What is an SMA Connector? Male vs Female, Jack & Uses

Aug 22,2025

Introduction

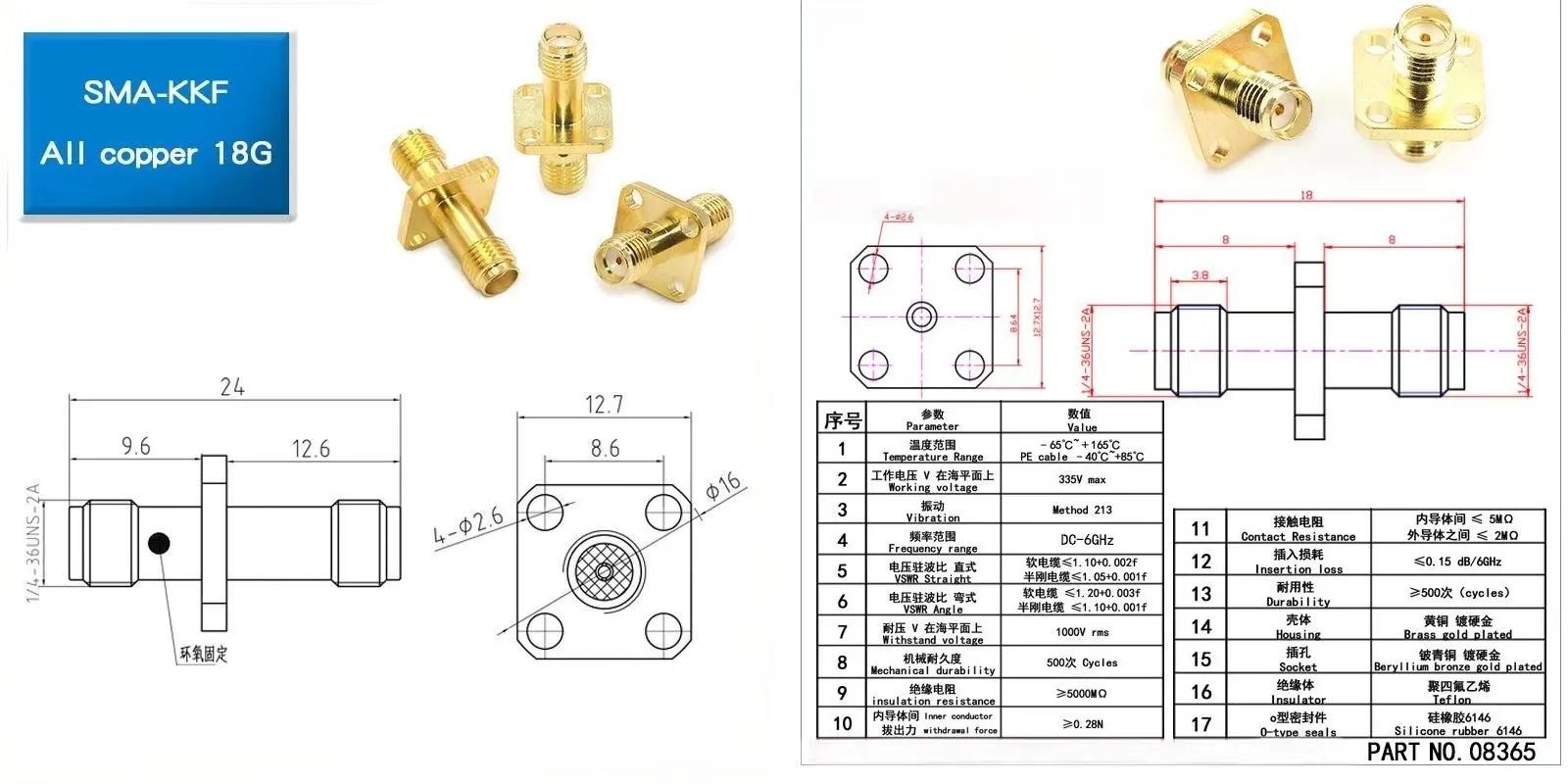

SMA connectors are widely used in consumer and professional electronics, providing stable threaded connections for signals up to 18 GHz.

