SMA Male to Female Adapter: Angles & Feedthroughs

Sep 20,2025

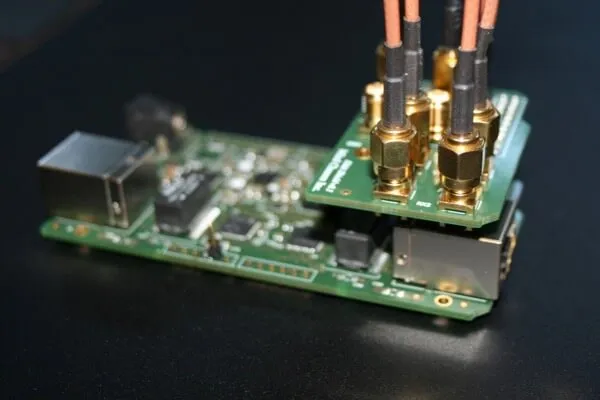

The image introduces SMA male to female adapters, used to connect mismatched ports, reduce stress, and provide flexible integration in RF chains.

Identify your ports and polarity before choosing M to F

The image highlights the polarity difference—SMA male has a pin, SMA female a socket, while RP-SMA reverses this, critical for WiFi routers and IoT devices.

One of the easiest mistakes to make is ordering the wrong connector type. A sma male to sma female adapter is not the same as its RP-SMA counterpart, even though at first glance they look nearly identical. The difference lies in the pin and socket. Standard SMA males have an inner pin with external threads, while the SMA female accepts it with a socket and internal threads. RP-SMA reverses the center conductor, so a “male” jack actually shows a hole instead of a pin.

This subtle change matters more than you might expect. Many Wi-Fi routers and IoT gateways ship with RP-SMA female jacks, meaning you’ll need an adapter that mates with that reversed polarity. In contrast, SDR modules and most RF lab gear stay with the standard SMA format, so a straightforward sma male female adapter will usually fit without issue.

From experience, the safest habit is to pause before checkout and look closely at the port. If you see a pin, you know it’s SMA male. If it’s a hollow socket, then it’s SMA female—or RP-SMA, depending on the thread. That ten-second check saves hours of troubleshooting and avoids returns.

For engineers handling larger runs, it’s smart to standardize on clear part numbers. TEJTE’s 08822-05744 inline coupler, for instance, specifies gender and frequency rating up to 6 GHz right in the datasheet. Having that clarity in your BOM reduces confusion across purchasing teams. More background on how these connector families relate to one another can be found in TEJTE’s RF connector guide, which outlines polarity and thread standards in detail.

Do you need an inline, right-angle, or bulkhead feedthrough adapter?

The image shows a straight inline SMA female to female adapter, widely used to extend or couple SMA male cables in RF systems. It provides stable 50Ω impedance and minimal insertion loss.

The image shows a straight inline SMA male to female adapter, commonly used to connect coaxial cables or extend ports in RF devices. It provides stable impedance and minimal insertion loss.

The image presents a 90° SMA male to female adapter, designed to redirect cable connections in tight spaces. It prevents sharp bends and reduces mechanical stress on device ports.

The image shows a waterproof inline SMA female to female adapter with a sealing cap. It is designed for outdoor RF applications, ensuring IP67 protection against rain, dust, and humidity.

Not every sma m to f adapter is designed for the same situation. The simplest is the inline coupler—essentially a straight-through bridge. It’s compact, low-loss, and quick to use. Still, when space is tight inside an enclosure, a right-angle sma male to female adapter (90° or even 135°) is often the better choice. By redirecting the cable, it prevents sharp bends that could otherwise damage the dielectric or strain the solder joints.

For chassis work, the bulkhead or panel feedthrough style becomes indispensable. These adapters come with extended threads, a securing nut, and usually an O-ring. That design lets you pass the connector cleanly through a housing wall, seal it against moisture, and keep sensitive electronics protected inside. In outdoor systems—think CPE units, IP cameras, or small cell radios—this approach is often the only reliable option. TEJTE’s SMA-KKF bulkhead adapter, for example, pairs sealing gaskets with ~8.6 mm of usable thread length, giving enough margin for painted panels and washer stacks.

The decision often comes down to geometry and service life:

- Inline to when space isn’t a concern and simplicity matters.

- Right-angle to when cable routing needs relief from sharp bends.

- Bulkhead to when you must cross a panel and maintain environmental sealing.

