SMA Connector Choices for Compact RF Systems

Feb 18,2026

This image shows a typical SMA connector, with its threaded coupling nut and center contact. In early design stages, SMA connectors are often taken for granted, yet their behavior in real hardware—especially after enclosure integration—can introduce subtle variations in link margin.

The sma connector is one of those parts that almost never gets discussed during early RF design. It’s there by default. Everyone knows what it is. Everyone has used it. Most teams assume it will behave the same way in every product, as long as the frequency stays within range.

That assumption usually survives bring-up. It often survives first measurements. Where it starts to crack is later—after the enclosure is closed, after the cable routing is finalized, or after someone in the field touches the antenna lead and the numbers shift just enough to raise questions.

What makes SMA connectors tricky in compact RF systems isn’t a single flaw. It’s the fact that the same connector ends up doing very different jobs, often without anyone explicitly deciding that it should.

This article isn’t trying to redefine what an SMA connector is. It’s about how SMA connectors actually behave once a system stops being a schematic and starts being hardware.

Map where an SMA connector actually sits in your RF chain

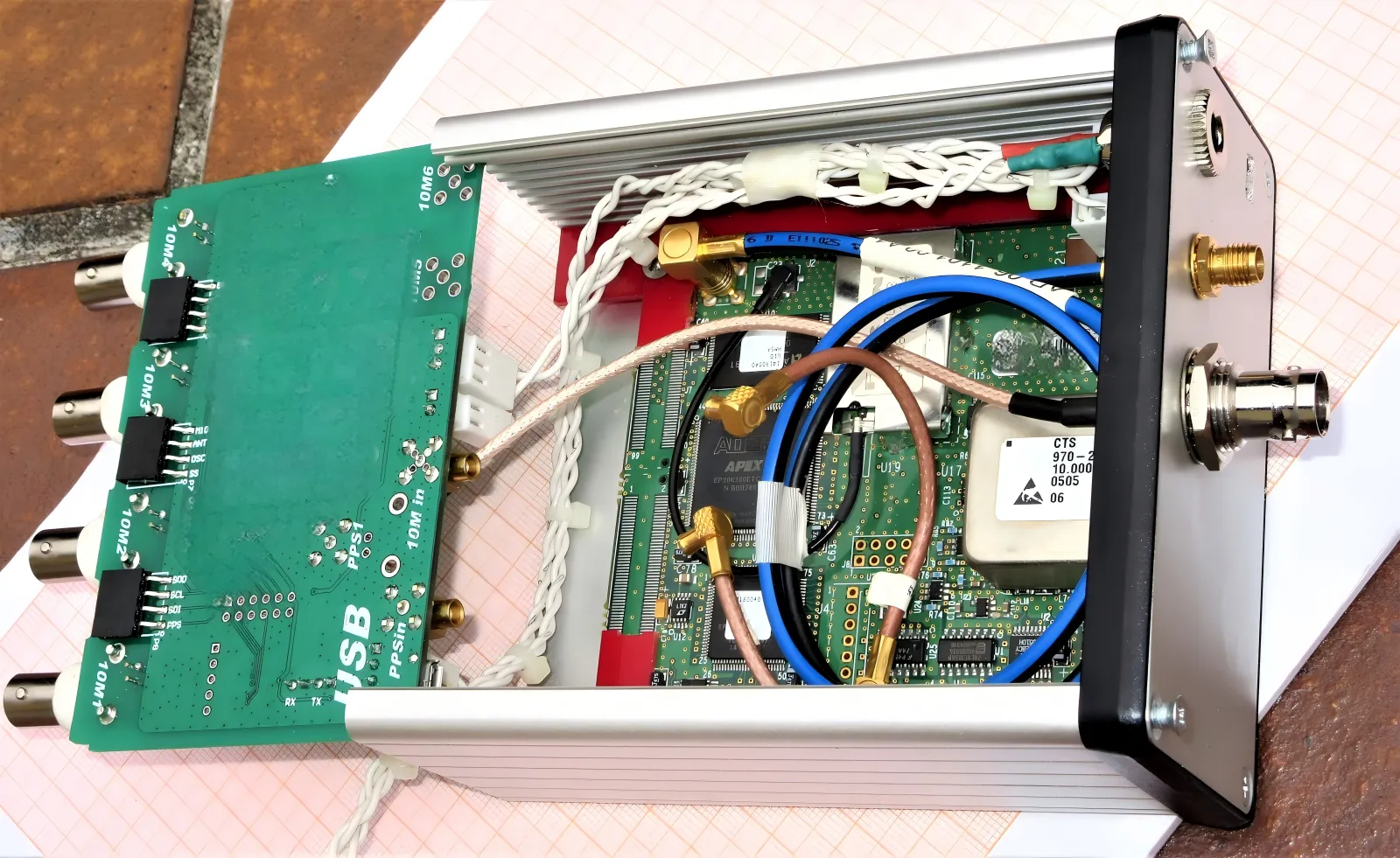

This figure maps where SMA connectors physically appear in a system: at the enclosure boundary (antenna port), as internal board-to-board jumpers, and as temporary test access points. Recognizing these roles helps avoid assigning a single connector type to all three, which often leads to premature wear or inconsistent measurements.

Identify SMA connector roles in radios, antennas, and test gear

In most compact RF builds, SMA connectors show up in familiar places. There’s usually one on the RF module or front-end. There’s often one on the enclosure for the antenna. And there’s almost always at least one used as a test access point during development.