Ever tightened an antenna onto your WiFi router? Or maybe plugged a GPS module into a dev board? Chances are, you’ve handled an SMA connector without even realizing it. They look simple—just a small threaded plug and socket—but beneath that plain appearance lies careful engineering that keeps high-frequency signals clean, often well beyond 10 GHz.

The name itself tells the story. SMA stands for SubMiniature version A, a reference to its compact size and screw-on interface. Born in the 1960s, this little connector quickly won over RF engineers because it was tough, accurate, and dependable. Fast forward to today, and you’ll spot SMA everywhere: on consumer WiFi gear, GPS antennas, cellular base stations, aerospace modules—even in military radios.

Here’s where it gets tricky. The terms SMA male connector, SMA female connector, and SMA connector jack sound straightforward, but mixing them up can cause expensive headaches. Understanding the difference isn’t trivia; it’s the key to reliable connections and proper system performance.

In this guide, we’ll unpack what makes SMA connectors unique. You’ll see how they’re built, where they came from, how they compare with other types like BNC and F-type, and what to watch for when choosing the right version. Whether you’re just starting with RF or you’ve been sourcing components for years, this overview will help you navigate the SMA landscape with confidence.

What is an SMA Connector?

The pin-and-socket design of SMA connectors ensures vibration resistance and consistent 50Ω impedance, making them suitable for RF communication.

An SMA connector is a coaxial RF connector designed to provide a secure, threaded connection for high-frequency signals. Unlike larger connectors from earlier generations, SMA versions are compact yet capable, operating effectively up to 18 GHz (and even beyond 26 GHz for precision models).

The SMA assembly has two parts:

- The SMA male connector has a center pin and external threads.

- The SMA female connector (also called the SMA connector jack) has a socket and internal threads.

That simple design—pin meets socket, screw threads hold them tight—makes SMA connectors vibration-resistant and stable, which is why they’re trusted in fields like aerospace, telecom, and RF test equipment.

Compared with push-and-twist types such as BNC, the screw-on SMA design maintains a consistent 50-ohm impedance, which minimizes signal reflections. This matters when every decibel counts, whether in a 5G antenna, GPS receiver, or WiFi module.

In real-world setups, SMA connectors show up in three main ways:

- Cable assemblies (joining RF cables to devices).

- Board-mounted connectors (soldered directly onto circuit boards).

- Adapters (linking SMA to other connector types).

In short: compact, precise, and rugged, the SMA connector bridges the gap between consumer gadgets and professional RF systems.

History and Standardization of SMA Connectors

The SMA connector has its roots in the 1960s, back when engineers were shrinking radios and microwave gear but still stuck with oversized connectors like Type N and UHF. Those older designs were solid, sure, but hardly practical for the new generation of compact devices. Something slimmer was badly needed.

That’s when the SubMiniature version A (SMA) stepped in. With a screw-on body, small footprint, and a rock-steady 50-ohm impedance, it gave designers exactly what they were missing. Pretty quickly, SMA showed up in military radios, aerospace gear, and precision lab instruments—places where both reliability and accuracy were non-negotiable.

It didn’t stay confined to defense and labs for long. Soon, SMA made its way into everyday electronics. If you’ve swapped an antenna on a WiFi router or worked with a GPS receiver, you’ve already benefited from that shift. And this widespread use was only possible because organizations like the IEEE and IEC laid down strict rules for dimensions, materials, and tolerances. Thanks to that, an SMA male connector from one factory will still mate cleanly with an SMA female connector—or the SMA jack—from another. Without such standards, the RF world would be chaos.

Today you’ll usually see two versions:

- Standard SMA – works fine up to about 18 GHz, covering most commercial gear.

- Precision SMA – machined to tighter specs, running well past 26 GHz, perfect for test equipment and advanced systems.

So the SMA’s success isn’t just about clever engineering. It’s also about the early push for standardization, which gave it staying power across industries and decades.

Structure of an SMA Connector

Each component of the SMA connector is engineered to maintain 50Ω impedance, ensuring low-loss and high-frequency signal transmission.

