SMA Male to SMA Female: Direction Check & 50-Ω Ordering Guide

Dec 03,2025

Figure serves as the document’s “physical anchor.” Before delving into abstract concepts like directionality and impedance matching, it first confirms for the reader the specific object being discussed. A high-quality product close-up (likely including brand logos and clear pin/hole details) not only establishes professionalism but also immediately immerses the reader in a concrete engineering decision-making scenario: how to correctly select and use the type of connector shown. It provides a unified visual reference for all subsequent direction checks, solution comparisons, and ordering guidelines.

Are You Sure You Need SMA Male to SMA Female for This Chain?

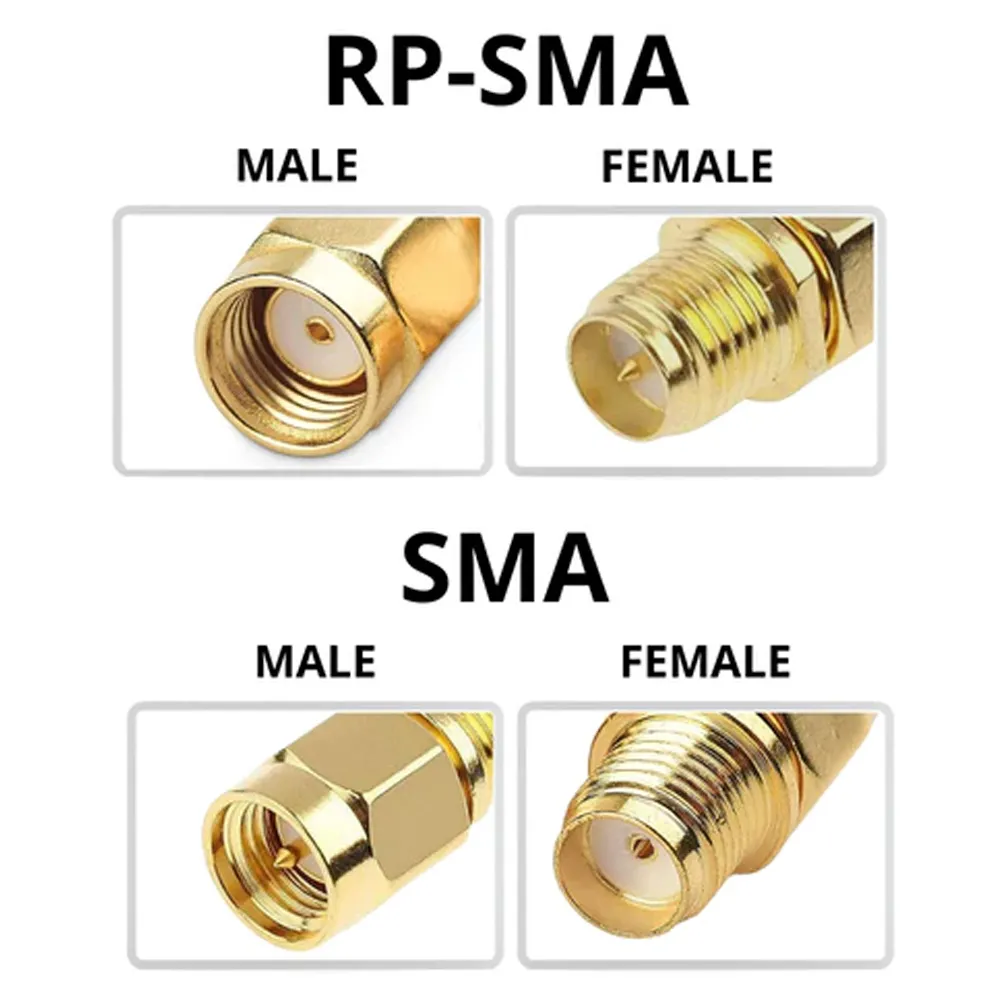

Figure plays a key role as a “pitfall avoidance guide.” It juxtaposes two connector variants that look similar but have opposite polarities and are incompatible, emphasizing the necessity of careful identification in specific scenarios like Wi-Fi equipment and antenna testing. This figure is the first line of defense against low-level but costly mistakes.

