SMA Male-to-Male Cable RG316/RG316D: Specs & Ordering Guide

Sep 27,2025

Introduction

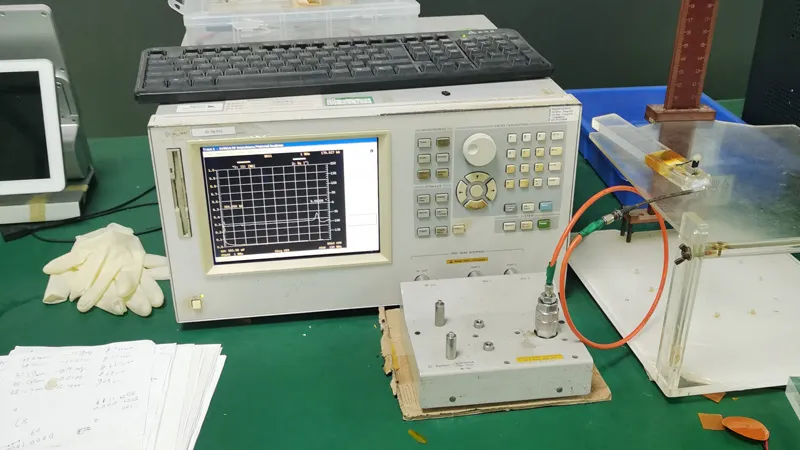

This introductory figure highlights the practical considerations when choosing between RG316 and its enhanced version, RG316D, for SMA male-to-male cable assemblies, focusing on their construction, signal loss characteristics, and application scenarios to prevent post-installation issues.

When engineers talk about an SMA male-to-male cable, two names almost always come up: RG316 and its tougher cousin, RG316D. Both are rated at 50 ohms, wrapped in flexible FEP jackets, and at first glance look nearly identical. But once you start working with them, the differences show up quickly—in shielding, attenuation, and how much heat they can take.

This guide isn’t just a pile of specs. It’s about making practical choices: how far you can run an RG316 cable before the SMA cable loss eats into your link budget, when a right-angle connector is smarter than forcing a bend, and why RG316D’s dual shielding is worth it in noisy environments.

A quick tip from field experience: many people only realize the limits of RG316 after installing a Wi-Fi or LTE setup and wondering why the signal suddenly dropped. Knowing the loss figures, bend radius, and shielding differences up front can save you hours of troubleshooting later.

How do I choose between RG316 and RG316D?