On a block diagram, these ports look identical. In real hardware, they age differently. A test connector might be mated and unmated dozens of times a week. An antenna connector might get tightened once and then ignored for the rest of the product’s life. Treating both the same is common, and it’s also where subtle problems start, especially when lightweight sma cable assemblies are involved.

What often happens is that the test setup looks rock solid, while the deployed unit slowly drifts. Nothing is obviously broken. Measurements just stop lining up the way they used to.

Distinguish boundary, internal, and temporary SMA interfaces

One useful way to think about SMA connectors is to stop grouping them by connector family and start grouping them by role.

Boundary interfaces are exposed to the outside world. They see torque, vibration, temperature swings, and installers who don’t own torque wrenches. Internal interfaces sit inside the enclosure, usually on short coax runs between boards or modules. Temporary interfaces exist mainly for development and test, and they tend to see far more mating cycles than anyone originally plans for.

Most problems show up when one connector is quietly expected to cover all three roles. A connector chosen for internal routing ends up becoming the external antenna port. A connector meant for occasional test access becomes part of the production workflow. None of this causes immediate failure, which is why it keeps happening.

Relate SMA interfaces to other RF connectors in the same system

In compact systems, SMA connectors rarely operate alone. It’s common to see them paired with smaller internal connectors like mmcx connector, while SMA is reserved for the enclosure interface. In larger assemblies, BNC or N-type connectors may appear upstream.

What causes layout and reliability issues is the habit of defaulting to SMA everywhere simply because it’s familiar. Internally, smaller connectors reduce stress on the PCB and make routing easier. Externally, SMA remains popular because it’s easy to handle and widely supported. When those roles are mixed, adapters and awkward cable paths tend to follow.

How should you match SMA connector style to SMA cable and RG316 runs?