Choosing carefully at this stage avoids rework later. If you’d like to see how panel-mount connectors are applied in real builds, TEJTE’s article on SMA bulkhead connector types walks through panel mount and flange configurations with practical examples.

Will a male-to-female coupler add more loss than a short pigtail?

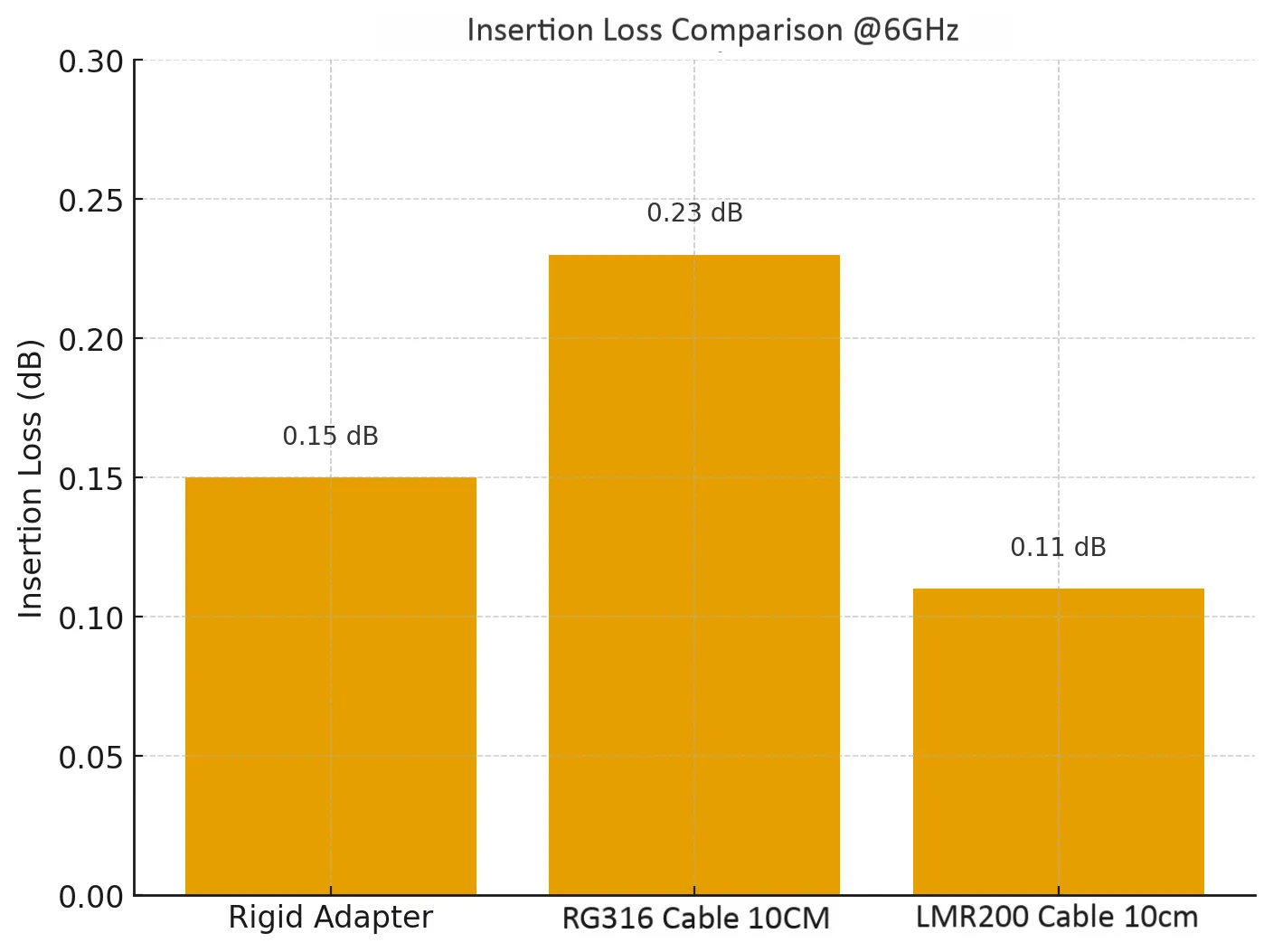

Signal integrity often gets overlooked until the link begins to underperform. Any sma male to female coupler introduces insertion loss and a small mismatch. For quality adapters, the figure is usually ≤0.15 dB at 6 GHz with VSWR around 1.2:1—negligible for short connections, but not always trivial in higher-frequency or low-margin systems.