Construction & materials: silver-plated copper, PTFE, FEP jacket

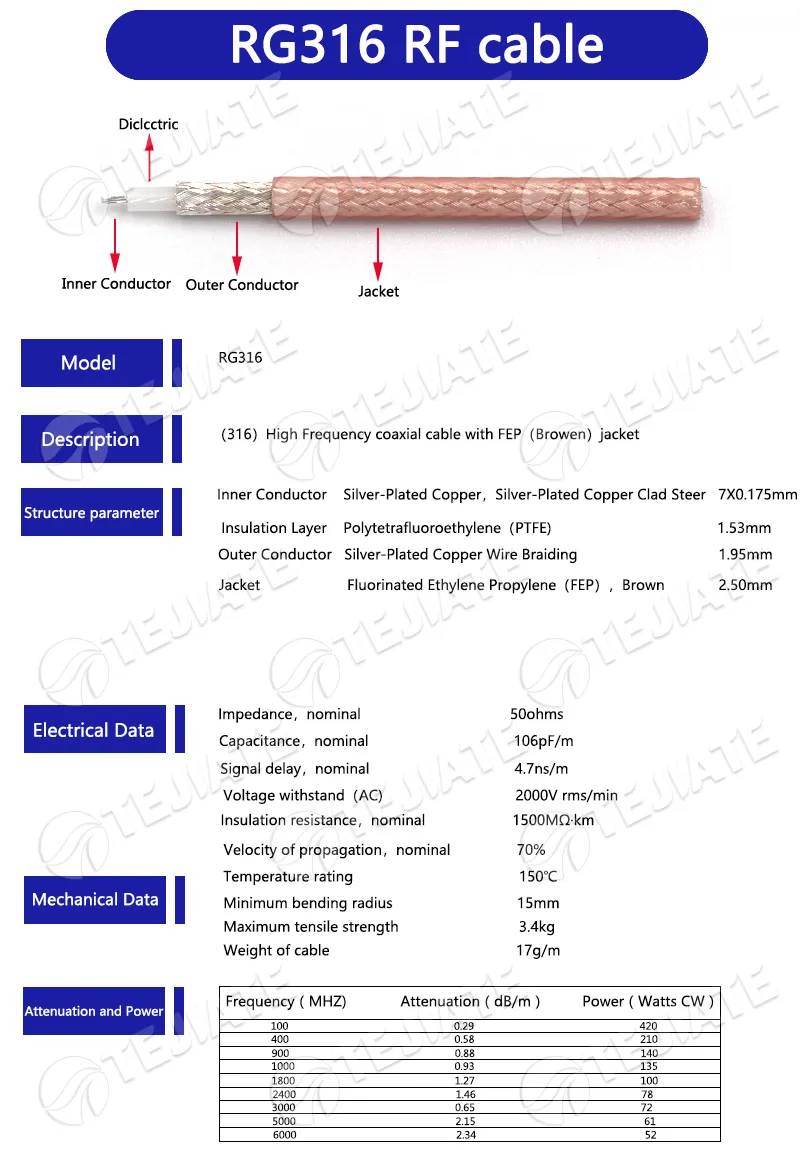

Provides a detailed cutaway view and tabulated specifications for the RG316 cable, including its inner conductor, dielectric, shielding, jacket materials, impedance, capacitance, attenuation values at various frequencies, power handling, mechanical data like bend radius, and temperature rating.

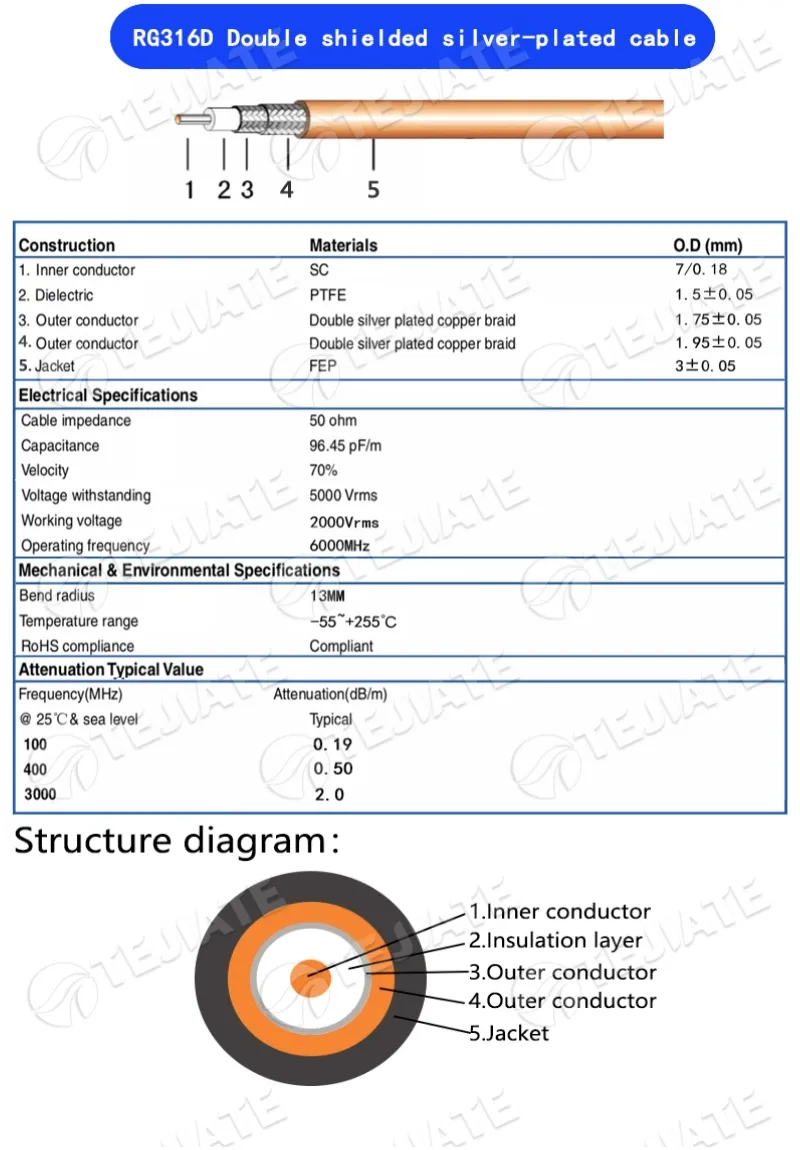

Illustrates the superior construction of RG316D cable, highlighting its dual silver-plated copper braid shielding, key electrical parameters (impedance, capacitance, voltage withstand), mechanical specs (tighter bend radius of 13mm, wider temperature range up to 255°C), and typical attenuation values compared to RG316.