From the outside, an SMA connector looks like a simple threaded plug or socket. Inside, though, every detail is engineered for performance. Each part is built to maintain that critical 50-ohm impedance, which keeps signals from degrading.

Here’s how the SMA connector is put together:

Outer Body with Threaded Coupling

Provides strength and the screw-on interface. Unlike quick-lock connectors such as BNC, the SMA resists vibration and stays locked in.

Center Contact

In the SMA male connector, it’s a pin. In the SMA female connector (or jack), it’s a socket. This pin-to-socket relationship defines gender compatibility.

Dielectric Insulator

Usually made of PTFE (Teflon), it holds the center conductor in place and preserves impedance.

Ferrule & Cable Interface

These components clamp onto the coaxial cable, ensuring both electrical continuity and mechanical relief.

To make things crystal clear, here’s a comparison table:

| Component | SMA Male Connector | SMA Female Connector (Jack) |

|---|---|---|

| Center Contact | Pin (protrudes) | Socket (receptacle) |

| Thread Type | External thread | Internal thread |

| Common Use | Cable ends, plugs | Device ports, antenna jacks |

Because of this structure, SMA connectors can handle up to 18 GHz in standard form, or more than 26 GHz in precision builds. That’s why they remain a favorite for IoT devices, antennas, RF boards, and aerospace equipment.

SMA Male vs SMA Female Connectors

Knowing the difference between SMA male and female types avoids costly mismatches in RF systems and ensures proper performance.

Confusion often arises here. What’s “male,” what’s “female,” and why is the SMA connector jack mentioned so often? Let’s clear it up.

- The SMA male connector has a center pin and external threads. You’ll typically see it at the end of RF cables, or attached to plug-style adapters.

- The SMA female connector—frequently called the SMA jack—features a socket with internal threads. You’ll usually spot it on antennas, device panels, or ports of test equipment.

When the two connect, the male’s pin fits snugly into the female’s socket, and the threaded coupling ensures electrical stability.

Here’s a side-by-side look:

| Feature | SMA Male Connector | SMA Female Connector (Jack) |

|---|---|---|

| Center Contact | Pin (protruding) | Socket (receptacle) |

| Thread Type | External thread | Internal thread |

| Typical Location | Cable ends, plugs | Device ports, antenna jacks |

| Common Confusion | Mistaken as “plug” only | Jack vs female naming |

A practical tip: remember male = pin + external thread and female = socket + internal thread. That simple rule avoids mix-ups when ordering adapters, replacing antennas, or building RF setups.

SMA Connector Jack Explained

SMA jacks are mounted on panels, antennas, and devices, serving as stable connection points for SMA male plugs.

The phrase SMA connector jack trips up many engineers. Does “jack” mean something different from “female,” or are they interchangeable? In practice, the terms point to the same component—but the naming can cause headaches when you’re sourcing parts.

Here’s the deal: the SMA female connector, also known as the SMA jack, contains a socket and internal threads. It’s usually mounted on panels, device housings, or antennas. The jack is designed to receive the pin from an SMA male connector.

This “female = jack” convention isn’t unique to SMA—it’s common across most connector families. Yet catalogs and datasheets don’t always use the same wording. One vendor may call it SMA female, another lists SMA connector jack. Both are correct. The reliable way to identify it? Focus on the mechanics: socket + internal threads = female/jack.

Here’s a quick reference:

| Feature | SMA Male Connector | SMA Female Connector (Jack) |

|---|---|---|

| Center Contact | Pin (protruding) | Socket (receptacle) |

| Thread Type | External thread | Internal thread |

| Typical Location | Cable ends, plugs | Device ports, antenna jacks |

| Common Confusion | Mistaken as "plug" only | Jack vs female naming |

When ordering, don’t rely only on names. Always check thread type and center contact style. That habit alone can save a project from costly mis-mates.

Applications of SMA Connectors

Ever wondered why the SMA connector pops up in so many RF systems? It’s because it hits the sweet spot: compact size, solid durability, and dependable performance at high frequencies. From a simple home router to a satellite module, SMA delivers stable, low-loss connections that you can count on.

