What Is a 4.3-10 Connector? Specs, Torque & 5G Uses

Aug 28,2025

Introduction

Climb a tower today and you’ll spot a compact silver interface labeled 4.3-10. It looks like any coax fitting, but the 4.3-10 connector was built for the LTE/5G era: low Passive Intermodulation (PIM), tighter port spacing, and quicker installs. For years, the heavy 7/16 DIN dominated high-power work. As gear shrank and ports multiplied, crews needed something smaller that still protected link budgets. The 4.3-10 answered with low PIM, lower torque, and dependable weather sealing.

Clean side-by-side photo highlighting the male center pin and the female receptacle of 4.3-10 connectors, suitable for high-density panels.

This guide explains what the 4.3-10 connector is, why networks prefer it over N-Type and 7/16 DIN, how to choose coupling styles and cables, and where adapters fit. We’ll also share field habits—like re-torquing after the first week of thermal cycling—that keep PIM in check and maintenance predictable.

Definition & Use Cases

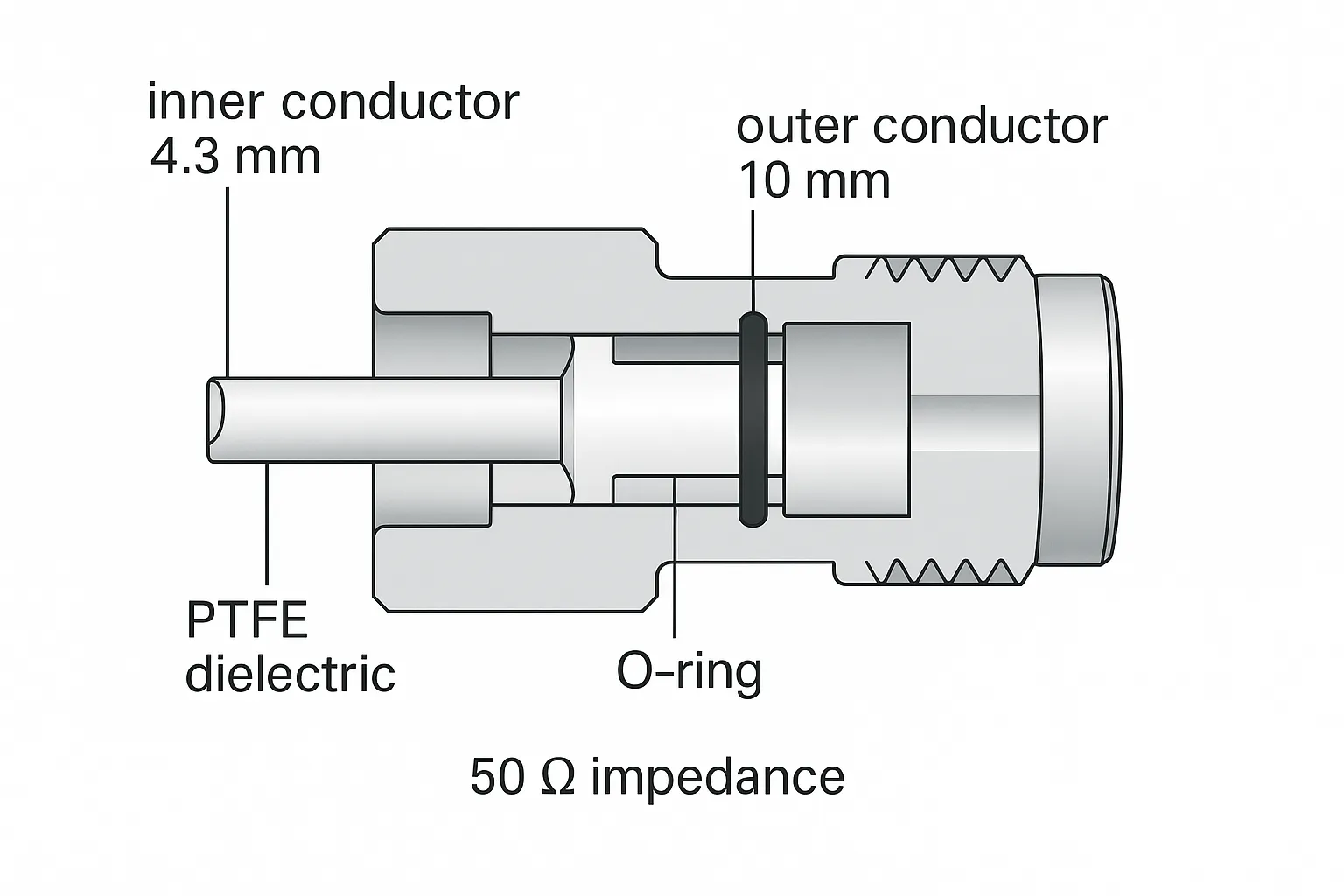

The 4.3-10 connector is a 50-ohm coaxial RF interface optimized for dense, multi-carrier infrastructure. The numbers reference its approximate inner (4.3 mm) and outer (10 mm) conductor geometry, enabling a compact footprint without sacrificing matching or stability.

Where you’ll see it

- Macro radios & sector antennas in multi-band LTE/5G.

- DAS/small cells across stadiums, airports, campuses.

- Massive-MIMO arrays where high port density is non-negotiable.

- Filters, combiners, amplifiers crowded inside outdoor cabinets.

- Outdoor antennas that demand IP-rated connectors.

Why operators care

- Low PIM for clean multi-carrier paths.

- Lower torque (typically 5–8 N·m) for faster, safer installs.

- High density layouts that keep radios compact and lighter.

Field note: On tower jobs, we log torque at install and re-torque after the first week of thermal cycling. It’s cheap insurance against drifting PIM.

Anatomy & Specs

Labeled cutaway diagram showing inner/outer conductor geometry, dielectric, and O-ring placement for weather sealing.

Every element of a 4.3-10 connector—contact geometry, dielectric, O-ring—serves stability and longevity. While exact limits are vendor-specific, telecom deployments cluster around the envelope below.

A quick snapshot of typical 4.3-10 specs:

Table A – Specification Snapshot

| Parameter | Typical Value | Field Note |

|---|---|---|

| Impedance | 50 Ω | Industry standard |

| Frequency Range | 0–6 GHz* | Many units tuned for 700–3800 MHz |

| PIM Performance | ≤ –155 to –160 dBc | Clean multi-carrier operation |