| Feature | RG316 cable | RG316D cable |

|---|---|---|

| Inner Conductor | Silver-plated copper or copper-clad steel, 7 × 0.175 mm | Silver-plated copper, 7 × 0.18 mm |

| Dielectric | PTFE, Ø1.53 mm | PTFE, Ø1.50 mm |

| Shielding | Single silver-plated braid | Dual silver-plated braids |

| Jacket | FEP, Ø2.50 mm, usually brown | FEP, Ø3.0 mm, brown/blue/black/clear |

| Capacitance | ~106 pF/m | ~96.5 pF/m |

| Velocity Factor | 70% | 70% |

The RG316 cable is slimmer and easier to route through crowded enclosures. Its single-braid shield makes it more flexible but leaves it slightly more vulnerable to leakage and interference. RG316D, on the other hand, adds a second braid. That extra layer tightens up EMI performance and helps keep the signal chain cleaner, especially in test benches or outdoor RF links.

From experience, if you’re wiring a compact IoT device, RG316’s smaller diameter is usually a blessing. But in a lab rack full of transmitters, the stronger shielding of RG316D will save you from chasing noise that wasn’t in your design. Assemblies in TEJTE’s RF adapter cable section show how both types find their place, depending on whether flexibility or shielding is the higher priority.

Bend radius & temperature rating compared

Flexibility and temperature range often decide the winner:

- RG316 bend radius ≈ 15 mm; usable up to 150 °C.

- RG316D bend radius ≈ 13 mm; withstands heat up to 255 °C.

RG316D not only bends a little tighter but also handles extreme environments better. That’s why it often shows up under the hood in automotive systems or in aerospace modules where temperatures swing wildly.

RG316, lighter and thinner, shines in small devices where space matters more than heat. A lesson many installers learn the hard way: it’s better to pick RG316D upfront for harsh environments rather than swap cables later after failures. Think of RG316 as nimble, while RG316D is the heavyweight that keeps working when things get rough.

What cable length keeps my loss under control?

Signal loss—often called SMA cable loss—is one of those details that looks small on paper but can wreck a system if ignored. The math itself is simple:

Loss (dB) = α(f) × L

- f = frequency

- L = cable length in meters

- α(f) = attenuation coefficient at that frequency

Still, once you see how fast loss climbs with frequency, you’ll realize why engineers keep a close eye on cable length.

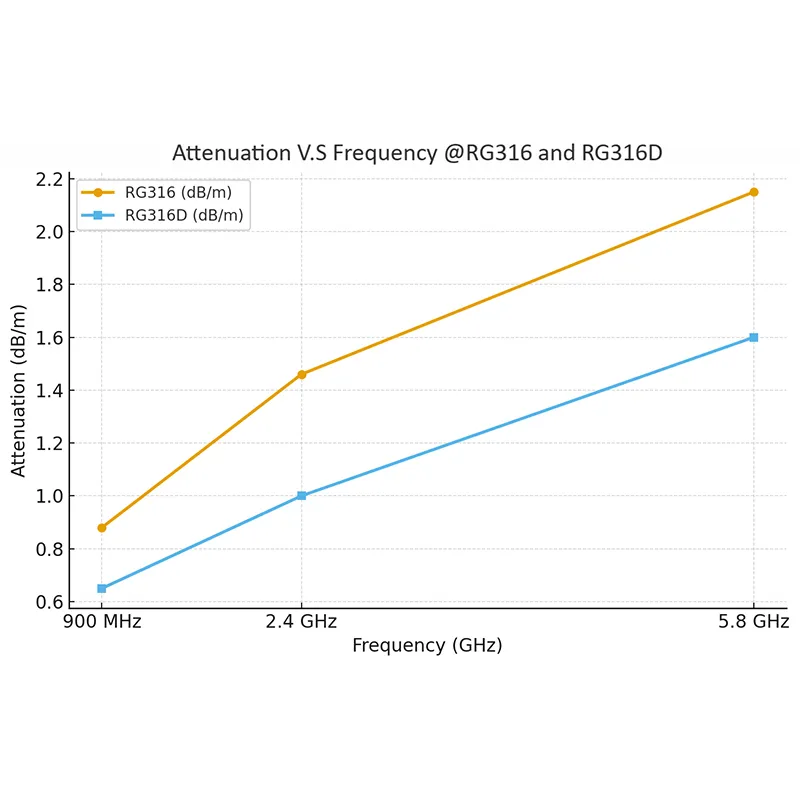

Quick reference table (900/2.4/5.8 GHz)

