SMA Antenna Extension Cable Guide: Outdoor Use & IP67

Sep 28,2025

Introduction

used to visualize the topic. It emphasizes the importance of choosing the right SMA antenna extension cable to maintain signal stability and resist heat, moisture, and interference in outdoor environments.

Choosing the right cable for an outdoor antenna might look like a small detail, but in practice it often decides whether your system delivers stable performance or struggles with weak, unstable signals. An sma antenna extension cable is more than just a length of coax with connectors—it’s part of your RF chain, shielding your signal from heat, moisture, and interference that would otherwise creep in.

Think about it this way: every extra meter you add introduces loss. The wrong choice can eat up antenna gain so quickly that even a strong Wi-Fi router or LTE modem feels underpowered. On the other hand, the right extension keeps noise low and ensures your GNSS receiver, IoT gateway, or access point gets the clean signal it was designed for.

Installers know this tradeoff well. Many compare RG316 and RG316D before making a purchase, since these two cables are among the most common for 50-ohm SMA extensions. Both can work, but the differences in shielding, jacket size, and bend radius really start to matter once the cable leaves the lab and gets routed through an outdoor box or up a mast.

One quick tip from the field: never treat the cable as an afterthought. A carefully chosen extension often saves more dB than swapping antennas later. With TEJTE’s RF adapter cable assemblies, small design details like braid count or jacket thickness can shift flexibility, loss, and even long-term weather resistance. And those details are what set RG316 and RG316D apart, which is exactly where we’ll begin.

How do I choose between RG316 and RG316D?

At first glance, RG316 cable and RG316D cable could be mistaken for twins. Both share a 50 Ω impedance, use PTFE dielectric, and can operate comfortably up to 6 GHz. On paper they look almost identical, but once installed, the small design differences begin to show.

- RG316 cable: This version uses a single silver-plated copper braid with PTFE insulation, all wrapped in a slim 2.5 mm FEP jacket. Its minimum bend radius is about 15 mm. Attenuation measures around 0.88 dB/m at 900 MHz, ~1.46 dB/m at 2.4 GHz, and climbs to 2.34 dB/m at 6 GHz. With a light weight of just 17 g/m, it’s easy to route through test benches or short outdoor runs.

- RG316D cable: The “D” stands for double-shielded. It uses two layers of silver-plated copper braid, improving EMI resistance. The jacket is thicker at 3.0 mm, with a bend radius of 13 mm. It’s also far more resilient to heat, rated for –55 °C to +255 °C compared to +150 °C for RG316. Typical attenuation values include 0.50 dB/m at 400 MHz and about 2.0 dB/m at 3 GHz.

| Parameter | RG316 | RG316D |

|---|---|---|

| Impedance | 50 Ω | 50 Ω |

| Outer diameter | 2.5 mm | 3.0 mm |

| Shielding | 1 braid, SPC | 2 braids, SPC |

| Bend radius | 15 mm | 13 mm |

| Attenuation @ 2.4 GHz | ~1.46 dB/m | ~1.0-1.2 dB/m |

| Temp. range | -55 °C to +150 °C | -55 °C to +255 °C |

| Weight | ~17 g/m | ~20 g/m |

| Typical use case | Short Wi-Fi, test gear | Outdoor IoT, EMI areas |

So which should you order? For short indoor extensions or lab setups, RG316 is the lighter, more affordable option. But if you’re working outdoors—especially with multiple bends, constant sun, or high interference—RG316D is the safer investment.

A practical note from installers: the switch often happens around the 3 m mark. Below that, RG316 usually holds up fine. Above it, attenuation and shielding demands push many buyers toward RG316D, especially for outdoor sma antenna extension cable builds where long-term reliability matters more than saving a few grams of weight.

What length keeps antenna performance loss under control?

Every meter of coax adds loss—it’s unavoidable. The real question is how much attenuation you can tolerate before your antenna gain is effectively canceled. When choosing an sma antenna extension cable, this single factor often decides whether your link budget holds up in practice.

