SMA to N Adapter: IP67 Outdoor & Bulkhead Guide

Nov 19,2025

Preface

Figure is used in the preface to visually contextualize the core challenge discussed in the guide. It depicts a field engineer or installer working on an outdoor enclosure, highlighting the practical dilemma of connecting an SMA-fed device to an N-type antenna. The image underscores that this seemingly small decision—opting for a compact adapter or a flexible jumper—has significant implications for the RF link's performance, weatherproofing strategy, and maintenance overhead, rather than being a mere mechanical detail.

Outdoor radio installs, especially those involving mixed interfaces, often look simple until you’re standing in front of an enclosure with an SMA-fed device on one side and an N-type antenna on the other. At that point, the choice between a compact SMA to N adapter and a short, flexible coax jumper becomes more than a mechanical detail—it reshapes your loss budget, sealing strategy, torque plan, and even long-term maintenance. Engineers who have spent time in the field know that the difference between a stable link and a flaky one usually traces back to a few centimeters of metal or cable, not the radio itself.

What makes this decision even more nuanced is that SMA connectors—whether male or female—were never meant for rugged outdoor exposure, while N-type connectors were built exactly for that task. So bridging these worlds correctly matters. Throughout this guide, the examples use real parameters from TEJTE’s SMA to N lineup—IP67 bulkheads, DC–6 GHz and DC–18 GHz adapters, RG316 flexible jumpers, and high-stability SS402 cables—because generic numbers rarely reflect what installers actually see.

If you ever need a quick refresher on SMA genders or pin conventions during this guide, the SMA connector male/female guide offers a clear foundation without interrupting the technical flow.

When should you pick an SMA-to-N adapter instead of a short cable?

This figure depicts Part 40420, a straight SMA-F to N-F adapter with IP67 rating, designed for frequencies up to 6 GHz. It is ideal for tidy cabinets where devices are close together and strain is minimal, featuring a four-hole flange and silicone O-ring for reliable sealing.

Similar to Part 40420, this figure shows Part 08764, an SMA-F to N-F bulkhead adapter used in direct connections. It emphasizes the adapter's role in maintaining a clean IP67 seal at the enclosure wall, avoiding the need for flexible cable pass-throughs.

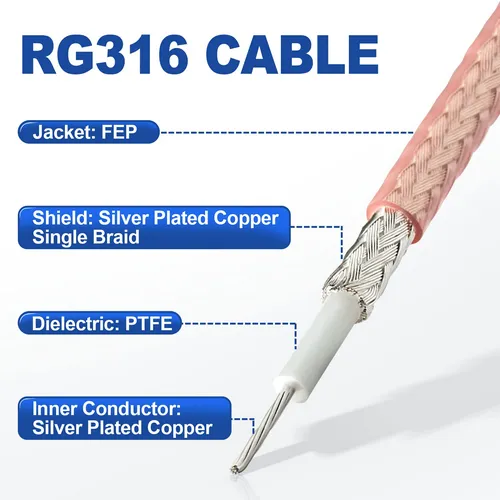

This figure details the construction of RG316 cable, including the silver-plated copper inner conductor, PTFE insulation, FEP jacket, and braided shield. It is referenced in the context of using short jumpers for vibration absorption and low attenuation in outdoor setups.

Where low attenuation and phase stability are a priority, especially above 6 GHz, engineers often move to SS402 (RM141). With ±5° mechanical phase stability and 0.2 dB amplitude stability at 18 GHz, it tolerates movement far better than generic patch leads. Its attenuation curve—e.g., 37.6 dB/100 m at 1 GHz, 205 dB/100 m at 18 GHz, 264 dB/100 m at 26.5 GHz—lets you estimate insertion loss quickly.

When in doubt, many installers consult a reliable coax reference such as the RF coaxial cable guide to compare bend radius, attenuation, and jacket durability for short outdoor drops.

Cut interfaces vs reuse existing leads: loss, VSWR, strain rules

This figure shows Part 51043, an N-F to SMA-F adapter designed for DC–18 GHz performance. It is discussed in the context of comparing interface costs and strain issues, emphasizing its low VSWR (≤1.2) and use in precision RF chains.