Pair SMA connectors with common RF cable families

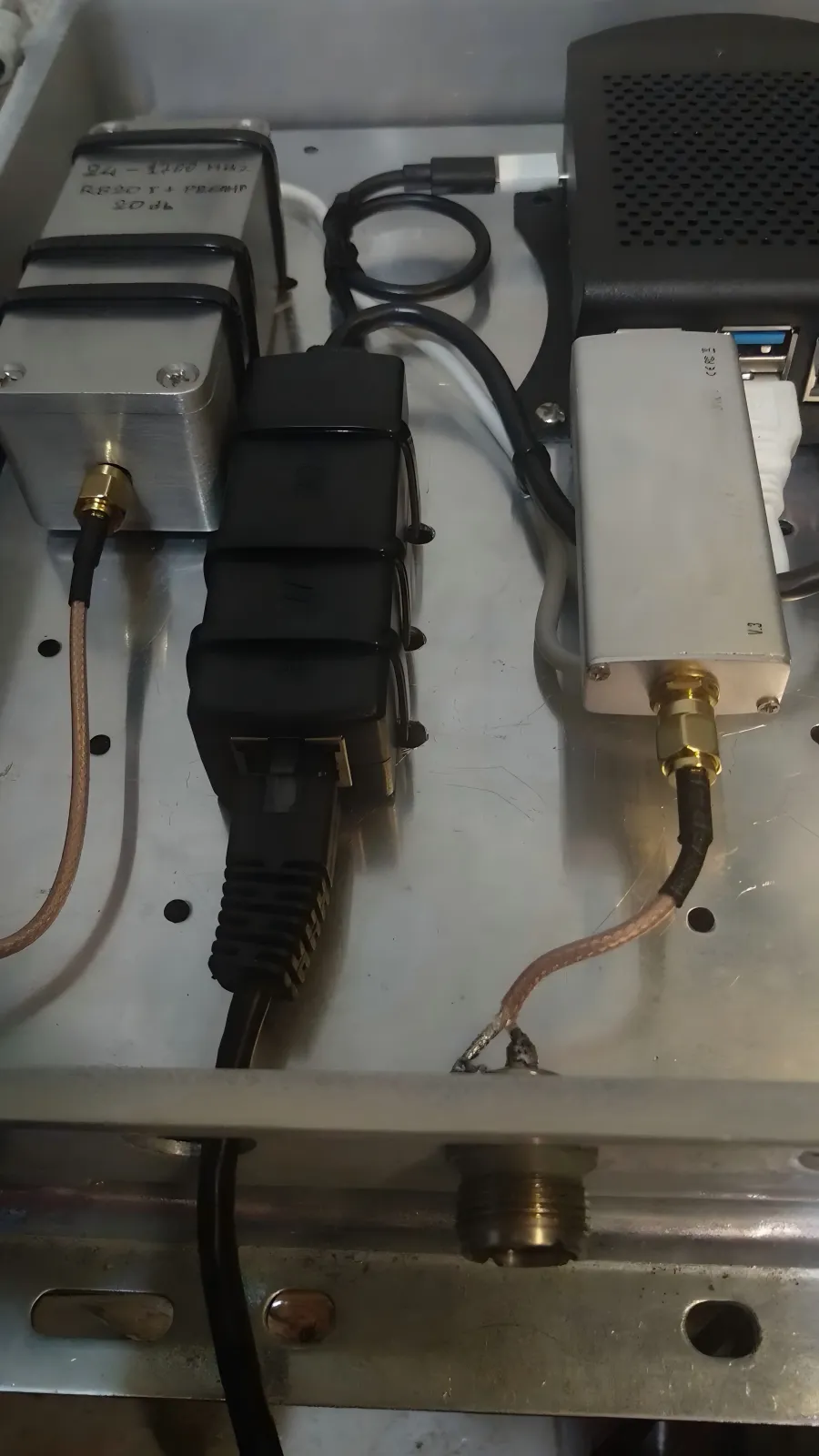

This image shows an SMA connector terminated onto RG316 coaxial cable. The assembly relies on proper crimping and strain relief to maintain RF performance. RG316’s flexibility makes it suitable for internal routing, but mechanical stress at the connector-cable junction can degrade return loss over time if not carefully managed.

This photograph depicts an SMA connector assembled onto RG174 cable. While electrically similar to RG316 at lower frequencies, RG174 has higher loss and less robust shielding. In compact systems, the choice between RG316 and RG174 affects both loss budget and mechanical durability, especially when cables are routed in tight spaces.

In compact RF assemblies, SMA connectors are most often paired with RG316 coaxial cable, RG174, or low-loss LMR-type cables. Among these, rg316 cable shows up everywhere, mostly because it’s flexible, thermally stable, and easy to source.

That popularity sometimes hides the fact that not every SMA connector is well matched to RG316 mechanically. Crimp dimensions, ferrule support, and strain relief design vary more than many engineers expect. Assemblies that look fine electrically at first can slowly degrade because the cable is doing more mechanical work than it should. When that happens, the connector usually takes the blame last.

If you’ve seen systems where swapping cables “fixes” a measurement without changing anything else, this is often part of the story. The same issue comes up repeatedly in discussions around cable behavior in guides like the SMA RF Cable Selection and Application Guide, even when the connector itself isn’t the obvious suspect.

Choose between flexible, semi-rigid, and low-loss SMA coax assemblies

Cable construction ends up shaping how the SMA connector behaves over time. Flexible assemblies like RG316 tolerate movement and vibration well and tend to be forgiving in compact enclosures. Semi-rigid coax offers predictable impedance but doesn’t like being touched after installation. Low-loss cables reduce attenuation but transmit mechanical stress very efficiently.

In lab setups, flexibility usually wins. In deployed systems, stiffness creeps back in as teams chase lower loss numbers. The trade-off is that stiff cables push more force into the connector body. The result is rarely a clean break. More often, it’s a slow change in return loss that only shows up when someone reroutes a cable or opens the enclosure.