| Frequency | RG316 Loss (dB/m) | RG316D Loss (dB/m) | Max Length for <1 dB |

|---|---|---|---|

| 900 MHz | 0.88 | ~0.65 | 1.1 m (RG316), 1.5 m (RG316D) |

| 2.4 GHz | 1.46 | ~1.0 | 0.68 m (RG316), 1.0 m (RG316D) |

| 5.8 GHz | 2.15 | ~1.6 | 0.46 m (RG316), 0.63 m (RG316D) |

This chart graphically compares the attenuation (signal loss in dB/meter) of RG316 and RG316D cables across the frequency spectrum (e.g., 900 MHz, 2.4 GHz, 5.8 GHz), clearly showing RG316D's lower loss advantage, especially at higher frequencies, which is critical for determining maximum usable cable length in applications like Wi-Fi and LTE.

A real-world takeaway: at 2.4 GHz, an RG316 cable runs out of margin past about 70 cm. With RG316D, you can stretch closer to a meter. At 5.8 GHz, both shrink quickly, with sub–half-meter limits unless you move to a larger coax.

If you’ve ever set up a Wi-Fi link and wondered why the signal tanked after adding “just a short extension,” chances are you hit that invisible 1 dB wall.

Mitigations when length is fixed

Of course, sometimes the cable length isn’t negotiable. In those cases, here are a few workarounds:

- Swap the long run for a lower-loss coax like LMR-200, then adapt to SMA only at the ends.

- Place a low-noise amplifier near the antenna to recover gain before loss piles up.

- In measurement setups, calibrate the instrument to account for known loss.

Another trick: instead of dragging out the RF side, bring the radio module closer to the antenna and run digital lines (Ethernet or USB) over distance. This keeps the RF portion short and stable. TEJTE explains this design trade-off in their RF cable attenuation guide, and it’s one of those small choices that pays off big later.

Straight or right-angle—when and why? Impact on VSWR

Depicts an SMA cable assembly featuring a straight connector on one end and a right-angle (90-degree) connector on the other, built with RG174 coaxial cable. This example illustrates the alternative connector styles available to facilitate easier routing and reduce mechanical strain in confined enclosure layouts, compared to forcing a straight connector to bend sharply.

Shows a typical SMA male-to-male cable assembly with straight connectors on both ends, constructed using RG174 coax. This represents the default, straightforward configuration suitable for most applications where space allows and sharp bends are not required.

Layout benefits and pitfalls

The default choice for most builds is a straight SMA male-to-male cable—simple, reliable, and usually fine. But when you’re working inside a cramped enclosure, or mounting equipment flush against a wall, that straight plug can quickly turn into a problem. That’s where right-angle SMA connectors (90°, 45°, or even 135°) come in handy.

On paper, angled connectors show a slightly higher mismatch. A straight assembly may test at VSWR ≤1.10, while a right-angle sits closer to VSWR ≤1.20. Technically, that’s a small hit. In practice, forcing a straight cable to bend too sharply does far more damage to return loss and durability.

An old RF shop saying sums it up: “A clean elbow beats a crushed coax.” If you’ve ever had to replace a kinked jumper, you already know why.

Practical routing tips

When routing RG316 or RG316D cables, a few habits keep your assemblies healthy:

- Respect the bend radius: 15 mm for RG316, 13 mm for RG316D.

- Add strain relief where cables exit bulkheads or enclosures.

- Avoid adapter stacking—each joint adds mismatch and insertion loss.

For tight spaces, pre-terminated angled jumpers are a better investment than forcing a straight plug to bend. TEJTE’s SMA connector catalog includes right-angle and bulkhead options, all factory-tested to maintain proper impedance and low loss.

Do I need stainless-steel heads or brass gold-plated?