The math is straightforward:

Loss (dB) = α(f) × L

- f = frequency in MHz or GHz

- L = cable length in meters

- α(f) = attenuation per meter (from datasheet)

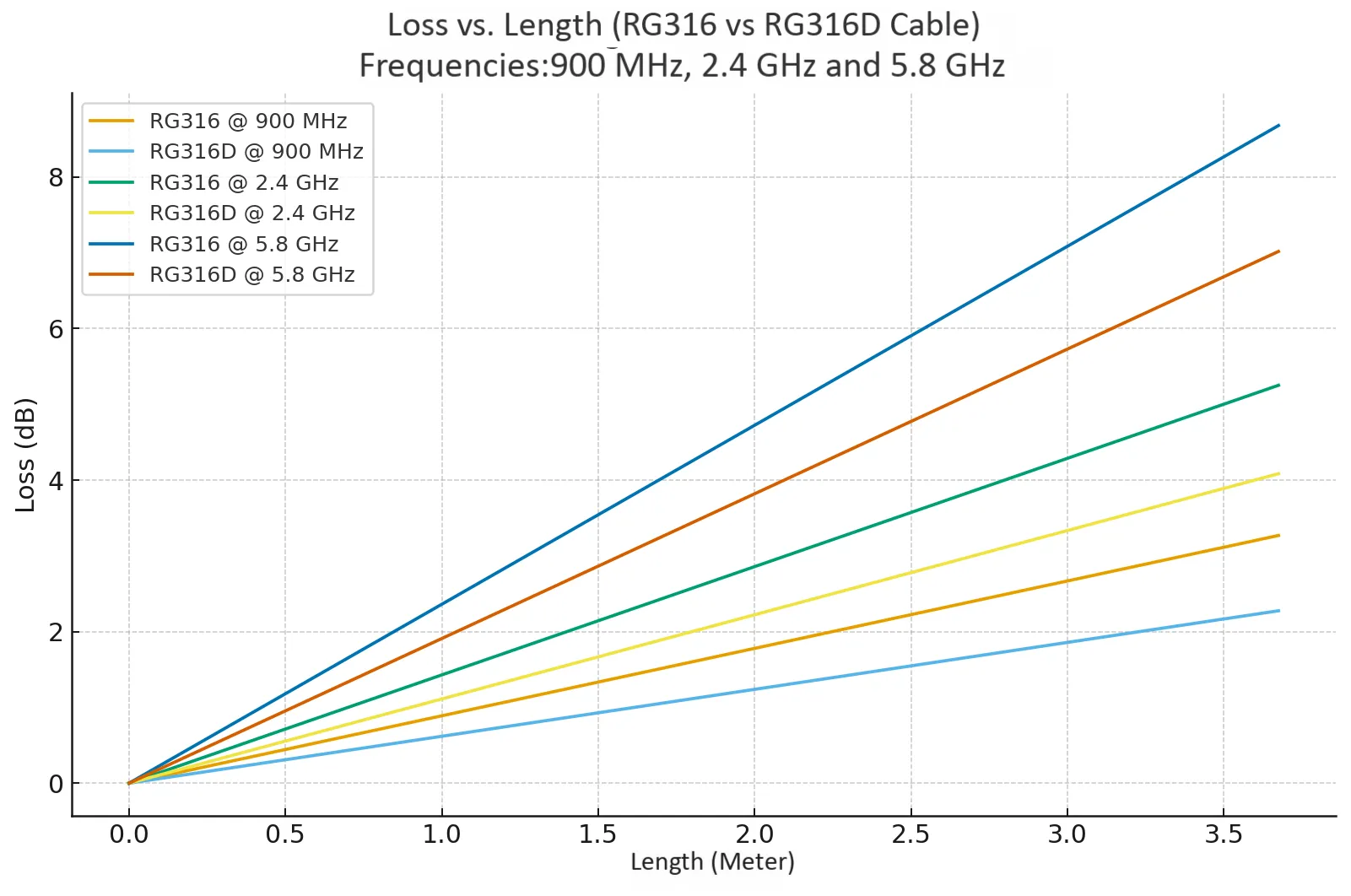

For example, the rg316 attenuation at 2.4 GHz is about 1.46 dB/m. A 3 m run would cost nearly 4.4 dB—that’s more than enough to cut your Wi-Fi signal strength in half. With RG316D cable, shielding improves performance, but loss still stacks up quickly.

