What is RG178 Coaxial Cable? Specs, Loss & Applications

Sep 01,2025

Introduction

This image is the hero shot introducing the RG178 cable. It focuses on the cable's most prominent feature: its exceptionally small size (~1.8mm OD). The visual likely includes a scale or is shot in a way that immediately communicates its thinness, reinforcing the text's description of it being "among the thinnest options" and suitable for "pigtail assemblies" and "compact IoT modules" where space is at a premium.

In RF design, space is often the enemy. When circuit boards are crammed with components and there’s barely room for another trace, cable choice becomes critical. That’s where the RG178 coaxial cable steps in. With an outer diameter of only about 1.8 mm, this micro coax cable is among the thinnest options in the 50-ohm family..

You’ll usually spot it in pigtail assemblies—the kind that link a tiny U.FL or IPEX connector on a PCB to a bulkhead-mounted SMA or RP-SMA jack on the chassis. It also shows up in wearables, compact IoT modules, and even medical devices, where small size and high flexibility matter more than raw power.

Of course, there’s a trade-off. RG178 cable handles heat well and bends easily, but it loses more signal per meter than sturdier mini-coax like RG316. That makes it perfect for short, low-power RF links, but not for long-distance or high-power transmission.

In this guide, we’ll break down its construction, specifications, attenuation behavior, and use cases. We’ll also compare RG178 with close cousins such as RG174 and RG316, so you’ll know when it’s the right tool—and when you should pick something thicker.

What is RG178 Coaxial Cable?

This technical diagram provides a foundational understanding of the RG178 cable's build quality. It clearly delineates the four key layers that contribute to its performance: the central conductor (often silver-plated copper for good conductivity), the fluoropolymer dielectric (PTFE or FEP for stable insulation and high temp tolerance), the braided shield (for EMI protection), and the tough FEP outer jacket (for mechanical and environmental protection). This visual complements the text by explaining how the materials achieve its small size and capabilities.

At its simplest, RG178 is a miniature 50-ohm coaxial cable engineered for tight spaces and short runs. Like all coax, it’s built around four layers:

- A central conductor—usually silver-plated copper, sometimes stranded to make bending easier.

- A dielectric made of fluoropolymer (PTFE or FEP), which insulates the conductor and maintains the impedance.

- A woven shield of silver-plated copper strands, giving protection against interference.

- A thin outer jacket, typically FEP, that resists heat and chemicals.

This stack keeps the diameter near 1.80 ± 0.05 mm, slimmer than most other mini-coax options. That small size is why engineers turn to RG178 coaxial cable when every millimeter of clearance counts.

Why Engineers Choose RG178

- Compact build – at just 1.8 mm OD, it fits into spaces where RG174 or RG316 would be too bulky.

- High heat tolerance – rated roughly –55 °C to +200 °C, useful for aerospace and industrial setups.

- Flexibility – bends tightly without cracking the dielectric, which helps in cramped enclosures.

Where It Falls Short

- Signal loss – attenuation is higher compared with thicker mini-coax types.

- Not for long runs – performance drops quickly as length increases.

- Low power capacity – it’s not built for transmitting high RF power.

In short, RG178 coaxial cable is a space-saver: small, flexible, and reliable in the right conditions, but best kept for short, low-to-moderate power connections.

RG178 vs RG316: Key Differences

Size and Handling

- RG178: about 1.8 mm OD. Extremely slim, great for ultra-compact layouts.

- RG316: about 2.5 mm OD. Still thin, but more rugged and easier to handle during repeated installs.

Loss and Signal Integrity

- RG178: higher attenuation. For instance, at 1 GHz its loss per meter is noticeably higher than RG316.

- RG316: lower attenuation, making it the better pick for test setups, lab jumpers, or when signals travel a bit farther.

Thermal & Environmental Ratings

Applications in Practice

- RG178: ideal for ultra-short pigtails, like U.FL to RP-SMA inside Wi-Fi or Bluetooth modules.

- RG316: more common in test equipment, antenna feeders, or short but critical links where loss has to be minimized.