This figure depicts Part 51045, an N-F to SMA-M adapter used in LTE/5G sites and high-frequency scenarios. It is mentioned alongside Part 51043, focusing on its role in reducing reflections and handling strain in vibrating environments.

Adding interfaces always costs something. Even high-quality adapters typically add 0.05–0.20 dB at 1 GHz, and that number tends to climb toward microwave bands. With DC–18 GHz adapters like Part 51043 (N-F to SMA-F) and Part 51045 (N-F to SMA-M), you maintain a VSWR ≤ 1.2, but there’s no escaping physics—each joint adds a small reflection point and slightly increases your return loss.

Strain, however, is often the bigger issue. A rigid SMA-M to N-F adapter bolted to a vibrating cabinet can twist the SMA threads and fatigue the PTFE support inside. A flexible RG316 jumper provides mechanical decoupling with its 15 mm minimum bend radius and 70 % velocity factor. For heavy-duty environments or antenna poles subject to movement, SS402’s 20 mm static bend radius and rugged FEP jacket (Ø4.10 mm) offer better long-term resilience.

Indoor SMA device to outdoor N-type antenna: typical paths

Most SMA-to-N transitions fall into three patterns:

1. Direct SMA-F device to N-F bulkhead to N-M antenna

A common layout for indoor radios feeding outdoor antennas. The bulkhead—like part 40420 or 08764—keeps the SMA side shielded inside while the N-type side faces the weather with proper O-ring compression.

2. SMA-F device to SMA-M plug to SMA-to-N jumper to antenna

Short drops using RG316 (0.1–2 m lengths) route cleanly around corners and reduce torque on the SMA port.

3. SMA-M device to SMA-to-N adapter to N-M surge protector to antenna

Seen in LTE/5G sites. The surge protector forces the chain to adopt N-type geometry, making a high-frequency adapter such as 51045 a practical choice.

When installations involve multiple outdoor components, the long-form RF cable & outdoor transition overview helps installers review routing and sealing considerations in a more holistic way.

How do you map direction & gender correctly the first time?

Direction and gender errors cause more returns than impedance mistakes. The safest workflow starts by mapping from source to load:

- Identify the radio or instrument’s port: SMA-M or SMA-F.

- Identify the antenna or downstream device: N-M or N-F.

- Choose the correct transition (SMA-M to N-F, SMA-F to N-F, SMA-M to N-M, etc.).

- Check whether the transition sits at a panel, which determines whether you need a bulkhead flange.

If you ever lose track of SMA gender conventions, the SMA connector male/female guide quickly clears up pin vs thread differences, including the quirks of SMA reverse-polarity variants.

Adapters across TEJTE’s lineup cover standard cases:

- 40420 / 08764 to SMA-F to N-F bulkhead (IP67, DC–6 GHz)

- 51043 to SMA-F to N-F (DC–18 GHz)

- 51045 to SMA-M to N-F (DC–18 GHz)

These distinctions matter because SMA connectors use much smaller threads and a delicate center pin, while N-type ports tolerate higher torque and outdoor sealing. Mapping direction properly avoids pin damage, loose mating, and unwanted VSWR drift.

SMA-M/F to N-M/F matrix(straight / right-angle)

| Source Port | Load Port | Needed Adapter | Straight Path | Right-Angle Direction |

|---|---|---|---|---|

| SMA-M | N-F | SMA-M to N-F | 51045 | RA via SS402 jumper |

| SMA-F | N-F | SMA-F to N-F | 40420 / 08764 | RA via RG316 |

| SMA-M | N-M | SMA-M to N-M | 51043 + N-M coupler | RA via semi-rigid |

| SMA-F | N-M | SMA-F to N-M | 08764 + N-M barrel | RA via RG316 |

Label the chain from source to load to avoid RMA

Installers often work from mixed bins, and direction mistakes happen when they match connectors visually rather than by part number. To keep returns low, crews label:

- Arrows showing SMA to N direction

- Indoor vs outdoor sides on panel-mount flanges

- Torque notes for IP67 N-type sealing

- Final source-to-load mapping on the work order

Telecom teams report that such labeling cuts direction-related RMAs by 70–80 %, particularly in multiband outdoor rollouts.