Corrosion/IP sealing/torque

Illustrates a brass gold-plated SMA connector, highlighting its suitability for lab environments, test benches, and indoor use where excellent conductivity, oxidation resistance, and moderate cost are key considerations. It contrasts with stainless steel options used in harsher environments.

- Brass with gold plating → the go-to choice for lab work, test benches, and short SMA extension cables. Conductivity is excellent, the plating resists oxidation, and torque requirements stay moderate.

Depicts a stainless steel SMA connector, emphasizing its robust construction designed to withstand harsh conditions outdoors, in industrial settings, or in corrosive environments (e.g., salt air). It offers superior thread durability, resistance to galling, and longer mating cycle life compared to brass, though at a higher weight and potentially cost.

- Stainless steel → built for abuse. Stronger threads, better resistance to galling, and much higher tolerance to corrosion. If you’re deploying jumpers outdoors, near salt air, or on a factory floor, stainless saves you from premature wear.

Some assemblies also integrate O-rings or silicone seals for IP67/IP68 ratings, which is essential in marine or outdoor wireless systems. TEJTE’s RF connector line shows both options, giving you flexibility depending on whether longevity or cost is more important.

Durability vs cost vs weight

Each metal comes with trade-offs:

- Durability → stainless can handle thousands more mating cycles before thread wear shows.

- Cost → brass gold-plated is generally cheaper, which matters for volume production.

- Weight → stainless is heavier, which can be a downside in aerospace or handheld devices.

From practical experience, brass works perfectly for everyday lab use or low-stress environments. Stainless earns its place when conditions are tough and failure isn’t an option. As TEJTE’s RF coaxial cable guide points out, the trick is to match the connector metal to the operating environment, not just the datasheet.

How do I verify it’s truly 50 Ω and DC–6 GHz capable?

Acceptance checklist

| Test Item | Typical Requirement | Why It Matters |

|---|---|---|

| Impedance | 50 Ω ±2 | Keeps reflections and return loss low |

| Frequency Range | DC-6 GHz | Covers Wi-Fi, LTE, GNSS, and lab test bands |

| VSWR | ≤1.10 (straight), ≤1.20 (angled) | Prevents mismatch issues |

| Insertion Loss | ≤0.15 dB @ 6 GHz (short run) | Protects link margin |

| Dielectric Withstand | 1000 Vrms | Confirms insulation strength |

| Insulation Resistance | ≥5000 MΩ | Stops leakage across conductors |

| Mechanical Durability | ≥500 cycles | Ensures connector life span |

| Pull Force | ≥0.28 N on inner conductor | Guards against pin damage |

| Jacket & Markings | Clear print, batch traceable | Simplifies compliance and reordering |

Red flags in poor assemblies

Not all cables are equal. Even when they look fine on the outside, a few clues reveal when something’s off:

- No or faded jacket markings → usually a sign of generic stock without traceability.

- Crimps that don’t match spec → often from the wrong tooling, which can spike VSWR.

- Odd return loss spikes → when tested on a network analyzer, these point to bad terminations.

A practical tip: always keep a known-good SMA jumper cable on hand as a reference. Comparing a suspect batch against a trusted assembly makes it easy to spot problems early. TEJTE’s SMA connector blog series highlights these checks, and they’re worth building into your own acceptance process.

Which FEP jacket color should I pick—brown/blue/ black/clear?

Color for BOM & routing

Performance doesn’t change with jacket tint—the FEP layer keeps the same heat and chemical resistance whether it’s brown, blue, black, or clear. But in real projects, color is more than decoration. It simplifies routing, inventory, and even troubleshooting when multiple RG316 or RG316D cables are in play.

- Brown → the standard option, found in most stock RG316 cable assemblies.

- Blue → favored in labs; easier to spot and swap during testing.

- Black → adds better UV protection, making it the safer pick for outdoor runs.

- Clear → allows visual inspection of the braid, handy in QC-heavy environments.

TEJTE’s RG316 assembly catalog shows all these jacket variants, a reminder that color choice can be a functional decision, not just an aesthetic one.

Lab/factory color-coding tips

Anyone who has managed a busy RF bench knows how fast identical brown cables get mixed up. A simple coding system avoids crossed lines and wasted debug hours:

- Blue for test jumpers → temporary, easy to identify.

- Black for outdoor runs → UV resistance plus easy field recognition.

- Brown for standard stock → the go-to for production lines.