Quick Comparison: RG178 vs RG316

| Feature | RG178 | RG316 |

|---|---|---|

| Impedance | 50 Ω | 50 Ω |

| Outer Diameter (OD) | ~1.8 mm | ~2.5 mm |

| Dielectric | FEP | PTFE with FEP jacket |

| Attenuation @ 1 GHz | Higher (varies by vendor) | Lower (varies by vendor) |

| Temperature Range | -55 °C to +200 °C | -55 °C to +200 °C |

| Best Use | Ultra-short, compact jumpers | Shorter runs with lower loss |

Construction & Specifications of RG178

Every coaxial cable follows the same basic recipe, but the exact proportions and materials make all the difference. RG178 coaxial cable is designed with a focus on miniaturization without losing reliability.

As a micro coax cable, RG178 relies on a careful balance of conductor size, dielectric thickness, and braid density to achieve stable impedance and predictable performance in real-world conditions.

Inside the Cable

- Center Conductor – Typically silver-plated copper wire, sometimes stranded for added flexibility. TEJTE’s RG178, for instance, uses 7 strands of 0.102 mm SPC, giving a conductor OD of about 0.30 mm. This provides a good mix of conductivity and mechanical endurance.

- Dielectric (Insulation) – Fluoropolymer material, usually FEP (Teflon). This transparent layer surrounds the conductor and keeps the impedance locked at 50 Ω. Thickness is around 0.30 mm, with a dielectric OD close to 0.89 mm.

- Outer Conductor (Shielding) – A dense silver-plated copper braid. TEJTE’s version specifies roughly 92% coverage, significantly higher than the “industry typical” range. That extra braid density improves EMI resistance and stabilizes insertion loss.

- Jacket – The final protective skin. In most RG178 builds, it’s a thin FEP jacket, keeping the overall diameter at 1.80 ± 0.05 mm. FEP doesn’t just resist heat; it also stands up to harsh chemicals, which is why RG178 can survive in demanding lab and industrial environments.