Here’s a practical table based on datasheet values:

| Frequency | RG316 Max Length (<1 dB) | RG316 Max Length (<2 dB) | RG316D Max Length (<1 dB) | RG316D Max Length (<2 dB) |

|---|---|---|---|---|

| 900 MHz | ~1.1 m | ~2.3 m | ~1.5 m | ~3.5 m |

| 2.4 GHz | ~0.7 m | ~1.4 m | ~0.9 m | ~1.8 m |

| 5.8 GHz | ~0.4 m | ~0.9 m | ~0.5 m | ~1.1 m |

The chart aims to visualize the difference in attenuation characteristics between RG316 and RG316D, helping engineers quickly determine the maximum allowable cable length for specific applications (e.g., Wi-Fi, LTE, GNSS) based on frequency and available link budget. The document emphasizes that ignoring this relationship is a common cause of system performance degradation.

Quick rules of thumb from installers:

- At 2.4 GHz, keep RG316 runs under 1.5 m if possible.

- Once you need 3 m or more, switch to RG316D or a lower-loss alternative.

- At 5.8 GHz, even a 1 m extension can cost ~1 dB, so longer runs demand something like LMR-200.

A field tip: Don’t just measure distance—factor in connectors, adapters, and bends. Each adds a little extra sma cable loss. When configuring builds on TEJTE’s SMA extension page, these thresholds are already considered, so you know if your design will pass the target loss budget before ordering.

Do I need stainless-steel heads or brass gold-plated?

gold-plated SMA connectors". The document states that these connectors are common in labs or short-term outdoor setups, but brass can corrode faster than expected in salty air or chemical-heavy sites.

- Brass, gold-plated SMA connectors: Lightweight, cost-effective, and conductive. These are common in labs or short-term outdoor setups where exposure is minimal. The downside? In salty air or chemical-heavy sites, brass can corrode faster than expected. I’ve seen balcony Wi-Fi extensions show green corrosion within a year when brass was used.

corresponding to the description of the "Stainless steel SMA connectors". The document emphasizes that stainless steel resists rust, handles torque without deforming, and has passed extended salt-spray tests, making it the go-to choice for telecom towers, marine IoT stations, and other long-term outdoor deployments.

- Stainless steel SMA connectors: Slightly heavier and pricier, but designed to survive. Stainless resists rust, handles torque without deforming, and pairs with O-rings to achieve IP67 sealing. TEJTE stainless-steel types have cleared extended salt-spray tests, making them the go-to for telecom towers, marine IoT stations, and long-term rooftop LTE units.

So which one should you pick? If it’s a hobby setup—a Wi-Fi router moved to a window or an indoor GNSS receiver—brass will do the job and save some cost. But for permanent installs outdoors, stainless steel SMA connectors are worth the investment. It’s the difference between replacing cables every year and letting them run reliably for five or more.

You’ll find detailed specs, including torque ranges and sealing options, in TEJTE’s RF connector catalog. And a quick note from the field: over-tightening brass connectors can crush the PTFE dielectric, while stainless usually tolerates the same torque without issue.

How do I avoid SMA vs RP-SMA mix-ups for Wi-Fi antennas?

designed to help users quickly identify and avoid confusion between SMA and RP-SMA connectors. The document notes that this is one of the most common mistakes buyers make, and wrong polarity can render an SMA antenna extension cable useless.

One of the most common mistakes buyers make is ordering the wrong connector type. SMA and RP-SMA look almost identical at first glance, but the center pin arrangement is reversed. That tiny detail is enough to make an expensive sma antenna extension cable useless if you choose the wrong one.

Here’s the quick breakdown:

- SMA: Standard in LTE modems, GNSS receivers, and many RF modules. The male has a center pin; the female has a center socket.

- RP-SMA (reverse polarity): Mostly used on Wi-Fi routers and access points. The RP-SMA male has no pin, while the RP-SMA female carries the pin.

A cheat sheet that installers often keep taped to their toolboxes:

- Wi-Fi router antennas → RP-SMA

- LTE gateways and modems → SMA

- IoT devices → varies by vendor, always check before buying

Now, if you do end up with mismatched gear, adapters are an option (e.g., SMA–RP-SMA, SMA–N, SMA–BNC). But keep in mind: every adapter introduces a bit of extra loss, and when you’re already fighting attenuation on a long rp-sma antenna extension cable, that small penalty can push performance below spec.

For a deeper look at pin orientation and device compatibility, TEJTE’s SMA connector guide has diagrams and examples that make identification foolproof.

Should I pick straight or right-angle plugs (90°/45°/135°)?

corresponding to the description of "Straight plugs". The document states that straight plugs have the lowest insertion loss and typically the best VSWR values (≤1.2), making them the go-to choice for lab test setups.

