LMR-240: Loss, Bend & Outdoor Routing

Oct 23,2025

Should you pick LMR-240 over RG58 cable/RG316 cable for this run?

This image illustrates the exterior, shielding, and jacket details of LMR-240 cable, aiding users in understanding its advantages over RG58 and RG316, such as lower attenuation and better outdoor suitability.

When choosing a 50-ohm coax cable, the decision often narrows down to LMR-240, RG58, or RG316—each with its own trade-offs. For most Wi-Fi, LTE, and RF applications, LMR-240 stands out as the sweet spot between low signal loss, flexibility, and durability.

Let’s break it down.

At 2.4 GHz, LMR-240 typically loses only 4.25 dB per 10 m, while RG58 drops about 6.4 dB and RG316 can exceed 9 dB. That difference means your signal stays stronger over longer distances, particularly when linking antennas, routers, or test gear. For engineers deploying outdoor access points, ham radio feeds, or 5 GHz backhaul links, that 2–4 dB improvement often translates to visibly better throughput.

What about handling and weight? LMR-240 maintains a manageable outer diameter of 6.1 mm, making it flexible enough to route around racks or conduit, yet robust enough for rooftop or mast installations.

Its foam PE dielectric and dual-shielded construction (aluminum + tinned copper braid) help block interference, while the PVC jacket protects against abrasion and mild UV exposure.

If your setup runs under 10 m and you’re using high-frequency bands (5 GHz, 6 GHz, or 10 GHz), LMR-240 will outperform RG58 cable or RG316 cable hands down. For extremely tight spaces or short jumpers, though, RG316 still wins on bend radius.

Compare loss, bend radius, and jacket for indoor vs outdoor use

- LMR-240 cable: 6.1 mm OD, 30 mm static bend radius, PE foam dielectric, PVC jacket — optimized for both indoor and outdoor routing.

- RG58 cable: 4.9 mm OD, slightly tighter bends, higher attenuation; suitable for short indoor runs.

- RG316 cable: 2.5 mm OD, ultra-flexible PTFE jacket; best for internal or lab jumpers.

In harsh environments—like rooftops, base stations, or radar systems—LMR-240 wins due to its abrasion resistance and UV protection. RG58 and RG316 simply degrade faster under sunlight and moisture.

When a 50 ohm coax cable upgrade pays off in 2.4/5/6 GHz Wi-Fi

If your link budget struggles beyond 5 GHz, switching from RG58 to LMR-240 can reclaim up to 2 dB per 5 m—a margin that can make or break Wi-Fi coverage.

This is particularly relevant for outdoor APs, wireless bridges, and IoT gateways, where every decibel matters.

Upgrading also reduces VSWR mismatches, which means less reflected power and improved transmission stability.

In practical terms, your radio runs cooler and maintains a stronger RSSI under load.

How long can an LMR-240 cable be before loss breaks your budget?

Every RF cable introduces attenuation, but the trick is finding how much loss your system can afford.

For LMR-240, losses scale roughly linearly: around 0.42 dB per meter at 2.4 GHz, 0.68 dB/m at 5 GHz, and 0.95 dB/m at 10 GHz.

That’s based on its rated attenuation curve at 20 °C.

So, what’s the break-even point? If your system allows up to 3 dB total loss, then your maximum length should be:

- ~7 m at 5 GHz

- ~4 m at 10 GHz

Beyond that, your signal will degrade faster than it’s practical to compensate.

Still, connectors and adapters add their own mini losses—typically 0.1–0.3 dB per joint. Using multiple SMA to SMA adapters instead of a single jumper may look convenient, but it often costs 0.5 dB in total chain loss.

Link-budget heuristics at 2.4/5/6 and 10 GHz; add connector/adapter loss

A simplified budget formula works well here:

Loss_total = α(f, cable) × L + N × Loss_conn

Where:

- α(f, cable) = cable attenuation per meter (dB/m)

- L = cable length (m)

- N = number of connector pairs

Example:

At 6 GHz, a 10 m LMR-240 with two SMA connectors yields:

0.74 dB/m × 10 m + 0.2 × 2 = 7.8 dB total loss — still manageable for most 6 GHz links.

Use TEJTE’s RF Cable Loss Calculator to plan attenuation across bands.

Swap “adapter stacks” for a short jumper vs SMA to SMA adapter

One common rookie mistake is stacking adapters—like using an SMA to N adapter, followed by an N to SMA coupler, just to extend a few inches.

