount SMA connector, it’s smart to pause and check the fundamentals. What cutout size will you drill? How thick is the panel wall? Do you need a quick bulkhead nut fit or a sturdier flange type? These aren’t small details—get them wrong and you’ll face poor sealing, vibration failures, or even a leaky enclosure. For outdoor jobs especially, an IP67-rated waterproof SMA bulkhead can be the difference between years of reliable service and a connector that fails after the first rainy season.

At TEJTE, we’ve tested a wide range of models. Some are compact PCB-mounted parts like the SMA-50KY (0–6 GHz, PTFE insulation, brass gold-plated body). Others extend with bulkhead threads from 8 mm to 33 mm to suit different wall thicknesses. That mix lets designers match enclosure walls across networking gear, IoT boxes, or RF test equipment without sacrificing signal integrity.

Verify your series, gender, and direction before you drill

Illustrates a specific variant from the SMA-KE/KHD series, demonstrating the thread length (15mm) designed to securely mount through a panel within the specified thickness range.

Shows an SMA-KE connector with a longer (23mm) thread, necessary for thicker enclosure walls to ensure the nut has sufficient engagement for a secure and vibration-resistant hold.

Before you pick up a drill, ask yourself: which series and gender are you really ordering? A sma male panel mount connector looks almost identical to a female one—until you check the center pin. That tiny detail decides whether the cable mates or leaves you with an open circuit.

Take the SMA-KE/KHD series as an example. These connectors cover DC–6 GHz and come in several leg lengths (8 mm, 11 mm, 13 mm, 15 mm). That range means you can adapt the same series for slim router housings or deeper instrument panels without redesigning the entire RF path. It’s a small choice up front that saves redesigns later.

If you’re working with a thicker wall—say a cast aluminum enclosure over 5 mm—you’ll likely need a sma male bulkhead panel mount connector. Extended thread versions such as TEJTE Part No. 09656 or 11847 provide 15 mm and 23 mm of thread, ensuring the nut fully engages. Without that extra reach, the nut might bite only a couple of turns, which won’t hold under vibration.

Avoid RP-SMA mix-ups by checking pin/socket and labeling

This side-by-side diagram clearly differentiates standard SMA and Reverse Polarity SMA (RP-SMA) connectors by their center contact (pin or socket), preventing mating errors that can cause RF signal failure.

Here’s a mistake many installers have lived through: mixing RP-SMA and standard SMA. The threads are identical, but the polarity flips—the RP version swaps the pin and socket. On paper it looks harmless; in reality, the RF chain goes dead. I’ve seen teams burn hours troubleshooting “faulty equipment” only to discover the wrong feedthrough was used. The quick fix? Always check the datasheet, and clearly label ports when bulk ordering. A bit of tape or a marker can save a service call.

Related reading: SMA Connector Dimensions: Cutouts & Thread

Size your sma panel cutout and panel thickness to fit the thread?

Allows designers to visually compare the 13mm and 15mm thread length options within the same connector series, facilitating the selection of the optimal model for the specific panel thickness in their application.

Depicts the final installed state of a 15mm thread-length SMA-KE connector, emphasizing the importance of full nut engagement on the panel for mechanical stability.

The SMA standard thread is 1/4-36 UNEF, but that’s only the starting point. What really matters is how your sma panel mount connector dimensions line up with the enclosure wall. If the cutout is too small, you’ll fight the connector into place and risk scraping the plating. Too large, and the O-ring may never compress evenly.

For most TEJTE bulkhead connectors, a 6.5 mm panel cutout hits the sweet spot. The tolerance window is tight—about ±0.1 mm—so it’s worth drilling with a step bit or reamer rather than a dull twist drill. I’ve seen installers force a connector through an undersized hole, only to shear the O-ring on the way in. That mistake usually means moisture ingress later.

Panel thickness is the next piece of the puzzle. If you’re working with a 1–3 mm steel sheet, a standard 8 mm thread version (Part No. 06307) will clamp just fine. Move to a thicker enclosure wall, though—such as double-walled housings or die-cast aluminum—and you’ll want extended threads. TEJTE’s 13 mm (Part No. 08836) and 15 mm (Part No. 09657) options make sure the nut still grabs at least two to three full thread pitches, which is the minimum for vibration safety.

