Your Trusted Custom RF Connector Manufacturer

As the premier destination for trusted RF connector manufacturing, we redefine reliability and innovation in high-frequency connectivity. For over years, brands, engineers, and industry leaders have chosen us as their strategic partner, confident in our ability to deliver precision-engineered solutions that power mission-critical applications—from 5G telecom infrastructure to aerospace radar systems and next-gen IoT devices.

At the heart of our expertise lies the ability to translate your most complex requirements into custom RF connectors that excel in performance, durability, and signal integrity. We don’t just manufacture components; we collaborate with you to solve challenges

You Just Choose Any RF Connector Types or Specs, and We'll Take Care of the Rest

As a trusted RF connector manufacturer, we offer a regularly updated catalog of proven RF connector types and specs—from industry-standard SMA, BNC, and N-type to specialized millimeter-wave designs—for you to choose as the foundation for your customization, minimizing market risk and accelerating time-to-market. With a team of experienced and certified engineers, designers, and sales consultants who specialize in RF connector R&D and bulk production, we bring deep expertise in translating complex technical requirements into precision components. Our state-of-the-art facilities house advanced testing equipment for rigorous validation (insertion loss, VSWR, durability), precision manufacturing machinery for seamless production, and integrated packaging solutions to ensure your connectors meet global standards and arrive ready for deployment. Whether you need minor modifications to an existing design or a fully customized solution, our goal is to collaborate with you every step of the way, leveraging our cross-functional expertise and cutting-edge capabilities to turn your vision into reliable, high-performance RF connectors that power your success—because your innovation is our mission, and we’re here to handle every detail from concept to delivery.

MHV connector

SHV connector

SHV5000V-C-K/JY wiring male and female 50-3-5 coaxial connector

Custom RF Connectors Catalog

Customized MHV connector→

Customized SHV connector→

Customized SHV5000V-C-K/JY wiring male and female 50-3-5 coaxial connectorr→

RF Connectors: Built for High-Frequency, High-Reliability

Tejte offers a full range of RF connector types, including QMA, TNC, SMA, and N-type, designed for stable signal transmission, secure mating, and high-frequency performance. From panel-mount PCB connectors to flange-mount and compression types, our RF connectors are engineered to meet real-world application demands in 5G base stations, military systems, GNSS modules, and lab testing environments.

Antenna Connectors

Specialized RF Interfaces for Board-Level and Automotive Antennas

Antenna connectors ensure impedance-matched signal transfer between radio modules and antennas.

Common types include U.FL (IPEX) connectors for Wi-Fi and GPS in laptops and mobile devices, and FAKRA connectors for automotive GPS and RF links. These connectors vary in size and mounting style, from ultra-miniature SMT jacks to rugged vehicle-grade housings.

BNC Connector

Standard Bayonet RF Connector for Test and Video Equipment

BNC connectors are industry-standard quick-lock RF interfaces found in broadcast, CCTV, and test labs.

These 50 Ω or 75 Ω connectors use bayonet coupling for quick connects, typically operating up to 2–4 GHz. They are widely used in test instruments, oscilloscope probes, and analog video transmission, offering secure locking without tools.

BNC Adapter

Specialized RF Interfaces for Board-Level and Automotive Antennas

Antenna connectors ensure impedance-matched signal transfer between radio modules and antennas.

Common types include U.FL (IPEX) connectors for Wi-Fi and GPS in laptops and mobile devices, and FAKRA connectors for automotive GPS and RF links. These connectors vary in size and mounting style, from ultra-miniature SMT jacks to rugged vehicle-grade housings.

MCX/MMCX Connectors

Snap-On Miniature RF Interfaces for GPS and Wireless

MCX and MMCX connectors are small, lightweight, and easy-to-use RF connectors operating up to 6 GHz. MCX (Ø3.6 mm) and MMCX (Ø2.4 mm) both use snap‑on mating and are ideal for space-constrained applications like GPS receivers, laptops, and wireless modules. MMCX supports 360° rotation after mating, allowing flexibility in compact antenna connections.

MHV / SHV Connectors

High-Voltage Bayonet Connectors for Lab and Safety Applications

MHV and SHV connectors are derived from BNC but engineered for high-voltage applications.

MHV (Miniature High Voltage) supports up to 1.5 kV RMS and is often used in photomultiplier and lab test setups.

SHV (Safe High Voltage) adds safety features like recessed insulators and reversed gender to prevent mismating. These 5 kV-rated connectors ensure that high-voltage lines disconnect only after the ground, ensuring user protection.