| VSWR / Return Loss | ≤ 1.2 across band | Low reflection, stable matching |

| Weatherproofing | IP67 (with sealing) | Rooftop/tower ready |

| Mating Durability | High cycle count | Built for repeated service |

- Always confirm in the datasheet.

In practice: After storms, if VSWR creeps up, we inspect connector faces for moisture tracks before touching radios or antennas. We wipe both sides with 99% IPA and use canned air—tiny fibers can become big PIM rumors.

Coupling Options & Torque

One advantage of the 4.3-10 connector is flexible mating. Choose the style that fits your environment and service routine.

Let’s turn this into a field checklist your crew can follow:

- Screw type — Threaded and stable for permanent outdoor work. Typical torque 5–8 N·m (vs. 25–30 N·m on 7/16 DIN).

- Hand-screw type — Knurled nut for quick tool-free installs; verify with a torque wrench if your SOP requires it.

- Push-pull type — No wrench, click-lock convenience for dense racks or frequent swaps.

Table B – Torque Checklist

| Step | Best Practice |

|---|---|

| Clean surfaces | Lint-free wipes + isopropyl alcohol; keep debris off contacts |

| Pre-align | Hand-seat to prevent cross-threading |

| Tighten | 5–8 N·m on screw type; confirm hand-screw engagement |

| Re-check | Inspect after high winds or rapid hot-cold cycles |

| Record | Log torque and photos of sealing for traceability |

Minimal infographic with three labeled ranges highlighting typical torque specs for 4.3-10, 7/16 DIN, and N-Type connectors.

Tower routine: Screw types get 5–8 N·m at install; we re-check torque after the first rapid hot–cold cycle and after the first major storm. For push-pull, a quick tug test confirms full engagement.

Power, PIM & Field Performance

The 4.3-10 connector targets mainstream LTE/5G power levels while keeping PIM low and port density high. It won’t beat 7/16 DIN in extreme broadcast roles, but it covers the vast majority of urban/suburban deployments.

At-a-glance performance for day-to-day LTE/5G work:

Table C – Performance Summary

| Metric | 4.3-10 | Field Meaning |

|---|---|---|

| PIM | ≤ -155 to -160 dBc | Stable with multi-carrier loads |

| Port Density | High | More ports per radio/antenna |

| Torque | 5–8 N·m | Faster installs; fewer thread issues |

| Outdoor Sealing | IP67 (with O-ring) | Resists water/dust when sealed correctly |

| Power Handling | Medium-High | Suits LTE/5G; extreme broadcast may need DIN |

Acceptance test: We run a two-tone PIM and a sweep; if results drift, we clean and re-torque before swapping hardware. If PIM persists, we swap jumpers first—the cheapest variable moves first.