If you’ve ever mixed SMA connectors on a bench, you know the pain of realizing—too late—that the direction is reversed. SMA male to SMA female may sound obvious, but mis-ordering costs teams hours of rework and shipping delays. The error usually comes down to how we read “male/female” and the confusing mix of “plug/jack” labels in different datasheets. In a rush to prototype or debug, it’s easy to get one end wrong.

A quick visual rule helps:

- Male = pin inside a threaded outer shell.

- Female = hole with outer threads visible.

Yet, you’ll still see some vendors use jack for the female threaded side and plug for the male one. That contradiction trips many engineers new to RF. At TEJTE’s RF connector page, you can verify each end with clear pin photos before ordering.

Before placing a PO, map your DUT (device under test) and instrument ports on paper. Mark which side is female and male. If you’re bridging between two males on a scope and module, you need a female-to-female adapter or a short jumper with those ends. That one-minute sketch prevents mix-ups that otherwise show up at the worst time — during a tight validation window.

For tight racks or panel mounts, double-check the orientation too. If the male side is buried inside an enclosure, consider using a bulkhead feedthrough such as TEJTE’s SMA-KF series to keep the external interface female. That simple mechanical decision saves both torque wear and finger room later.

Should You Use a Gender-Changer Adapter or a Short Extension Cable?

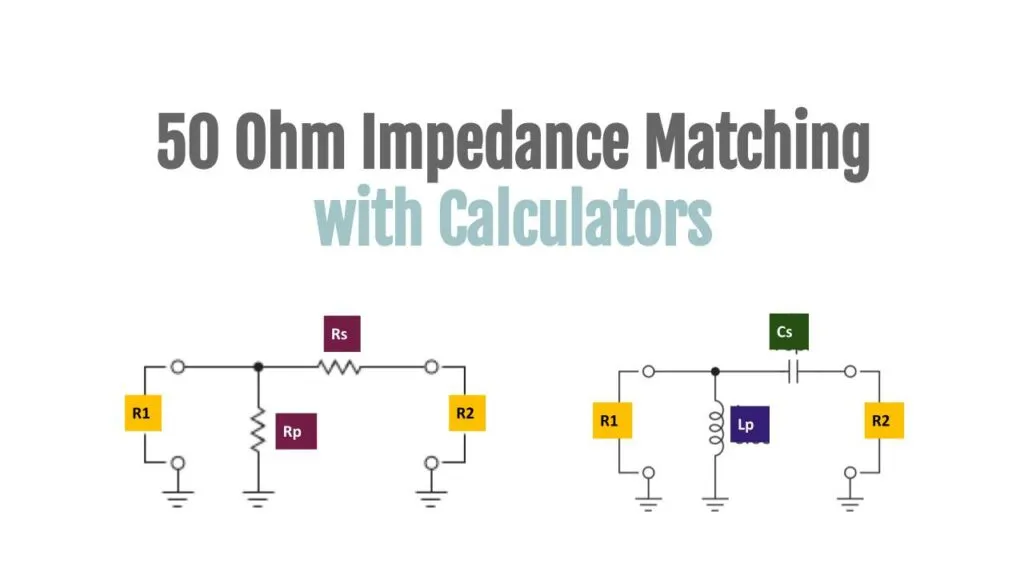

Figure visualizes engineering decision-making. It guides readers to think beyond “as long as it connects” and consider the cost of each interface in the link. The adapter solution represents “minimizing physical size,” while the short extension cable solution represents “optimizing mechanical and electrical performance.” This figure is the foundation for understanding subsequent discussions on cumulative insertion loss and mechanical reliability.

The moment you discover a direction mismatch, the quick fix is tempting — grab a small adapter and bridge the gap. Yet that tiny metal block can quietly undermine signal integrity. A better option is often a short SMA extension cable, typically 0.3 to 0.6 meters long, built with a 50-Ω RG316 coax core.