N / M / SL16 (UHF) Connectors

Threaded Heavy-Duty RF Interfaces for Outdoor and Legacy Use

N-type and UHF (PL‑259/SO‑239) connectors are large-format threaded connectors used in infrastructure and radio gear.

N-type is a rugged, 50 Ω connector rated up to 11–18 GHz, ideal for antennas and base stations.

UHF (SL16) connectors are older 50 Ω designs (up to ~100 MHz), still found in amateur radio and legacy equipment. While N is precision-rated for microwave use, UHF is suitable for VHF/UHF applications with relaxed impedance control.

SMA Adapter

Modular Adapter Interfaces for SMA-Equipped Systems

SMA adapters provide flexible connectivity between SMA and other RF connector types.

These include gender changers, SMA-to-N, SMA-to-BNC, and angle adapters. SMA’s fine threading and high-frequency support make it the preferred interface in test labs, Wi-Fi modules, and antenna installations. SMA adapters enable quick reconfiguration of coaxial setups without sacrificing performance.

SMA / SMC Connectors

Precision Threaded Interfaces for Microwave and Board-Level RF

SMA and SMC connectors are screw-coupling RF interfaces for high-frequency performance and stability.SMA (SubMiniature A) supports up to 26.5 GHz and is used on RF modules, antennas, and lab-grade equipment.

SMC (SubMiniature C) is even smaller, threaded with a #10-32 interface, and operates up to ~4 GHz. SMC jacks use external threads, offering a compact solution for embedded or miniature designs.

SMB / SSMB Connectors

Miniature Snap-On Interfaces for Dense RF Circuitry

SMB and SSMB are small, push-on RF connectors that deliver solid performance in constrained spaces.

SMB connectors (up to ~4 GHz) are ideal for high-density board layouts. SSMB (nano‑SMB) offers even greater compactness and supports up to ~12.4 GHz. Their snap-on design simplifies mating in embedded RF systems, antennas, and instrumentation.

SMP Connectors

- High-Frequency Push-On Connectors for Compact Modules

SMP (SubMiniature Push‑on) connectors are compact RF connectors designed for high-frequency performance up to 40 GHz. They feature snap‑on or push‑on mating and are commonly used in board‑to‑board RF interconnects or microwave modules. Compared to MMCX, SMP connectors offer broader bandwidth and are often paired with floating “bullet” adapters to accommodate slight misalignment in tight RF assemblies.

TS9 / CRC9 Connectors

Miniature Antenna Interfaces for 3G/4G Dongles and Routers

TS9 and CRC9 are compact 50 Ω RF connectors designed for mobile broadband equipment.

TS9 (3.5 mm) and CRC9 (3.0 mm) are push-on connectors used in LTE routers, USB dongles, and 4G/5G antennas. Though visually similar, they are not interchangeable due to slight size differences. Their compact size makes them ideal for antenna attachment in tight enclosures.

TNC / F / FME / TV Connectors

Threaded and Push-On Interfaces for TV, Mobile, and Cable

This group includes four types of RF connectors used across TV systems, mobile radios, and wireless networks.

TNC connectors are 50 Ω, threaded variants of BNC, supporting up to 11 GHz with improved vibration resistance.

F-type connectors (75 Ω) are common in cable TV and maintain impedance for high-frequency signals.

FME connectors are miniature, low-profile threaded interfaces used in vehicle-mounted systems and mobile antennas.

TV (IEC/Belling-Lee) connectors are standard push-on 75 Ω interfaces used for antenna connections on home TVs.

Three-Way / Two-Way (Reverse) Adapter

RF Signal Splitters and Combiners for Flexible Distribution

Two-way and three-way RF adapters enable parallel signal routing and instrumentation sharing.

They allow one signal to be routed to multiple devices or multiple signals to combine into one input. These passive adapters (e.g., BNC T-splitters) are used in test benches, RF distribution networks, and temporary diagnostic setups.

Material & Craft Customization – Tailored for Your Industry Nee

As you browse our RF adapter cables, connectors, and adapters, use this material‑craft guide to choose the optimal build configuration—from conductors and plating to insulation and shielding—for your performance, durability, and application demands.

1. Material Categories by Application

- Gold‑Plated Connectors: Enables low‑loss RF jumper cables up to 6 GHz; corrosion-resistant for test labs and telecom systems (common in “gold-plated RF cable”).