Form Factors & Part Naming

The 4.3-10 connector comes in shapes that make routing sane and serviceable inside cramped cabinets or on windswept masts.

A parts map to keep ordering clean and error-free:

Table D – Form Factor Overview

| Form Factor | Description | Typical Use Case |

|---|---|---|

| Plug (Male) / Jack (Female) | Standard genders | Cable ends vs. equipment ports |

| Straight / Right-angle | Orientation options | Tight cabinets, strain relief |

| Bulkhead / Panel-mount | Pass-through installation | Enclosures, rack panels |

| Coupler (M-M / F-F / M-F) | Gender/extension adapters | Test benches, temporary connections |

Why naming matters: Ordering “4.3-10 male to 4.3-10 male” when you needed M-F can stall a maintenance window. For larger buys, we request dimensional drawings and label samples.

Field tip: Crews often carry M-M couplers for quick bypass tests; right-angle plugs reduce bend stress on thick feeders.

Weatherproofing & IP

Moisture, dust, UV, and thermal cycles can turn a perfect port into a PIM generator. The 4.3-10 connector includes seals; paired with proper technique, it achieves IP67.

A simple sealing SOP that survives real weather:

- Clean — Remove dust/oil before mating.

- Self-amalgamating tape — First barrier, wrapped snugly around the joint.

- Heat-shrink tubing — Secondary shield against UV and water ingress.

- Weather boots/caps — Added defense in heavy rainfall regions.

- Routine inspections — Post-storm and seasonal checks for cracks/condensation.

- Drip loop — Ensure water can’t migrate into the connector.

We’ve learned the hard way that a good seal beats a good excuse; one hairline crack in tape can undo an entire sector’s gains.

