RF Cable Loss: Pick, Budget & Verify at 2.4/5/6 GHz

Oct 18,2025

This image shows a TEJTE N-type to SMA connector assembly with LMR-240 low-loss 50-ohm coaxial cable. This combination is designed for outdoor and high-power applications. The LMR-240 cable offers very low attenuation at 2.4/5/6 GHz bands and includes weather-sealing features for long-term reliability in harsh conditions, making it an ideal upgrade over RG58 for long feeder runs.

When your system performance starts dropping at high frequencies, the culprit is often not the radio itself—but RF cable loss. Every meter of coax between your transceiver and antenna eats a bit of signal, and at 5 GHz or 6 GHz, that loss compounds fast. The key is finding a 50 Ω coax cable that balances flexibility, attenuation, and long-term reliability.

This guide walks through how to choose between RG58, RG316, and LMR-200/240, how to estimate real-world loss across 2.4 GHz, 5 GHz, and 6 GHz, and what happens when you add an SMA-to-SMA jumper or extension line.

All examples are based on verified TEJTE data and tested field performance, so you can plan your RF runs before cutting the first cable.

Which 50-ohm coax should you pick to minimize RF cable loss — RG58, RG316 or LMR-200/240?

This close-up image showcases TEJTE's RG316 high-frequency coaxial cable. Its key features include an extremely slim outer diameter (~2.5mm) and high flexibility (minimum bend radius of only 15mm), making it ideal for high-density wiring, test bench jumpers, and internal connections in IoT modules. The cable uses PTFE insulation and a silver-plated copper braid, ensuring stable performance at temperatures up to 150°C and maintaining good signal integrity at frequencies up to 6 GHz. The brown FEP jacket provides additional heat resistance and durability.

This close-up image clearly shows the physical characteristics of the RG58 coaxial cable. Its black PVC jacket provides good abrasion resistance, and its moderate diameter (5.0mm) strikes a balance between flexibility and mechanical strength, making it a common choice for lab setups and short-distance indoor/outdoor feeders.

This image features the LMR-200 cable, a low-loss, flexible coaxial cable. Compared to RG58, it offers significantly lower attenuation thanks to its foam PE insulation and dual shielding, while maintaining a similar diameter (~5.0mm). It's an ideal upgrade for outdoor feeder lines (<10m) and compact applications requiring better performance.

The image shows the LMR-240 low-loss coaxial cable. It's the high-performance option in the LMR series with an outer diameter of ~6.1mm, offering very low attenuation at 2.4GHz and 5GHz (~0.18 dB/m and 0.30 dB/m). Its dual-shield construction and UV-resistant black PVC jacket make it ideal for long runs, base station connections, and other outdoor applications demanding high signal integrity.