- Nickel‑Plated Connectors: Cost-effective and rugged; suitable for outdoor/industrial RF equipment.

- Braided Copper Shielding: Typically ≥85% coverage, blocking EMI up to −85 dB (IEEE-standard braid coverage).

- PTFE / PE Insulation: Withstands temperatures from –55 °C to +200 °C; ideal for aerospace and rugged applications.

2. Craft Specifications & Performance Impact

- Plating Thickness: Common options like 5 μm (standard) and 10 μm (enhanced reliability) improve corrosion resistance and maintain low insertion loss.

- Shield Braid Coverage: 85% standard vs. 100% for extreme EMI, directly correlating with shielding performance.

- Dielectric Tolerance: Precision-extruded PTFE with ±0.1 mm tolerance supports tight impedance control and stable VSWR.

3. Tailored Material + Craft Combinations

- Kevlar‑Reinforced Jackets: enhance tensile strength and abrasion resistance; ideal for rugged, outdoor, or defense‑grade cable assemblies.

- Medical‑Grade Silicone Jackets: support steam sterilization and biocompatibility for medical connector applications.

- Heavy‑Duty Plating + Shielding: extra‑thick gold plating and dense copper braid for marine, satellite, and harsh EMI environments.

4. Validation & Quality Assurance

- Material Traceability: RoHS, UL, MIL‑STD batch‑lot documentation per MIL‑DTL‑17 standards for high‑reliability builds.

- Performance Reports: includes S‑parameter plots, mating‑cycle durability logs, and thermal‑cycling test data—100% tested per high‑reliability specs.

- Batch Traceability: Each batch of cables is bar coded with a serial or batch number; traceable to manufacturing records and test batches.

Precision manufacturing and customer-focused service

We prioritize efficiency throughout the OEM and custom production process, ensuring a seamless experience. Our focus extends beyond delivering high-quality electronic components to providing exceptional service that meets your expectations.

Flexible Solutions

Tailored options are available to match your specific needs.

Fast Turnaround

Time is valuable, and we are committed to delivering solutions efficiently.

Advanced Manufacturing

We utilize cutting-edge facilities and technologies to ensure product reliability.

Cost-Effective Process

Our one-stop service helps you reduce expenses and maximize profitability.

Make A Sample First?

High-Voltage MHV/SHV Solutions: Reliable Power and Signal Transfer up to 3KV DC Engineered for critical test environments, our SHV-to-crocodile-clip cables deliver uncompromised performance with 30-strand tinned copper conductors, silicone/PVC insulation (-60℃~200℃), and 3KV DC rated voltage, ensuring ultra-low resistance and optimal heat dissipation for 7A continuous current. Precision-engineered copper-alligator clips (5mm shaft/13mm jaw) support solder/crimp terminations, while flame-retardant, corrosion-resistant materials guarantee safety in harsh conditions. Validate dielectric integrity, current stability, and mechanical resilience with 3 low-cost samples—fully tested for ≤0.2mm OD tolerance and 5000V+ surge withstand—cost deductible from bulk orders. Claim Free Samples or Custom Design Rendering Today.

Quality Inspection Of MHV/SHV connector

To bridge cross-border trust gaps, High-definition real-life photos show the quality inspection specialists’ work site in full view – scanning the contact welding accuracy point by point under the eyepiece magnifier, repeatedly checking the calibration parameters in front of the vector network analyzer data screen, and each inspection process is carried out under strict standards. These real-time records from the final inspection link are our visual commitment to product reliability.. Our structured requirement forms streamline communication, while 3 low-cost validation samples (detailed test reports included) mitigate bulk order risks. With a defect rate of 0.15% (vs. industry 1.8%), our premium RF adapter cables redefine precision. Claim your free sample or design rendering today—sample costs apply to bulk orders. Precision isn’t a promise; it’s a 25-point verified standard.