- Straight plugs: Lowest insertion loss, typically showing the best VSWR values (≤1.2). These are the go-to in lab test setups where space isn’t an issue.

corresponding to the description of "Right-angle (90°) plugs". The document explains that right-angle connectors are easier to route in small housings, with the tradeoff of a very slight mismatch (usually VSWR ≤1.3), which is acceptable for most 50-ohm systems.

- Right-angle (90°): Easier to route in small housings. The tradeoff? A very slight mismatch—usually VSWR ≤1.3, which is acceptable for most 50-ohm systems.

showing the combination of SMA male and female connectors. This combination is typical for SMA antenna extension cables (male-to-female), used to relocate an antenna to a new position.

- 45° or 135° connectors: Niche options, often reserved for equipment with odd layouts or compact PCBs where neither straight nor 90° fits well.

One rule you can’t ignore: bend radius. For RG316, keep bends larger than 15 mm; for RG316D, at least 13 mm. Go tighter than that, and the coax starts to degrade, raising sma cable loss or even breaking the shield.

From experience, installers often choose right-angle plugs for enclosures under 200 mm wide, since straight connectors can stick out too far and press against the housing cover. A right-angle exit avoids that stress and extends connector life.

If you want visuals of how these layouts look in practice, TEJTE has diagrams in its SMA right-angle adapter guide that illustrate how routing choices affect both strain relief and VSWR.

How do I reach IP67 outdoors: which seals and bulkheads to use?

When an sma antenna extension cable is routed outdoors, waterproofing becomes as critical as attenuation. Even the best RG316D cable won’t survive long if water seeps into the dielectric or corrodes the connector. To achieve IP67, you’ll need the right combination of O-rings, caps, and bulkhead fittings.

- O-rings: Usually made of silicone rubber (grade 6146 is common). They compress between the connector nut and panel, sealing against dust and moisture.

- Sealing caps: Essential when one end of the extension isn’t permanently connected. A cap keeps the connector dry and maintains IP67 rating while idle.

- Bulkhead pass-throughs: Allow an SMA male-to-female feedthrough across enclosure walls. TEJTE bulkhead types include hex nuts and washers, designed to fit standard Ø6.5 mm cutouts.

In vehicle or outdoor cabinet installs, many engineers also mount antennas on magnetic bases with ground plates. These not only hold the antenna securely but also stabilize return paths, reducing VSWR variation in real-world conditions.

For more detail on sealing configurations and cutout sizing, see TEJTE’s panel-mount SMA waterproof guide. It covers O-ring placement, torque ranges, and sealing accessories in depth.

Do I need an extension, or a jumper/patch instead?

appearing during the discussion of the differences between "extension," "jumper," and "patch" cables. The document describes jumper cables as short, flexible, and designed for low loss between instruments in test labs or inside RF enclosures.

The terms “extension,” “jumper,” and “patch” often get used interchangeably, but in RF work, they’re not quite the same. Picking the right one saves time, money, and in many cases, frustration.

- Extension cable: Usually longer, often built as an sma male to female cable. Its main purpose is to relocate an antenna to a new position—for example, moving a Wi-Fi antenna from inside a router case to an outdoor pole.

- Jumper cable: Short, flexible, and designed for low loss. These are the short links between instruments in test labs or inside RF enclosures. Many installers casually call them sma jumper cables.

- Patch cable: Borrowed from networking language. In RF, it’s essentially another word for jumper, but less precise.

So, how do you know what you need?

- Relocating an antenna 2–5 meters away → go with an extension.

- Linking two RF devices sitting side by side → pick a jumper.

- Passing through a chassis wall → a bulkhead extension with nut, washer, and sometimes sealing hardware.

For a deeper dive into cable categories and routing practices, see TEJTE’s RF coaxial cable guide. It explains when to use each type and how system integration choices affect loss and durability.

What specs must I submit before ordering?

Before you place an order for a custom sma antenna extension cable, suppliers need more than just “3 meters, SMA both ends.” A complete spec sheet avoids delays, ensures compatibility, and helps the factory deliver the exact build you want.

Here are the essentials:

- Length & tolerance – For rg316 cable, length tolerance is typically ±2%; for rg316d cable, ±1.5%. Even a 5 cm difference can matter in tight enclosures.