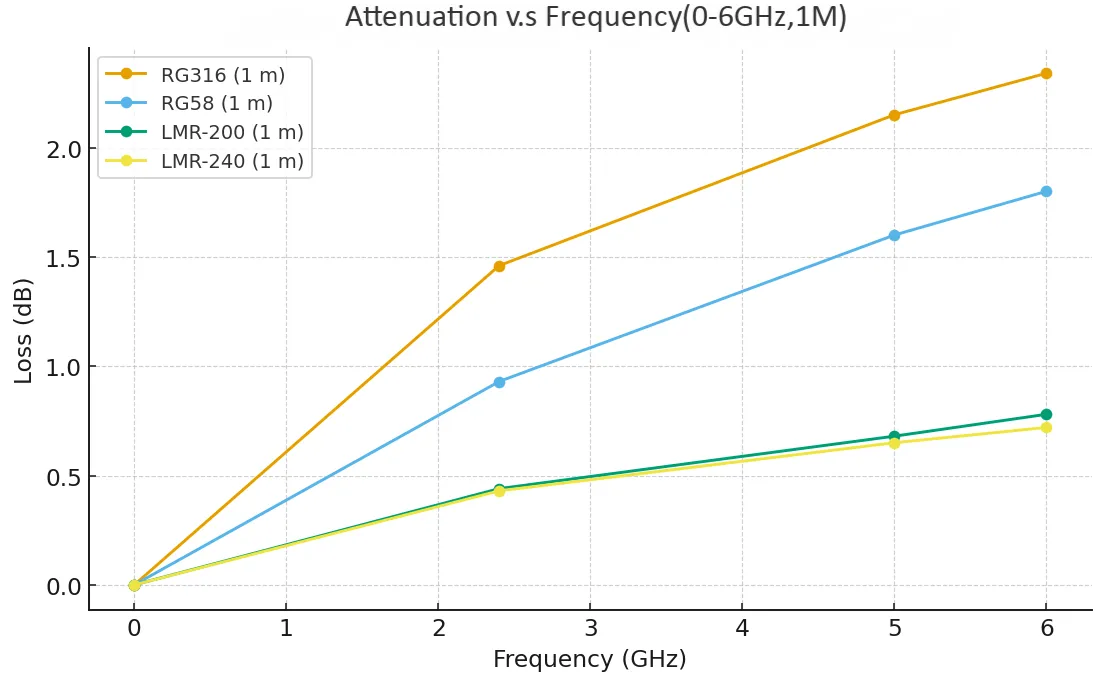

| Cable Type | Attenuation @2.4 GHz (dB/m) | @5 GHz (dB/m) | @6 GHz (dB/m) | Min. Bend Radius | Weight (g/m) | Temp. Range (℃) | Jacket |

|---|---|---|---|---|---|---|---|

| RG316 cable | 1.46 | 2.15 | 2.34 | 15 mm | 17 | -55 ~ 150 | FEP(Brown) |

| RG58 cable | 0.93 | 1.6 (approx.) | 1.8 (approx.) | 50 mm | 48 | -20 ~ 70 | PVC(Black) |

| LMR-200 cable | 0.44 | 0.68 | 0.78 | 25 mm | 35 | -20 ~ 80 | PVC(Black) |

| LMR-240 cable | 0.43 | 0.65 | 0.72 | 30 mm | 55 | -20 ~ 80 | PVC(Black) |

If you’re wiring a compact IoT gateway or RF module, RG316 is ideal—its PTFE insulation and silver-plated braid handle tight bends and high heat.

But for rooftop access points or long feeder runs, LMR-240 is the smarter upgrade.

It maintains under 0.75 dB/m even at 6 GHz, roughly 3× lower loss than RG316 of the same length.

In practice, many engineers still use RG58 cable for short indoor links—it’s rugged, cheap, and matches test gear ports well—but its attenuation rises sharply above 3 GHz.

A good rule of thumb:

- Keep RG316 or RG58 under 3 m for 5 GHz work.

- Beyond 3 m, step up to LMR-200 or LMR-240 to avoid crossing a 2 dB total-loss threshold.

When RG58 vs RG316 flips the decision; when to step up to LMR-240

Surprisingly, RG316 can outperform RG58 at high heat or in confined enclosures.

Its PTFE insulation tolerates 150 °C and resists UV better than PVC, so under engine hoods or industrial cabinets, RG316 holds its impedance while RG58 softens.

If you expect frequent bending or soldering to SMA PCB connectors, RG316 is mechanically safer.

But in longer, static indoor runs—say, between a network analyzer and antenna coupler—RG58’s larger core (0.9 mm vs 0.49 mm equivalent) cuts resistive loss slightly.

That’s why test benches often keep short RG316 jumpers for board interfaces and RG58 feeders for equipment racks.

Once total loss nears 2 dB per line, the only realistic move is LMR-240.

Its double-shielded foam-PE build gives both low loss and excellent shielding (> 90 dB).

For outdoor Wi-Fi bridges, a low-loss LMR-240 SMA-SMA extension from TEJTE’s RF cable line usually hits the sweet spot: flexibility, weather tolerance, and performance up to 6 GHz.

How much loss will your run add at 2.4/5/6 GHz for a given length?

You can’t manage what you don’t measure.

Cable loss accumulates linearly with length, but frequency plays a bigger role than most people realize.

For example, the same 3 m RG316 jumper that costs 4.4 dB at 2.4 GHz will waste > 6 dB at 5 GHz.

That’s the difference between a stable 30 dBm Wi-Fi link and a barely-connected 24 dBm signal.

