RF Adapter Cable Low‑Loss Jumper Assemblies

Our RF adapter cable range supports over 12 interface combinations, including SMA-BNC, BNC-coax, UFL-SMP, MMCX-SMA, and more. Engineered for minimal insertion loss and high shielding, these low-loss RF jumper cables are ideal for RF testing equipment, antenna bridging, and wireless module prototyping.

Types of RF Adapter Cables

Have you ever had to reconfigure during a presentation due to a mismatched device interface? Or missed a decisive moment in a game from cable jams? As a 13‑year veteran in cross-border electronic accessories, Tejte redefines reliable connection with our CE/FCC/ROHS‑certified RF adapters. Simply choose your length—we handle stable signals and interface compatibility for you.

Custom RF Adapter Cables Catalog

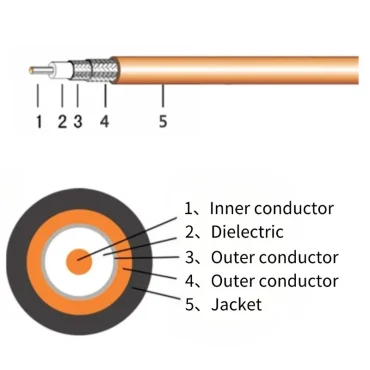

Coaxial Cable Cores: Diverse Materials for Robust Signal Pathways

In RF Adapter Cables, the coaxial cable core is a crucial carrier for signal transmission. Different materials of coaxial cable cores possess unique performances and application scenarios, providing strong support for diverse radio – frequency application requirements.

Coaxial cable series

- RG58 & RG142: These 50 Ω cables offer excellent EMI resistance and low signal loss, ideal for communication base stations, vehicle radios, and drone video links.

- RG178: Compact size, suitable for space-constrained devices.

- RG316: Features a Teflon dielectric and stranded silver-plated center conductor for flexibility. Suitable for aerospace, military, and test gear support up to 0~6 GHz.

- RG402 / RG141: Ideal for tight spaces like 5G base stations or microwave racks, offering rigidity to maintain signal integrity under vibration.

- RG405: With its unique blue outer sheath, this cable is tailored for precision high-frequency testing and aerospace use.

- IPEX / RF1.13: Ultra-thin (1.13 mm) coax for smartphones, IoT modules, and Wi‑Fi antennas—crafted for compact devices with minimal loss.

Metal Materials

- Solid Copper Conductors: Pure copper provides minimal resistance and stable signal transmission—common in test instruments and communication gear.

- Silver-Plated Copper: Silver enhances conductivity at high frequencies such as 5G/6G and radar modules, reducing losses in demanding applications.

- Gold-Plated Connectors: Resistant to corrosion, supporting ≥3,000 mating cycles while maintaining stable contact—perfect for outdoor base stations and maritime gear.

- Oxygen-Free High-Purity Copper: Ensures high conductivity and low signal distortion—ideal for HD video links and RF measurement systems.

Shielding Layers

- Silver-Plated Braided Shielding: Offers exceptional EMI attenuation (up to –85 dB at 1–10 GHz), making it essential in lab settings or industrial environments.

- Dual-Layer Shielding (Foil + Braid): Combines aluminum foil and braided mesh to provide 50% better interference defense than single-layer shields—critical for medical and aerospace use.

- Silver-Plated Copper Braid: Delivers flexibility and high shielding, suitable for portable devices like handheld meters and wireless sensors.

Insulation Materials

- FEP (Fluorinated Ethylene Propylene): Excellent high-temperature stability and low dielectric loss—great for harsh environments and high-frequency applications.

- PTFE (Polytetrafluoroethylene / Teflon): Resilient to extreme temperatures and low loss at GHz frequencies. High-temp tolerant—can be soldered—and ideal for precision deployments.

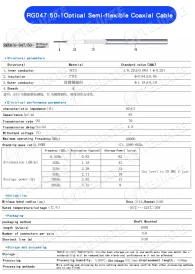

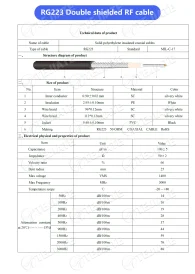

The following are the models and parameters of our cable products. Click on the thumbnail to view details.

Material & Craft Customization – Tailored for Your Industry Nee

As you browse our RF adapter cables, connectors, and adapters, use this material‑craft guide to choose the optimal build configuration—from conductors and plating to insulation and shielding—for your performance, durability, and application demands.

1. Material Categories by Application

- Gold‑Plated Connectors: Enables low‑loss RF jumper cables up to 6 GHz; corrosion-resistant for test labs and telecom systems (common in “gold-plated RF cable”).

- Nickel‑Plated Connectors: Cost-effective and rugged; suitable for outdoor/industrial RF equipment.

- Braided Copper Shielding: Typically ≥85% coverage, blocking EMI up to −85 dB (IEEE-standard braid coverage).

- PTFE / PE Insulation: Withstands temperatures from –55 °C to +200 °C; ideal for aerospace and rugged applications.

2. Craft Specifications & Performance Impact

- Plating Thickness: Common options like 5 μm (standard) and 10 μm (enhanced reliability) improve corrosion resistance and maintain low insertion loss.

- Shield Braid Coverage: 85% standard vs. 100% for extreme EMI, directly correlating with shielding performance.

