SMA Bulkhead Connector: Selection, Mounting & IP67 Tips

Oct 8,2025

Choose by panel thickness: which thread length should you order?

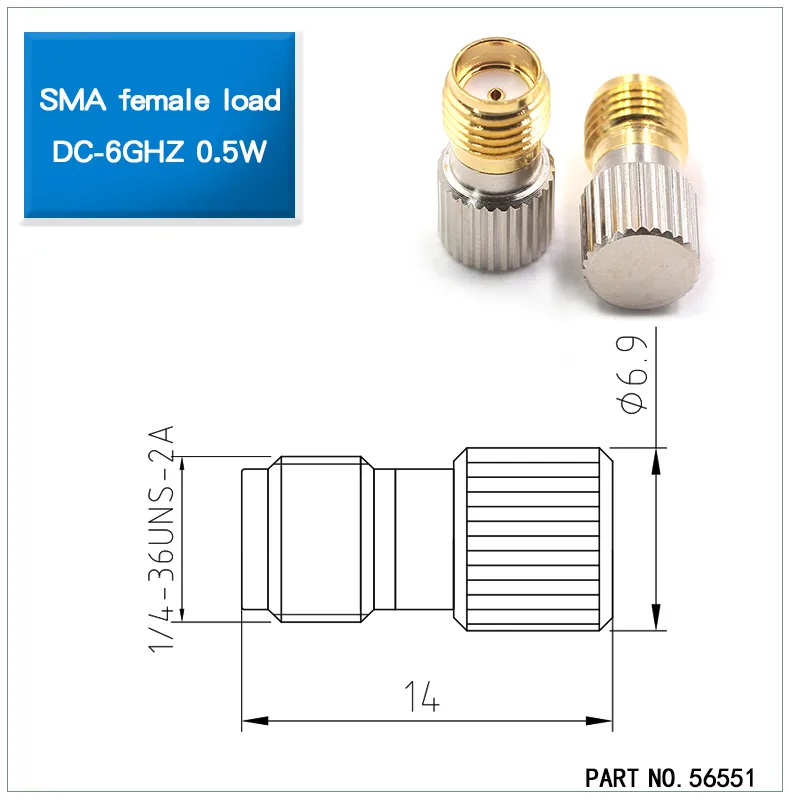

This figure serves as a physical reference in the document's discussion on "thread length selection." It visually illustrates the connector's overall structure, helping engineers understand how thread length (e.g., 13.5mm for SMA-KKY) corresponds to different panel thicknesses, forming the basis for correct selection.

The thread length of an SMA bulkhead connector isn’t just a mechanical detail. It directly affects whether the connector seats securely or leaves you with a nut barely holding on. Panels in telecom gear, routers, and test instruments range widely—from thin 1 mm sheet metal to heavy 8 mm die-cast walls. If the thread is too short, you’ll never achieve reliable torque; too long, and it wastes space inside the housing.

Take TEJTE’s SMA female connector options as a real-world example. The SMA-KKY (Part No. 53353) offers a 13.5 mm thread, perfect for 2–5 mm aluminum panels with enough margin for a nut and lock washer. When the enclosure is thicker—say closer to 8 mm—a bulkhead like the SMA-KE offset pin (Part No. 05860) with a 17 mm thread is the safer choice. I’ve seen cases where engineers picked a shorter thread, only to watch the connector spin loose after vibration testing.

A simple rule helps avoid that headache:

Thread length ≥ Panel thickness + Washer/Nut stack + 2–3 exposed threads.

That extra margin ensures proper torque without stripping threads. It also gives you flexibility if you later add a wave washer or change the enclosure material. In practice, a few millimeters make the difference between a connector that holds firm for years and one that fails after shipping stress.

Map your enclosure wall (1–10 mm) to 8/11/13/15/17/21/23/33 mm threads

A quick mapping makes connector selection far less guesswork. Thin sheet-metal panels around 1–2 mm typically pair well with 8 mm threads, which you’ll find on many compact bulkheads. Step up to 3–5 mm aluminum, and an 11–13 mm thread is the safer bet—the 53353 bulkhead at 13.5 mm is a common solution. For enclosure walls in the 6–8 mm range, a 17 mm thread connector like TEJTE’s 05860 offset-pin bulkhead offers the right balance. And when you’re dealing with thick housings, gaskets, or layered shielding, extended lengths of 21–23 mm may be the only option.