Check wrench clearance around the sma nut and nearby heat-sinks

Thread engagement is important, but don’t overlook the space around the sma nut. Most nuts take an 8 mm spanner, and you’ll need clearance not just for the nut itself but for your hand or torque wrench. In one rackmount RF switch project, the heat-sink fins came so close to the cutout that the installer couldn’t get a wrench on the nut. The fix? They swapped to a sma flange connector, which shifted the load to screws and cleared the obstruction. It’s a good reminder: always look beyond the hole—think about the wrench swing too.

Related: RF Connector Guide

Choose bulkhead vs flange—when does an sma flange connector win?

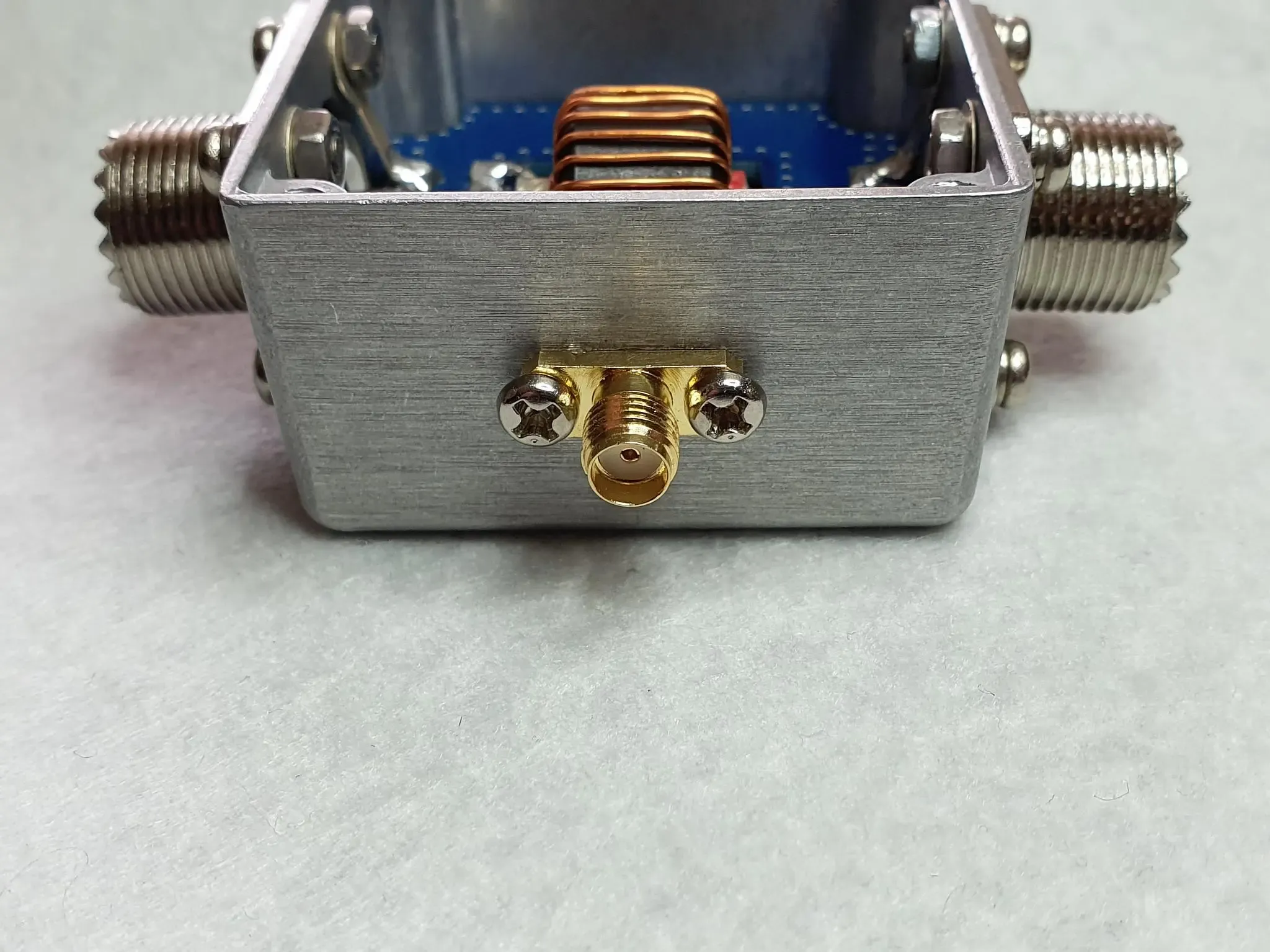

Illustrates a typical use case for a flange-mount SMA connector, where it is secured with multiple screws to distribute load and prevent rotation under vibration or cable stress, such as on utility poles or in industrial settings.

A sma bulkhead connector is the go-to choice for most builds. It’s simple: drill one hole, slide in the connector, tighten the nut, and you’re done. That speed and convenience explain why models like the SMA-KE/KHD series (with thread lengths from 8 mm to 20 mm) show up everywhere—from Wi-Fi routers to compact RF modules. For sheet-metal panels, it’s usually all you need.

But bulkheads have a weakness. Under constant vibration, or when a stiff coaxial cable twists against the nut, the connector can rotate. Even a slight movement risks loosening the O-ring seal or shifting the RF alignment. That’s when a sma flange connector really earns its keep. By anchoring with two or four screws, the flange spreads the mechanical load and locks the connector against rotation.

A practical example: one of our customers built a smart meter housing mounted on a utility pole. The first prototypes used a bulkhead mount. After six months of wind and cable stress, several connectors rotated enough to break the internal solder joints. Switching to TEJTE’s N/SMA-KKF flange series solved the problem. These connectors, rated DC–11 GHz and IP67 with silicone O-rings, held up through both vibration and outdoor weathering.