Each interface adds resistance, mismatch, and potential moisture ingress.

Instead, order a custom-length LMR-240 SMA extension cable with pre-crimped ends.

It’s mechanically stable and performs cleaner. TEJTE supports lengths from 0.1 m to 10 m, with SMA male/female, N-type, or TNC options—all 50 Ω precision matched and IP67 ready.

Is it OK to bend LMR-240—how flexible is it?

Despite its thick jacket, LMR-240 is surprisingly adaptable.

It supports a minimum static bend radius of 30.5 mm, and a dynamic (repeated) bend radius of 61 mm. That means you can loop it around panel edges or mast bases without fear—just don’t kink it tightly around a sharp corner.

The foam PE dielectric allows a bit of compression, but repeated tight bends can fatigue the tinned copper braid over time.

If you’re running cables through hinges or moving joints (e.g., rotating antennas), it’s safer to switch to LMR-240-UF (Ultra-Flex), which uses a stranded center conductor instead of solid copper.

Is it OK to bend LMR-240? Minimum bend radius (static vs repeated)

| Condition | Cable Type | Recommended Bend Radius |

|---|---|---|

| Static installation | LMR-240 | 30 mm |

| Repeated motion | LMR-240 | 61 mm |

| Tight bends / hinges | LMR-240-UF | 25 mm |

| Compact modules | RG316 | 10 mm |

How flexible is LMR-240? Routing tips around hinges, rack doors, and masts

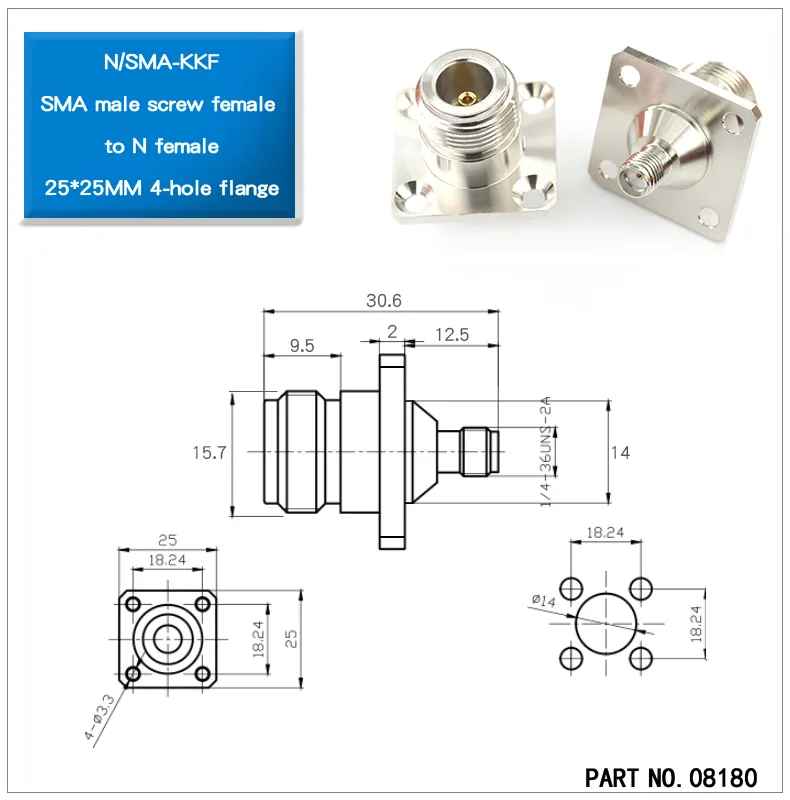

This image shows the mechanical structure and sealing design of the adapter, ensuring stable connections and protection against moisture and corrosion in rooftop, marine, and other harsh settings.

When routing cables along racks or through enclosure doors, always keep a gentle sweep instead of a sharp bend.

Use nylon ties or flexible clamps spaced every 30 cm to relieve strain.

For outdoor masts, leave a drip loop to prevent water ingress.

If you need to mate with heavy antennas or N-type bulkheads, TEJTE’s N/SMA-KKF waterproof connector (Part No. 40420) ensures both mechanical stability and DC–11 GHz bandwidth with VSWR ≤ 1.2—ideal for IP67-rated installs.

Will LMR-240 work at 10 GHz in your application?

