SMA RF Cable Selection and Application Guide

Feb 16,2026

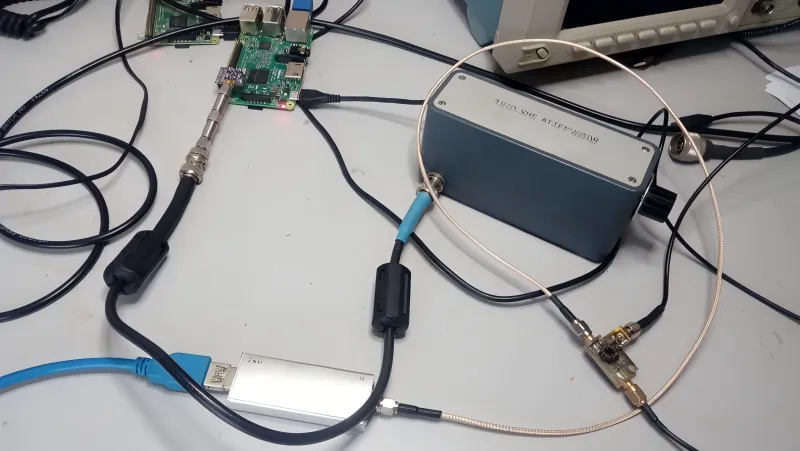

This introductory figure shows a typical SMA RF cable assembly, setting the stage for the guide's core argument: that cables are often overlooked but play a critical role in link margin, VSWR, and measurement repeatability. The surrounding text emphasizes that cables rarely create clean failures but quietly erode performance, making deliberate selection essential.

In RF systems, cables almost never get blamed first. When a link underperforms, engineers tend to look at the radio, the antenna, or firmware settings. The sma rf cable sitting between them is usually treated as background hardware—something passive, assumed stable, and rarely questioned.

That assumption causes problems.

An SMA RF cable rarely creates a clean failure. More often, it quietly reduces link margin, shifts VSWR, or makes measurements sensitive to handling and routing. Designs that appear solid during bring-up begin to drift once they leave the lab. That’s why sma rf cable selection deserves to be treated as part of RF system design, not as a last-minute accessory choice.

If you’re building a broader RF interconnect strategy, this article fits naturally alongside a system-level view like the RF Connector Guide for Cables, Antennas and Test Systems, but here the focus stays tightly on cables.

Map where an SMA RF cable actually sits in your RF link

This figure illustrates the typical placement of an SMA RF cable within an RF link, connecting a radio module to an antenna via board-mounted SMA connectors and the cable itself. The surrounding text distinguishes SMA RF cable from generic SMA cable, noting that RF-grade cables are chosen for predictable electrical behavior, while generic versions may be adequate for less critical applications. The image helps engineers visualize the cable's role as part of a complete signal chain, not an isolated component.

Clarify how SMA RF cable differs from generic SMA cable

Online listings often blur terms like sma cable, sma coax cable, and sma coaxial cable. Electrically, they may all be 50-ohm assemblies with SMA connectors. Functionally, they serve different expectations.

An sma rf cable is typically chosen for predictable RF behavior: controlled insertion loss, stable impedance, and repeatable performance across frequency and temperature. Generic “SMA cable” products are often aimed at antenna extensions or consumer equipment, where absolute repeatability is less critical.

This distinction matters when your link budget assumes known loss and stable VSWR. Treating all SMA cables as interchangeable works on the bench—until it doesn’t.

Trace typical paths: radio – SMA connector – SMA RF cable – antenna

A common RF path looks straightforward: RF IC or module → board-mounted SMA → sma rf cable → antenna or test instrument.

In real products, that path is rarely so clean. Compact radios may expose internal connectors, while the enclosure requires SMA on the panel. Short jumpers, adapters, or transition cables get added quietly. Each transition introduces loss and a potential impedance discontinuity.

Seeing the entire path early—rather than focusing on the cable alone—helps explain why systems with identical radios and antennas behave differently once assembled.

How do you translate RF specs into SMA RF cable requirements?

Start from link budget, not from cable length

One of the most frequent errors is choosing cable length first and checking loss later. A better approach starts with the link budget. How much loss can the system tolerate before performance degrades?

Once allowable path loss is defined, the acceptable sma rf cable loss becomes a design constraint. Cable length, diameter, and construction follow from that constraint—not the other way around.

This way of thinking mirrors how engineers approach amplifiers or filters. Cables deserve the same discipline.