Cable Pairing & Loss Planning

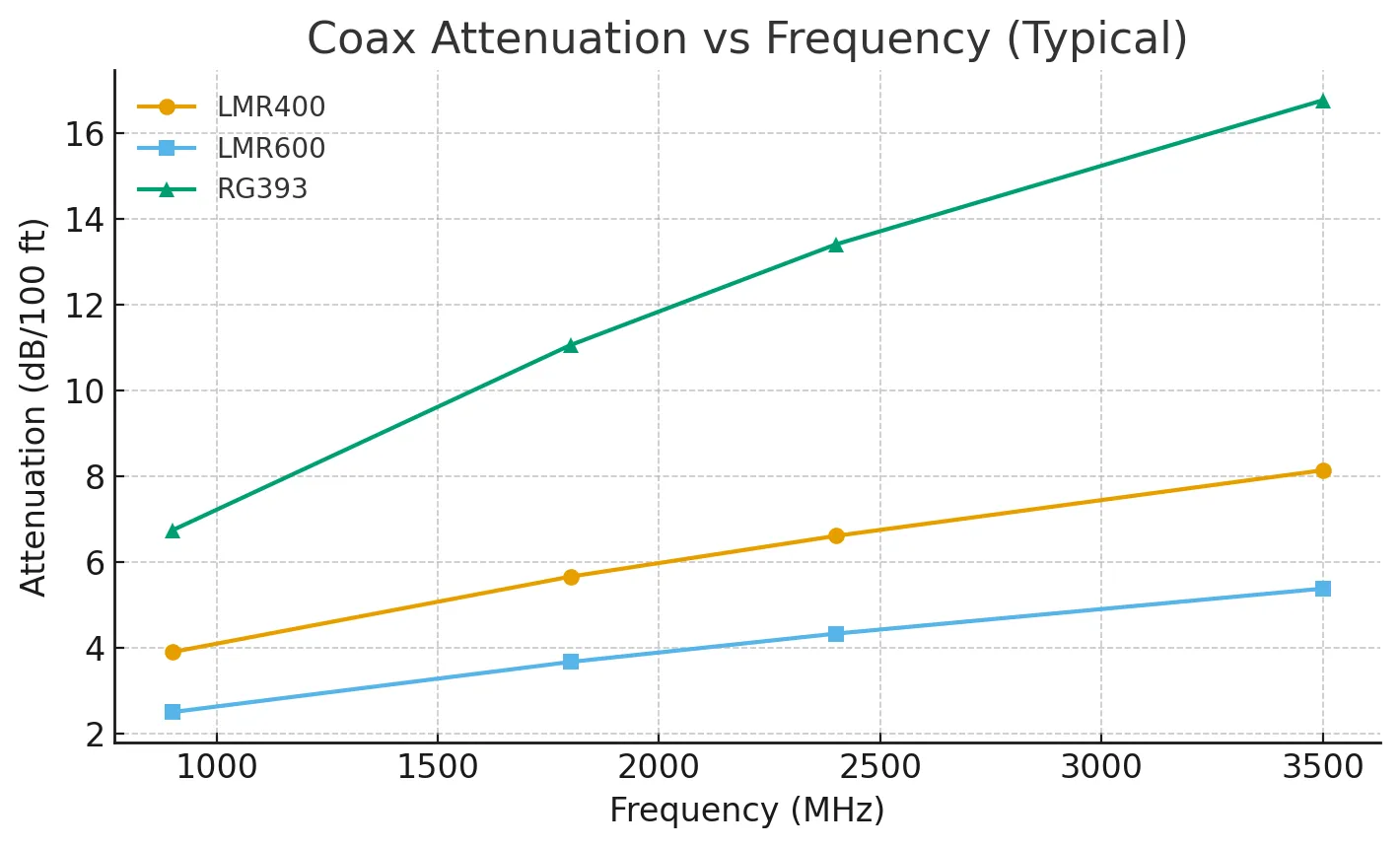

A clean port still fails if the feeder budget is blown. Pair the 4.3-10 connector with cables sized for frequency and distance.

Minimal line chart showing typical attenuation (dB/100 ft) versus frequency for three telecom coaxial cables—LMR400, LMR600, and RG393—at 900, 1800, 2400, and 3500 MHz. Helps plan feeder length and cable selection.

A planning cheat sheet for loss by band and cable (approximate):

Table E – Attenuation Planner

| Band (MHz) | Cable Type | Loss per 100 ft | Typical Use Case |

|---|---|---|---|

| 700–900 | LMR-400 | ~3.6–4.0 dB | Medium tower / DAS feeders |

| 1800 | LMR-600 | ~4.4 dB | Long feeders up a tower |

| 2500 | RG-393 | ~6.7 dB | Short jumpers in racks |

| 3500 | LMR-600 | ~6.8 dB | 5G mid-band feeders |

Planner habit: We keep a cut-sheet of 100-ft losses by band; after any connectorization we run a quick sweep to confirm the run stayed on budget.

4.3-10 vs 7/16 DIN vs N-Type

Comparing standards clarifies where each shines.

Side-by-side: where each connector fits best:

Table F – Connector Comparison

| Feature | 4.3-10 | 7/16 DIN | N-Type |

|---|---|---|---|

| Size / Density | Small / High density | Large / Low density | Medium / Moderate density |

| Torque | 5–8 N·m | 25–30 N·m | ~1.5 N·m (by spec) |

| PIM | Very low (-155 dBc class) | Very low | Moderate |

| Power Handling | Medium-High | Very high | Medium |

| Outdoor Sealing | IP67 (with accessories) | IP67-68 | Needs additional sealing |

| Best Fit | LTE/5G high density | Broadcast/extreme power | Cost-sensitive/legacy upgrades |

Bottom line: New LTE/5G builds → 4.3-10. Extreme power → 7/16 DIN. Budget or legacy → N-Type.

Common Adapters & When to Use

Mixed environments are normal. Adapters bridge standards—but each joint adds insertion loss and PIM risk. Use them sparingly and seal them well outdoors.

Datasheet-style image for the 4.3-10 to N-Type male–male adapter (N-JJ), showing 50 Ω, DC–6 GHz, DWV ≥2500 V RMS, –45~+125 °C, ≥500 cycles, PTFE dielectric.

An adapter map for mixed-vendor or legacy sites:

Table G – Adapter Map

| Adapter Type | Typical Use Case | Caution |

|---|---|---|

| 4.3-10 → N-Type | New 4.3-10 radios to older N gear | Extra joint = added PIM; verify sealing |

| 4.3-10 → 7/16 DIN | Legacy broadcast / macro transitions | Torque mismatch; ensure full seating |

| M-M / F-F / M-F | Gender correction, test benches | Best as temporary or certified low PIM |

Datasheet-style image for the 4.3-10 to N-Type female–female adapter (N-KK), showing 50 Ω, DC–6 GHz, DWV ≥1500 V RMS, –45~+125 °C, ≥500 cycles, PTFE dielectric.