- Connector ends – State clearly if it’s an sma male to female cable, male-to-male, or a bulkhead type. Don’t forget polarity (SMA vs RP-SMA).

- Torque & sealing – If IP67 is required, specify O-ring type or sealing grease. Some marine projects even call for fluorosilicone O-rings for better chemical resistance.

- Color coding – Standard RG316 jackets are brown; RG316D jackets are slightly thicker and often translucent. Black or transparent options can also be ordered. Color helps when you’re bundling multiple 50 ohm sma cables.

- QC & traceability – TEJTE marks each assembly with batch IDs. Typical checkpoints include insertion loss ≤0.15 dB @ 6 GHz, VSWR ≤1.2 (straight), and insulation resistance ≥5000 MΩ.

A typical supplier checklist looks like this:

| Spec | Typical Value | Notes |

|---|---|---|

| Impedance | 50 Ω ± 2 Ω | Standard for SMA |

| VSWR | ≤1.2 (straight), ≤1.3 (angle) | Verified up to 6 GHz |

| Insertion loss | ≤0.15 dB @ 6 GHz | Per connector pair |

| Pull strength | ≥0.28 N | Confirms crimp and relief |

| Mechanical durability | ≥500–1000 cycles | Stainless heads last longer |

| Sealing | IP67 with O-ring | Required for outdoor builds |

How do I accept a compliant 50-ohm antenna extension?

Once your sma antenna extension cable arrives, don’t just plug it in and move on. A quick acceptance check ensures what you received actually matches the promised spec—and it can save you from troubleshooting weak signals later.

Here’s a practical checklist used by RF engineers when verifying 50 ohm sma cables such as rg316 cable or rg316d cable assemblies:

Acceptance Checklist

| Parameter | Threshold | Notes |

|---|---|---|

| Impedance | 50 Ω ± 2 Ω | Confirm with a VNA sweep |

| Frequency rating | DC-6 GHz | Matches RG316 / RG316D datasheet |

| VSWR | ≤1.2 (straight), ≤1.3 (angle) | Measure at 2.4 & 5.8 GHz |

| Insertion loss | ≤0.15 dB @ 6 GHz | Per connector pair |

| Pull strength | ≥0.28 N | Confirms crimp and strain relief |

| Crimp height | Within datasheet range | Avoids under/over-crimping |

| Jacket integrity | FEP/PTFE intact | No cuts, nicks, or exposed braid |

| Markings | Batch ID visible | Needed for lot traceability |

| Mechanical cycles | ≥500 (stainless up to 1000) | Durability over repeated mating |

If you see unusual return-loss peaks on a network analyzer, or notice a crimp joint shifting under a light pull, that’s a red flag. Reject the batch and request retesting. Small issues like these tend to get worse once deployed outdoors.

For traceability, TEJTE maintains full inspection records, from raw material IDs to final QC. You can read more about how this process works in their RF adapter QC notes. This level of quality control is especially important if you’re deploying dozens of extensions across a larger RF system.

What band-specific limits apply for Wi-Fi/LTE/GNSS/IoT?

Different applications push cables to their limits in different ways. A sma antenna extension cable that works fine for LTE may not hold up for 5.8 GHz Wi-Fi. Loss budgets vary, and ignoring them often leads to disappointing performance.

- Wi-Fi 2.4 GHz → With rg316 cable, keep runs under 1.5 m. For longer paths up to 3 m, step up to rg316d cable, which holds loss lower thanks to double shielding.

- Wi-Fi 5.8 GHz → Here the margin is tight. Even 1 m of RG316 eats ~1 dB. Beyond that, you’ll want a 50 ohm sma cable in the LMR-200 or LMR-240 class.

- LTE (700–2600 MHz) → More forgiving. 2–3 m on RG316D is usually acceptable without noticeably hurting link quality.

- GNSS (GPS/BeiDou, 1575 MHz) → Critical. Signals are weak at the antenna to begin with, so even 1 dB can cause dropouts. Try to stay under 2 m unless you’re using an active antenna with built-in LNA.

- IoT / LPWAN (433, 868, 915 MHz) → Loss adds up slower, but don’t get sloppy. Keeping runs under 3 m ensures sensor nodes and gateways maintain stable coverage.

For grounding tips and integration practices, TEJTE’s RF coaxial cable guide includes examples from Wi-Fi and IoT deployments. Following these rules makes sure your extension performs as expected across different frequency bands.