Most engineers associate LMR-240 with 2.4 GHz Wi-Fi or 5 GHz backhaul work—but it actually performs well up to 10 GHz when used correctly. Its attenuation at 10 GHz is roughly 0.95 dB per meter, which means a 5 m run introduces about 4.8 dB total RF cable loss. That’s perfectly acceptable for many test setups, satellite links, or radar telemetry systems that already account for small insertion losses in their link budgets.

Where problems begin is not frequency itself but connector quality. At these high bands, the SMA connector becomes the bottleneck—any mechanical play, poor plating, or rough surface can raise VSWR above 1.3 : 1. Choosing precision-machined SMA male/female ends or switching to an N-type connector for outdoor assemblies ensures cleaner reflections.

If you’re routing cables to X-band radar, microwave analyzers, or Wi-Fi 6E test benches, pair LMR-240 with a stable 50 ohm coax cable chain and avoid multiple adapters. TEJTE’s N-type outdoor connectors are built for DC–11 GHz and maintain VSWR ≤ 1.2, ideal for these frequencies.

Loss slope with frequency; when to consider LMR-400 or waveguide

This image includes a cable cross-section and attenuation curve, helping users understand LMR-400's advantages in long-distance and high-frequency scenarios compared to LMR-240.

Every coax type has a frequency-dependent loss slope. LMR-240’s attenuation roughly doubles when moving from 5 GHz to 10 GHz.

So once your cable exceeds 6 m at 10 GHz, it’s usually smarter to upgrade to LMR-400 or even semi-rigid waveguide assemblies.

| Frequency | LMR-240 Loss (dB/m) | LMR-400 Loss (dB/m) | Recommended Max Length @ 3 dB |

|---|---|---|---|

| 2.4 GHz | 0.42 | 0.23 | 7 m vs 13 m |

| 5 GHz | 0.68 | 0.36 | 4.4 m vs 8.3 m |

| 10 GHz | 0.95 | 0.49 | 3.1 m vs 6.1 m |

Connector choice at X-band: SMA connector vs N-type connector

| Connector Type | Typical Frequency Range | Mechanical Stability | Waterproof Option |

|---|---|---|---|

| SMA connector | DC – 18 GHz | Compact / Precision | Optional boot/O-ring |

| N-type connector | DC – 11 GHz | Stronger threaded coupling | Fully IP67 sealed |

Should you use LMR-240 on a boat or other harsh outdoor sites?

Yes—but only if you respect environmental realities. LMR-240 was built with outdoor durability in mind: a PVC jacket resists abrasion and mild UV exposure, and its tinned copper braid prevents oxidation. Yet, constant salt-mist, vibration, and sunlight on marine decks can shorten its lifespan without proper protection.

For boat installations, route cables through sealed feed-throughs, use O-ring boots, and keep all connectors above deck level. TEJTE’s IP67 bulkhead kits and waterproof SMA connectors simplify this task while keeping signal reflection low.

If the line flexes often—say between a radar dome and mast—switch to LMR-240-UF, which tolerates movement better thanks to its stranded core.

Should I use LMR-240 in a boat? Salt-mist, UV, and vibration practices

| Environment | Risk Factor | Mitigation |

|---|---|---|

| Salt spray | Corrosion on braid and pins | Use nickel-plated or gold-plated connectors |

| UV exposure | Jacket brittle over years | Shield with conduit or UV-rated sleeves |

| Vibration | Micro-fracture at connector joint | Add strain relief or UF variant |

| Moisture | Ingress through threads | Seal with heat-shrink and O-ring boots |

Is LMR-240 water-resistant? Boots, O-rings, and IP67 feed-through

This image illustrates how to prevent water ingress through seals and proper installation steps, suitable for damp environments like boats and base stations.

By itself, LMR-240’s PVC jacket is only splash-resistant. To reach IP67 waterproofing, you’ll need external sealing—O-rings, heat-shrink tubing, or molded boots.

That’s why professional installers often combine LMR-240 with N-type bulkhead connectors (like Part No. 08180) and silicone gaskets.

For details on sealing methods, read RF Connector: Install, Clean & Waterproof, which explains proper torque, boot use, and dielectric sealing for outdoor assemblies.

Is TWS-240 the same as LMR-240—and what is LMR-240-UF?

Many buyers confuse these three labels. In practice, TWS-240, LMR-240, and LMR-240-UF share identical impedance and outer diameter, but differ slightly in structure and handling.