A short coax jumper can be a smarter alternative in some cases. For instance, 10 cm of RG316 typically adds about 0.23 dB loss at 6 GHz, while LMR200 of the same length drops closer to 0.11 dB. Compared to a rigid adapter, the cable absorbs mechanical stress and protects fragile board-mounted SMA jacks. The trade-off is slightly higher loss, but far less risk of cracked solder joints.

From field experience, if you’re working with SDRs or outdoor CPE devices, a short jumper often saves you from costly port repairs. In lab setups where speed and convenience matter, a rigid coupler still makes sense—you can swap gear without tangling extra cable.

TEJTE covers this balance in its SMA extension cable guide, which explains how short pigtails help reduce lever stress while keeping loss within budget. Keeping both options in mind allows you to match the adapter type to the application instead of applying a one-size-fits-all approach.

Choose the right frequency rating for your link (6/18/26.5 GHz)

Not every sma male to sma female adapter can handle the same frequency range. Entry-level brass versions are usually rated up to 6 GHz. They’re perfectly adequate for Wi-Fi at 2.4 or 5 GHz, LTE bands, or IoT gateways. Yet, once you step into 5G mid-band, radar prototypes, or wideband test benches, those same adapters may no longer cut it.

For more demanding applications, you’ll want higher-grade models. Stainless-steel housings with beryllium-copper contacts—like TEJTE’s SMA-JKG (Part No. 55523)—are specified up to 26.5 GHz with VSWR kept at ≤1.2:1. That level of precision is what allows spectrum analyzers and mmWave setups to run reliably. In between sits the 18 GHz outdoor bulkhead design, such as the SMA-KKF, which balances environmental sealing with respectable high-frequency performance.

When weighing brass gold-plated against stainless steel, it isn’t only about price. Brass has lower contact resistance and excellent plating adhesion, making it a cost-effective choice for indoor networks. Stainless steel, on the other hand, resists corrosion and extends service life in outdoor or industrial conditions. A quick way to decide:

- 6 GHz brass adapters to consumer routers, Wi-Fi repeaters, IoT devices.

- 18 GHz waterproof bulkheads to outdoor CPE units, surveillance gear, weatherproof enclosures.

- 26.5 GHz stainless adapters to aerospace labs, 5G test beds, and advanced R&D.

For a broader comparison of how connector ratings line up with cable performance, you can explore TEJTE’s RF cable guide, which highlights when higher GHz capability actually translates into real-world benefits.

Select waterproof or indoor-only based on environment

The image presents a waterproof SMA M-F bulkhead adapter, designed for outdoor routers, CPEs, and antenna systems requiring IP67 sealing.

Where the adapter is installed can be just as critical as its frequency rating. An indoor sma male to female adapter without seals may perform flawlessly on a bench, yet once exposed to rain or humidity the story changes. Corrosion builds up, VSWR drifts, and over time the chain degrades. Engineers sometimes discover this only after field units start failing.

For outdoor setups—think rooftop Wi-Fi bridges, LTE gateways mounted on poles, or IP cameras—you’ll need a waterproof sma male to female adapter. These usually include an O-ring and longer threads to compress against the panel, maintaining a weather-tight seal. TEJTE’s SMA-KKF flange bulkhead is one example, designed for IP67-style applications and capable of supporting frequencies up to 18 GHz.

Indoor-only couplers, such as compact brass inline adapters, remain a smart choice for SDRs, lab instruments, or router upgrades. They save cost and space where environmental sealing isn’t required. The trade-off is clear: waterproof units are bulkier and more expensive, but they pay for themselves in reliability once deployed outside.

For buyers weighing options, TEJTE’s product section on SMA adapters and bulkheads shows how environmental sealing is integrated into different models. Reviewing those details before ordering avoids mismatches between lab expectations and field realities.

Size thread length for panel thickness and gasket stacks

When selecting sma bulkhead male to female adapters, one detail that often slips through the cracks is thread length. It might look trivial, yet if the adapter threads are too short, the nut won’t engage properly after accounting for paint layers, washers, and O-ring compression. The result? A loose mount, poor grounding, or even water ingress.

Take a simple case: a 2.0 mm aluminum panel with 0.2 mm paint, plus a 1.0 mm washer stack. Add at least 2.0 mm of nut engagement for mechanical strength and about 0.3 mm O-ring compression. The calculation is straightforward:

2.0 + 0.2 + 1.0 + 2.0 + 0.3 = 5.5 mm required thread length.