In some factories, jacket colors even act as silent BOM labels, guiding technicians without extra paperwork. TEJTE’s SMA jumper guides note the same practice—it’s a small step that keeps both labs and production floors organized.

Do I need an extension or a jumper/patch?

Terminology + wiring sketches

The terms SMA extension cable and SMA jumper cable often get used as if they mean the same thing. Technically, both are SMA male-to-male assemblies built on coax like RG316 or RG316D. What really sets them apart is how they’re applied.

- An extension cable usually pushes an antenna farther from the device—for example, relocating a Wi-Fi antenna outside a metal cabinet.

- A jumper (or patch) cable usually means a short, flexible link between devices, patch panels, or test instruments in the lab.

So while the build is identical, the name shifts with context. TEJTE’s SMA adapter cable catalog shows the same RG316 assemblies sold both ways, depending on whether customers picture them in the field or on a bench.

When to use adapters/bulkheads

Not every case calls for another extension. Sometimes a bulkhead SMA feedthrough does the job better, letting you cross an enclosure wall without extra slack inside. Other times, a simple SMA-to-BNC adapter can replace two different jumpers and clean up the signal path.

The golden rule: every extra connection adds mismatch and insertion loss. TEJTE’s SMA vs BNC vs N connector guide makes the same point—minimize cascades, and your RG316 jumper cables will perform far closer to spec.

What specs do I submit for a custom order?

Length tolerance, ends, torque, caps/O-ring, IP rating

When ordering a 50 ohm SMA male-to-male cable, clear specifications make life easier for both you and the supplier. At the very least, include:

- Cable length and tolerance (e.g., 200 mm ±5 mm).

- Connector type → straight, right-angle, or bulkhead.

- Thread style → standard SMA or RP-SMA, since a mismatch can ruin compatibility.

- Torque requirement if repeatable tightening is important.

- Environmental sealing → dust caps, O-rings, or IP67/IP68 rating if the cable goes outdoors.

One practical tip: don’t underestimate tolerance. In a cramped rack, being a centimeter short can mean the connector won’t reach at all. TEJTE’s custom RF cable assemblies are typically built to ±5 mm precision to avoid these headaches.

Compliance & traceability

In industries like aerospace, defense, or telecom, technical fit alone isn’t enough—you’ll need paperwork too. That usually means:

- Batch traceability with printed lot numbers.

- QC reports documenting VSWR, insertion loss, and pull force.

- Compliance certificates (RoHS, REACH) for regulatory approval.

It might feel like red tape, but it pays off when something fails in the field. With full traceability, you know exactly which production run a cable came from. TEJTE covers this in their RF compliance guides, stressing that accountability is as important as performance.

How do I mate it correctly (and avoid RP-SMA mix-ups?)

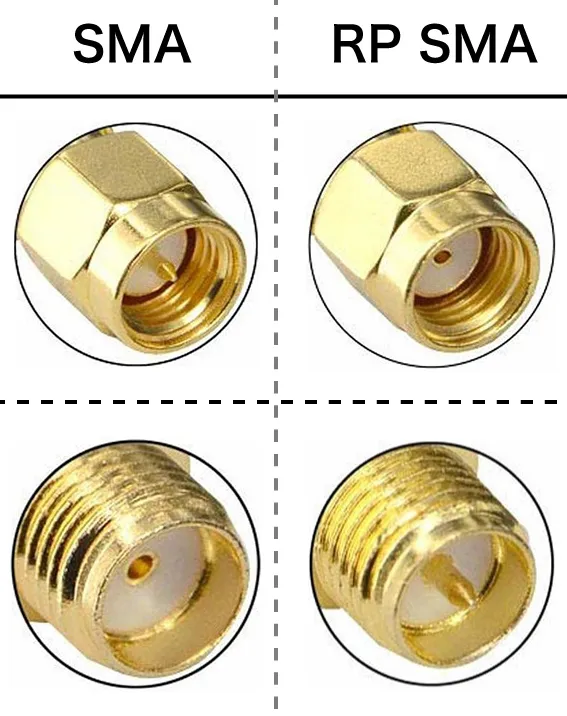

This crucial diagram provides a clear visual comparison between standard SMA and Reverse Polarity (RP-SMA) connectors, highlighting the swapped center contacts (pin vs. socket) despite identical outer threads. It serves as a vital reference to avoid common ordering and mating mistakes that can render cables incompatible with devices.