- LMR-240 – solid bare-copper conductor, foam PE dielectric, dual shield (aluminum foil + tinned copper braid), PVC jacket. Best for fixed outdoor runs.

- TWS-240 – third-party equivalent with minor material variations (e.g., different foil adhesion). Typically interchangeable in most 50 Ω systems.

- LMR-240-UF – “Ultra-Flex” version with a stranded center conductor and rubberized jacket, trading a slight (~0.2 dB/10 m) loss increase for superior bend life.

Is TWS-240 cable the same as LMR-240 cable? Spec compatibility and swaps

Technically, yes—you can swap TWS-240 for LMR-240 in most RF links because both maintain 50 Ω impedance and similar velocity factors.

Just verify that attenuation stays within ±10 % of the spec and shielding > 90 dB.

In enterprise WLANs or CCTV setups, mixing them causes no issue as long as connectors are crimped to matching die sets.

What is LMR-240-UF? Ultra-Flex trade-offs (loss, bend, weight)

This image highlights its stranded center conductor and soft jacket design, compared to standard LMR-240, emphasizing its suitability for rotating antennas or test equipment.

LMR-240-UF (Ultra-Flex) is designed for motion-heavy environments—portable test gear, rotating masts, or repeated setup/teardown events.

Its stranded center conductor improves flexibility by ~40 %, but adds a touch more attenuation—around 0.1 dB/m at 6 GHz.

The jacket uses a softer thermoplastic, so clamp it gently under strain reliefs to avoid cuts.

| Parameter | LMR-240 | LMR-240-UF |

|---|---|---|

| Center Conductor | Solid Bare Copper | Stranded Bare Copper |

| Attenuation @ 5 GHz (dB/10 m) | 6.8 | 7.8 |

| Min. Bend Radius (mm) | 30 | 25 |

| Flex Cycles | ≈ 500 | ≈ 1000 |

| Weight (g/m) | 66 | 69 |

In the field, installers often combine LMR-240-UF jumpers with SMA extension cables for rack or mast transitions, then terminate to fixed LMR-240 trunks for long runs.

This hybrid approach keeps both performance and flexibility optimized.

Can you route, seal, and verify LMR-240 in minutes?

This image shows the assembled cable appearance and connection details, emphasizing the use of custom lengths and precision connectors to minimize loss and mismatch.

Routing LMR-240 isn’t just about connecting two ends—it’s about preserving impedance, sealing against moisture, and confirming loss integrity. Done right, even first-time installers can finish within minutes.

Start with layout and strain relief. Plan gentle curves, not sharp corners; maintain at least a 30 mm bend radius. Use nylon clamps every 25–30 cm to avoid sagging. For outdoor routing, always include a drip loop before the cable enters an enclosure or antenna mount. It keeps water from tracking down into connectors.

Next, focus on sealing and torque. Apply dielectric grease sparingly on the male pin, seat the SMA connector finger-tight, and finish with a calibrated SMA/N-type torque wrench—around 0.8 N·m for SMA and 1.5 N·m for N-type fittings. Tightening beyond that risks deforming the interface and raising VSWR.

Once installed, perform a quick continuity and RF loss check.

Use a handheld VNA or simple power-through test at your working band (2.4 / 5 / 6 GHz).

Typical return loss for a healthy LMR-240 run should exceed 20 dB, while insertion loss should match your expected attenuation table.

For reference, TEJTE’s RF Cable Loss: Pick, Budget & Verify at 2.4 / 5 / 6 GHz guide details step-by-step verification using real cable data.

Safety tip: Never pull LMR-240 by its connector; always grip the jacket near the crimp ferrule. The foam dielectric can stretch under tension, altering impedance.

Drip loops, strain reliefs, torque values; avoid twist while tightening

| Step | Task | Key Detail | Time |

|---|---|---|---|

| 1 | Route cable loosely | Maintain ≥ 30 mm bend radius | 1 min |

| 2 | Secure with clamps | Every 25–30 cm | 2 min |

| 3 | Add drip loop | Before enclosure entry | 1 min |

| 4 | Tighten connector | SMA = 0.8 N·m / N = 1.5 N·m | 1 min |

| 5 | Verify continuity | RL > 20 dB, no mismatch | 2 min |

Quick acceptance: continuity + spot RF cable loss / return-loss checks

A simple acceptance test confirms the line is healthy:

- DC continuity test: inner to outer must show open; inner to inner shows low resistance.