Adapters add two extra interfaces. Each joint introduces tiny impedance discontinuities and a fraction of a decibel of insertion loss. It doesn’t sound like much — 0.1 dB here, 0.2 dB there — but on a 6 GHz bench chain, that stack builds up fast. Over time, these interfaces also become mechanical stress points when cables move or the bench vibrates.

A short SMA extension cable acts as a flexible buffer. It absorbs motion and reduces side loads on the instrument port. If your oscilloscope or spectrum analyzer ports are frequently connected and disconnected, use a 0.3 m jumper to take the abuse instead of the scope’s front-end connector. This approach is standard in RF labs where reliability and repeatability matter more than saving $10 on a part.

That said, inline gender-changers still have their place. On a fixed bench where nothing moves, a compact adapter can cleanly close a direction gap without clutter. Choose a precision 50-Ω unit with gold-plated contacts and torque it lightly to 8 lbf-in. Never stack more than two adapters in series; if you see a “tower,” it’s time to redesign the path or order a custom jumper from TEJTE’s RF cable assembly page.

How Do You Keep a True 50-Ω Match End-to-End?

Figure is an instructional diagram connecting theory and fault phenomena. It helps engineers develop a holistic view that “the entire signal chain is a transmission line system,” understanding how local discontinuities (even a small connector or a misused cable segment) can affect overall measurement accuracy. This figure enhances the reader’s ability to diagnose intermittent issues in complex systems.

Once you’ve locked in the direction and the hardware type, the real question is how to preserve a clean 50-Ω impedance across the entire chain. At microwave frequencies, even a small mismatch shows up as ripple on a VNA trace or a ghost in your time-domain capture. Here’s what usually breaks the match — and how to avoid it.

- Eliminate accidental 75-Ω video leads.

Many labs keep old CCTV coax around, and its BNC ends look identical to RF ones. A single 75-Ω segment in a 50-Ω line causes return-loss drops of 5–10 dB. Label and color-code your cables to prevent mix-ups.

- Standardize terminators and couplers.

Always check that terminators and splitters match the same impedance rating. Mixing 50 and 75 ohms leads to measurement errors and wasted calibrations. At TEJTE, all bench-grade adapters are clearly marked “50 Ω” on the body for this reason.

- Use proper torque and strain relief.

Loose connectors are a silent killer of return loss. Tighten to 8–10 lbf-in for SMA, and support the cable so its weight doesn’t pull the joint sideways. Use strain-relief boots or mount a feedthrough adapter on panels to take stress off the core.

- Minimize interfaces.