Here are some of the most common places you’ll encounter them:

- WiFi & Networking

Threaded SMA connectors provide vibration-resistant links, making them ideal for outdoor and mobile IoT equipment.

On many routers, you’ll see an SMA female jack fixed on the back panel. The detachable antennas use an SMA male connector. Want better coverage? Just unscrew the stock antenna and swap in a high-gain version.

- IoT and Embedded Systems

SMA connectors provide stable impedance and low-loss performance, making them ideal for GPS antennas that require reliable long-term outdoor operation.

Think GPS trackers, LTE modems, or LoRa nodes. These compact devices rely on SMA connectors because vibration can’t easily loosen a threaded joint. That security is vital when the device is mounted outdoors or inside moving equipment.

- Test & Measurement

Walk into any RF lab and you’ll find SMA male and female connectors everywhere—oscilloscopes, analyzers, RF evaluation boards. Precision SMA versions handle 26 GHz and beyond, making them indispensable for serious testing.

- Aerospace, Defense & Automotive

Here, ruggedness is non-negotiable. SMA connectors show up in radar arrays, avionics gear, military radios, and even in-vehicle comms. When failure isn’t an option, SMA is often the safe bet.

Quick Application Overview

| Application Area | Typical Connector Used | Example Devices |

|---|---|---|

| Wi-Fi & Routers | SMA Female (Jack) + SMA Male | Router antennas, access points |

| IoT Devices | SMA Female (Jack) | GPS, LTE, LoRa modules |

| Test Equipment | SMA Male + Female | Spectrum analyzers, RF boards |

| Aerospace & Defense | Precision SMA | Radar, satellite communications |

In short, the SMA connector plays a double role: it’s small and affordable enough for consumer gear, yet strong and precise enough for mission-critical military and aerospace systems. Few connectors can claim that kind of range.

SMA vs Other Connector Types

The SMA connector is popular, but it isn’t the only player in the RF world. Sometimes engineers have to weigh SMA against other connector families like BNC, F-type, or SMB. The choice often comes down to frequency range, impedance, and ease of use.

These use a bayonet lock. Fast to connect and disconnect, they’re great for lab work and video transmission. But their frequency ceiling (about 4 GHz) makes them less suited for high-frequency RF.

Cheap, simple, and common in TV and satellite setups. They’re designed for 75-ohm systems, which makes them a mismatch for professional 50-ohm SMA RF chains.

Smaller than SMA, with a snap-on interface. Handy in compact modules, but less robust mechanically and frequency-limited compared to SMA.

Where SMA stands apart is its ability to combine a threaded, vibration-resistant interface with operation up to 18 GHz (or 26 GHz for precision). That’s why it’s the default choice in WiFi, IoT, and aerospace.

Comparison snapshot:

| Connector | Impedance (Ω) | Frequency Range | Locking Mechanism | Common Applications |

|---|---|---|---|---|

| SMA | 50 Ω | Up to 18 GHz (26 GHz precision) | Threaded (male + female/jack) | Wi-Fi, IoT, test equipment, aerospace |

| BNC | 50 / 75 Ω | Up to ~4 GHz | Bayonet twist-lock | Video, lab setups |

| F | 75 Ω | Up to ~3 GHz | Threaded | TV, satellite, broadband |

| SMB | 50 Ω | Up to ~4 GHz | Snap-on | Compact RF modules |

So while other connectors excel in cost or convenience, SMA connectors remain the go-to when high-frequency precision and mechanical stability matter most.

How to Choose the Right SMA Connector

Picking the correct SMA connector isn’t just a detail—it can decide whether your RF system works smoothly or fails under load. Since SMA connectors show up in so many contexts (routers, IoT boards, aerospace modules), the selection process comes down to a few critical checks.

Gender (Male vs Female/Jack)

The SMA male connector has a pin + external threads. The SMA female connector (or SMA connector jack) has a socket + internal threads. If you mix them up, they won’t mate at all.

Frequency Rating

- Standard SMA: good up to 18 GHz.

- Precision SMA: supports 26 GHz+, ideal for test gear or 5G systems.

Mounting Style

- Cable-mounted for antennas and jumpers.

- PCB-mounted for IoT modules and RF boards.