Convert power, frequency and VSWR targets into cable specs

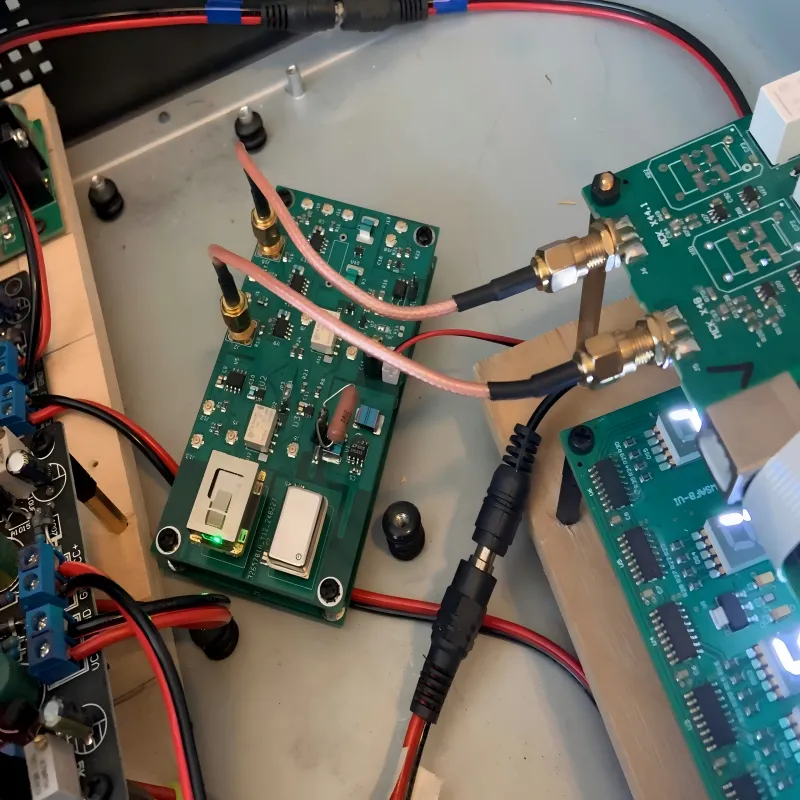

This figure likely depicts the relationship between system-level requirements (frequency, power, VSWR) and the resulting cable specifications (attenuation, impedance, construction). The surrounding text emphasizes that cable selection should start from the link budget, not cable length. Frequency drives attenuation, power affects dielectric limits, and VSWR defines mismatch tolerance. The image visually reinforces this top-down design approach, helping engineers avoid the common mistake of choosing cable length first and checking loss later.

Frequency drives attenuation. Power affects dielectric heating and connector limits. VSWR targets define how tolerant the system is to small mismatches.

At lower frequencies and short runs, thin options like rg316 coaxial cable are often sufficient. As frequency increases or runs get longer, that same rg316 cable can consume margin faster than expected. In those cases, thicker or lower-loss alternatives become necessary.

If you already work with RG families in other parts of your system, it’s useful to anchor cable decisions to a broader reference such as the RG Cable Guide, then narrow down to SMA-terminated assemblies.

Define minimum datasheet parameters for SMA RF cable

Any sma rf cable intended for an engineered RF system should clearly specify:

- Characteristic impedance (50 ohms)

- Rated frequency range

- Insertion loss versus frequency

- Return loss or VSWR

- Shield construction and coverage

- Minimum bend radius

- Operating temperature range

When these details are missing or vague, the cable may still pass signal—but it’s a weak foundation for predictable RF performance.

Segment SMA RF cable choices by frequency, power and environment

Group SMA RF cable for sub-1 GHz, 2.4 GHz and 5–6 GHz use

Below 1 GHz, RF loss is relatively forgiving. Many sma coax cable assemblies perform adequately, even with smaller diameters.

At 2.4 GHz, losses rise quickly. Short rg316 coaxial cable jumpers are common in Wi-Fi and IoT devices, but length discipline becomes important. What works at 20 cm may not scale to several meters.

At 5–6 GHz, tolerances tighten further. Cable construction, shielding quality, and connector consistency start to dominate performance. Small routing changes can produce measurable effects.

Match SMA RF cable diameter to power handling and routing constraints

Thin cables route easily and tolerate tighter bends. Thicker cables reduce loss and handle more power but demand space and proper strain relief.