So, when should you pick flange over bulkhead? If your panel is thin sheet metal in a low-vibration environment, bulkhead saves time. But for cast housings, outdoor gear, or anything subject to torque and shock, the flange mount is the safer investment.

Related: SMA Bulkhead Connector: Panel Mount, Flange Types & Waterproof Use

Do you need an ip rated or waterproof sma bulkhead for outdoor use?

If your application moves outdoors, sealing stops being a “nice-to-have” and becomes a requirement. A standard sma panel mount connector without an O-ring can survive inside a rack, but once it faces rain, dust, or salt air, failure is only a matter of time. That’s why choosing an IP-rated waterproof sma bulkhead is critical for outdoor gear like mast-mounted antennas, surveillance cameras, and marine IoT devices.

TEJTE’s extended bulkhead line solves this with silicone O-rings (used in models 06307, 09656, and 11847) designed to compress 15–30% under torque. That compression range strikes the balance: too little, and the panel leaks; too much, and you risk deforming the enclosure wall. Pairing the O-ring with a brass gold-plated housing helps resist corrosion while maintaining conductivity, though in harsher salt-spray or UV-heavy environments, stainless steel may be the safer long-term bet.

We’ve seen this play out in the field. In one coastal deployment, installers initially used non-sealed bulkheads. Within half a year, corrosion crept in around the panel edge, forcing expensive retrofits. A properly chosen IP67-rated SMA bulkhead connector with UV-stable seals would have prevented that downtime entirely.

So if you’re wondering whether to spec waterproof or not, ask yourself a simple question: will the enclosure ever see weather, humidity, or salt? If the answer is “yes,” an IP-rated bulkhead isn’t optional—it’s insurance.

Related blog: SMA to N Adapter: 50Ω Straight & Weatherproof Picks

Prevent detuning—how much nut torque is safe on panel jacks?

Tightening the sma nut isn’t just a mechanical step—it directly affects RF performance. Over-torqueing can squeeze the dielectric and shift impedance, raising VSWR. Go too light, and vibration or cable pull may loosen the joint over time. The sweet spot lies in the 0.34–0.57 N·m torque range, which most TEJTE bulkheads are rated for.