Polarity diagrams and device ports

One of the most common slip-ups with SMA male-to-male cables is mixing them up with RP-SMA parts. The outer threads look the same, so at a glance it’s easy to assume they’re interchangeable. The real difference is at the center:

- SMA male → outer thread with a pin.

- SMA female → inner thread with a socket.

- RP-SMA male → outer thread but no pin.

- RP-SMA female → inner thread but with a pin.

It’s a tiny detail, yet it’s behind countless wrong orders. Before you buy, double-check the device port on your router, LTE modem, or IoT board. TEJTE’s SMA vs RP-SMA guide has clear side-by-side visuals—worth a look if you’ve ever been caught out by polarity.

Alternative adapter paths with minimal cascades

Sometimes, polarity mistakes or device mismatches are unavoidable. In those cases, the cleaner fix is a single direct adapter—for example, an RP-SMA to SMA—rather than stacking jumpers.

The same applies when bridging connector families like SMA to BNC or SMA to N. One adapter in the chain keeps insertion loss and mismatch low. Stack two or three, and you’ll notice the difference on a network analyzer. TEJTE’s BNC-to-SMA adapter guide walks through this with real use cases.

From field experience: it’s tempting to grab whatever adapters you have in the drawer, but every extra joint adds risk. Fewer connections nearly always means better performance.

What should I watch out for in Wi-Fi/LTE/GNSS/IoT?

Practical loss ceilings per band

Different systems tolerate loss differently, so knowing the limits saves time and frustration. With RG316 and RG316D SMA male-to-male cables, here are some field-tested rules of thumb:

- Wi-Fi / Bluetooth (2.4 GHz) → try to stay under 1 dB of SMA cable loss, which means less than ~70 cm with RG316, or up to 1 m with RG316D.

- Wi-Fi (5.8 GHz) → loss climbs fast. Even a 0.5 m run of RG316 is pushing it, while RG316D gives you a little more breathing room.

- LTE (~900–2100 MHz) → you can stretch closer to 1 m before hitting 1 dB, but attenuation still matters if the link margin is tight.

- GNSS (GPS, BeiDou, GLONASS) → signals are already weak; even 0.5 dB of extra loss can throw off reception. Keep jumpers as short as possible or switch to RG316D for added shielding.

TEJTE’s RF coaxial attenuation guide explains how these numbers play out across frequencies, and it’s a useful reference when planning IoT deployments.

Enclosure pass-through and grounding

Length isn’t the only trap. How you bring a cable through an enclosure can make or break performance.

Don’t force a 50 ohm SMA extension cable through a drilled hole and call it done. That breaks shielding continuity and invites interference. A bulkhead SMA feedthrough is a far better choice—it maintains the shield, provides strain relief, and gives you a solid ground point.

Poor grounding is another hidden culprit. In IoT boxes, a badly grounded feedthrough often shows up as random link drops. TEJTE’s SMA connector blogs treat enclosure layout and grounding as part of the RF path, not an afterthought—and from experience, that’s exactly the mindset that prevents headaches later.

Order now: configure and submit your request at TEJTE

5-step flow with internal links

Placing an order for an SMA male-to-male RG316 assembly doesn’t need to be complicated if you lay out the specs upfront. Here’s the process many engineers follow at TEJTE:

- Select the cable type → choose RG316 cable for flexibility or RG316D cable for better shielding and higher temperature tolerance.

- Define connector style → straight, right-angle, or bulkhead, depending on layout.

- Set length and tolerance → for example, 300 mm ±5 mm. Even a small margin matters in rack builds.

- Add compliance needs → IP67 sealing, RoHS certificates, or full batch traceability if required.

- Submit details via TEJTE’s RF adapter cable page → the team will confirm lead time and send a quote.

This 5-step flow mirrors the approach outlined across TEJTE’s RF connector blogs, keeping purchasing decisions consistent with engineering specs.

Lead time, QC, after-sales

Once your request is in, here’s what to expect:

- Lead time → standard builds using RG316 are usually quick; RG316D or stainless-steel heads may take slightly longer.

- Quality checks → each lot goes through impedance, VSWR, insertion loss, and pull-force tests before shipment.

- After-sales support → TEJTE provides technical assistance, whether it’s troubleshooting a mismatch or verifying attenuation values in your setup.

In practice, this means you’re not just buying a SMA extension cable off the shelf—you’re securing tested, traceable assemblies that match your requirements.