Order now: how to configure and submit at TEJTE

Ordering a custom sma antenna extension cable shouldn’t feel like guesswork. At TEJTE, the process is broken into a clear five-step flow that ensures you get the right build the first time.

- Select the cable type → Choose rg316 cable for short flexible runs, or rg316d cable for outdoor routes where double shielding and higher heat resistance matter.

- Set the length → Define it in meters, including tolerance. Even a 10 cm difference can affect routing inside small housings.

- Pick connector ends → Specify male-to-female, male-to-male, or bulkhead feedthroughs. Don’t forget to confirm SMA vs RP-SMA polarity.

- Add sealing → If outdoor-rated, include O-rings, IP67 caps, or bulkhead hardware.

- Mark QC needs → Note if you want insertion loss data at a specific frequency, or full batch traceability for critical systems using multiple 50 ohm sma cables.

Lead times are usually 1–2 weeks. Each batch undergoes random QC, covering VSWR, insertion loss, and pull strength. A report comes with your shipment, so you know the cable was tested before it left the factory.

To configure your build, go to TEJTE’s SMA extension cable ordering page. The form guides you step by step, cutting down on emails and miscommunication. Align your specs with the rules we’ve covered, and you’ll end up with an extension that’s plug-and-play ready—no wasted gain, no extra adapters, no stress.

FAQ

Q1. At 2.4 GHz, how long can an SMA antenna extension run before loss exceeds 1 dB?

With rg316 cable, you’ll hit about 0.7 m before crossing 1 dB of loss. RG316D cable stretches that to ~0.9 m thanks to double shielding and slightly better attenuation. Go longer, and you’re quickly in the 2 dB zone. For longer outdoor routes, installers usually recommend moving to lower-loss coax like LMR-200.

Q2. Is RG316D a better pick for outdoor routes with multiple bends?

Yes. Its 13 mm bend radius and –55 °C to +255 °C range give it more resilience than standard RG316. In practice, RG316D’s double braid also shields better in noisy RF environments. If you’re pulling cable through enclosures or conduits, RG316D is less likely to degrade under stress. More detail is in TEJTE’s RG316 vs RG316D comparison.

Q3. How do I tell SMA vs RP-SMA quickly when pairing with Wi-Fi antennas?

It comes down to the center pin. For SMA, the male has a pin and the female has a socket. For RP-SMA, the polarity is flipped—the male is hollow, and the female carries the pin. Most Wi-Fi routers use RP-SMA, while LTE modems and GNSS units rely on SMA. If you’re buying an rp-sma antenna extension cable, double-check polarity before ordering. TEJTE’s connector guide includes diagrams that make it foolproof.

Q4. Will right-angle plugs noticeably worsen VSWR on antenna extensions?

Not in most builds. A sma right angle cable typically measures VSWR ≤1.3, compared to 1.2 for straight connectors. That’s a minor difference for most 50 ohm sma cable runs. In fact, right-angles often improve reliability by preventing sharp bends that cause more serious mismatch. Many installers prefer them inside compact IoT housings where space is tight.

Q5. What sealing parts are required to reach IP67 on a bulkhead pass-through?

You’ll need a silicone O-ring (grade 6146) compressed between the connector nut and the panel, plus a sealing cap for any unused ports. In harsh marine setups, some engineers add dielectric grease for extra safety. TEJTE’s panel-mount waterproofing guide shows how to size cutouts and torque connectors correctly.

Q6. Do stainless-steel SMA heads change RF performance compared with brass?

Electrically, no—both maintain 50 Ω impedance and similar insertion loss. The difference is durability. Stainless-steel heads handle 500–1000 mating cycles and extended salt-spray tests without corrosion, while brass gold-plated types wear out faster outdoors. For critical outdoor links, TEJTE’s stainless-steel SMA connectors are a safer investment.

Q7. When should I switch from RG316 to a lower-loss cable (e.g., LMR-200)?

Once your rg316 attenuation exceeds 2 dB in the band you’re using, it’s time to upgrade. That usually means: runs longer than 3 m at 2.4 GHz, or longer than 1 m at 5.8 GHz. RG316D buys you a little more margin, but for anything beyond, LMR-class coax is the practical choice. TEJTE’s RF coaxial cable guide explains where each cable type fits.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.