Electrical and Environmental Ratings

| Parameter | Industry Typical RG178 | TEJTE RG178 Specification |

|---|---|---|

| Impedance | 50 Ω | 50 Ω |

| Overall OD | ~1.8 mm | 1.80 ± 0.05 mm |

| Dielectric / Jacket | Fluoropolymer (FEP/PTFE) | FEP / FEP |

| Braid Coverage | ~80 % typical | ~92 % |

| Temperature Range | -55 °C to +200 °C | -55 °C to +200 °C |

| Insulation Resistance | Vendor dependent | ≥ 3000 MΩ·km |

| Conductor Resistance | Vendor dependent | ≤ 345 Ω/km (at 20 °C) |

| Withstand Voltage | Varies | 2000 V |

Why It Matters

Performance: Attenuation, Loss & Power Handling

Attenuation and Signal Loss

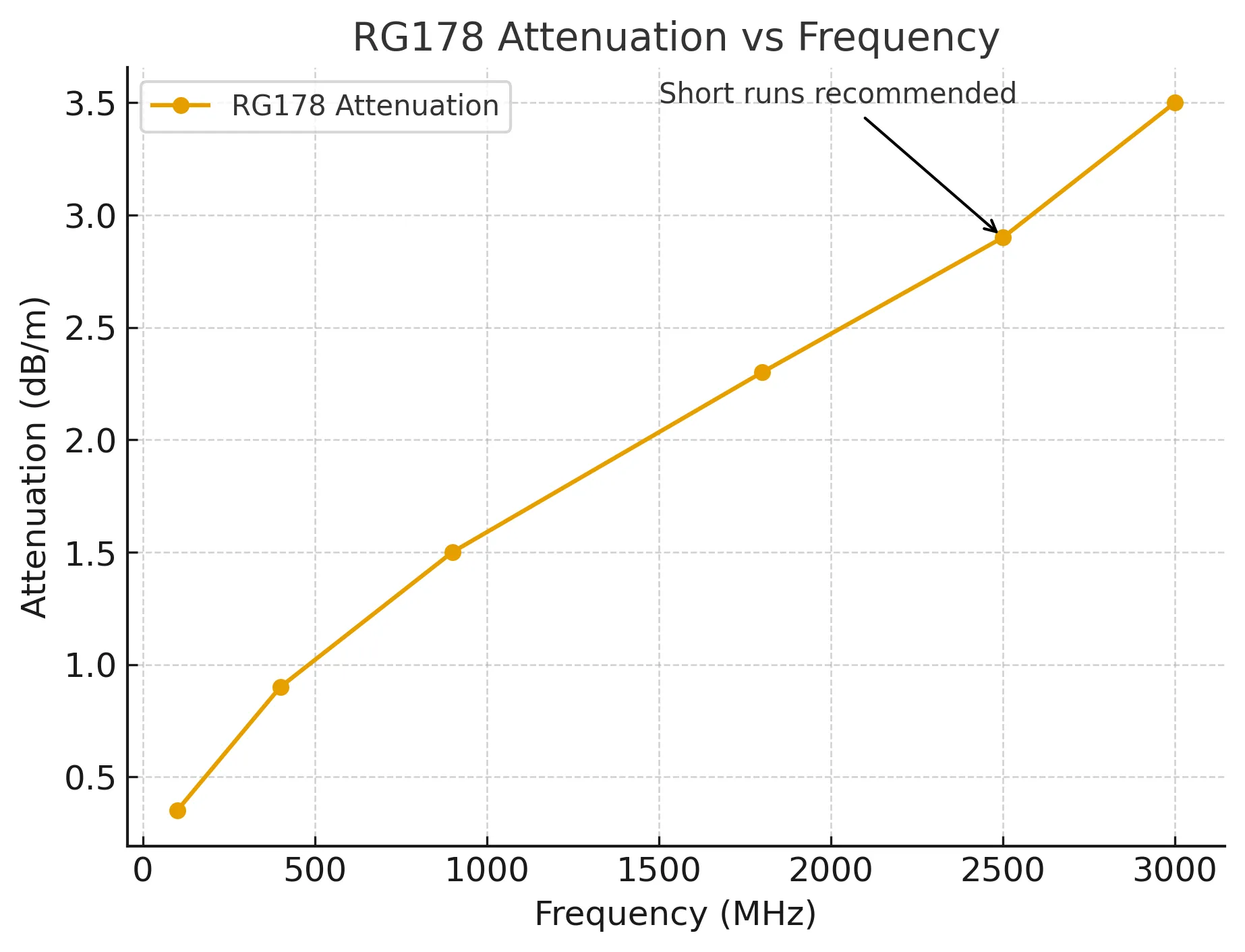

This line chart is a critical visual for understanding the primary electrical characteristic and limitation of RG178 cable: its high attenuation, especially at microwave frequencies. The graph quantitatively shows how signal loss per meter (dB/m) increases dramatically as the frequency rises from lower UHF bands (e.g., a few hundred MHz) into the GHz range common for Wi-Fi, Bluetooth, and cellular signals. This reinforces the text's warning that RG178 is "fine for short internal RF cables up to a few tens of centimeters" but suffers significantly in longer runs at high frequencies.

The reality is simple: the thinner the cable, the more loss you’ll see. RG178, at just 1.8 mm OD, will always have more attenuation than RG316 or RG58. But for very short runs—think U.FL to SMA pigtails inside a Wi-Fi router—the loss is usually acceptable.

Loss depends on frequency and length. Vendors publish slightly different figures, but here’s a ballpark comparison for RG178 attenuation per meter:

| Frequency (MHz) | RG178 Attenuation (dB/m) | Notes |

|---|---|---|

| 100 | ~0.3 – 0.4 | Good for low-band VHF short jumpers |

| 400 | ~0.7 – 0.9 | Still usable for telemetry / control links |

| 900 | ~1.2 – 1.5 | Typical for GSM/IoT modules |

| 1800 | ~2.0 – 2.3 | Loss becomes more significant |

| 2500 | ~2.5 – 3.0 | OK for very short LTE/Wi-Fi leads |

| 3000 | ~3.2 – 3.5 | Marginal beyond a meter |

Note: Values vary by supplier. TEJTE specifies stable performance thanks to tighter braid density, but overall loss trend remains the same.