Evaluate connector–cable transitions under frequency and power stress

As frequency increases, the connector–cable transition becomes less forgiving. Small impedance mismatches that don’t matter at low frequencies start to show up in VSWR plots. Add RF power, and contact quality matters even more, because current density concentrates at the weakest point in the interface.

These effects don’t announce themselves loudly. What engineers usually see is inconsistency—numbers that move slightly depending on handling, or links that meet margin one day and miss it the next. Thinking of the connector and cable as a single structure, rather than two separate parts, helps make sense of this behavior.

Select SMA connector gender, polarity, and interface variants for your hardware

Decide on SMA connector gender and panel vs board mounting

SMA connectors differ by gender and by how they mount into the system. Panel bulkhead connectors define the enclosure interface. Edge-mount and end-launch connectors integrate directly with PCB traces. Each choice affects not just RF launch quality, but how the product is assembled and serviced.

Edge-mount connectors can produce very clean launches when the PCB is done correctly. They also leave little room for mechanical error. Panel-mounted connectors are easier to access but introduce tolerances that have to be managed across the enclosure, the nut, and the board. In compact systems, poor placement often causes assembly pain long before it causes RF problems.

Avoid SMA vs RP-SMA polarity mistakes in antennas and Wi-Fi gear

This diagram illustrates the difference between standard SMA and reverse-polarity SMA (RP-SMA) connectors. In standard SMA, the plug has a pin (male) and the jack has a sleeve (female). RP-SMA reverses this: the plug has a sleeve and the jack has a pin. This distinction is critical in Wi-Fi and antenna interfaces where polarity mismatches are common. Using adapters may work electrically but complicates logistics and field service.

Reverse-polarity SMA connectors still show up regularly, especially around Wi-Fi hardware. Mixing standard SMA and RP-SMA often appears to work when adapters are involved, which is why the mistake survives so long.

The cost shows up later, in inventory confusion and field replacement errors. Clear polarity decisions made early are boring, but they save far more time than adapter-based fixes introduced after the fact.

Compare standard SMA connectors with SSMA and SMP options

In many compact RF designs, SMA connectors stay in place longer than they probably should. Not because they are wrong electrically, but because changing connector families late in a project is painful. SMA is mechanically forgiving, easy to handle, and familiar to everyone involved—from layout engineers to technicians.

That said, as layouts tighten, ssma connector and smp connector options start to look attractive. SSMA reduces footprint and weight but gives up some handling margin. SMP enables blind-mate and floating interfaces, which can be useful in stacked or modular assemblies, but it requires tighter mechanical control and more discipline in enclosure design.

What usually happens in practice is not a clean switch. SMA remains at the system boundary, while SSMA or SMP appears internally. Teams that think about this split early tend to avoid adapter chains later, which is where loss and reliability quietly disappear.

Build an SMA connector planning scorecard for each RF interface

A simple scorecard forces those trade-offs into the open. It doesn’t pick a connector for you, but it makes it obvious why one option keeps winning discussions and another keeps getting deferred.

Below is a practical structure that works well in design reviews and sourcing discussions. It’s intentionally not perfect. Teams usually tweak it after using it once or twice.

SMA Connector Planning Scorecard

| Field | Description |

|---|---|

| Interface_ID | Unique identifier for the RF interface |

| Role | Boundary I/O / Internal link / Test port |

| Frequency_band_GHz | Main operating band |

| Max_power_dBm | Expected maximum RF power |

| Return_loss_target_dB | Target return loss |

| Connector_series | SMA / RP-SMA / SSMA / SMP |

| Gender | Plug / Jack |

| Polarity | Standard / Reverse |

| Mounting_style | Panel bulkhead / Edge-mount / End-launch / Cable |

| Cable_type | rg316 cable / rg316 coaxial cable / other |

| Expected_mating_cycles | Estimated mating count |

| Environment | Lab / Outdoor / Vehicle / Industrial |

| Sealing_level | None / IP50 / IP67 / IP68 |

| Torque_spec_Nm | Recommended torque |

| Availability_score (1–5) | Supply stability |

| RF_performance_score (1–5) | Electrical margin |

| Mechanical_robustness_score (1–5) | Durability |

| Total_score | Weighted result |

A common weighting that works reasonably well looks like this:

Total_score = RF_performance_score × 0.4

+ Mechanical_robustness_score × 0.3

+ Availability_score × 0.3

The value of this table is not the math. It’s the conversation it forces. When a connector scores poorly on availability but well on RF performance, that trade-off becomes explicit instead of implicit.