It’s easy to underestimate how much a washer stack changes the requirement. A wave washer and nut together can consume nearly as much thread as an extra millimeter of panel thickness. That’s why many engineers double-check not only wall depth but also the complete stack-up. In practice, if your enclosure requires repeated maintenance, it’s worth specifying a sturdier SMA panel connector. Its design ensures better thread engagement, reducing the chance of loosening during frequent cycles.

Think of it this way: too little thread and you’re fighting with stripped nuts; too much and you’re wasting enclosure space. Matching panel thickness to the right thread length means fewer installation headaches and more reliable RF performance down the line.

When to use two nuts + wave washer for locking?

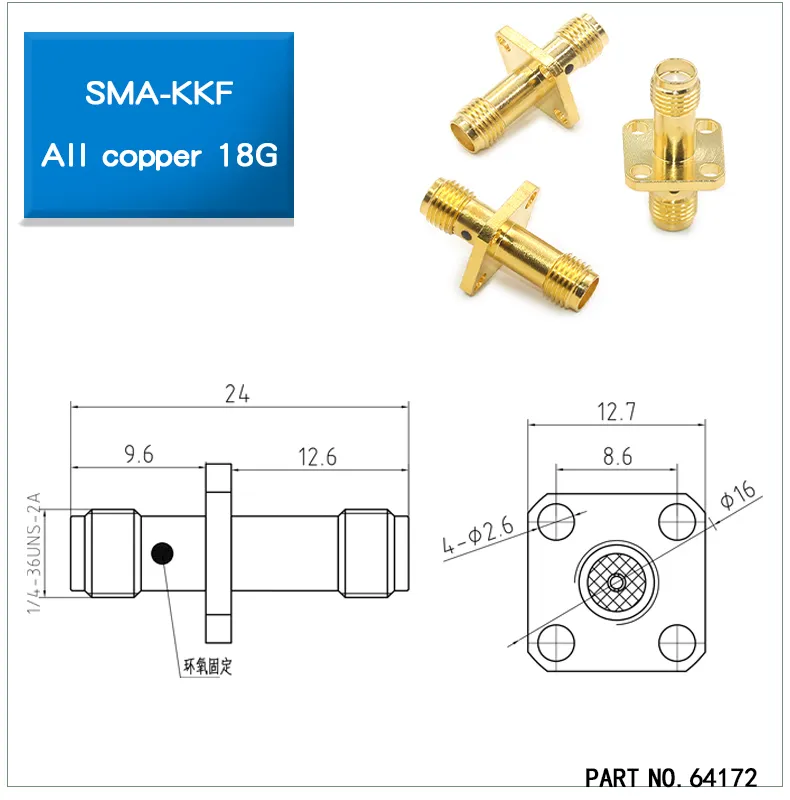

This figure depicts a flange-mounted SMA bulkhead connector. The document context uses it as a typical example for the "double-nut plus wave washer" anti-vibration locking method. This connector type offers robust mounting and excellent grounding via multiple screw holes on the flange, often used in high-reliability applications like rack-mounted instruments.

For equipment that spends its life in controlled labs, a single nut may be enough. But once the gear goes into the field, vibration becomes the silent enemy. Transport trucks, outdoor telecom cabinets, or even rooftop routers can shake connectors loose over time. That’s where the double-nut plus wave washer stack proves its value.

Here’s how it works: the first nut locks the washer against the panel, while the second nut secures the connector body. TEJTE’s SMA-SMA-KKF flange style (Part No. 08765) is a common example—often paired with this method in rackmount instruments. The result is impressive: over 500 mating cycles, with contact resistance kept under 5 mΩ.

When used as an SMA connector for antenna applications—like outdoor base stations or Wi-Fi routers—this approach becomes even more important. Wind and temperature swings can loosen a single nut in weeks. Adding the second nut and wave washer is cheap insurance, sparing you the trouble of climbing a tower or opening a sealed cabinet later.

It may sound like a small step, but in real deployments, this little hardware upgrade often decides whether a system runs flawlessly for years or needs emergency service after the first storm.

Pick the right pin pitch (0.8 / 1.2 / 1.6 mm) for your PCB?

Not every SMA bulkhead connector stops at the chassis wall. In many compact RF modules, the pins feed straight into the PCB. Here, the pin pitch—whether 0.8, 1.2, or 1.6 mm—affects both manufacturability and signal integrity.