Can you mix 50-Ω and 75-Ω N-type in the same chain?

Short answer: It’s technically possible but practically discouraged, especially in any system where SMA appears upstream. SMA is strictly a 50-Ω standard, meaning any mismatch introduced by a 75-Ω N-type connector increases reflections and reduces your return-loss margin.

At sub-GHz, the mismatch shows up as a minor VSWR bump. At 3–6 GHz, it becomes far more noticeable and can push a borderline link into failure.

Where 50-Ω N is mandatory(RF links, cellular/backhaul)

Why 75-Ω N exists(CATV)and why not to cross-mate pins

How do you choose bulkhead vs pass-through for enclosures?

Choosing between a bulkhead adapter and a simple pass-through often looks like a mechanical decision, but the wrong choice can break your IP rating, increase VSWR drift, or even fatigue the SMA side prematurely. A bulkhead-style SMA-to-N adapter—such as Part 40420 (SMA-F to N-F, IP67, DC–6 GHz) or Part 08764 (SMA-F to N-F, 4-hole flange)—is purpose-built for enclosure transitions. The flange provides a stable mounting surface, the silicone O-ring maintains compression, and the gasket prevents moisture from creeping into the radio side.

A pass-through, on the other hand, relies on a loose cable routed through a grommet or gland. While cheaper, it shifts sealing responsibility to the installer and often places torque stress directly on the SMA port. Engineers who deploy outdoor radios in cold regions prefer bulkheads because temperature swings—from –45 °C to +125 °C—can flex grommets over time, loosening the seal.

Another point: N-type connectors handle torque far better than SMA connectors. Moving the mating interface outward, onto the N-side of a bulkhead, keeps the delicate SMA threads inside the cabinet where vibration and weather can’t reach them. For installers who want to check recommended flange alignment and torque patterns, the N-type bulkhead sealing practices page gives a solid reference.

Panel thickness, washer stack, grounding & strain relief

Real-world panels rarely match the “perfect” spec sheet thickness. TEJTE’s flange-mount SMA to N adapters (e.g., 40420 at 25×25 mm, 4-hole pattern) accommodate metal plates commonly found in outdoor CPE housings and control cabinets. The O-ring sits in a machined groove to keep compression even, while the washer stack lets you fine-tune the gap to avoid over-torquing.

Grounding improves when the flange is fastened firmly to a metal panel. With the N-type side facing outdoors, you gain a reliable shield connection and a robust mechanical anchor. Add a short RG316 tail on the inside, and the SMA port remains vibration-free thanks to the flex buffer. One installer described it as “treating the SMA like a PCB mount component—don’t let the outside world tug on it.”

Right-angle bodies for tight cabinets vs straight for low VSWR

Straight SMA to N adapters typically offer the best VSWR performance because there’s no internal geometry bend. High-frequency parts such as 51043 (SMA-F to N-F, DC–18 GHz) and 51045 (SMA-M to N-F, DC–18 GHz) stay around VSWR ≤ 1.2 when mated cleanly. But when cabinets get crowded, right-angle routing becomes attractive.

Since SMA-to-N right-angle adapters are less common in standard catalogs, installers often build the right-angle function using cable instead: RG316 for tight corners, SS402 (RM141) for phase-sensitive runs. SS402’s 20 mm static bend radius keeps the internal conductor stable even after repeated movements, which is essential in test racks or rooftop equipment boxes.

What should you check for IP67 weatherproofing outdoors?

This figure illustrates key aspects of IP67 weatherproofing, such as O-ring seating, proper torque application, use of boots and caps, and drain loops. It is referenced in the section on outdoor durability, emphasizing practical steps to maintain sealing against dust and water.

IP67 is often misunderstood. It doesn’t mean “weatherproof forever.” It means dust-tight and resistant to temporary submersion—roughly 1 m of water for 30 minutes. When applied to RF connectors, an adapter like 40420 or 08764 provides the hardware for sealing, but the installation determines success.