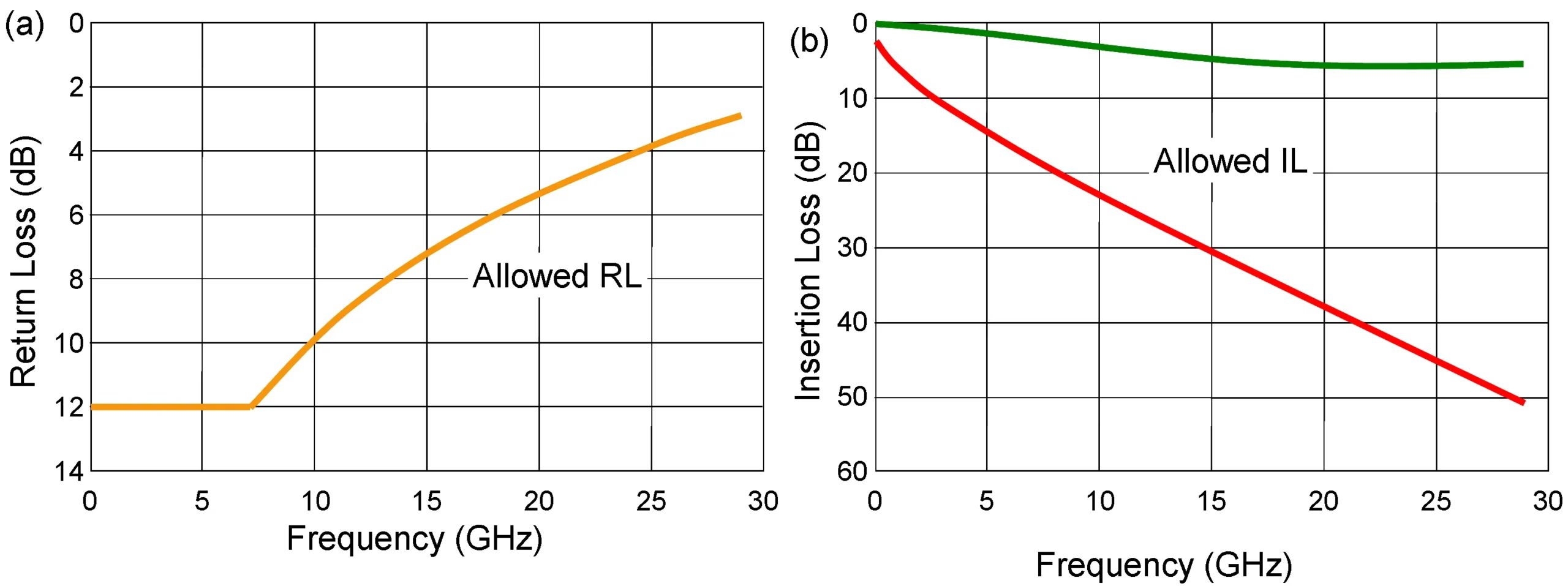

Figure is a key tool for transforming qualitative advice into quantitative analysis. It turns the textual statement “each extra connector adds tiny reflections” into intuitive, measurable graphical evidence. The “Allowed RL/IL” threshold lines in the graph serve as clear “pass/fail” criteria, enabling engineers to quickly assess the compliance of their designed link or existing setup. This method of data visualization significantly enhances the persuasiveness and practical value of the technical guide, helping readers develop data-driven decision-making skills.

Each extra connector adds tiny reflections. Keep chains simple: DUT to extension jumper to instrument. Fewer interfaces mean better VSWR and fewer retest headaches.

For most benches, aim for return loss ≥ 20 dB and insertion loss < 0.5 dB total over the chain. Our calculator in the later section lets you estimate these in two minutes before you even touch a VNA.

Which Cable Family Fits: RG316 vs RG174 at Your Length/Frequency?

Figure elevates cable selection from empiricism to data-driven decision-making. It not only shows appearance differences but, more importantly, reveals quantified disparities in electrical performance (attenuation vs. frequency) and mechanical characteristics (minimum bend radius). This figure is crucial for designing high-frequency (e.g., Wi-Fi 6E/7) test links or space-constrained embedded applications.

Choosing between RG316 and RG174 looks simple until you measure real-world loss. Both are 50-Ω miniature coax cables widely used for SMA male to SMA female jumpers, but they behave differently once frequency and environment come into play.

RG174 is thinner (≈ 2.8 mm OD) and more flexible, perfect for very tight enclosures or pigtails inside housings. Yet its attenuation climbs fast beyond 3 GHz—around 1.1 dB per meter at 2 GHz, doubling near 6 GHz. In contrast, RG316 coax (≈ 2.5 mm OD but with Teflon dielectric and silver-plated braid) offers lower loss—≈ 0.6 dB/m @ 2 GHz—and retains stability up to 6 GHz and beyond.

If your setup involves Wi-Fi 6E, 5 GHz test loops, or Wi-Fi 7 validation benches, RG316 clearly wins. For short control lines below 2 GHz, RG174 remains acceptable.

| Cable Family | Outer Dia (mm) | Loss @ 2 GHz (dB/m) | Max Usable GHz | Min. Bend Radius (mm) | Typical Use |

|---|---|---|---|---|---|

| RG316 | 2.5 | 0.6 | 6 | 12 | Bench coax jumpers / Wi-Fi 6E links |

| RG174 | 2.8 | 1.1 | 3 | 10 | Internal pigtails / control signals |

For cramped panels, RG174’s smaller bend radius can still help. The key is respecting each cable’s bend limit—about 5× diameter for semi-rigid, 10× for flexible types. Exceeding that radius causes impedance ripple. TEJTE’s RG316 cable assembly line includes right-angle boots and heat-shrink reliefs that preserve matching even under repeated bending.