On a simple 2-layer board, a 1.6 mm pin is usually the most forgiving choice: easy to drill, solid mechanical strength, and low stress during soldering. But in multilayer designs running at higher frequencies, the smaller 0.8 mm pitch minimizes pad capacitance and helps maintain controlled impedance. TEJTE’s SMA-KE offset pin (Part No. 05860) illustrates this balance, with its 1.7 mm offset giving more routing clearance on dense boards.

In some cases, designers deliberately pair a PCB-mounted bulkhead with a short SMA extension cable. This hybrid approach gives layout flexibility without committing to a rigid board location. The trick is to keep that jumper as short as possible—ideally under 50 mm—so insertion loss doesn’t creep up. It’s a small trade-off between routing freedom and RF efficiency.

Choosing the right pitch is more than a mechanical decision. It directly affects solder reliability, grounding, and long-term durability. As with most RF design details, the safest approach is to model the footprint in a field solver before committing to production.

Hole size, annular ring, solder mask keep-out recommendations

This figure appears when the document discusses recommendations for "hole size, annular ring, and solder mask keep-out." It serves as a specific component reference, helping readers visualize key areas to optimize in the PCB layout, such as pin holes, pad size, and surrounding keep-outs, to ensure good solder quality and signal integrity.

Designing the footprint is where many bulkhead-to-PCB transitions succeed or fail. A simple guideline helps: drill holes about +0.2 mm larger than the pin diameter. For example, a 0.8 mm pin should sit in a 1.0 mm finished hole. Around that hole, extend the annular ring at least 0.3 mm, and clear the solder mask another 0.2–0.3 mm beyond it. These margins give the solder room to wet properly and strengthen the joint.

One mistake I’ve seen on new RF boards is letting the mask hug too close to the pad. That traps flux and sometimes leads to cold joints. Pulling the mask back just a fraction creates a clean fillet and avoids rework later. This is particularly important when working with an SMA female connector in bulkhead form, since its center pin often requires consistent solder flow for low contact resistance.

The extra care pays dividends. With a properly dimensioned pad, you’ll not only meet mechanical pull strength but also hold insertion loss within spec. TEJTE’s acceptance data shows that even at 6 GHz, a well-designed footprint keeps insertion loss under 0.15 dB. That kind of margin can make the difference between a design that ships smoothly and one that struggles to pass qualification.

Straight pins vs. offset pins—when does each help assembly?

Straight pins are the simplest to design around. They line up with the connector body, offer slightly lower inductance, and are often the default choice when broadband performance is required. For lab instruments or test fixtures that see signals up to 18 GHz, a straight-pin SMA bulkhead connector remains the most predictable option.

Offset pins, on the other hand, solve real layout headaches. TEJTE’s SMA-KE offset pin (Part No. 05860) shifts the centerline by 1.7 mm, creating just enough clearance to bypass a standoff or nearby capacitor. In wave soldering, the offset reduces pad shadowing, which makes assembly cleaner and lowers the risk of cold joints. I’ve personally seen offset pins save a design when last-minute board changes left no room for the straight launch.

When the assembly needs environmental sealing—say in outdoor routers or cellular modules—you can combine these pin options with an IP67 SMA connector. In such builds, the pin style decides how the PCB is routed, while the sealing features (O-ring, plating, torque) decide whether the connector survives moisture and dust. Choosing both correctly ensures the design is electrically solid and mechanically reliable in the field.

Panel mount vs PCB mount: which SMA bulkhead connector fits your build?

This figure provides precise mechanical dimensions for a flange-mounted SMA bulkhead connector (P/N 64172). This is crucial for engineers to design panel cutouts, verify installation space, and ensure proper connector-chassis matching. The document uses this figure to differentiate the applications of panel-mount versus PCB-mount connectors.

The first question many engineers ask is simple: what exactly is an SMA bulkhead connector, and when should you pick it instead of a standard PCB jack? The distinction lies in where the connection is made. A panel-mounted bulkhead passes through the chassis wall, allowing an external coax to connect inside the system. A PCB-mounted SMA connector sits directly on the board, which removes the need for an extra jumper cable but demands precise footprint design.