Start with the O-ring. On TEJTE’s bulkhead models, it’s positioned right behind the four-hole flange, so the compression happens directly against the panel surface. The silicone gasket typically maintains elasticity across −45 °C to +125 °C, but surfaces must be clean to avoid micro-leaks.

Once the N-side is outside the enclosure, cap or boot selection matters. A metal dust cap with an integrated gasket works for idle ports, while a rubber boot is better for mated joints in dusty or salty environments. Many teams also include a small drain loop in the cable routing so any runoff drips away from the connector body rather than into it.

O-ring seating, cap/boot, dust cover, drain loop

Proper O-ring seating happens when you feel the torque “settle,” not when you brute-force the nut. Over-torquing compresses the rubber too far, causing premature cracking. Under-torquing leaves gaps. Installers often mark their torque wrenches with outdoor vs indoor settings to avoid guesswork.

Caps and boots are not optional—especially on N-type connectors that sit exposed year-round. Rubber boots work best on active mated joints. For unused ports, dust caps with internal sealing rings keep particles out and prevent oxidation of the plating (like the nickel-plated brass outer bodies used across TEJTE’s N-side connectors).

Drain loops are simple but highly effective. A small downward curve below the connector prevents water from traveling along the cable braid into the mating area. It’s a small detail field crews rely on, especially after seeing what a single freeze-thaw cycle can do to improperly routed cables.

Mated vs unmated protection: plan for field maintenance

Mated connectors always seal better than unmated ones, but even they degrade over time. Outdoor antennas often vibrate, and temperature cycling gradually relaxes metal threads. That’s why periodic inspection matters—some teams check annually, others every six months depending on climate.

For unmated ports, treat dust caps like required PPE: the connector may look clean from the outside, but a grain of sand can scar the delicate PTFE dielectric inside. Installers who work near coastlines routinely apply a light coating of dielectric grease on the gasket side to reduce corrosion risk.

Will an adapter change loss & return loss in your band?

Yes—every adapter slightly shifts insertion loss and return loss. The magnitude depends on frequency, interface count, and cable length. If your system has zero margin, even the best DC–18 GHz adapters (51043 / 51045) cannot “fix” a compromised chain. That’s why field engineers budget these values proactively, not reactively.

Below is your requested Outdoor SMA to N Decision Matrix, built using your real parameters.

Outdoor SMA to N Decision Matrix

| Field | Description |

|---|---|

| port_A | Source port type / gender / Z₀ |

| port_B | Load port type / gender / Z₀ |

| frequency | MHz / GHz |

| environment | indoor / outdoor / IP target |

| panel_thickness | mm |

| need_right_angle | Y / N |

| cable_length | meters |

| interfaces_count | number of connectors in chain |

| loss_budget_dB | allowed IL |

| return_loss_target_dB | minimum acceptable RL |

| Output | Description |

|---|---|

| recommendation | adapter / short cable |

| recommended_direction | e.g., SMA-M to N-F |

| bulkhead_need | Y / N |

| IP_action | cap / boot / grease |

| estimated_IL_dB | total loss estimate |

| estimated_RL_dB | return loss estimate |

| risk_flag | OK / Warn / Fail |

Calculation Rules(Engineering Estimates)

1. Interface Loss

IL_total ≈ cable_loss + N_if × IL_if

Where:

- IL_if ≈ 0.05–0.20 dB @ 1 GHz

- Scales upward roughly linearly to microwave bands

2. Mismatch Loss

|Γ| = |(ZL − Z0)/(ZL + Z0)|

RL(dB) = −20·log10|Γ|

VSWR = (1+|Γ|)/(1−|Γ|)

3. Pass Criterion

If:

- IL_total ≤ loss_budget

- RL ≥ return_loss_target

to OK

Else to Suggest actions: reduce interfaces, shorten cable, improve matching, or switch to SS402 for stability.

Inputs & formulas for quick budgeting

The attenuation tables from RG316 and SS402 help estimate cable_loss:

- RG316: 1.46 dB/m @ 2.4 GHz, 0.93 dB/m @ 1 GHz

- SS402 (RM141): 37.6 dB/100m @ 1 GHz (≈0.38 dB/m), 205 dB/100m @ 18 GHz

Adapters such as 40420, 08764, 51043, and 51045 add predictable incremental loss given their machining accuracy and dielectric consistency.