The trade-off is unavoidable. In dense enclosures, routing constraints may force a smaller diameter even if loss increases slightly. In longer external runs, lower loss may justify the added stiffness.

Choose jacket and shielding for indoor vs outdoor vs vehicle

Indoor lab environments are forgiving. Outdoor enclosures and vehicle installations are not.

Jacket material, braid coverage, and sealing at the SMA interface often determine whether an sma rf cable survives UV exposure, moisture, vibration, and temperature cycling. Many field failures trace back not to RF specs, but to environmental mismatch.

Can you reuse one SMA RF cable design across lab, field, and production?

On paper, reusing one sma rf cable everywhere looks efficient. Fewer part numbers. Fewer mistakes during purchasing. Less time explaining differences to new team members.

In real projects, that simplicity rarely survives contact with hardware.

Lab setups, field installations, and production harnesses stress cables in very different ways. Trying to force one design to satisfy all three usually means it does none of them particularly well.

Compare lab-grade SMA RF test cables vs field harnesses

Lab-grade SMA RF cables are built for stability, not survival. They’re optimized to behave the same today as they did yesterday. Phase stays consistent. Insertion loss doesn’t drift when the cable is nudged. Torque feels repeatable.

Field harnesses live in a different world. They get pulled, twisted, routed around sharp corners, and sometimes installed by people who don’t think about minimum bend radius. Durability matters more than measurement purity. Cost matters too, once quantities grow.

This mismatch explains a common frustration: a system that measures cleanly on the bench but becomes unpredictable after installation. The radio didn’t change. The antenna didn’t change. The cable environment did.

Most experienced teams end up separating these roles, even if both cables terminate in SMA.

Decide when MMCX to SMA adapters belong in the path

Small RF modules often expose an mmcx connector instead of SMA. It’s not a downgrade. MMCX exists because space, weight, and mating force matter in compact designs.

What usually happens next is predictable. A short mmcx cable adapts the module to the enclosure, where everything else expects SMA. Sometimes this is done with a single mmcx to sma connector. Sometimes with a cable plus an mmcx to sma adapter. Sometimes with both.

Electrically, each transition is a small discontinuity. One is rarely a problem. Several stacked together can be. The issue isn’t that MMCX is “worse” than SMA. It’s that transitions added late tend to accumulate without scrutiny.

A good rule of thumb is intent. If MMCX is used internally and the transition to an external sma rf cable is mechanically stable, the RF impact is usually manageable. Letting adapters pile up because “they were already there” is where systems quietly lose margin.

Set clear roles for “golden” SMA RF cables in validation

Many RF teams keep a few trusted sma rf cable assemblies that never leave the lab. They’re short. They’re low loss. They’re handled carefully and replaced early.

These cables aren’t special because of branding. They’re special because their behavior is known. When results shift while using a golden cable, engineers know the problem is almost certainly elsewhere.

It’s an informal practice, but it’s one of the simplest ways to keep validation results meaningful.

Control loss, VSWR, and shielding in SMA RF cable runs

Estimate insertion loss for common SMA RF cable families

Loss numbers are often quoted as properties of the cable alone, but in practice they belong to the entire path. Thin cables like rg316 coaxial cable show higher attenuation as frequency increases, especially compared to thicker alternatives.

That doesn’t make RG316 a poor choice. It makes it a bounded one. Short internal runs tolerate the loss easily. Longer runs may not.

Connector losses and transitions matter too. Engineers sometimes underestimate how quickly a few tenths of a decibel add up. If you want a refresher on why attenuation rises with frequency in coaxial structures, the general explanation of coaxial signal behavior on Wikipedia gives useful background without diving into vendor data.

Keep SMA RF cable bends and tie-downs within safe limits

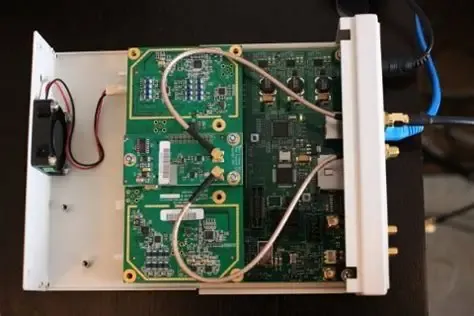

This figure illustrates the importance of respecting minimum bend radius for SMA RF cables, especially near connector terminations. Tight bends locally distort impedance and can cause long-term reliability issues. The surrounding text notes that mechanical handling changes RF behavior subtly—systems often pass initial tests but degrade after routing is finalized or during maintenance. The image visually contrasts correct and incorrect bending practices, emphasizing that respecting bend radius preserves performance without added cost.