TEJTE offers both solutions. The SMA-SMA-KKF flange type (Part No. 64172) bolts to the panel with four screws, giving rock-solid durability for test instruments. Meanwhile, the SMA-KE offset pin (Part No. 05860) shows how a PCB bulkhead can save space in tight layouts. And when unused ports need to stay clean, pairing either type with a simple SMA dust cap ensures dust or moisture won’t compromise VSWR. It’s a low-cost accessory, but in practice it makes the difference between a clean lab measurement and a noisy test result.

So which direction should you take? For routers, outdoor antennas, or any system that relies on sealed enclosures, a panel-mounted SMA connector with nut-and-washer hardware offers robustness. For IoT boards where size and cost dominate, a PCB-mounted SMA connector minimizes parts count. And in mixed systems, engineers often use both: a panel bulkhead feeding a short jumper into a PCB jack, with dust caps protecting the ports during transport.

Bulkhead through-panel + pigtail vs. board-mounted jack trade-offs

A through-panel bulkhead with a short pigtail offers flexibility that board-mounted jacks can’t always match. You can place the PCB almost anywhere inside the enclosure, as long as the coax reaches. That’s why TEJTE’s SMA-KKY bulkhead (Part No. 53353) with its 13.5 mm thread is a staple in wireless access points and small routers. The downside is measurable: even a 50 mm jumper can introduce 0.1–0.2 dB loss at 6 GHz.

Some engineers address this by using an SMA extension cable. It lets them mount the bulkhead exactly where they want on the panel, while still connecting to a board or module that isn’t positioned right behind it. The trick is keeping the extension short—every extra centimeter adds loss. For prototypes or modular builds, though, the flexibility often outweighs the small penalty.

Board-mounted jacks remove the cable entirely, cutting out the insertion loss and simplifying assembly. But they demand precision. A misjudged keep-out zone or missing ground stitch can show up immediately as poor return loss. So the trade-off is clear: pigtails and extension cables buy freedom of placement, board jacks buy performance consistency. Knowing your project priorities makes the choice much easier.

Vertical SMT jack: when low profile or reflow is required

Not every design can tolerate tall connectors. In compact modems, embedded modules, or IoT devices, even a few extra millimeters of height can cause mechanical conflicts. That’s where a vertical SMT jack makes sense. It’s built for automated reflow soldering and keeps the overall profile low, saving precious board height.

The trade-off, of course, is mechanical robustness. These SMT jacks don’t handle side loads well. If your device will see vibration, field technicians tugging cables, or frequent maintenance, you’re better off choosing a sturdier SMA female connector in bulkhead form. The threaded housing, nut, and washer stack add stability that a pure SMT part simply can’t match.

In real-world projects, I’ve seen vertical SMT jacks perform brilliantly in consumer-grade gear where space is everything, but fail quickly in industrial deployments. TEJTE’s vertical SMT SMA jack guide dives deeper into torque considerations and mechanical stress points. If your design rides the line between space-saving and durability, it’s worth comparing both options before locking in the BOM.

Do you need IP sealing and corrosion resistance?