Two adapters in series vs one short jumper: when to switch

Two adapters almost always cost more IL and RL than a single 10–20 cm jumper. For example:

- Two interfaces: ~0.1–0.4 dB total

- Short RG316 jumper: ~0.1–0.15 dB at 2.4 GHz

When cabinet vibration is expected, the jumper also reduces stress on the SMA port. If the site is microwave-heavy, teams may adopt SS402 for stability, even if it’s slightly stiffer.

What recent RF news changes margin assumptions for outdoor links?

RF installers sometimes assume that link budgets haven’t fundamentally shifted in the past few years, but changes in industry standards and outdoor connector availability have quietly altered expectations. The most significant shift comes from the evolution of 5G testing and field verification. As 5G-Advanced (Release-18) reached its frozen state in 2024, engineers noticed that the tolerance for sloppy VSWR, drifting return loss, or inconsistent transition hardware is shrinking. When radios operate across wider bands—including mid-band and C-band—the tiny mismatch introduced by a low-grade sma to n adapter or misaligned bulkhead can erode the safety margin more quickly than in LTE-era links.

Outdoor hardware availability has also changed. IP-rated N-type connectors—straight, right-angle, and flange-mount—are no longer specialty items. Bulkhead units like 40420 and 08764, built with nickel-plated brass housings, gold-plated inner pins, and PTFE dielectric, support DC–6 GHz performance for mainstream wireless deployments. Meanwhile, high-frequency n male to sma female adapters like 51043 continue to serve microwave test needs up to 18 GHz, ensuring installers can standardize transition hardware instead of mixing and matching questionable third-party parts.

If your team works with wideband radios, or you’re evaluating outdoor units for enterprise Wi-Fi or private 5G nodes, link budgets need to reflect these new norms: fewer extra interfaces, higher-quality transitions, and greater emphasis on stable sma to n cable drops when clearance or vibration introduces risk.

3GPP Release-18 (5G-Advanced) frozen in 2024 to tighter RF budgets for field tests

With Release-18 in place, radios increasingly operate across more contiguous and fragmented spectrum. These environments magnify mismatch effects. A connector chain that once passed acceptance during LTE testing may now fall short by a few tenths of a decibel in return loss or insertion loss. Engineers observing field tests note that even small inconsistencies—like a slightly worn SMA port or a generic sma male to n female adapter—Show up faster under 5G-Advanced’s wide instantaneous bandwidth.

This is why installers have started relying more on consistent hardware families. Adapters like 51045 maintain VSWR ≤ 1.2 across DC–18 GHz, giving crews confidence that their measurement error isn’t hiding behind connector imperfections.

IP-rated N-type families widely available(IP67 straight/RA/bulkhead) to standardize parts for CPE/antenna installs.

Outdoor units once required custom fabrication or unpredictable third-party parts to achieve IP67 sealing. Now IP-rated N-type hardware—both bulkhead and right-angle—is widely available, and field engineers can standardize enclosure penetrations using consistent geometry. For example, the sma to n adapter options across TEJTE’s 40420 / 08764 lineup all share the same 25×25 mm four-hole flange and predictable O-ring compression, which means installers can reuse drill patterns and torque practices across deployments.

The availability of right-angle and semi-rigid alternatives also helps. When antennas are mounted on tight steel poles or inside compact radio housings, a right-angle path built using SS402 (RM141) provides phase-stable routing up to 26.5 GHz, while still maintaining rugged outdoor durability.

How do you order the exact SKU with zero back-and-forth?

Ordering RF connectors should not feel like debugging. Yet in many organizations, purchase orders bounce back multiple times because direction, gender, flange style, or IP rating were unclear. A clean ordering process starts with mapping your ports, then describing the transition in unambiguous terms.

First, specify the direction: SMA-M to N-F, SMA-F to N-F, or the less common SMA-M to N-M. Then include your mechanical needs—straight, right-angle, or bulkhead. Outdoor installs must list the IP requirement. If you’re passing through a metal panel, note the panel thickness and confirm whether your adapter needs a 4-hole N type bulkhead like the 40420/08764 pattern.