- Dielectric Tolerance: Precision-extruded PTFE with ±0.1 mm tolerance supports tight impedance control and stable VSWR.

3. Tailored Material + Craft Combinations

- Kevlar‑Reinforced Jackets: enhance tensile strength and abrasion resistance; ideal for rugged, outdoor, or defense‑grade cable assemblies.

- Medical‑Grade Silicone Jackets: support steam sterilization and biocompatibility for medical connector applications.

- Heavy‑Duty Plating + Shielding: extra‑thick gold plating and dense copper braid for marine, satellite, and harsh EMI environments.

4. Validation & Quality Assurance

- Material Traceability: RoHS, UL, MIL‑STD batch‑lot documentation per MIL‑DTL‑17 standards for high‑reliability builds.

- Performance Reports: includes S‑parameter plots, mating‑cycle durability logs, and thermal‑cycling test data—100% tested per high‑reliability specs.

- Batch Traceability: Each batch of cables is bar coded with a serial or batch number; traceable to manufacturing records and test batches.

Precision manufacturing and customer-focused service

We prioritize efficiency throughout the OEM and custom production process, ensuring a seamless experience. Our focus extends beyond delivering high-quality electronic components to providing exceptional service that meets your expectations.

Flexible Solutions

Tailored options are available to match your specific needs.

Fast Turnaround

Time is valuable, and we are committed to delivering solutions efficiently.

Advanced Manufacturing

We utilize cutting-edge facilities and technologies to ensure product reliability.

Cost-Effective Process

Our one-stop service helps you reduce expenses and maximize profitability.

Make A Sample First?

As your trusted partner for premium RF adapter cables, we take pride in translating your technical requirements into reliable, high-performance solutions—whether you come with print-ready specifications or just a concept sketch, our dedicated engineering team is excited to bring your vision to life. With years of expertise in crafting custom RF adapter cables for diverse industries—from telecom infrastructure to aerospace testing—we specialize in addressing the unique challenges of signal integrity, environmental resilience, and form-factor flexibility. Our skilled technicians use only top-tier connectors, shielded cables, and advanced manufacturing techniques to ensure every adapter meets rigorous standards for insertion loss, VSWR, and durability, backed by comprehensive testing in our state-of-the-art facilities. We understand the risks of large-scale orders, which is why we offer low-cost sample production—start with 3 precision-engineered samples to validate performance before scaling to bulk manufacturing. Whether you need standard SMA-to-BNC adapters or fully customized millimeter-wave solutions, our streamlined process guides you from specification gathering to delivery, minimizing cross-border communication hurdles with structured requirement forms and dedicated project managers. Elevate your product reliability with our versatile RF adapter cables, and mitigate risks with our exclusive offer: get a Free Sample or Product Design Rendering now, with sample costs fully deductible from your bulk order—because we’re not just suppliers, we’re partners in powering your technological success.

Quality Inspection Of RF Coaxial Adapter

To bridge cross-border trust gaps, High-definition real-life photos show the quality inspection specialists’ work site in full view – scanning the contact welding accuracy point by point under the eyepiece magnifier, repeatedly checking the calibration parameters in front of the vector network analyzer data screen, and each inspection process is carried out under strict standards. These real-time records from the final inspection link are our visual commitment to product reliability.. Our structured requirement forms streamline communication, while 3 low-cost validation samples (detailed test reports included) mitigate bulk order risks. With a defect rate of 0.15% (vs. industry 1.8%), our premium RF adapter cables redefine precision. Claim your free sample or design rendering today—sample costs apply to bulk orders. Precision isn’t a promise; it’s a 25-point verified standard.

International Certification

You can totally trust us with all certifications shown below.

Is it mandatory to replace RF adapter cables for 5GmmWave base stations?

Global RF adapter procurement for base stations increased by 27% in 2024

Key drivers:

▸ Phase stability ≤ ±0.5° required at 28/39GHz (industry standard: ±2°)

▸ Each station requires 12-16 IP68-rated salt-corrosion-resistant cables

▸ Wi-Fi 7 regulations: Non-compliant cables banned from 2025

What payment methods do you accept?

We accept wire transfer, Western Union, and MoneyGram,For more information, please click here

Where are your cable assemblies manufactured?

All of our cable assemblies are manufactured in our factory in Shenzhen, China.

DoesTEJTE build OEM cables?

Yes, we have a dedicated OEM sales and support team.please click here

Is technical assistance available to determine the cable assembly l need?

Yes, our sales and product support team have many years of industry experience and are always available to provide any needed

technical assistance. We can even help you determine the exact assembly requirement from incomplete information.

What is your minimum order quantity?

We have no minimum order quantity. We also accept sample orders and can customize the logo, packaging and design of the products. However, we recommend buying more than 100 sets to save shipping costs.

What if the goods received are damaged? How do you solve it?

If the product you received is damaged, please contact us in time. We have a professional team and will solve the problem as soon as possible.

Have a question that doesn't appear here?

If you have searched our Help/FAQ page and still cannot find the answer to your question, please feel free to e-mail us at cc7480917828@gmail.com

Frequently Asked Questions

Welcome to the FAQs on custom RF adapter cables, where we address your key queries about specifications, procurement, and post – purchase support. Whether you’re navigating 5G infrastructure upgrades, optimizing test setups, or scaling OEM projects, we’ll clarify details like technical compatibility, order requirements, and quality assurances—empowering you to make confident, project – aligned decisions.