- Panel/bulkhead for routers, enclosures, or instruments.

Operating Environment

Indoors, a standard SMA works fine. Outdoors or in military conditions? Choose ruggedized, weather-sealed versions.

Quick reference guide:

| Selection Factor | Options | Example Use Case |

|---|---|---|

| Gender | Male (pin) / Female (jack/socket) | Antenna cable vs router port |

| Frequency | Standard (≤18 GHz) / Precision (≤26 GHz) | Wi-Fi router vs spectrum analyzer |

| Mounting Style | Cable / PCB / Panel (bulkhead) | IoT module vs antenna port |

| Environment | Indoor / Outdoor (sealed) | Home router vs base station |

Always double-check drawings and datasheets before ordering. It’s a small step that prevents big headaches later.

TEJTE SMA Connector Solutions

When it comes to sourcing SMA connectors, numbers on a datasheet only tell part of the story. Reliability and consistency matter just as much. That’s why many engineers turn to TEJTE.

Our catalog isn’t just a list of parts—it’s built around real-world needs:

SMA adapter cables ensure 50Ω impedance for stable RF performance in networking and IoT systems.

SMA Adapter Cables – Handy for connecting routers to antennas or bridging IoT modules. These assemblies are tested to hold 50Ω impedance, so your signal stays clean.

SMA converters simplify equipment compatibility, allowing engineers and hobbyists to connect devices with different RF connector standards.

SMA Adapter Series – Need flexibility? This lineup covers gender changers and SMA-to-other-interface adapters (like N or BNC). Whether you’re linking an SMA male connector to an SMA female jack or adapting across standards, these tools cut down on custom work.

Custom SMA solutions help meet project-specific needs, providing flexibility for industrial, automotive, and IoT applications.

- Custom Assemblies – Sometimes off-the-shelf just isn’t enough. For those cases, TEJTE builds tailored SMA solutions, from compact PCB-mounted connectors to ruggedized outdoor assemblies.

Working with TEJTE means you’re not only getting connectors, but also peace of mind: supply stability, tight tolerances, and designs proven in the field. That’s what keeps prototypes moving and production lines running.

FAQ: SMA Connectors

Q1: What is an SMA connector used for?

You’ll find it in WiFi antennas, GPS receivers, IoT modules, and RF test gear. Its threaded design keeps signals steady even when the environment isn’t.

Q2: What does SMA stand for?

It’s short for SubMiniature version A—a nod to its compact size compared to earlier coaxial connectors.

Q3: Is SMA the same as F connector?

Not at all. SMA connectors are 50Ω and built for RF and microwave. F connectors are 75Ω, cheaper, and common in TV or satellite setups.

Q4: How do you tell SMA male from SMA female (jack)?

Here’s the trick: male = pin + external threads. Female (jack) = socket + internal threads. Think of the jack as the “socket” waiting for the plug.

Q5: Is SMA better than BNC?

For higher frequencies, yes. SMA goes to 18–26 GHz, while BNC maxes out around 4 GHz. That’s why lab test gear often uses SMA.

Q6: Can you crimp an SMA female connector yourself?

Yes—but precision is key. Strip the coax to spec, slide the ferrule, insert the connector body, then crimp with a calibrated tool. Done right, you’ll have a low-loss, durable connection.

Q7: Are there different SMA types?

Absolutely. There’s standard SMA, high-precision SMA, and RP-SMA (reverse polarity), which you’ll often see on WiFi routers.

Conclusion

The SMA connector has earned its reputation over decades. From WiFi routers at home to aerospace systems in orbit, it provides a rare balance of compact size, durability, and frequency performance.

Here’s the part most people underestimate: knowing whether you need an SMA male connector, an SMA female connector, or the SMA connector jack isn’t just semantics. It’s the difference between a system that works first time and one that doesn’t connect at all.

Sure, alternatives like BNC or F connectors serve their niches, but when you need high-frequency precision and rock-solid stability, SMA is the go-to.

At TEJTE, we back that reliability with a full portfolio—from standard connectors to custom assemblies for specialized applications. Whether you’re troubleshooting a lab prototype or scaling up for production, our SMA solutions are built to perform—and built to last.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.