Take the SMA-KE series as an example. These panel connectors, rated up to 6 GHz, have been vibration-tested under Method 213 and still maintain <0.15 dB insertion loss after torque cycling. That level of reliability doesn’t happen by accident—it’s the result of combining precise sma panel mount connector dimensions with controlled torque.

From field experience, installers often rely on “finger-tight plus a little extra.” While it works short term, it risks detuning or damaging thin panels. A better habit is to keep an 8 mm torque wrench in the kit. One engineer I worked with said he could cut troubleshooting calls in half simply by enforcing torque checks at assembly. The small upfront discipline prevented connectors from backing off during shipping or field vibration.

And remember, thin sheet metal needs extra care. Clamp too hard on a 1 mm panel and you might bow the wall or crush the O-ring seal. In such cases, switching to a sma flange connector helps by spreading force across multiple screws, protecting both the seal and the enclosure.

Related blog: SMA Connector Dimensions: Cutouts & Thread

Route cable—will lmr100 sma male panel mount connector simplify tight builds?

Shows an SMA panel mount connector featuring a short, flexible LMR100 cable (pigtail). This design simplifies routing in compact enclosures, minimizes sharp bends in the coaxial cable, and relieves strain on the internal solder connections, enhancing reliability.

Not every challenge with a panel mount sma connector happens on the outside of the panel. Inside the enclosure, space is often just as tight. A straight feedthrough can force stiff coax into sharp bends, putting stress on solder joints or even cracking insulation. That’s where an lmr100 sma male panel mount connector with a short pigtail earns its keep.

LMR-100 is thinner and more flexible than RG-316, with a tighter bend radius that makes it ideal for compact housings. We’ve seen it used successfully in IoT gateways, drones, and handheld radios where space behind the panel is less than 20 mm. Instead of fighting with rigid coax, installers route the pigtail smoothly to the board, avoiding sharp bends that could raise loss or create long-term reliability issues.

One customer told us they cut assembly failures in half by switching from RG-316 to LMR100 pigtail panel mount SMA connectors. The reasoning was simple: flexible tails relieved stress at the bulkhead, while strain relief boots provided extra protection during cable handling. That kind of small design decision can save hours of troubleshooting later.

If you’re building in a cramped enclosure, it’s worth weighing whether a short pigtail might actually simplify your layout. In many cases, it’s not just about saving space—it’s about ensuring the connector lasts through vibration, transport, and daily use.

Related blog: SMA Pigtail Guide: RG174 vs RG316, Loss, Bends & Waterproofing

Calculate cutout, stack height, and sealing compression before you buy

TEJTE Panel-Mount SMA Fit & Sealing Planner

| Model (TEJTE) | Thread Length | Panel Thickness | Recommended Cutout | O-ring / Seal | Torque Range | Insertion Loss | Durability Range |

|---|---|---|---|---|---|---|---|

| 06307 | 8 mm | 1-3 mm | 6.3-6.5 mm | Silicone O-ring, IP65 | 0.34-0.57 Nm | ≤0.15 dB @ 6 GHz | ≥500 cycles |

| 08836 | 13 mm | 2-5 mm | 6.4-6.6 mm | Silicone 6146, IP67 | 0.34-0.57 Nm | ≤0.15 dB @ 6 GHz | ≥500 cycles |

| 09657 | 15 mm | 3-6 mm | 6.4-6.6 mm | UV-stable O-ring, IP67 | 0.34-0.57 Nm | ≤0.15 dB @ 6 GHz | ≥500 cycles |

| 11847 | 23 mm | 5-8 mm | 6.4-6.6 mm | Silicone 6146, IP67 | 0.34-0.57 Nm | ≤0.15 dB @ 6 GHz | ≥500 cycles |

Field tip: always confirm thread engagement ≥2–3 full pitches. Anything less means the nut may back off under vibration. Likewise, O-ring compression should stay in the 15–30% range. Too soft, and you’ll lose sealing; too hard, and you may bow the panel.