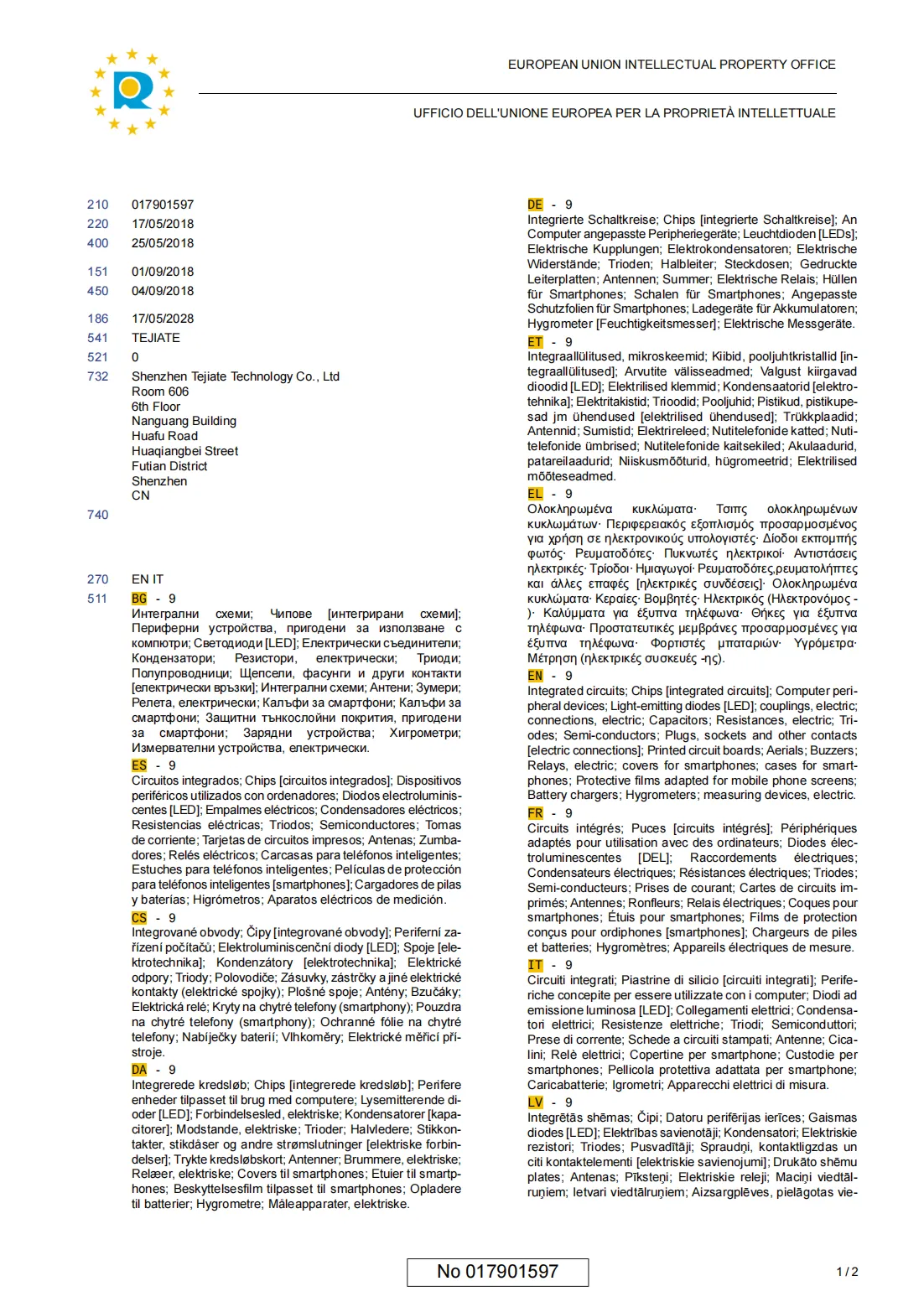

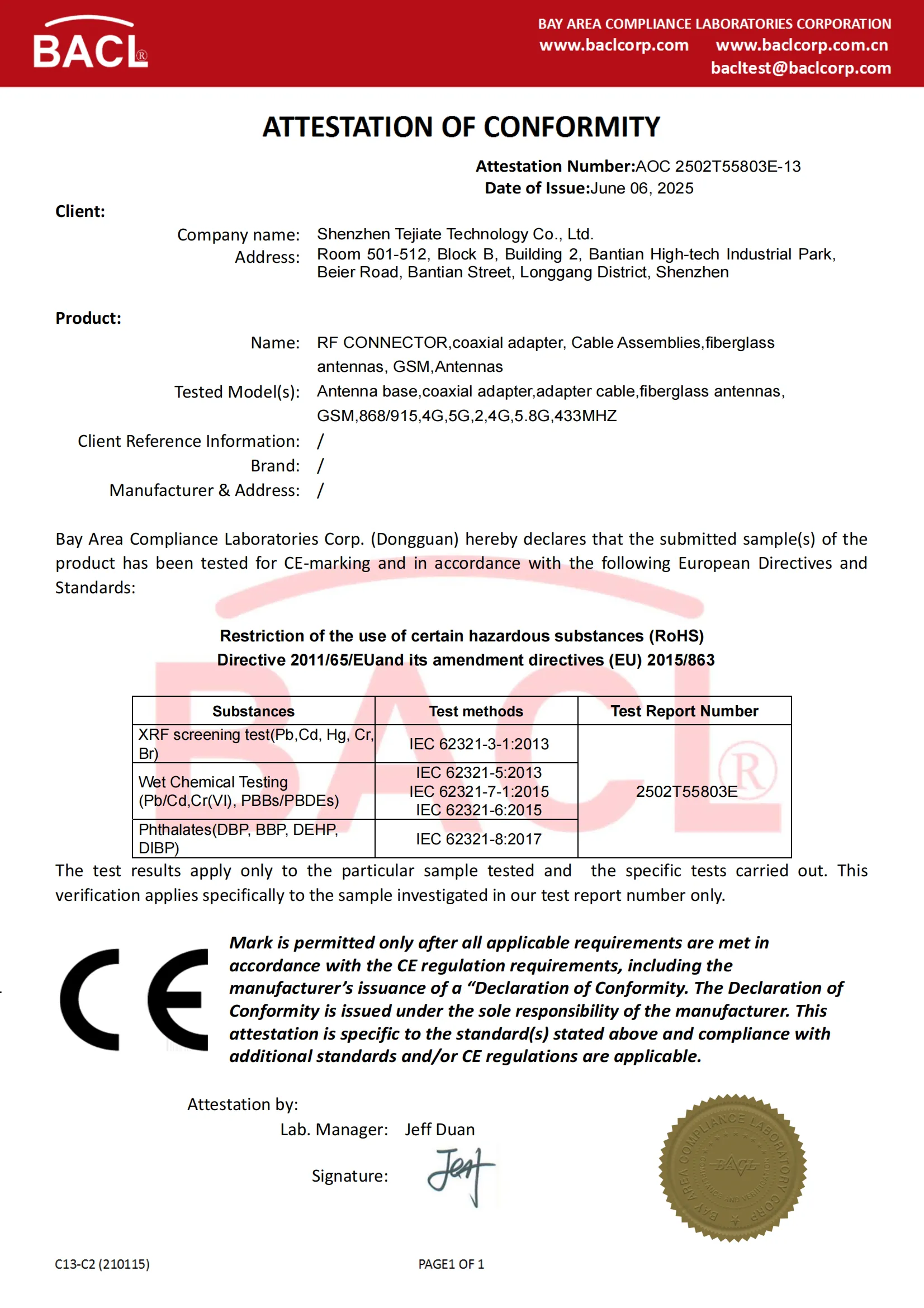

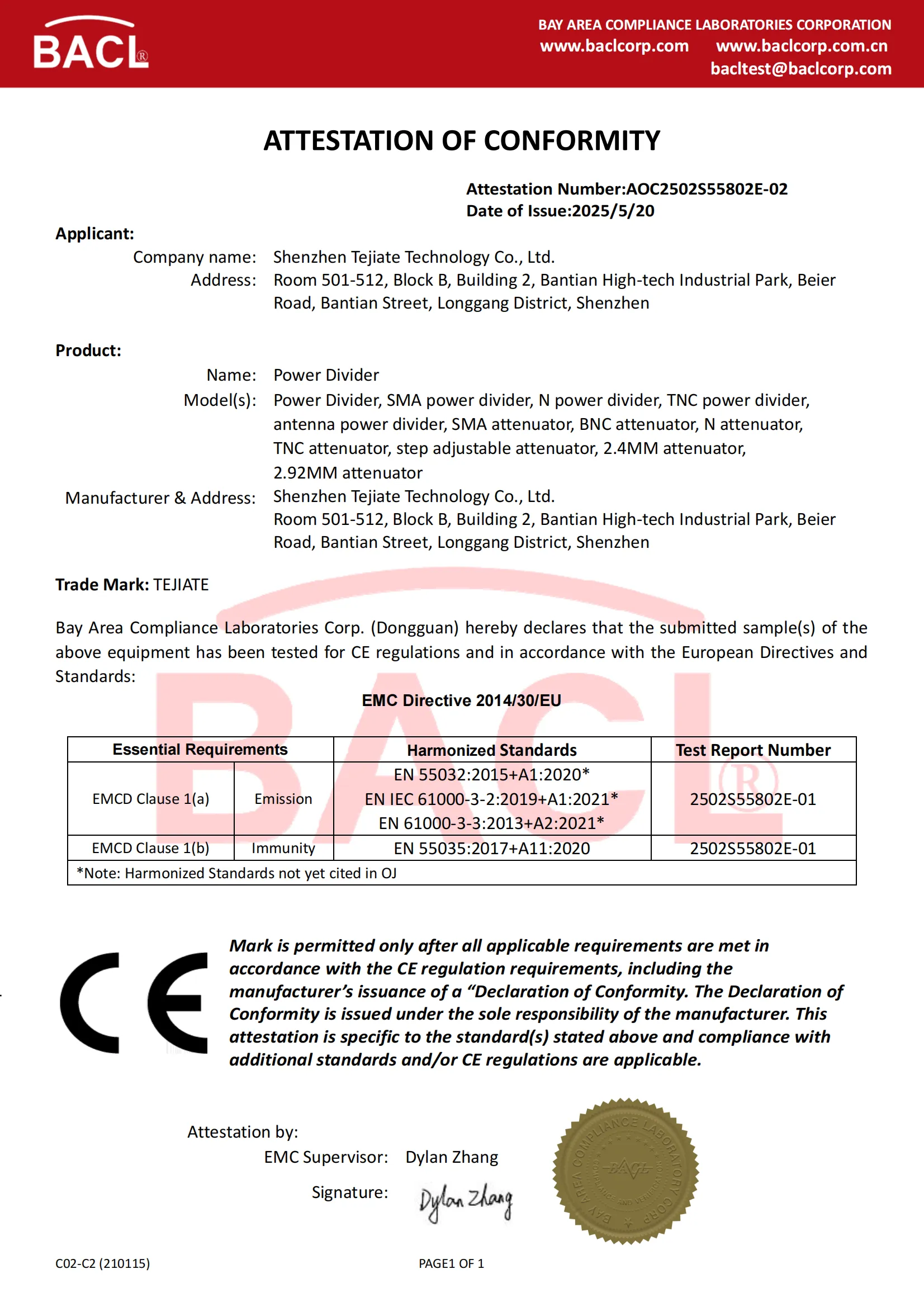

International Certification

You can totally trust us with all certifications shown below.

What is the structural difference between SHV and MHV connectors?

SHV connectors feature extended insulating boots to prevent accidental contact with the high‑voltage pin.

MHV connectors have a shorter insulation sleeve and require more care during mating, suitable for medium‑to‑high‑voltage applications.

What payment methods do you accept?

We accept wire transfer, Western Union, and MoneyGram,For more information, please click here

What cable diameters do SHV/MHV connectors accept?

They generally accommodate high‑voltage coax cables with outer diameters between 5 mm and 8 mm. Always verify with the manufacturer’s cable‑to‑connector dimension chart.