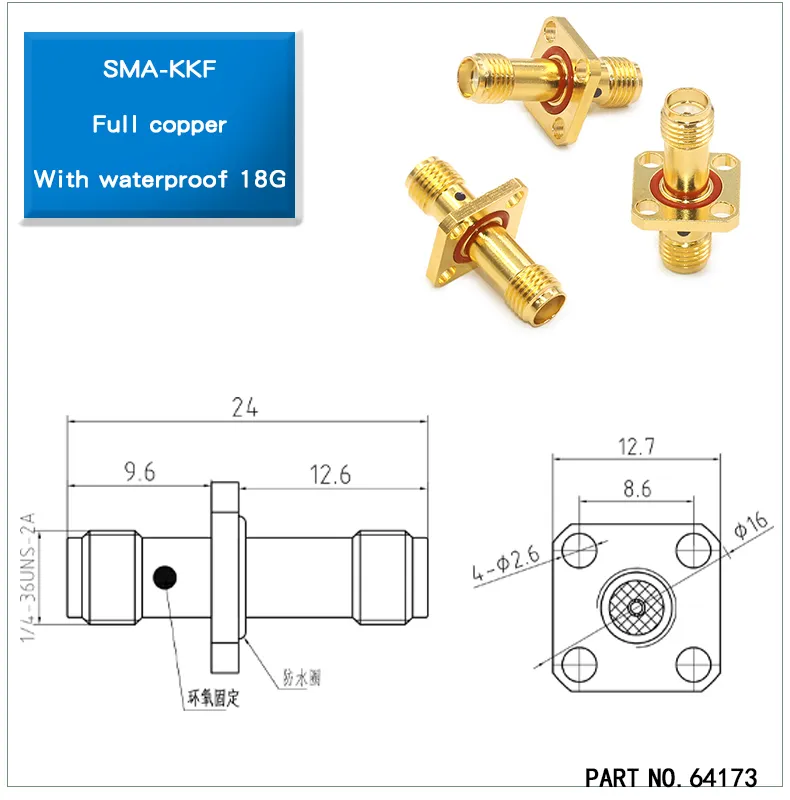

This figure shows an SMA bulkhead connector (P/N 64173) with an IP67 environmental rating. The document highlights its sealing features, like the integrated O-ring, designed to prevent ingress of water and dust in outdoor, humid, or dusty environments, ensuring long-term reliability and stable performance under harsh conditions.

Not every SMA bulkhead connector spends its life in a clean lab rack. Many are mounted outdoors on telecom towers, base stations, or rooftop routers, where rain, dust, and salt fog become daily challenges. In these environments, sealing and corrosion resistance aren’t optional—they’re survival features. A small amount of moisture inside the connector can corrode plating, shift impedance, and cause return loss spikes.

TEJTE’s 64173 waterproof bulkhead is a prime example of an IP67 SMA connector. It integrates a silicone O-ring at the flange, delivering protection against both dust ingress and temporary immersion. Properly torqued, this seal keeps the dielectric dry and stable even in harsh weather. If you’ve ever opened a connector after a storm and seen green oxidation inside, you’ll know why IP67 matters.

Unused ports also deserve protection. A simple SMA dust cap prevents dirt and humidity from settling on the mating surface. In outdoor systems, leaving a port uncapped for just a week can degrade VSWR measurably. Indoors, the cap mainly keeps connectors clean during storage or maintenance, but outdoors it’s a must-have. TEJTE’s RF connector accessories list dust caps with or without chains, making them easy to integrate into field kits.

So, if your application faces outdoor exposure or frequent maintenance cycles, pair the right bulkhead with sealing features and always cap unused ports. It’s a small investment that pays off in reliability and lower service costs.

O-ring placement, torque, and metal finish: gold-plated vs nickel-plated

Getting the O-ring right is just as critical as picking the thread length. It should compress evenly against the panel face, creating a seal without tearing. Too much torque—anything beyond 0.8 N·m on a brass body—can slice into the rubber and ruin the IP rating. Too little, and the connector may loosen during vibration tests. The safe range is 0.6–0.8 N·m, a detail often overlooked in field installs.

Finish matters, too. Gold-plated connectors provide excellent corrosion resistance and lower contact resistance, making them ideal for outdoor or marine applications. Nickel plating, by contrast, is harder and withstands repeated matings in lab setups or test instruments. Both finishes appear in TEJTE’s catalog, letting you match the finish to the environment rather than treating it as an afterthought.

In many designs, especially where sealing is critical, engineers lean toward a flange-mounted SMA panel connector. The flat surface allows the O-ring to seat more reliably, reducing the risk of leaks compared to lighter nut-only bulkheads. Pairing the right plating with the right hardware stack gives you a connector that not only measures well at the factory but also survives years in the field.

Outdoor & test-instrument use: when to add a dust cap

Even when you’ve sealed the connector with an O-ring, the exposed interface still needs protection. Dust, sand, or tiny droplets can settle on the mating surface and change return loss over time. A simple SMA dust cap is the cheapest insurance you can buy. It slips over the port and keeps contaminants out, ensuring that your next measurement or field test starts with a clean connection.

In outdoor setups—think Wi-Fi base stations or cellular towers—the risk multiplies. Leaving an SMA connector for antenna ports open, even for a few days, can invite moisture or corrosion that permanently degrades VSWR. In one rooftop deployment, an uncapped bulkhead showed a 2 dB increase in return loss after just a week of summer storms. Adding dust caps from the start would have avoided costly maintenance.

Even in test labs, dust caps aren’t overkill. Sensitive instruments benefit from connectors staying pristine between tests. TEJTE lists protective caps—with or without retention chains—on its RF connector accessories page. For field engineers, keeping a few in the tool kit is as essential as carrying torque wrenches.

How do you mount and torque an SMA bulkhead correctly?