High-frequency or test-bench orders should call out the desired bandwidth (DC–6 GHz vs DC–18 GHz) and the connector durability class. For instance, microwave labs often select 51043 or 51045 specifically because they hold performance under repeated torque cycles and maintain predictable return loss.

Specify: direction(SMA-M/F to N-M/F), straight/RA, bulkhead, IP rating, length fallback

A complete order sheet usually looks something like this:

- Interface direction: e.g., SMA-F to N-F

- Style: straight / RA / 4-hole bulkhead

- Frequency class: DC–6 GHz (40420 / 08764) or DC–18 GHz (51043 / 51045)

- IP target: IP67 for outdoor enclosure transitions

- Length fallback: if clearance is tight, specify a short sma to n cable (RG316 or SS402) as an alternative

Adding even a simple fallback—like “10 cm RG316 jumper if right-angle clearance fails”—prevents delays.

Add documents: RoHS/REACH, serialization, torque note

Procurement teams often forget documentation, yet these details prevent headaches later. RoHS/REACH compliance, batch serialization, and torque instructions help ensure consistency across deployments. Outdoor N-type hardware benefits especially from torque notes: over-torquing can deform the O-ring seat, while under-torquing fails IP67.

For bulk projects, many engineers attach a reference to their preferred connector family, such as “use the same flange pattern as the 40420 unit,” which cuts installation variation and reduces training time.

FAQ (Frequently Asked Questions)

1. Can I connect a router’s SMA port directly to an outdoor N-type antenna using a single adapter?

Yes—if both ends share 50-ohm impedance, using a single sma to n adapter is perfectly acceptable. This is actually a common pattern in outdoor CPE deployments. The only real requirement is matching direction and gender correctly (e.g., sma male to n female if your router uses SMA-F and the antenna uses N-M).

Where engineers sometimes run into trouble is not electrical, but environmental. SMA connectors were never designed for direct outdoor exposure, while N-type connectors are made for it. That means the SMA side should generally remain inside the enclosure, with the N-type side exposed externally. A bulkhead adapter—such as a 4-hole flange unit—keeps the SMA threads protected while allowing the N connector to mate outdoors with proper torque and boot/cap protection.

If the cabinet vibrates or cables hang off the port, consider using a very short sma to n cable (RG316 or SS402) to absorb mechanical stress. Electrically, the loss of a 10–15 cm jumper is negligible, usually well under 0.2 dB in the sub-6 GHz range.

2. Should I choose an adapter or a short SMA-to-N cable for the enclosure wall?

It depends on what’s happening mechanically at the wall. A bulkhead N type bulkhead solution is the cleanest choice when the transition must be sealed. Bulkhead adapters handle torque better than SMA ports and maintain a consistent O-ring compression across a wide temperature range (–45 °C to +125 °C).

A direct sma to n adapter works well if clearance is generous and nothing is tugging on the connector. But if the internal device is mounted on standoffs or the cabinet vibrates, installers often switch to a short RG316 jumper to isolate the SMA port. RG316’s small bend radius (15 mm) and modest attenuation make it the easiest flexible option.

For high-frequency test benches or microwave radios, engineers may choose SS402 (RM141) for stability. With ±5° mechanical phase stability at 18 GHz and a rugged FEP jacket, SS402 maintains performance even under repeated movement.

If sealing is the priority, the bulkhead wins. If strain relief is the priority, the short jumper wins.

3. Do I need a bulkhead to achieve IP67 on outdoor enclosures?

For practical outdoor deployments, yes. IP67 ratings rely on consistent mechanical compression—something a gland + cable combination rarely guarantees on its own. Bulkhead connectors designed for outdoor RF use integrate their O-ring at the correct depth, so the sealing force sits exactly where it needs to be.

A 4-hole N type bulkhead with a silicone O-ring maintains sealing even when the cabinet expands or contracts due to temperature changes. Direct cable pass-through methods can work, but installers often note inconsistent sealing over time, especially when using softer grommets that deform after months of UV exposure or cold snaps.