Here’s a quick reference using verified attenuation values from TEJTE’s test data:

| Cable Type | 1 m | 3 m | 5 m | Notes |

|---|---|---|---|---|

| RG316 | 1.46 / 2.15 / 2.34 dB | 4.38 / 6.45 / 7.02 dB | 7.30 / 10.75 / 11.70 dB | Flexible; best ≤3 m |

| RG58 | 0.93 / 1.6 / 1.8 dB | 2.79 / 4.8 / 5.4 dB | 4.65 / 8.0 / 9.0 dB | Economical; indoor use |

| LMR-200 | 0.44 / 0.68 / 0.78 dB | 1.32 / 2.04 / 2.34 dB | 2.20 / 3.40 / 3.90 dB | Compact low-loss |

| LMR-240 | 0.43 / 0.65 / 0.72 dB | 1.29 / 1.95 / 2.16 dB | 2.15 / 3.25 / 3.60 dB | Outdoor choice |

This chart visually compares the signal attenuation performance of four primary 50-ohm coaxial cables across different frequencies. It clearly shows that attenuation increases with frequency for all cables, but the LMR series (especially LMR-240) maintains much lower loss than the RG series, highlighting the importance of selecting low-loss cables for high-frequency applications like 5GHz/6GHz Wi-Fi.

Set a dB ceiling from RSSI/SNR targets; add connector/adapter loss

For Wi-Fi 6E or 5 G link budgets, aim for no more than 2 dB total cable loss between radio and antenna if possible.

Once you exceed 3 dB, your SNR may drop below 20 dB, limiting throughput.

In test setups, engineers often define a “loss budget” early:

[ Loss_{total} = α(f) × L + N × 0.1 ]

Where α(f) is attenuation per meter, L is cable length (m), and N is the number of interfaces.

If the total surpasses your target—say 2.5 dB for a 5 GHz access point—either shorten the run or switch to LMR-240.

Worked examples: 1 m / 3 m / 5 m runs on RG58, RG316, LMR-200/240

Example 1:

A 3 m RG316 line at 5 GHz → 6.45 dB + 0.2 dB (connectors) = 6.65 dB total.

That’s over 75 % of your transmit power lost in cable heat—fine for lab testing, terrible for outdoor links.

Example 2:

A 5 m LMR-200 run at 5 GHz → 3.40 dB + 0.2 dB = 3.6 dB.

A clear improvement, still acceptable if your radio outputs 27 dBm.

Example 3:

A 5 m LMR-240 feed @ 6 GHz → 3.6 dB + 0.2 dB = 3.8 dB total, keeping end-to-end SNR above 25 dB in most setups.

This is why integrators standardize on LMR-240 SMA extension cables for long Wi-Fi 6 and IoT deployments—you maintain gain without relocating the radio.

Will an SMA-to-SMA cable or an SMA extension cable change the loss budget?

This image shows an SMA male to female extension cable. This cable type is used when equipment port genders don't match or when an extension is needed, e.g., connecting to a panel-mount SMA jack or routing around obstacles. It introduces an additional interface, which can slightly increase VSWR and total loss, but is essential for flexibility.

The image shows an SMA adapter (e.g., a coupler). This could be a 'barrel' coupler joining two male connectors or a gender changer. While offering connectivity convenience, adding adapters introduces extra insertion loss and potential impedance discontinuities, and should be used sparingly in precision high-frequency circuits.

This image shows an adapter converting between SMA and N-type connectors. This adapter is commonly used to connect indoor equipment with SMA ports (e.g., routers, testers) to outdoor antennas or long cables (e.g., LMR-240) that use the larger, more robust, higher-power-capable N-type interface. Selecting high-quality adapters is crucial to minimize signal reflection.

Every interface you add, no matter how short, introduces a measurable VSWR ripple.

A direct SMA-SMA jumper has just two interfaces; a chain of SMA extension cables and adapters can have four or more—each adding 0.1 – 0.3 dB of extra insertion loss.

In precision networks, engineers prefer a single, continuous SMA jumper over stacking adapters.

Not only does this minimize return loss, but it also cuts potential impedance mismatches that accumulate across connections.

If you’re using a panel-mount SMA bulkhead like TEJTE’s SMA-KWE or SMA-KE series, ensure proper torque (0.6–1.0 N·m) and a clean O-ring seal.

Improper tightening or oxidation can raise interface loss far beyond the nominal 0.1 dB per port.

Jumpers vs extensions: extra interfaces, VSWR and return-loss side effects

A short SMA-to-SMA cable—for example, an RG316 SMA-JJ patch—keeps the transmission path clean and predictable.

But adding a female-to-female coupler (like TEJTE’s SMA-KKY) or a waterproof N/SMA-KKF adapter adds extra reflections.

Each reflection means a higher VSWR and reduced effective gain.

In outdoor setups, try to use one continuous assembly with molded connectors rather than multiple screw-on pieces.