- Return-loss scan: RL > 18 dB across band.

- Insertion-loss check: compare with expected α(f) × L + ΣLoss_conn formula.

Once verified, label both ends with length, date, and connector type for future maintenance.

Professional installers often record this data into their maintenance logs to ensure long-term RF performance.

Order once: which LMR-240 SKU and ends match your gear?

When ordering LMR-240 jumpers or trunk cables, the goal isn’t just to match length—it’s to ensure the connectors, shielding, and environmental rating truly fit your setup. A well-chosen assembly saves hours of troubleshooting later.

Start by confirming connector gender and sealing grade. SMA male-to-female suits most router or indoor AP links, while N-type male-to-female handles outdoor or marine loads better. If the environment is exposed or vibrates often, consider the LMR-240-UF variant; its stranded center conductor survives constant motion far longer.

Below is the Length–Loss–Use Case Matrix, a quick reference engineers use in the field when balancing loss budget and flexibility.

The data are derived directly from TEJTE’s in-house measurements and QC records, where every batch of LMR-240 is tested for attenuation and impedance consistency before shipment. That’s why installers who’ve handled both generic and TEJTE cables can usually feel the difference—the jacket stiffness is just right, and the connectors seat cleanly without the “snap” of over-tight plating.

LMR-240 “Length–Loss–Use Case” Selection Matrix

| Use Case | Band (GHz) | Max Length @ 3 dB Loss | Cable Type | Connector Ends | Est. Loss (dB) | Waterproofing | Suggested TEJTE P/N |

|---|---|---|---|---|---|---|---|

| Router / AP | 2.4 / 5 | 7 m | LMR-240 | SMA (M-F) | 2.8 | Heat-shrink Y | SMA-JK / LMR240-7M |

| Outdoor mast | 5 / 6 | 5 m | LMR-240 | N (M-F) | 3.4 | O-ring Y | N-JK / LMR240-5M |

| Boat antenna | 2.4 | 4 m | LMR-240-UF | N (M-F) | 2.5 | Boot Y | N-JK UF / 4M |

| Test bench | 6 / 10 | 2 m | LMR-240 | SMA (M-M) | 1.9 | None | SMA-JJ / 2M |

| Ham station | 2.4 / 5 | 10 m | TWS-240 | SMA (M-F) | 3.8 | Heat-shrink Y | SMA-JK / TWS240-10M |

Formula used:

Loss_total = α(f,cable) × L + ΣLoss_connectors (0.1–0.3 dB each)

This table reflects the actual stock options in TEJTE’s RF Cable Collection — available in 0.1 m to 10 m increments with SMA, N-type, and TNC interfaces. Engineers who order custom assemblies from TEJTE often note that the measured loss in the lab matches the rated figure within ±0.2 dB—a reassuring sign that the specifications printed on the datasheet really hold up in the field.

Installer note: If you’ve ever spent a morning tracing signal drop only to find a poor crimp on a third-party cable, you’ll appreciate why verified LMR-240 assemblies matter. Reliable testing upfront saves hours later.

FAQs

1. Is it OK to bend LMR-240, and what’s the minimum bend radius?

Yes. Static installations: 30 mm radius. For repeated motion: 61 mm. Tighter than that risks dielectric deformation.

2. How flexible is LMR-240 compared with LMR-240-UF and RG58?

LMR-240-UF is ≈ 40 % more flexible thanks to its stranded core; RG58 bends tighter but loses more signal.

3. Will LMR-240 still work at 10 GHz, or should I upgrade to LMR-400?

Below 4 m, LMR-240 performs nearly identical to LMR-400; longer runs should upgrade to reduce attenuation.

4. Is TWS-240 truly the same as LMR-240—can I swap them?

Yes, both maintain 50 Ω impedance and comparable loss; verify shielding and manufacturing tolerance before mixing.

5. Should I use LMR-240 on a boat—how do I protect it from salt and vibration?

Use nickel-plated or gold-plated connectors, seal with O-rings and heat-shrink, and add strain relief to absorb motion.

6. Is LMR-240 water-resistant on its own?

Its PVC jacket is splash-proof only. Combine with IP67 boots or bulkhead gaskets for full waterproof rating.

7. What length threshold makes LMR-240 a better choice than RG58 or RG316?

Anything over 2–3 m at 5 GHz justifies LMR-240—its lower loss improves SNR and link stability measurably.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.