Step-by-step: washer order, nut torque, strain relief, ESD safety

- Insert the connector through the panel cutout (usually around 6.5 mm).

- Place the wave washer first, followed by a flat washer if required.

- Thread the nut carefully by hand to avoid cross-threading.

- Tighten to 0.6–0.8 N·m—enough to secure the brass body without crushing the O-ring.

- Attach coax or PCB pads, but never let the connector carry cable weight. Strain relief is key.

- Confirm chassis bonding with a multimeter; you want a reading close to 0 Ω.

- Follow ESD precautions—center pins are delicate and bend easily.

I once saw a field team torque bulkheads with pliers, thinking “tight is tight.” Six months later, the connectors spun loose during vibration testing. Don’t repeat that mistake—torque wrenches exist for a reason.

Acceptance criteria: contact resistance, insertion loss, pull test limits

After mounting, test the basics. TEJTE’s acceptance specs are a good benchmark:

- Contact resistance: inner ≤ 5 mΩ, outer ≤ 2 mΩ

- Insertion loss: ≤ 0.15 dB at 6 GHz

- Durability: ≥ 500 mating cycles

- Pull strength: models like the 53353 SMA female connector withstand ~20 N without detaching

If your results fall outside these numbers, recheck washer order, torque, and grounding. Often, a missing lock washer or under-torqued nut explains most failures. For more reference data, TEJTE’s RF connector acceptance guide outlines QC points used in production.

Can the (RP-)SMA bulkhead connector be grounded properly?

This figure depicts a Reverse Polarity (RP-SMA) bulkhead connector. The surrounding document context focuses on "proper grounding," emphasizing that while the RP-SMA has a reversed center contact, its shell grounding principle remains the same as standard SMA, requiring good electrical contact via the panel or PCB to maintain signal integrity.

Grounding often decides whether your RF design performs flawlessly or suffers from reflections. An SMA bulkhead connector doesn’t just pass a signal through; it must also bond electrically to the chassis. Without that bond, return currents wander, raising VSWR. The same applies to the RP-SMA bulkhead connector often used in Wi-Fi routers—reverse polarity only changes the pin gender, not the grounding principle.

TEJTE’s SMA-SMA-KKF flange types (Part No. 64172, 08765) provide multiple screw holes, ensuring solid contact with bare panel metal. Nut-mounted designs like the 53353 (13.5 mm thread) can achieve similar performance when paired with a star washer. The washer teeth cut through paint or oxidation, exposing clean metal for bonding. In harsher environments, many engineers prefer a flange-mounted SMA panel connector, which gives more surface contact and better long-term reliability.

For PCB-mounted designs, TEJTE’s SMA PCB connector layout guide shows how to use via fences around the pad to stitch shell currents into the ground plane. A good practice is to measure continuity after assembly—you want resistance from shell to chassis ground below 0.05 Ω. Anything higher means your connection isn’t trustworthy.

Shell-to-chassis bonding and PCB ground strategy

- Chassis bonding: Always expose bare metal at the panel cutout. Powder coat or anodizing blocks conductivity; scrape it away where the nut or flange seats.

- PCB ground: Place vias close to the connector pad—spacing of 1.0–1.2 mm is common up to 6 GHz.

- Hybrid builds: Some connectors, like TEJTE’s 05860 SMA-KE offset pin, bond both to the chassis and the PCB simultaneously.

In practice, always validate grounding with a multimeter before powering up. It’s a quick check that can save hours of debugging later.

Paint/oxide removal and star-washer bite for reliable ground

Even a thin oxide layer can block conduction. That’s why star washers remain a staple. Their serrated edges bite through coatings and guarantee metal-to-metal contact. Combined with correct torque, this approach keeps grounding stable over years of service.

For outdoor deployments, plating also plays a role. Gold-plated connectors excel at corrosion resistance, while nickel-plated brass shells endure frequent matings without wear. Both options are available in TEJTE’s RF connectors catalog, letting you match finish to the environment.

Order faster: what part number matches my thickness and pitch?

When you’re sourcing for production, the challenge isn’t just thread length. You need to match panel thickness, washer stack, pin pitch, plating, and sometimes sealing—all without slowing down procurement. Guesswork here can leave you with boxes of unusable stock. That’s why TEJTE provides a practical matrix based on real part numbers.

The basic rule still holds true:

Thread length ≥ Panel thickness + Washer/Nut stack + 2–3 exposed threads.