Another advantage: bulkheads move all torque to the metal flange, not the SMA port inside the cabinet. SMA threads are comparatively delicate, and high torque from an outdoor mate can twist the device’s internal connector. A bulkhead isolates that risk completely.

If your enclosure must face rain, dust, or salt air, a bulkhead is the most repeatable path to maintaining IP67.

4. What happens if I accidentally mix 50-Ω and 75-Ω N-type connectors?

Mixing is technically possible but rarely advisable. The impedance mismatch introduces reflection, and at higher frequencies (2–6 GHz), that reflection grows quickly. In many cases, you’ll see return loss fall below acceptable thresholds—especially if your system requires 14–20 dB of margin.

The mechanical differences are even more concerning. 75-Ω N-type connectors use a thinner center pin. If you mate a 75-Ω male into a 50-Ω female, you risk permanently spreading the female contact fingers. After that, even a correct 50-Ω pin may wobble or show inconsistent VSWR, forcing an early connector replacement.

If your chain includes SMA at any point, always standardize on 50-ohm N-type parts to keep continuity predictable. This avoids both performance drift and long-term mechanical damage.

5. How weatherproof are IP67 N-type connectors in real deployments?

IP67 hardware, including outdoor N-type connectors, is designed to survive dust and temporary submersion, but installers shouldn’t confuse that with full-time immunity. Water ingress usually doesn’t occur through the front face—it sneaks in through improper torque, a misaligned O-ring, or a cracked boot after months of UV exposure.

For mated joints, rubber boots protect the coupling while a simple drain loop in the cable routing prevents water from creeping along the braid toward the connector. For unmated ports, dust caps with internal gaskets help prevent oxidation or contamination that can degrade insertion loss during later maintenance.

Engineers in coastal regions sometimes apply a thin dielectric grease on the gasket side to slow corrosion. As long as the O-ring is seated correctly and torque is applied properly, an IP67 N-type interface remains extremely reliable across harsh temperature swings.

6. What changed with 5G-Advanced that affects SMA-to-N outdoor links?

5G-Advanced (3GPP Release-18) increases instantaneous bandwidth in several mid-band and C-band allocations. Wider bandwidth amplifies every reflection and every mismatch in your connector chain. A link that passed comfortably during LTE testing may now sit closer to the margin, especially if the SMA port has seen wear or the sma male to n female adapter has accumulated minor thread damage.

Field teams also report that unit-to-unit variability becomes more visible during 5G-Advanced verification. To reduce error bars, they rely on consistent connector families—bulkhead N-type transitions for the enclosure wall, and DC–18 GHz adapters like 51043 or 51045 for measurement points. Cleaner hardware means fewer “mystery losses” during drive tests or site acceptance.

7. Are right-angle SMA to N adapters worse than straight versions?

Straight adapters almost always offer slightly better VSWR because the internal geometry stays aligned with the signal path. Right-angle adapters introduce a bend, and that bend can shift the internal field distribution enough to increase minor reflections.

But performance isn’t the whole picture. In cramped cabinets or tight outdoor housings, a straight adapter may force the cable to bend sharply, placing stress on the SMA port. In those cases, many installers treat a short jumper—RG316 for flexibility or SS402 (RM141) for phase-critical work—as the “right-angle” solution. The electrical penalty is small, and the mechanical reliability improves dramatically.

If space isn’t an issue, straight versions are ideal. If it is, a stable jumper becomes the safer choice.

Conclusion

SMA-to-N transitions may look small, but they shape the reliability of long-term outdoor RF links. With wider bands appearing in 5G-Advanced deployments and IP67 expectations rising across enterprise networks, engineers can no longer rely on whatever adapter happens to be in the toolbox. Real-world components—bulkhead units like 40420 / 08764 for enclosure walls, precision adapters like 51043 / 51045 for high-frequency work, and stable jumpers like RG316 or SS402—give installers predictable behavior across temperature swings, vibration, and wideband operation.

By mapping direction properly, choosing the right flange or right-angle approach, budgeting insertion loss, and standardizing ordering details, field teams cut failures dramatically. And when the chain runs from an indoor SMA port to an outdoor N-type antenna, a carefully chosen sma to n adapter becomes more than a convenience—it becomes part of the link’s structural integrity.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.