Can SHV/MHV be adapted to other high‑voltage connectors?

Yes. Common adapters include BNC‑to‑MHV or SHV‑to‑SMA, but always maintain consistent impedance and voltage ratings—do not mix incompatible connectors.

How do I protect SHV/MHV connectors against dust and moisture?

Use protective dust caps.

Add sealing kits (O‑rings plus sealing nuts) for outdoor or humid environments.

Choose silicone or fluorosilicone seals for enhanced weather resistance.

What common mistakes occur when wiring SHV/MHV connectors?

Mating or unmating under live‑voltage conditions.

Using the wrong cable diameter or improper ferrule for crimping.

Ignoring recommended torque values, leading to poor contact or over‑compression damage.

What is your minimum order quantity?

We have no minimum order quantity. We also accept sample orders and can customize the logo, packaging and design of the products. However, we recommend buying more than 100 sets to save shipping costs.

What if the goods received are damaged? How do you solve it?

If the product you received is damaged, please contact us in time. We have a professional team and will solve the problem as soon as possible.

Have a question that doesn't appear here?

If you have searched our Help/FAQ page and still cannot find the answer to your question, please feel free to e-mail us at cc7480917828@gmail.com

Frequently Asked Questions

Welcome to the FAQs on SHV / MHV Connectors, where we’ll tackle your key questions—from structural differences and cable compatibility to adaptation, protection, and order support. Whether you’re designing high – voltage systems, troubleshooting wiring, or managing procurement, dive in for insights to make confident, safety – aligned decisions.