Mechanical handling changes RF behavior in subtle ways. Tight bends locally distort impedance. Over-tightened zip ties compress the dielectric. Repeated flexing creates small variations that don’t show up immediately.

What makes this tricky is that systems often pass initial tests. Problems appear later, after routing is finalized or cables are disturbed during maintenance.

Respecting bend radius and avoiding unnecessary stress doesn’t add cost. It preserves performance that would otherwise disappear quietly.

Manage ground references and panel transitions for SMA RF cable

Panel-mounted SMA connectors deserve more attention than they usually get. Poor bonding between the connector body and the chassis interrupts shield continuity and increases susceptibility to noise.

Bulkhead transitions should be treated as part of the grounding system, not just mechanical fixtures. This is especially important in mixed-signal designs where RF shares space with fast digital edges.

Understanding how SMA interfaces are defined mechanically and electrically—details summarized in the general SMA connector reference on Wikipedia—helps explain why small mounting choices can have measurable RF consequences.

How should you choose between RG316, RG58, and low-loss SMA RF cables?

Compare RG316 SMA RF cable vs thicker alternatives

This figure shows a side-by-side comparison of an RG316-based SMA RF cable and a thicker alternative (such as RG58 or low-loss coax). The surrounding text explains that RG316 is popular for its flexibility and compactness, making it ideal for dense enclosures, while thicker cables offer lower loss at higher frequencies but are stiffer and require more space. The image helps engineers visualize the trade-off between mechanical flexibility and electrical performance, emphasizing that neither is inherently better—they solve different problems.

RG316 SMA RF cable is popular because it fits where other cables don’t. It’s flexible, compact, and tolerant of high temperatures. For short runs in dense enclosures, it’s often the right answer.

Thicker cables like RG58 or LMR-style assemblies reduce loss, especially at higher frequencies. The trade-off is stiffness and connector stress if strain relief is inadequate.

Neither option is inherently better. They solve different problems.

Decide when a semi-rigid or low-loss SMA RF cable is justified

Semi-rigid and ultra-low-loss cables earn their place when margins are tight. Long runs, higher frequencies, or systems operating close to sensitivity limits justify their cost and installation effort.

Using them everywhere rarely does. In short internal jumpers, the benefit is often theoretical, while the assembly complexity is very real.

Factor connector quality and plating into the decision

Cable discussions often focus on the coax itself, but connectors dominate long-term reliability. Plating quality, material choice, and assembly consistency matter as much as dielectric specs.

A modest cable with well-made connectors often outperforms a premium cable terminated poorly. This is why connector standards and mating expectations—outlined in general RF connector references—remain relevant long after the cable type is chosen.

Verify SMA RF cable quality with simple bench tests

This figure depicts a basic bench test setup for verifying SMA RF cable integrity, likely showing a technician gently moving (wiggling) the cable near connectors while monitoring signal level or continuity. The surrounding text explains that cable problems often don't announce themselves—continuity checks, insulation resistance tests, and the wiggle test can catch intermittent faults that would otherwise cause instability later. The image reinforces the practical advice that simple, low-cost checks are often sufficient to identify marginal cables before they become field issues.

Run basic continuity, insulation, and wiggle tests

The simplest tests are still useful. Continuity checks catch assembly mistakes and broken shields. Insulation resistance checks reveal contamination or partial shorts that don’t show up immediately.

The most underrated test is the wiggle test. While monitoring signal level or continuity, gently move the cable near each connector and along tight bends. If readings jump, the cable is already marginal.

This kind of instability often passes initial bring-up, then resurfaces later when cables are re-routed or touched during maintenance.

Use return-loss or S-parameter checks when equipment is available

When a VNA or tracking source is available, return loss and insertion loss measurements provide far more insight. Look for smooth, repeatable curves across the intended band.

What matters is not just the absolute number, but how stable it is. If touching or slightly bending the sma rf cable causes visible changes, the issue is mechanical, not theoretical.

Engineers new to S-parameters often benefit from revisiting the fundamentals of scattering parameters and impedance behavior, which are summarized well in general RF measurement references such as the Wikipedia overview of S-parameters.