But instead of recalculating each time, you can reference the table below and jump straight to the right connector.

Ordering Decision Matrix

| Panel thickness (mm) | Recommended thread length (mm) | Washer/Nut stack | Pin style & pitch | PCB hole Ø / keep-out (mm) | Finish | Ingress seal | Suggested TEJTE P/N |

|---|---|---|---|---|---|---|---|

| 1-2 mm | 8 mm | Single nut + wave | Straight, 0.8 mm | 1.0 mm / 0.3 keep-out | Gold | No | 53353 (SMA-KKY) |

| 3-5 mm | 13.5 mm | Double nut + wave | Straight, 1.2 mm | 1.4 mm / 0.3 keep-out | Gold | No | 08765 (SMA-KKF flange) |

| 5-8 mm | 17 mm | Nut + star washer | Offset, 1.6 mm | 1.8 mm / 0.3 keep-out | Gold | Optional | 05860 (SMA-KE offset pin) |

| 5–8 mm (outdoor) | 17 mm | Nut + O-ring | Straight, 1.6 mm | 1.8 mm / 0.3 keep-out | Gold | Yes (IP67) | 64173 (outdoor SMA-KKF waterproof) |

| 8-10 mm | 21-23 mm | Double nut | Straight, 1.6 mm | 2.0 mm / 0.3 keep-out | Nickel | Optional | 64172 (SMA-KKF full brass) |

A small tip: if you’re still in prototyping, start with a longer thread (like 17 mm). It’s easier to add washers or spacers than to discover later that the nut won’t engage. For production runs, lock in the exact TEJTE part number early. Many engineers also keep a short SMA extension cable in their toolkit during prototyping—it allows quick swaps when testing different bulkhead lengths without redesigning the enclosure. Once the final thread and pitch are confirmed, the extension can be removed in favor of a permanent fit.

For readers comparing multiple configurations, TEJTE’s RF connectors catalog lists all stocked SMA bulkhead connectors alongside related accessories.

Reduce RF loss and reflections during bulkhead transitions?

Keep coax bend radius and pigtail length in check

Every coax has a minimum bend radius. For RG316, it’s around 6–8 mm. Push tighter than that, and you’ll see impedance spikes and rising insertion loss. Short pigtails are just as important. TEJTE usually recommends keeping jumper leads under 50 mm from the bulkhead to the board. At 6 GHz, each extra centimeter costs about 0.05 dB.

In practice, engineers sometimes use a SMA connector for antenna in the panel feedthrough, then couple it with a tiny extension inside the housing. This approach reduces strain on the board-mounted connector, while still controlling loss. The trick is not to let convenience outweigh physics—cable management matters as much as connector choice.

For full attenuation data, TEJTE’s RF cable guide covers RG174, RG316, and LMR families in detail.

Maintain 50-ohm launch and avoid unnecessary adapters

This figure is referenced when the document discusses "maintaining a 50-ohm launch and avoiding unnecessary adapters." It schematically represents the connector-to-PCB interface area, emphasizing that for good RF performance (low return loss), the PCB footprint must be designed for precise impedance control, following specific layout rules (e.g., trace width, dielectric thickness) matched to the connector's characteristics.

The SMA bulkhead connector is a 50 Ω standard, but your system may not be if the launch isn’t designed correctly. PCB footprints must be tuned to the stack-up, not guessed. A pad that looks fine to the naked eye can create several dB of mismatch. TEJTE’s SMA PCB layout tips are a good starting point for matching trace widths to board thickness.

Adapters are another silent killer. Each SMA-to-BNC or SMA-to-N transition adds reflections and return loss. Use them only if absolutely necessary. In outdoor deployments, protect every unused port with a SMA dust cap. Even a week of dust or humidity exposure can shift VSWR readings and shorten connector life.

Frequently Asked Questions

What is an SMA bulkhead connector and when should I pick it over a standard PCB jack?

Can an RP-SMA bulkhead connector be grounded through the chassis?

Which thread length matches my 2–5 mm aluminum panel, and how many nuts should I use?

Do I need a dust cap or O-ring for indoor racks, or only for outdoor enclosures?

Gold-plated vs nickel-plated housing: which finish lasts longer in salty or humid air?

Offset vs straight pins: which style eases assembly on dense PCBs?

What torque should I apply to the panel nut to avoid connector damage or loosening?

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.