Takeaway: RG178 is fine for short internal RF cables up to a few tens of centimeters. Push it past one meter at GHz frequencies, and attenuation quickly eats into your link budget.

Power Handling

Power rating is a tricky subject for micro-coax. Unlike larger cables, you can’t just publish one kW number and call it done. Power capacity depends on frequency, ambient cooling, VSWR, and whether the cable is bundled with others.

For RG178:

- Continuous power handling is limited—best kept to low-to-moderate power links.

- Peak power is mostly limited by heating at mismatches or in high-duty modulation modes.

In practice, this means RG178 is perfectly fine for Wi-Fi pigtails, BLE modules, GPS receivers, and IoT devices. But if you’re pushing RF amps or transmitting high-power LTE, you’ll want to step up to something like RG316 or RG58.

Temperature Stability

RG178 vs RG58 vs RG316: Which to Choose?

Size Matters

- RG178 is the slimmest of the three, about 1.8 mm OD. It’s perfect when you need to snake a cable through tight housings or fit it on a compact PCB module.

- RG316 is still a mini-coax, around 2.5 mm OD, and offers a good compromise between flexibility and lower loss.

- RG58 is much larger at about 5 mm OD, so it won’t fit inside cramped enclosures—but it shines in durability and lower attenuation over distance.

Signal Loss

- RG178 coaxial cable has the highest attenuation. At 2.4 GHz, even a one-meter run can eat a few dB.

- RG316 is better, keeping losses manageable for short jumpers, lab use, and antenna feeds.

- RG58 offers the lowest loss of the group, which is why it’s still widely used in test benches, longer patch runs, and some outdoor radio systems.

Power Capacity

- RG178: very limited. It’s meant for low-power links only.

- RG316: acceptable for moderate power at short lengths.

- RG58: handles higher power much better thanks to its size and lower resistance.

Environmental Range

At-a-Glance Comparison Table

| Feature | RG178 | RG316 | RG58 |

|---|---|---|---|

| Impedance | 50 Ω | 50 Ω | 50 Ω |

| Outer Diameter (OD) | ~1.8 mm | ~2.5 mm | ~5 mm |

| Dielectric | FEP | PTFE / FEP jacket | PE with PVC jacket |

| Attenuation @ 1 GHz | High | Medium-Low | Low |

| Temperature Range | -55 °C to +200 °C | -55 °C to +200 °C | -40 °C to +85 °C |

| Best Use Case | Ultra-short, ultra-compact | Short runs, lower loss | Longer runs, higher power |