If your adapter only offers 4.5 mm, it won’t seal correctly. That’s why designs like TEJTE’s SMA-KKF bulkhead—with ~8.6 mm usable thread—are trusted in outdoor equipment builds. They give enough margin to handle panel thickness plus gaskets without compromising torque or sealing pressure.

A small reminder from field installs: don’t overtighten just to “make up” for short threads. Over-compression ruins the O-ring and weakens the seal. Spending a few minutes checking thread specs avoids costly rework later.

If you want to see how these mechanical checks fit into real-world connector choices, TEJTE’s write-up on female-to-female vs male-to-female adapters highlights why thread length matters when comparing couplers and panel feedthroughs.

Avoid RP-SMA vs SMA mix-ups and “gender changer” confusion at checkout

It’s easy to think all adapters with SMA threads will fit together, but that’s where many engineers and buyers trip up. A sma to sma adapter can look almost identical to an rp-sma male to sma female adapter, yet they won’t mate if the polarity is wrong. The giveaway is the center conductor: a visible pin means SMA male, while a hollow socket means SMA female—or RP-SMA, depending on the thread type.

The confusion doesn’t stop there. Some catalogs use vague terms like “jack-to-plug” or “gender changer” without clarifying polarity. A part labeled as an sma male to female coupler might actually be RP-SMA, leaving you with the wrong fit. To avoid this headache, always double-check three things before you order:

- Thread type: inner vs outer.

- Center conductor: pin vs socket.

- Frequency rating: 6 GHz, 18 GHz, or 26.5 GHz.

One practical way to reduce errors is to standardize part numbers across projects. TEJTE’s 08822-05744 inline coupler, for example, clearly lists gender, polarity, and performance (VSWR ≤1.2 up to 6 GHz). Having this consistency in your BOM keeps procurement and assembly aligned. If you’re still unsure about polarity, TEJTE’s overview on RP-SMA vs SMA in Wi-Fi devices provides a quick reference for spotting differences in router and antenna ports.

Install and torque an M to F adapter the right way

The image illustrates how SMA male to female adapters are applied in antenna-related products, such as WiFi routers, LTE gateways, and outdoor base station equipment, enabling secure RF connectivity.

Even the best sma male to female adapter won’t perform as expected if it’s installed carelessly. Over-tightening can strip the threads, while under-tightening often causes intermittent connections. The recommended torque range for SMA connectors is 0.45–0.56 N·m (about 4–5 in-lbs). That’s finger-tight plus a gentle turn with a torque wrench—never brute force.

A reliable installation routine goes something like this:

- Inspect the threads and remove any burrs or debris.

- Hand-tighten until resistance is felt.

- Apply torque with a calibrated wrench to the specified range.

- In vibration-prone environments, use anti-loosening compound.

- Verify performance with a quick VSWR sweep on a network analyzer.

In the field, engineers often skip the last step. Yet a poorly seated bulkhead can easily show VSWR spikes above 1.3:1 at 5 GHz, which may go unnoticed until the system fails under load. Spending two minutes on verification is worth the peace of mind.

The image shows how SMA adapters paired with short coaxial pigtails absorb strain, protecting sensitive PCB connectors from cracking under load.

Compare quick-connect (push-on) vs threaded adapters for serviceability

Not every project benefits from the classic threaded SMA. In high-turnover labs or test environments, a sma quick connect male to female adapter can save valuable time. Instead of carefully threading each connection, engineers simply push to lock and pull to release. It’s fast and convenient, especially when hundreds of measurements are made each day. The trade-off is slightly higher VSWR and less mechanical security, which makes them less suited for outdoor or vibration-heavy environments.

Threaded adapters, by contrast, remain the standard for deployed systems. Their secure coupling maintains consistent impedance, provides stronger grounding, and works better with weather-sealed bulkhead designs. For example, stainless-steel threaded versions like TEJTE’s SMA-JKG are tested to endure more than 500 mating cycles without significant wear, making them dependable for rugged telecom or defense applications.

A practical way to split the use cases is this:

- Quick-connect SMA M to F to best for lab benches, calibration rigs, and test stations.

- Threaded SMA male female adapter to the safer choice for telecom racks, outdoor radios, and equipment that must stay sealed.

For a broader context of how different SMA designs support long-term serviceability, TEJTE’s RF connector families overview highlights where quick-connects fit compared to other threaded connector options.

When should you pair an M to F adapter with a short coax instead?