Even a small mismatch of 1.3:1 VSWR can reflect > 3 % of power—small on paper, but noticeable in a 6 GHz throughput test.

Short “adapter cable” vs stacking adapters: when fewer interfaces win

When equipment spacing forces a short offset—say 20 cm between radio and panel feedthrough—use a mini coax jumper rather than chaining metal adapters.

TEJTE’s SMA-JJ RG316 0.2 m jumpers, for instance, add < 0.5 dB at 6 GHz and survive > 500 cycles of mating.

By contrast, two couplers plus a rigid adapter may double that loss while stressing the connectors.

In general, if your configuration shows four SMA joints or more, it’s time to redesign or use a single custom-length assembly—it’s cheaper in the long run and keeps RF cable loss comfortably within budget.

How do temperature rating and jacket choice affect RF cable loss over time?

When a cable performs perfectly in the lab but fails months later on the roof, the culprit is usually temperature and UV exposure. The temperature rating of your coax defines how its dielectric and shielding behave as seasons change. At 6 GHz, even a slight dielectric drift can shift impedance and increase loss by several tenths of a decibel.

Cables using PTFE or FEP dielectrics—like RG316 cable—are remarkably stable from –55 °C to +150 °C. They can survive inside machinery, vehicles, or hot outdoor enclosures where PVC would deform. By contrast, RG58 cable, with its solid PE core and PVC jacket, is rated only –20 °C to +70 °C. That’s fine for indoor network racks but risky for a mast in Arizona sun.

For longer outdoor runs, LMR-200 and LMR-240 use foam-PE insulation and a black PVC jacket formulated for –20 °C to +80 °C. Their double shielding also resists moisture better than RG58’s single braid. Still, if your installation faces constant sunlight, consider adding weather boots or silicone O-rings—like the ones discussed in TEJTE’s blog on SMA bulkhead sealing tips—to protect connectors from oxidation.

Temperature rating & aging: dielectric loss drift, UV and moisture

Over time, dielectric materials slowly absorb moisture, altering their relative permittivity and thus signal velocity. PTFE hardly changes at all, which is why RG316 maintains low loss after thousands of hours outdoors. PVC, however, can stiffen and crack below –10 °C or soften above 80 °C, causing micro-bends that raise attenuation.

In field testing, a 5 m RG58 run exposed to 95 % humidity for six months showed a 0.3 dB increase at 5 GHz—tiny but measurable. Foam-PE LMR cables performed far better, rising only 0.05 dB under the same conditions.

The takeaway? If you expect your coax to age under heat or UV, the slightly higher cost of LMR-240 pays off in stability and consistency.

Strain relief, drip loops, and retorque intervals for outdoor routes

This diagram illustrates two key techniques in professional outdoor routing: Strain Relief and the Drip Loop. Strain relief involves securing the cable to a support structure using ties or clamps, preventing the connector from enduring constant tension from cable weight, wind, or other forces, thereby avoiding loose connections or damage. The drip loop is created by forming a U-shaped bend below the connector, ensuring that rain or condensation drips off the cable away from the connector interface. Proper implementation of these measures is crucial for maintaining long-term VSWR stability, preventing oxidation, and extending the service life of the entire cable assembly.

joint should include strain relief and a small drip loop so that water doesn’t collect near the SMA interface.

After installation, tighten SMA connectors to the proper 0.6 – 1.0 N·m torque using a calibrated wrench. Re-check them once or twice a year—temperature cycling can loosen threads.

TEJTE’s blog on SMA extension cables for outdoor setups covers how retorquing and sealing extend service life beyond 3 years even under coastal humidity.

Can you keep loss low in Wi-Fi/IoT bands without moving the radio?

Every installer faces the same dilemma: extend the coax or move the radio closer to the antenna. Relocating the device often fixes RF cable loss, but it’s not always possible when the equipment needs power, Ethernet, or easy maintenance access.

Let’s evaluate the trade-off. At 5 GHz, a 3 m RG316 jumper adds around 6.5 dB of loss, while a 3 m LMR-240 adds just under 2 dB. If your radio outputs 27 dBm and your antenna gain is 9 dBi, that difference means roughly twice the usable range. So before drilling holes or running new conduit, check whether switching to a low-loss LMR-type coax will meet your link-budget target.