Apply an SMA RF cable loss & margin scorecard

SMA RF Cable Loss & Margin Scorecard

| Field | Description |

|---|---|

| Frequency_GHz | Operating frequency (GHz) |

| Cable_Type | RG316, RG58, LMR-200, etc. |

| Loss_dB_per_m_at_Freq | Cable loss at frequency (dB/m) |

| Cable_Length_m | Cable length (m) |

| Connector_Count | Total RF connectors in path |

| Connector_Loss_dB_each | Estimated per-connector loss (0.1–0.2 dB) |

| Extra_Margin_Target_dB | Target margin (default 6 dB) |

| Budgeted_Path_Loss_dB | Max allowable system path loss |

| Calculated_Cable_Loss_dB | Loss_dB_per_m × Length |

| Calculated_Connector_Loss_dB | Connector_Count × Loss_each |

| Total_Path_Loss_dB | Cable + connector loss |

| Remaining_Margin_dB | Budgeted − Total |

| Risk_Score (0–1) | 0.2 healthy / 0.6 caution / 0.9 high risk |

Rules of use

- Remaining_Margin_dB < 3 dB → redesign required

- 3–6 dB → monitor closely in field tests

- ≥ 6 dB → generally healthy design

This scorecard turns cable discussions from opinion into engineering decisions.

How are 5G and IoT trends reshaping SMA RF cable usage?

Track demand for micro-coax SMA RF cable assemblies

In 5G and IoT hardware, density keeps increasing. Radios shrink. Antennas multiply. Internal routing space disappears.

As a result, micro-coax assemblies—often variants of rg316 cable or similar families—are increasingly terminated with SMA at system boundaries. The SMA interface remains familiar and serviceable, while the internal cable gets thinner and more constrained.

This trend shows up clearly in small-cell equipment, IoT gateways, and test fixtures built around modular radios.

Note design shifts toward higher density and higher frequency

Wi-Fi 6E and 5G FR1 push more systems into the 5–7 GHz range. At these frequencies, sma rf cable behavior becomes less forgiving.

Loss budgets tighten. Return loss becomes more sensitive to routing and connector quality. Cables that were “good enough” at 2.4 GHz suddenly matter.

This is one reason many teams revisit cable choices late in a project, even when the connector type hasn’t changed.

Highlight recent product patterns using SMA RF cable assemblies

Modern RF products often combine short internal micro-coax runs with external SMA jumpers. The SMA remains the user-facing interface, while the internal cable is optimized for density.

This hybrid approach preserves serviceability without sacrificing layout flexibility. It also reinforces why treating all SMA cables as interchangeable is no longer realistic.

Plan spares, documentation, and lifecycle for SMA RF cables

Standardize part numbers and drawings for SMA RF cables

Clear part definitions matter. Length, cable family, connector gender, plating, and torque notes should all be explicit.

Ambiguity invites substitutions. Substitutions introduce variability. Variability shows up as field issues months later.

Many teams regret not documenting sma rf cable assemblies as carefully as active RF components.

Define inspection intervals and replacement rules

Cables wear out quietly. Track insertion cycles. Watch for jacket cracking, connector looseness, or changes during wiggle tests.

Replacing a marginal cable early is cheaper than debugging an intermittent RF problem in the field.

Capture lessons learned from field failures back into design

Every failed cable tells a story. Maybe bend radius was too tight. Maybe an external run needed better sealing. Feed those lessons back into the selection rules discussed earlier.

This feedback loop is how RF designs actually improve over time.

Frequently Asked Questions

Is SMA RF cable the same as an SMA antenna cable?

Not exactly. Antenna cables usually assume fixed length and outdoor exposure. Sma rf cable is a broader category that includes jumpers and test leads with tighter RF performance expectations.

How long can an RG316 SMA RF cable run at 2.4 GHz before loss becomes an issue?

Short runs—typically a few meters—are common. Beyond that, margin calculations should drive the decision, not habit.

Can I mix SMA RF cables from different vendors in the same system?

You can, but consistency suffers. Mixed sources often increase unit-to-unit variation.

Is RG316 a good default for compact IoT designs?

Often yes for short runs at 2.4 GHz. For longer runs or higher frequencies, reassess.

Do SMA RF test cables need different specs from production harnesses?

Yes. Test cables prioritize stability and repeatability, not cost or durability.

Can one SMA RF cable design serve both 5G FR1 and Wi-Fi 6E?

Sometimes, but near 6 GHz tighter loss and VSWR control often require different cable choices.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.