How do you control RF loss and VSWR at the SMA connector interface?

Budget insertion loss including SMA connector and RF cable

At lower frequencies and short cable lengths, that assumption usually holds. At higher frequencies, or once multiple interfaces stack up, it stops holding.

An SMA connector by itself may only contribute a small fraction of a decibel. But real systems rarely have just one. There is the connector at the radio, another at the panel, sometimes an adapter in between, and then the cable itself. The cumulative effect is what matters. Teams that explicitly budget connector loss tend to catch margin issues earlier than those who don’t.

This is also where connector choices tie back into cable selection discussions, such as those outlined in SMA Coaxial Cable Structure & Selection. Loss and reflection are rarely isolated to one component.

Keep VSWR low with proper torque, alignment, and cable strain relief

VSWR problems blamed on radios often turn out to be mechanical. Slight misalignment, uneven torque, or constant side-loading from a cable can all change how the connector behaves.

What makes this frustrating is that the connector may still pass basic checks. It mates. It feels tight. Nothing looks obviously wrong. Yet small mechanical stresses shift the electrical interface just enough to matter at frequency. Proper strain relief and realistic torque practices reduce this sensitivity more than most datasheet specs suggest.

Compare SMA connector performance in lab vs field installations

Lab environments are kind to connectors. Cables are short. Temperatures are stable. Handling is controlled. Field installations are not.

Longer runs, repeated reconnects, vibration, and temperature cycling all push SMA connectors closer to their limits. Designs that look clean in the lab but lack margin in the field often suffer from connector assumptions rather than outright RF mistakes.

Design PCB launches and panel cutouts around an SMA connector

Route controlled-impedance microstrip to edge-mount SMA connectors

Edge-mount SMA connectors can produce excellent launches, but only when the PCB geometry is disciplined. Trace width, reference plane continuity, and via placement all matter. Small deviations don’t always show up immediately, which is why they often get overlooked.

What usually exposes these issues is repeatability. Measurements that shift slightly when cables are swapped or boards are reinstalled often trace back to marginal launch design rather than the connector itself.

Place SMA connectors to balance RF integrity and mechanical access

A connector that is electrically well placed but mechanically awkward creates downstream problems. If technicians can’t access it properly, torque becomes inconsistent. If cables have to bend sharply to reach it, strain builds up over time.

In compact systems, connector placement is often constrained by enclosure geometry. A small adjustment early in layout can save repeated headaches during assembly and service.

Align SMA connector, MMCX connector, and internal RG316 links

Many compact modules use mmcx connector internally with short rg316 coaxial cable jumpers leading to an external SMA interface. When these transitions are aligned cleanly, the system behaves predictably. When they are forced through tight bends or misaligned planes, mechanical stress accumulates.

This is one area where internal consistency matters more than individual component specs. A well-matched chain of modest components often outperforms a mix of high-end parts connected poorly.

Plan for durability, mating cycles, and environmental sealing on SMA connectors

Rate SMA connectors for mating-cycle requirements in your use case

Standard SMA connectors are not designed for unlimited mating cycles. Test environments often exceed what production connectors were meant to handle. When this isn’t acknowledged upfront, connectors wear out quietly.

Designs that separate high-cycle test interfaces from low-cycle production interfaces tend to remain stable longer, even if they look slightly more complex on paper.

Choose plating, gasket, and IP rating for outdoor SMA connectors

Outdoor and vehicle applications expose SMA connectors to moisture, dust, and temperature swings. Plating quality and sealing details start to matter more than headline frequency ratings.

Many field issues attributed to “aging electronics” are actually connector degradation. Once corrosion starts, electrical performance follows.

Schedule connector inspection and replacement in preventive maintenance

Integrate MMCX connector, MMCX cable and SMA connector transitions in compact modules

Decide when to keep MMCX connectors internal and expose SMA connectors outside

A layout that shows up repeatedly uses MMCX on the RF board and SMA on the enclosure. This is not because MMCX is better electrically. It is mostly because MMCX fits where SMA does not, and SMA is easier to deal with once a product leaves the lab.

In many builds, exposing MMCX directly to the outside world causes trouble. The connector itself is not fragile, but it does not tolerate uncontrolled handling well. SMA does. That difference alone explains why MMCX tends to stay inside the box and SMA ends up on the panel.