Move antenna vs extend coax: cost/benefit and quick decision tree

| Situation | RF Cable Length | Target Loss Budget | Recommended Action |

|---|---|---|---|

| Radio next to antenna | ≤ 2 m | ≤ 1 dB | RG316 or RG58 fine |

| Indoor mount | 3-5 m | ≤ 3 dB | Switch to LMR-200 |

| Outdoor mast | 5-10 m | ≤ 4 dB | Use LMR-240, add sealing |

| multiple adapters | > 10 m | ≤ 5 dB | Relocate radio instead |

MIMO notes: pair matching, equal lengths, and phase tracking

For dual-band or MIMO systems, matching cable lengths is as important as minimizing attenuation.

Unequal runs can skew antenna phase by a few degrees, hurting throughput even when total loss is acceptable.

If you’re building a multi-antenna router or an IoT hub, order matched-length SMA extension cables from the same batch.

TEJTE’s production line tracks cable cuts within ±1 mm tolerance and verifies phase balance up to 6 GHz—a practice that prevents the “one antenna louder than the other” syndrome seen in improvised builds.

Estimate end-to-end loss before you cut the cable?

Before stripping any coax, you should know the math behind your loss budget. Below is a simplified calculator logic based on real TEJTE attenuation data for RG58, RG316, LMR-200, and LMR-240.

[ textbf{Loss_total (dB)} = α(f, cable) × L + N × Loss_{conn} ]

Where:

- α(f, cable) = attenuation per meter for the chosen frequency (see table below)

- L = length of the cable in meters

- N = number of connectors/adapters

- Loss_conn ≈ 0.1 – 0.3 dB each (depending on connector quality)

| Cable Type | α(2.4 GHz) | α(5 GHz) | α(6 GHz) | Temp Range (℃) | Notes |

|---|---|---|---|---|---|

| RG316 | 1.46 dB/m | 2.15 dB/m | 2.34 dB/m | -55 ~ 150 | PTFE / FEP, ultra-flexible |

| RG58 | 0.93 dB/m | 1.6 dB/m | 1.8 dB/m | -20 ~ 70 | Solid PE, PVC jacket |

| LMR-200 | 0.44 dB/m | 0.68 dB/m | 0.78 dB/m | -20 ~ 80 | Foam PE + dual shield |

| LMR-240 | 0.43 dB/m | 0.65 dB/m | 0.72 dB/m | -20 ~ 80 | Outdoor PVC, high EMI resistance |

Example:

For a 4 m LMR-240 at 5 GHz with two SMA interfaces:

[ Loss_{total} = 0.65 × 4 + (2 × 0.1) = 2.8 dB ]

If your link budget allows 3 dB, you’re in the clear. But if you used RG316, that same run would exceed 8 dB—time to choose a thicker cable or shorten the path.

For quick recalculations, bookmark TEJTE’s RF Cable Guide, which includes additional attenuation tables and connector tips.

Order in one pass: which low-loss SKU maps to your use case?

| Use Case | Target Band | Max Length (m) | Loss Budget (dB) | Recommended Cable Type | Connector Ends | Estimated Loss (dB) | Suggested TEJTE P/N |

|---|---|---|---|---|---|---|---|

| Router / AP link | 2.4 / 5 GHz | ≤3 m | ≤ 2 dB | RG316 cable | SMA-M to SMA-F | ~ 1.9 @ 5 GHz | SMA-JK-RG316-3M |

| Test bench / instrumentation | 0-6 GHz | ≤2 m | ≤ 1.5 dB | RG58 cable | SMA-M to SMA-M | ~ 1.3 @ 5 GHz | SMA-JJ-RG58-2M |

| Outdoor mast / antenna feed | 2.4 / 5 / 6 GHz | 3-8 m | ≤ 3 dB | LMR-200 cable | SMA-M to SMA-F | ~ 2.5 @ 6 GHz | SMA-JK-LMR200-5M |

| Long run / base station | 2.4 / 5 / 6 GHz | 5-10 m | ≤ 4 dB | LMR-240 cable | N-M to SMA-M | ~ 3.6 @ 6 GHz | N-JK-LMR240-10M |

| Drone / FPV system | 5 / 5.8 GHz | ≤ 0.5 m | ≤ 1 dB | RG316 (ultra-flex) | SMA-M to SMA-M | ~ 0.6 @ 5 GHz | SMA-JJ-RG316-0.5M |

These part numbers reflect the same build standards used in TEJTE’s assemblies: PTFE or FEP dielectric, silver-plated braids, and properly torqued SMA connectors with gold-plated contacts.