Common Applications of RG178

Industry-Typical Uses

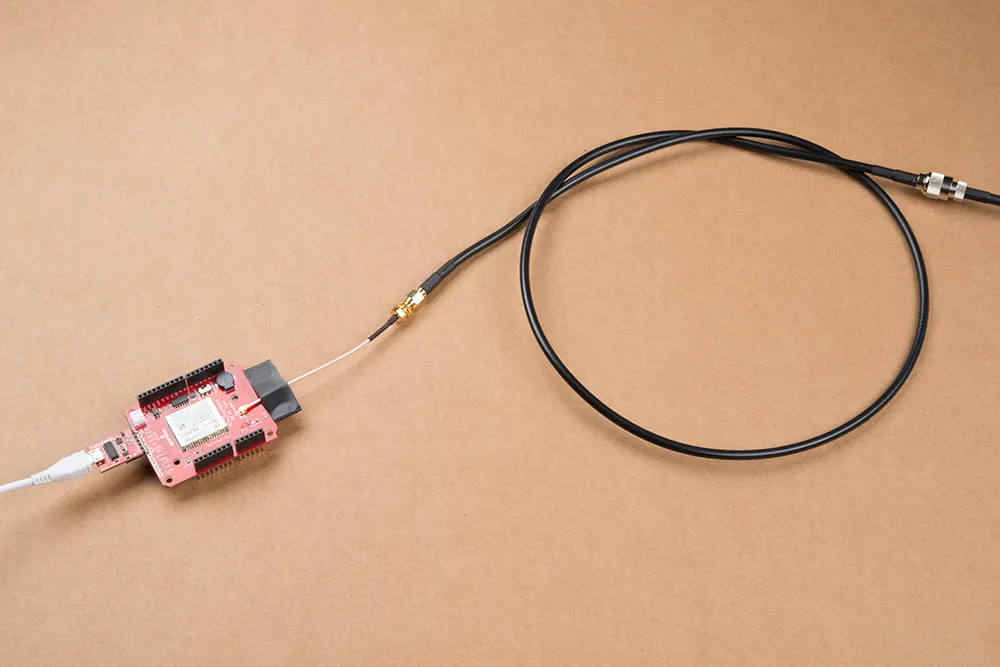

This image depicts the most standard and frequent use case for RG178 cable. It shows a complete, pre-terminated cable assembly. One end has a tiny, delicate U.FL (or IPEX) connector, designed to be soldered or clicked onto a corresponding surface-mount port on a printed circuit board (PCB) inside a device like a Wi-Fi router or IoT module. The other end terminates in a more robust, threaded SMA connector, allowing the device to be connected to an external antenna. This visual perfectly illustrates the "bridge" function described in the text.

- Pigtails and jumpers – You’ll often find RG178 in U.FL/IPEX to SMA or RP-SMA assemblies, bridging the gap between a board connector and an external antenna port.

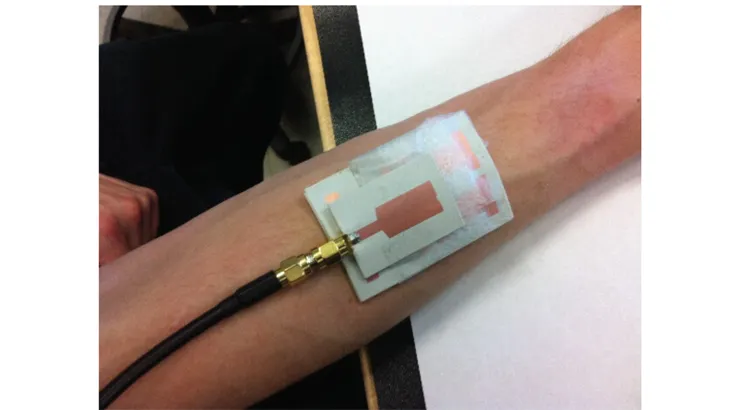

This image showcases the application of RG178 in scenarios where miniaturization is paramount. It likely shows the interior of a device like a smartwatch or a health monitor. The focus is on how the incredibly thin RG178 cable is routed through the tightest of spaces to connect a small antenna (perhaps printed on the casing or a separate element) to the main system board. This highlights its role in enabling wireless functionality in products where every cubic millimeter of volume is critically accounted for, justifying its use despite higher attenuation because it's often the only viable option.

- Wearables and medical electronics – Small devices like smartwatches, health trackers, or diagnostic gear often rely on RG178 for their RF antenna leads.

This image illustrates the mechanical property of RG178 that makes it suitable for complex internal layouts: its exceptional flexibility. The scene is likely the interior of a compact RF module or an IoT device PCB. The RG178 cable is shown making a very tight bend or being routed around other components without kinking or stressing, connecting a chip antenna or a module connector to the main processor. This visual reinforces the text's point about RG178 being chosen when cables need to "bend sharply without breaking" in "compact RF modules" for "short internal links."

- IoT and wireless modules – Compact RF modules need a cable that bends sharply without breaking. RG178 fits the bill for short internal links.

- Test equipment – Engineers use RG178 jumpers on the bench when they need ultra-short connections for prototypes.