By referencing these specs before ordering, you’ll avoid the two most common mistakes we see: undersized cutouts that shred seals, and short threads that barely hold a nut. A few minutes with the planner beats hours of rework.

Install in the right order and re-check VSWR after assembly

Even with the correct panel mount sma connector in hand, a rushed installation can undo all the engineering behind it. The sequence matters. Skipping steps or over-tightening may not only compromise the seal but also detune the RF path. Here’s the order we recommend:

- Prepare the cutout. Drill to 6.5 mm and deburr the edges so the O-ring won’t snag or tear.

- Insert the connector. Position the O-ring flush against the panel, then slide the connector through.

- Hand-start the nut. This avoids cross-threading the fine 1/4-36 UNEF threads.

- Align and torque. For flange mounts, line up screw holes. For bulkheads, torque the nut to 0.34–0.57 N·m with an 8 mm wrench.

- Seal check. Confirm the O-ring compresses 15–30%. A feeler gauge or caliper check makes this more precise.

- Continuity test. Verify that the center pin and shell show proper DC paths.

- High-pot test. Apply up to 1000 V RMS if required. TEJTE bulkheads pass this without breakdown.

- Insulation resistance. Check for ≥5000 MΩ at rated conditions—critical in high-reliability systems.

- Final RF sweep. Confirm VSWR ≤1.20:1 through 6 GHz and insertion loss <0.15 dB.

From field installs, we’ve learned that steps 7–9 are often skipped under schedule pressure. Yet those are the very checks that catch hidden issues. In one project, technicians shipped a cabinet without high-pot testing; the unit later failed under surge conditions. After adding dielectric withstand and VSWR checks to the workflow, returns dropped dramatically.

And don’t forget longevity: TEJTE’s SMA panel connectors are tested to withstand ≥500 mating cycles without degrading performance. If your design involves frequent connects/disconnects, tracking cycle counts is just as important as torque.

Related: SMA Right Angle Adapter: Solve Clearance Without Over-Torquing

FAQ

What hole size and panel thickness should I plan for a typical panel mount SMA connector?

Most sma panel mount connectors need a 6.3–6.5 mm cutout. For panel thickness, 1–3 mm is supported by standard 8 mm bulkheads (like TEJTE 06307). Thicker housings up to 8 mm require extended threads, such as 13–23 mm versions (Parts 08836, 09657, 11847).

When should I pick a flange-mount SMA instead of a single-nut bulkhead?

Use a sma flange connector when vibration or torque might rotate the nut. The flange anchors with two or four screws, spreading the load across the panel. Bulkhead is fine for thin sheet metal in low-vibration environments, but flange wins in outdoor or industrial housings.

Do I need an IP-rated waterproof SMA bulkhead if the enclosure already has a gasketed door?

Yes. Even if the enclosure door is gasketed, each feedthrough must seal on its own. An IP67-rated waterproof sma bulkhead with silicone or fluororubber O-rings ensures no water bypasses the door seal through the connector hole.

Which wrench size and torque range are safe for the SMA nut without detuning?

The nut flats measure 8 mm, so an 8 mm spanner fits. The correct torque is 0.34–0.57 N·m. This prevents loosening under vibration while avoiding over-compression of the O-ring and dielectric.

How much O-ring compression is ideal to reach IP67 while avoiding panel bowing?

Target 15–30% compression of the O-ring free height. Less won’t seal; more may bow thin sheet metal and shorten seal life. TEJTE’s silicone O-rings (model 6146) are designed around this window.

Is a short LMR-100 pigtail better than a straight feedthrough in cramped builds?

Yes. An lmr100 sma male panel mount connector bends tighter than RG-316, easing routing in enclosures with <20 mm clearance. It also relieves strain on solder joints, cutting assembly failures in half in some IoT and drone builds.

Will brass gold-plated hardware resist corrosion outdoors, or should I pick stainless?

Brass gold-plated connectors offer excellent conductivity and indoor corrosion resistance. Outdoors, especially in coastal or UV-heavy areas, stainless steel SMA bulkheads last longer against salt and weather exposure.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.