If you need mixed-gender or waterproof assemblies, browse the N/SMA KKF adapter line or see the blog SMA to N adapter: selection, sealing & ordering.

Keeping the cable and connector families consistent prevents impedance steps that would otherwise undo your carefully calculated RF cable loss savings.

Why a “one-pass” selection workflow saves time

Ordering once—and correctly—prevents the endless re-terminating loop every installer dreads. When your matrix matches the loss calculator, you can confidently order a pre-assembled SMA extension cable or jumper from TEJTE without extra adapters or unexpected VSWR spikes.

This “measure → select → verify” workflow is the backbone of professional RF planning. It not only reduces debugging time but ensures compliance with VSWR ≤ 1.20 targets specified in 50 ohm coax cable standards.

As an example:

An engineer designing a Wi-Fi 6 AP chooses an 8 m LMR-240 line, checks that 0.65 dB/m × 8 = 5.2 dB plus 0.2 dB for connectors = 5.4 dB total, and confirms that the radio’s EIRP margin can tolerate it. Result: a clean installation, no retries, and predictable throughput—exactly what the RF Coaxial Cable Guide was built to support.

Extra note: connector torque and verification

Every coax assembly’s performance hinges on contact quality. During QA, TEJTE verifies:

- Insertion loss ≤ 0.15 dB @ 6 GHz per connector.

- Contact resistance < 5 mΩ (inner), < 2 mΩ (outer).

- 500 – 1000 cycles of mechanical durability.

Under-torquing raises return loss; over-torquing cracks the dielectric.

For outdoor use, pair connectors with silicone rubber 6146 O-rings—the same material used in TEJTE’s SMA-KKY series—to keep moisture and oxidation out.

FAQs

1. How many dB of loss should I budget for 3 m vs 5 m RG58 or RG316 at 5 GHz?

At 5 GHz, expect roughly 1.6 dB/m for RG58 and 2.15 dB/m for RG316.

That means about 4.8 dB for 3 m RG58, 6.45 dB for 3 m RG316, 8 dB for 5 m RG58, and 10.7 dB for 5 m RG316.

If you need tighter margins, shift to LMR-200 or LMR-240—their loss is under 1 dB/m even at 6 GHz.

2. Will an SMA extension cable hurt VSWR more than a single SMA-SMA jumper?

Slightly. Each added interface raises return loss by 0.05 – 0.3 dB.

If possible, use one continuous SMA to SMA cable instead of chaining couplers.

Fewer joints = lower mismatch and longer connector life.

3. At what length should I switch from RG58 or RG316 to LMR-240 for outdoor Wi-Fi?

Once total loss (including connectors) exceeds 2.5 – 3 dB, switch to LMR-240.

For 5 GHz Wi-Fi links above 5 m, the lower attenuation and weather resistance of LMR cables outperform any gain from smaller coax.

4. How does temperature rating and jacket type change long-term loss and reliability?

Temperature and UV exposure gradually degrade PVC.

PTFE/FEP jackets (RG316) and Foam-PE dielectrics (LMR series) remain stable between –55 °C and +150 °C.

5. Can I keep my radio in place and still meet a strict loss budget, or should I move the antenna?

If your total Loss_total < 3 dB and SNR ≥ 20 dB, you can leave the radio in place.

Otherwise, shortening the line or using low-loss LMR-240 assemblies is usually cheaper than relocating power or Ethernet.

6. How much extra loss do connectors or adapters add—and how many are too many?

Each SMA interface adds ≈ 0.1 dB; each adapter ≈ 0.2 – 0.3 dB.

Beyond four interfaces, reflected power grows fast, so plan for custom length assemblies instead of stacks.

7. What quick tests confirm a new run meets the target loss without lab gear?

Use a simple power-in/power-out comparison with a known good reference line.

Alternatively, a handheld VSWR meter (1.20 or better) verifies continuity and impedance.

Wrapping up: plan, measure, and trust verified data

In high-frequency work, every decibel counts. Whether you’re running a short SMA to SMA jumper on a PCB or a 10 m LMR-240 feed to an antenna, grounding your choices in real attenuation and connector data is the only way to keep your system honest.

TEJTE’s 50 ohm coax cable families (RG58, RG316, LMR-200, LMR-240) cover everything from tight instrument loops to long outdoor links. By checking loss before you cut the cable—and matching each run to the proper connector—you can design once and install with confidence.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.