The image compares rigid SMA adapters with coax jumpers: couplers have lower insertion loss, while coax jumpers offer mechanical relief for long-term reliability.

A rigid sma male to sma female adapter isn’t always the best option. When a stiff coax or a heavy antenna connects directly into a PCB-mounted jack, the leverage can stress solder joints and eventually crack the port. In the field, this type of mechanical failure is more common than people expect—and it usually happens long before the adapter itself wears out.

The safer choice in these cases is to use a short jumper cable. A 10 cm RG316 pigtail adds roughly 0.23 dB at 6 GHz, while LMR200 of the same length keeps loss closer to 0.11 dB. By comparison, a rigid coupler may only add about 0.15 dB. The difference in electrical performance is small, but the mechanical relief provided by coax is significant. It absorbs bending, reduces lever stress, and helps extend the lifetime of the device port.

For outdoor systems—think rooftop bridges or antennas exposed to wind gusts—a coax jumper becomes even more valuable. It allows the antenna to move slightly without transferring all the force into the connector. TEJTE’s discussion in the SMA extension cable guide explains how short pigtails balance loss against reliability, offering a simple way to safeguard both the equipment and the signal chain.

M to F Adapter Selector & Panel Stack Calculator

Choosing the right sma male to sma female adapter can feel overwhelming when balancing frequency, form factor, and sealing. To simplify, here’s a checklist engineers often use before placing an order:

Selection Checklist

- Confirm Port A / Port B: SMA or RP-SMA, male or female.

- Select Form Factor: inline, right-angle, bulkhead, flange, or quick-connect.

- Match Frequency Rating: 6 GHz for Wi-Fi, 18 GHz for outdoor CPEs, or 26.5 GHz for lab testing.

- Pick Material & Plating: brass gold-plated for affordability and stable contact, stainless steel for durability in harsh environments.

- Evaluate Loss Budget: consider both adapter insertion loss and coax attenuation.

- Check Environment: indoor-only or outdoor-rated with O-ring sealing.

- Verify Thread Length: enough margin for panel thickness, paint finish, washer stack, nut engagement, and O-ring compression.

Panel Stack Formula

Required Thread Length = Panel Thickness + Finish + Washer Stack + Nut Engagement + O-ring Compression

Example Calculation

- Panel: 2.0 mm

- Paint: 0.2 mm

- Washers: 1.0 mm

- Nut: 2.0 mm engagement

- O-ring: 0.3 mm compression

Result to Required Thread Length = 5.5 mm

If the adapter provides less than this, sealing will fail. TEJTE’s SMA-KKF bulkhead has ~8.6 mm usable thread, leaving plenty of margin for reliable outdoor installations. More examples of how thread sizing aligns with product specs can be found in TEJTE’s section on SMA adapters and bulkheads.

FAQs

Does a right-angle M to F adapter add more loss than a straight one at 5.8 GHz?

Slightly. A quality right-angle sma male female adapter might measure ~0.20 dB loss at 6 GHz compared with ~0.15 dB for an inline version.

Should I use a waterproof M to F adapter or a short waterproof pigtail for outdoor CPE?

It depends on the load. For static units, a sealed bulkhead works well. If the antenna is likely to sway in the wind, a short waterproof coax jumper is safer.

How do I check if my router port is RP-SMA or standard SMA before buying?

Look at the center conductor: a pin means SMA male, while a hollow socket means SMA female—or RP-SMA depending on the thread. TEJTE’s guide on RP-SMA vs SMA in routers shows clear photos of both.

Will stainless-steel adapters change VSWR compared with brass gold-plated parts?

No significant difference if both are machined correctly—both can hold VSWR ≤1.2. The choice is usually about corrosion resistance and longevity.

What frequency rating should I choose—18 GHz or 26.5 GHz—for general lab work?

For most Wi-Fi, LTE, and mid-band 5G testing, 18 GHz is sufficient. For mmWave, radar, or high-end R&D, go with 26.5 GHz.

How much thread length is safe for a 2 mm painted aluminum panel with an O-ring?

At least 5.5 mm. Anything shorter compromises nut engagement and sealing pressure.

Can I daisy-chain multiple M to F adapters, or is coax better?

Avoid chaining more than two. Each adapter adds mismatch and insertion loss. A short coax pigtail is the better option for flexibility and signal quality.

For a broader overview of SMA connector families and related products, see TEJTE’s RF connector guide, which ties adapters, bulkheads, and pigtails into the bigger picture.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.