Buyer’s Checklist

Before you order, align the connector choice to bands, power, and maintenance.

- Bands & Power — Confirm site bands and maximum TX power. Extreme power may still favor DIN 4.3 10’s older cousin 7/16 DIN.

- PIM Target — For multi-carrier LTE/5G NR, specify ≤ –155 dBc with test reports.

- Coupling Type — Screw for permanent outdoor; push-pull for quick swaps; hand-screw for maintenance speed.

- Cable & Length — Match to LMR-400/600 or RG-393 per distance and band; verify attenuation.

- Weatherproofing — Plan O-rings, self-amalg tape, heat-shrink, boots; include drip loops; schedule inspections.

- Tools & Spares — Calibrated torque wrench (5–8 N·m), cleaning kits, spare O-rings, dust caps, 4.3-10 male to 4.3-10 male couplers for tests.

- Documentation — Acceptance plan (sweep + PIM + torque log + sealing photos) saves weeks later.

FAQs

Q1. What is the standard 4.3-10 connector?

A compact 50-ohm RF connector delivering low PIM for LTE/5G. It comes in screw, hand-screw, and push-pull styles.

Q2. 4.3-10 vs N connector—what’s different?

4.3-10 enables higher port density and lower PIM. N-Type is cost-effective for medium power but less ideal in multi-carrier, low-PIM networks.

Q3. 4.3-10 vs 7/16 DIN?

7/16 DIN excels at extreme power and remains in broadcast/legacy macro sites. 4.3-10 is lighter, needs less torque, and fits dense LTE/5G gear.

Q4. What is “4.3-10 male to 4.3-10 male”?

A male-to-male coupler or jumper used to connect two female ports—handy for extensions and test bypasses.

Q5. Is a 4.3/10 waterproof?

With proper sealing (O-rings, self-amalg tape, heat-shrink, boots), assemblies achieve IP67. Long-term reliability depends on technique.

Q6. Do I need a torque wrench?

For screw types, yes—best practice is 5–8 N·m with a logged reading. Push-pull/hand-screw are tool-free but must be fully engaged.

Q7. Are DIN connectors still used?

Yes. 7/16 DIN (a classic coax DIN connector) still serves high-power and legacy systems; new LTE/5G tends to standardize on 4.3-10.

Q8. Can I use a 4.3-10 adapter to N type long-term?

Prefer short-term use. Every adapter adds a joint (PIM risk). If you must, choose certified low-PIM parts and plan a native re-termination.

Conclusion

The 4.3-10 connector reflects where networks are headed: denser gear, cleaner signal paths, faster field work. By pairing low PIM with lower torque and a compact footprint, it’s the pragmatic choice for LTE and 5G builds. If you’re upgrading or migrating mixed-vendor sites, standardizing on 4.3-10, selecting low-loss feeders, and minimizing adapters will pay off in fewer service calls and steadier KPIs.

TEJTE supplies certified 4.3-10, 7/16 DIN, and N-Type solutions with custom low-PIM jumpers, weather-sealed kits, and adapter options for transitional sites. Ready to simplify your next build? Our team can assemble a bill of materials aligned to your bands, power, and PIM targets.

Explore Further

If this guide has helped you understand the 7/16 DIN connector, you may also find these resources useful for comparing related RF interfaces and planning your cabling strategy:

- SMA vs BNC vs N-Type: Which RF Connector Should You Use? – side-by-side breakdown of three widely used connectors.

- RF Adapter Guide: From SMA to 110 GHz – practical overview of adapters and when to use them.

- Best Coaxial Cables 2025: RG & LMR Guide – compare loss, flexibility, and cost.

- RF Connector Selection Guide – step-by-step process to choose the right interface.

- 7/16 DIN (L29) Connector Guide – uses, torque specs, adapters.

Your Project Toolbox

For engineers sourcing hardware, here are direct links to the categories most often paired with DIN 4.3-10 systems:

- L29 Adapter Series – full range of 7/16 DIN (L29) adapters.

- RF Connectors – SMA, BNC, N-Type, DIN, and more.

- RF Cables – pre-terminated jumpers and low-loss feeder cables.

- Outdoor RF Antennas – weather-rated solutions for rooftop and tower installs.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.