TEJTE-Optimized Use Cases

This image conveys the advanced, performance-oriented applications of TEJTE's specific version of RG178 cable. It might show the cable installed in a context beyond standard consumer electronics, such as routed near a heat source in an avionics bay, within a robust industrial control box surrounded by other equipment, or as part of a custom harness with clear OEM labeling. The image aims to visualize the text's claims about superior braid coverage (~92%) for better EMI shielding and its suitability for "high-temperature enclosures" and "EMI-sensitive applications" where standard RG178 might not perform as well.

From TEJTE’s datasheet and assemblies, RG178 gets pushed further:

- High-temperature enclosures – FEP jacket allows stable use near heating elements or in aerospace electronics.

- EMI-sensitive applications – The ~92% braid coverage means better shielding, useful inside RF-dense enclosures.

- Custom assemblies – TEJTE provides RG178 cable assemblies with labeling, lot traceability, and options for IPEX-K (U.FL) heads, giving OEM customers predictable performance.

Why Engineers Still Choose RG178

Best Practices for Using RG178

Working with RG178 coaxial cable can be tricky because of its thin size. If handled carelessly, you’ll end up with broken conductors, poor shielding, or degraded VSWR. Here are some field-tested tips to get the best results:

- Measure Twice, Cut Once

Leave a little slack when cutting. Micro-coax is unforgiving—too short and you’ll stress the connectors, too long and you risk messy bends.

- Respect the Bend Radius

A safe rule: keep bends no tighter than 5 × OD (~9 mm) for static installs and 10 × OD (~18 mm) for dynamic or moving cables. Anything sharper risks fracturing the dielectric.

- Use Proper Tools

Stripping RG178 with a utility knife usually ends in tears. Instead, use a mini-coax stripper and dies made for U.FL or SMA crimps. A light tinning of the center conductor before soldering helps prevent whiskers.

- Avoid Pulling on the Cable

Never yank on RG178 to disconnect it. Use the connector body. The thin conductor can easily stretch or break.

- Verify After Assembly

A quick continuity test and, ideally, a VNA sweep for return loss/VSWR helps catch bad crimps before the cable is sealed into a device.

- Mind the Environment

RG178 can handle –55 °C to +200 °C, but prolonged bending near heat sources can still stress it. If heat and vibration are high, consider moving up to RG316.

Pro tip: When in doubt, treat RG178 like a fragile thread. It can deliver excellent results—but only if you respect its limits.

Common Questions About RG178 Coaxial Cable

1. How to crimp RG178?

2. What is the frequency range for RG178 cables?

3. RG178 vs RG316 — when should I choose which?

- RG178: ultra-tight spaces, short pigtails, low power.

- RG316: when you want lower attenuation and more mechanical durability, at the cost of slightly larger diameter.

4. RG174 vs RG178 — what’s the difference?

- RG174: about 2.8 mm OD, uses PE/PVC insulation, cheaper, but limited to –40 °C to +85 °C.

- RG178: slimmer at ~1.8 mm OD, uses FEP, higher temp range up to +200 °C. RG178 is better in harsh or high-heat environments, but has higher loss.

5. What is the diameter and bend radius of RG178?

6. Can I use U.FL ↔ RP-SMA pigtails with RG178?

7. Is RG178 OK for high power?

8. Where can I buy RG178 cable assemblies?

Conclusion & CTA

The RG178 coaxial cable is a specialist tool. It won’t win awards for low loss or power handling, but when space is the real bottleneck, this 1.8 mm micro-coax earns its keep. From Wi-Fi pigtails and IoT modules to wearables and aerospace electronics, it delivers reliable short-range RF performance in places larger cables simply can’t fit.

Key takeaways:

- RG178 is a 50-ohm miniature coax, ~1.8 mm OD.

- Excels in tight spaces, high heat, and low-power links.

- Suffers from higher attenuation compared with RG316 or RG58.

- Best kept for short runs and compact assemblies.

- For longer or higher power runs, step up to RG316, RG58, or even LMR-series cables.

If you’re developing compact wireless devices, ordering a pre-terminated RG178 cable assembly often saves time and guarantees consistency. TEJTE provides assemblies built to spec—with high braid density, labeled packaging, and fast turnaround.

Explore related guides:

Or jump straight to our custom RF adapter cables to request a quote.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.