If you often replace test cables, pre-define three standard lengths: 0.3 m / 0.5 m / 1.0 m. These cover most lab distances between a DUT and instrument without leaving coils of unused slack that act as antennas. For multi-GHz work, keep jumpers under 0.5 m wherever possible—signal integrity loves short paths.

Flexibility vs Loss: Bending Rules and Boot Choices

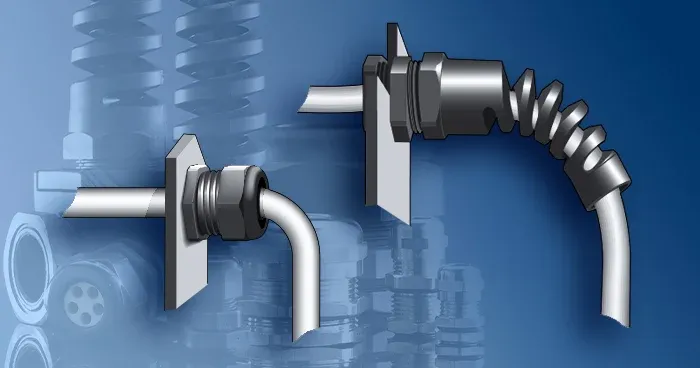

Figure focuses on an often-overlooked detail for the long-term reliability of RF links—mechanical protection. It conveys a simple engineering wisdom: even the best cable will fail if installed improperly. The strain relief boot is a low-cost, high-return solution. This figure guides engineers on how to apply it correctly, translating theoretical cable bend radius specifications into executable installation practices.

Inside compact boxes, cables tend to snake around shielding walls or modules. Using RG316 pigtails with slim straight or right-angle SMA connectors lets you route signals cleanly while maintaining VSWR ≤ 1.25.

A simple rule engineers follow:

“If you have to bend tighter than your pinky, you’re already stressing the coax.”

Choose strain-relief boots rated for your bend radius—TEJTE offers gray silicone and black FEP types for high-temp builds. They absorb tension when someone yanks a cable during maintenance. Combine that with a bulkhead feedthrough (e.g., SMA-KF series) on the panel wall so the internal pigtail never twists with the outside connector.

Will a Right-Angle SMA End Help Mechanics Without Hurting RF?

Figure corrects a common misunderstanding and provides a solution. It clearly distinguishes between the electrical path and the mechanical path. The right-angle connector adapts to limited space by changing the mechanical exit direction, while internally maintaining a continuous 50-ohm transmission line through a precisely crafted 90-degree bend. This figure helps engineers make wise choices that ensure electrical performance without sacrificing reliability when facing spatial constraints.

Right-angle SMA connectors often raise eyebrows—“Won’t that bend kill my VSWR?” The truth: a quality right-angle SMA male to female assembly adds less than 0.05 dB insertion loss at 6 GHz if the elbow is properly machined and plated. What you gain in mechanical relief often outweighs that negligible loss.

In dense racks or small enclosures, a straight connector can protrude too far, colliding with walls or neighboring ports. A right-angle SMA extension cable routes sideways, cutting strain on the mating port. You also avoid repeated bending near the connector body—a common failure spot when users “loop” straight cables to fit space.

When is RA the safer choice?

- Panel clearance under 30 mm or overlapping port rows.

- Vertical instruments on benches where cables hang downward.

- Field modules subject to vibration; RA ends reduce lever-arm stress.

When to avoid it?

- Rotating test fixtures needing free cable spin.

- Environments demanding minimal mechanical joints.