When teams reverse this arrangement, they often end up adding protection hardware, custom cables, or adapters later to compensate.

Use MMCX to SMA adapter and MMCX to SMA connector links without hidden loss

Adapters usually appear for practical reasons, not design reasons. A prototype needs to connect to existing test gear. A module revision changes the connector footprint. Someone adds an MMCX to SMA adapter and the system still works, so nobody revisits the decision.

Electrically, most MMCX to SMA adapters look fine when measured once. Mechanically, they stack tolerances. Every additional interface introduces another place where alignment, contact pressure, or torque can vary. None of this causes an obvious failure. What tends to happen instead is reduced repeatability.

Over time, when RF margin feels “smaller than expected,” these adapter chains often turn out to be part of the explanation.

Document connector–adapter–cable chains in RF test and production

In test setups, undocumented connector chains are common. A radio connects to a cable, then an adapter, then another cable, and finally the instrument. Everyone knows the setup works, but nobody remembers exactly what is in the path.

When something changes—new cable, new adapter, new technician—the numbers shift slightly. Without documentation, it is difficult to tell whether the system changed or the setup did. Teams that explicitly write down connector and cable chains usually waste less time arguing about measurements.

Use field test and inspection routines to catch SMA connector problems early

Verify SMA connector quality with simple visual and tactile checks

Visual inspection still matters. Bent center pins, damaged threads, contamination inside the connector body—these things change RF behavior even when continuity looks fine. Tactile feedback matters as well. A connector that tightens unevenly or feels different from others often is different.

These checks are basic, but they tend to be skipped once a system is considered “working.”

Correlate intermittent RF issues with connector movement or strain

One of the fastest ways to narrow down a problem is controlled movement. Gently moving the cable near the SMA connector while watching return loss or signal level often tells you whether the interface is involved.

If the numbers move with the cable, the connector or its strain relief is part of the story. That does not identify the root cause, but it avoids chasing the radio, antenna, or firmware unnecessarily.

Standardize SMA connector rework and replacement procedures

Connector rework is often treated as a craft rather than a process. Different technicians clean connectors differently. Some reuse parts that others discard. Over time, this creates variability that hides real problems.

Standardizing even simple steps—how connectors are removed, how contacts are cleaned, how replacements are installed—reduces this noise. The goal is consistency, not perfection.

Track new SMA connector trends in 5G, IoT, and test equipment

Note SMA connector use in modern 5G sub-6 GHz systems

In many sub-6 GHz 5G devices, SMA connectors are still used for antennas and debug ports. They remain easy to source and easy to handle. What has changed is that they are used more deliberately.

Instead of appearing everywhere, SMA connectors are increasingly limited to the system boundary, while internal RF links move to smaller interfaces.

Follow MMCX and SMP adoption for denser RF front-ends

As RF front-ends become denser, MMCX and SMP connectors appear more often inside the enclosure. These connectors are not replacements for SMA in every role. They solve different problems.

Designs that try to force SMA into high-density internal layouts usually end up adding compromises later. Designs that separate boundary interfaces from internal links tend to scale better.

Watch test-equipment vendors updating SMA-based front panels

Most RF test instruments still rely heavily on SMA connectors. Even when higher-frequency interfaces are added, SMA remains part of the front panel.

This reinforces a practical reality: SMA compatibility still matters, even as internal system designs move toward smaller connectors.

FAQ

How many mating cycles does an SMA connector really survive in daily lab use?

In practice, fewer than most teams expect. Connectors used as daily test interfaces usually wear out long before anything else in the signal path.

Is it a problem to mix SMA and RP-SMA if adapters are available?

It usually works electrically, but it creates confusion later. Inventory, labeling, and field replacement all become harder than they need to be.

Why do measurements change when I touch the cable near the SMA connector?

That almost always points to mechanical sensitivity at the connector–cable transition. The RF interface is reacting to small changes in alignment or strain.

When does it make sense to stop using SMA and move to SSMA or SMP?

Usually when layout density or blind-mate requirements start driving the design. SMA often remains fine at the enclosure boundary.

Can I tighten SMA connectors by feel in the field?

People do it all the time. The risk is variability. Designs that assume perfect torque in the field tend to be fragile.

Is a slightly damaged SMA connector acceptable for low-frequency testing?

Sometimes it appears to work, but damage usually means instability. Handling or movement can quickly change results.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

Standardize SMA connector rework and replacement procedures

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.