Selection Decision Tree

Choosing between RG316 cable and RG316D cable doesn’t have to feel like guesswork. The decision tree below condenses the main parameters into a step-by-step flow you can apply directly when selecting an SMA male-to-male jumper cable or SMA extension cable:

- Application frequency

- At 900 MHz or below → RG316 is usually enough.

- At 2.4 / 5.8 GHz → RG316D is safer thanks to lower attenuation.

- Target maximum loss

- If you can only allow <1 dB SMA cable loss, check the quick reference table in Section 2.

- If 1 dB is acceptable, RG316 can work for short runs.

- Planned length

- ≤0.5 m → RG316 typically does the job.

- 0.5 m–1 m → RG316D is the safer bet.

- Beyond that → consider switching to a lower-loss coax like LMR-200.

- Environment

- Indoor, moderate temperature → brass gold-plated SMA heads are fine.

- Outdoor, high temp, or corrosive conditions → stainless-steel SMA with IP67 sealing.

- Connector style

- Tight routing → right-angle assemblies help reduce strain.

- Straightforward layouts → standard straight SMA works well.

- Recommendation output

- Suggests RG316 or RG316D.

- Flags if you need a larger coax (LMR-200) or an in-line amplifier.

- Notes sealing if outdoor installation is planned.

This approach mirrors the logic outlined in TEJTE’s RF cable selection guides, but it’s laid out in a way you can use directly during procurement. Instead of juggling specs in your head, you just walk through the tree and land on the right choice.

Frequently Asked Questions

Q1. How long can an SMA male-to-male RG316 run at 2.4 GHz before loss exceeds 1 dB?

At 2.4 GHz, a standard RG316 cable reaches about 0.68 m before the attenuation crosses 1 dB. With RG316D, you get a bit more headroom—close to 1 m. Beyond that, you’ll need to switch to a lower-loss coax like LMR-200, or rethink the setup. TEJTE’s RF coax attenuation guide shows how frequency and length interact, which helps in planning Wi-Fi and IoT networks.

Q2. Is RG316D worth it if my layout has multiple 90° turns?

Yes. The RG316 bend radius is ~15 mm, while RG316D tightens that to about 13 mm. In real builds with several bends, the extra flexibility and dual shielding of RG316D hold up better over time. A regular RG316 jumper may kink or degrade faster if it’s forced around corners. For really tight spaces, pre-made right-angle SMA jumpers—like those in TEJTE’s SMA connector line—are a smarter call.

Q3. Will a stainless-steel SMA head change electrical performance vs brass?

Electrically, both stay at 50 ohm and cover the DC–6 GHz range. The difference lies in mechanics: stainless-steel threads survive more mating cycles and resist corrosion outdoors. Brass with gold plating is lighter and more cost-effective. TEJTE’s RF connector blog breaks down where each material fits best.

Q4. Can I use a right-angle plug without degrading VSWR noticeably?

A straight SMA typically holds VSWR ≤1.10, while a right-angle plug is closer to ≤1.20. On paper, that’s slightly worse. In practice, the real enemy is a sharp bend in the coax. So, if space is tight, a right-angle connector is the lesser evil. TEJTE’s tested SMA extension cables include right-angle builds to help manage cramped layouts.

Q5. What’s the practical bend-radius rule for RG316 inside small enclosures?

Stick to datasheet values: 15 mm for RG316 and 13 mm for RG316D. Anything tighter risks crushing the dielectric, which raises return loss and kills signal integrity. If your design doesn’t allow that radius, angled connectors or flexible SMA jumper cables are the safe alternative.

Q6. How do I tell SMA from RP-SMA at a glance when kitting cables?

Look at the center contact:

- SMA male → outer thread with a pin.

- RP-SMA male → outer thread with no pin.

This tiny difference causes many wrong orders. TEJTE’s SMA vs RP-SMA guide includes side-by-side photos to help you avoid the mix-up.

Q7. What acceptance checks should my supplier pass before shipment?

A reliable supplier should verify:

- Impedance: 50 Ω ±2

- VSWR: ≤1.20

- Insertion loss: ≤0.15 dB @ 6 GHz for short jumpers

- Dielectric withstand: ~1000 Vrms

- Traceability: batch-labeled jackets and QC reports

TEJTE follows these checks as part of its SMA cable QC workflow, ensuring consistency from lot to lot.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.