Use RA to solve mechanics—not to correct layout mistakes. Don’t build “RF elbows” by stacking straight + RA + adapter + bulkhead. Each extra metal-air boundary adds reflections. If geometry is complex, specify a custom RG316 assembly with a pre-crimped RA end instead of chaining adapters.

What 2025 Test & Wireless Updates Raise the Bar for Clean SMA Chains?

Figure extends the document’s perspective from a static technical guide to dynamic technological evolution. It reminds engineers that best practices are not static but iterate with the development of measurement needs and industry standards. This figure aims to stimulate readers’ forward-thinking, helping them understand that investing in high-quality SMA interconnect solutions today is to better meet tomorrow’s technological challenges.

The RF bench isn’t static — each new generation of instruments and wireless standards tightens the rules on your SMA male to SMA female cabling. Here’s why cable discipline matters even more this year:

- Rohde & Schwarz MXO 3 Scopes

The MXO 3 series (4/8-channel) brings up to 2 GHz bandwidth in a compact frame. At that speed, a 0.5 dB loss means visible distortion. Short, matched SMA extension cables are no longer optional — they’re part of the measurement spec. (Source: R&S release 2025)

- Anritsu Site Master VNA/VVM Upgrade

Field technicians can now measure return loss and insertion loss on site without a full lab. That means you can verify a 50-Ω link right at the antenna feed using portable gear. (Source: Anritsu Tech News)

- Wi-Fi 7 Enterprise Rollouts (Windows 11 24H2)

Labs testing 6 GHz and 7 GHz channels face tight loss budgets. Keep jumpers ≤ 0.5 m and use RG316 or RG223 families with return loss ≥ 20 dB to stay compliant. (Adapted from TechCommunity @ Microsoft)

- 3GPP Rel-19 for 5G-Advanced

The new spec extends mmWave benchmarks and RF front-end validation to sub-THz bands. Every extra adapter counts. Matching connectors and torque tracking are now standard practice in test plans. (Based on 3GPP updates 2025)

In short, your next-gen lab is only as good as its shortest jumper. Treat each SMA interface like a component, not a commodity.

Frequently Asked Questions

1. How do I confirm I’m buying SMA-male to SMA-female and not the reverse?

Check the center contact: male has a pin, female a receptacle. Thread direction helps too — male threads inside, female threads outside. Mark the direction on your PO and spec sheet.

2. When is a short extension cable better than a gender-changer?

If your bench moves or the cable is handled frequently, a 0.3–0.6 m jumper reduces strain and keeps the chain 50 Ω. Inline gender-changers are fine only on fixed racks.

3. What’s a safe maximum length for Wi-Fi 7 or 6E at 5–6 GHz?

Stay below 0.5–1.0 m on RG316 coax. Beyond that, attenuation and phase error rise rapidly.

4. Does a right-angle SMA end add noticeable loss?

Not significantly (< 0.05 dB @ 6 GHz). It often improves strain relief and longevity if used properly.

5. Which cable should I buy for a router or antenna jumper?

Use a 50-Ω RG316 for tight bends or space-limited installs. RG223 or RG58 fit longer runs where loss margin is wider.

6. Can I verify 50-Ω match without a lab VNA?

Yes. Modern handheld VNAs like Anritsu Site Master offer VVM functions to check return loss in the field within ±0.5 dB.

7. What recent industry updates affect SMA jumper choices?

The R&S MXO 3 scopes, Wi-Fi 7 enterprise deployments, and 3GPP Rel-19 progress push labs toward stricter loss control — shorter, matched SMA male to SMA female cables are the new baseline.

8. Where can I order pre-tested SMA-M to SMA-F jumpers?

Figure is a natural transition from “knowledge sharing” to “value offering.” It shows readers that all the rigorous practices advocated in this document—direction verification, impedance matching, cable selection, quality control—can be efficiently achieved by choosing a reliable supplier (like TEJTE). This figure not only displays the product but also showcases the entire traceable, repeatable quality management system behind it, providing engineers with a worry-free and reliable procurement solution.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.