SMA Male to Female Adapter Buying Guide: Angles, Feedthroughs & Loss

Sep 15,2025

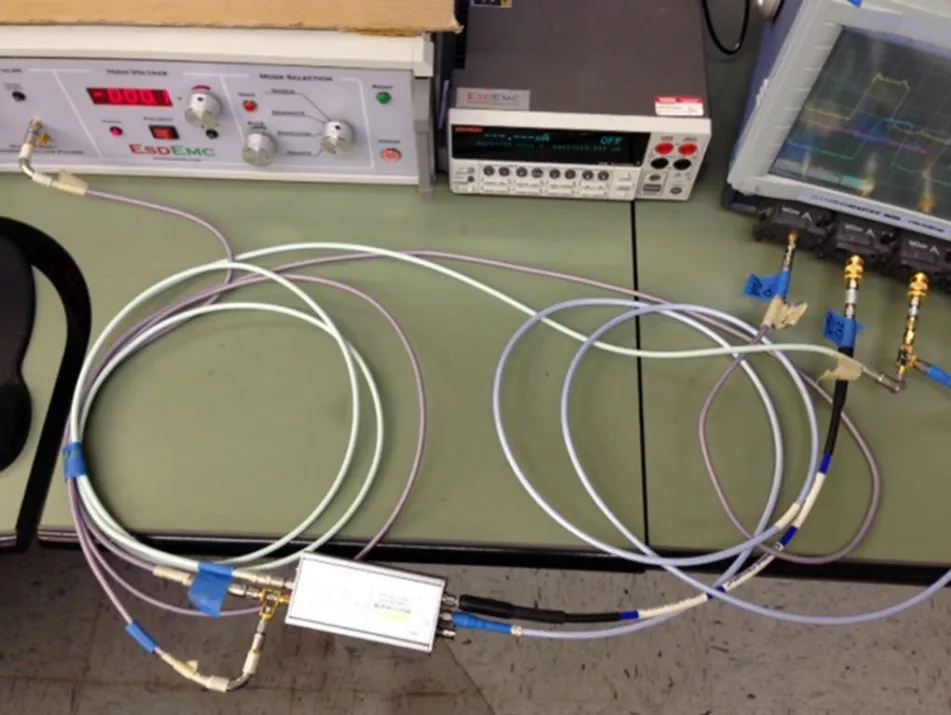

This image depicts a professional test and measurement environment where an SMA male to female adapter (likely a straight connector) is connected between the two ports of a Vector Network Analyzer (VNA), undergoing calibration or performance testing. The screen may display readings of VSWR (Voltage Standing Wave Ratio) or Insertion Loss curves. The image aims to emphasize the importance of selecting high-quality adapters and verifying their key RF parameters (such as 50Ω impedance matching, low VSWR (≤1.05), low insertion loss (≤0.15 dB @ 6 GHz)) through precise instrument measurement, ensuring they do not introduce significant loss or distortion to the signal chain. This is critical for high-frequency applications and precision measurements.

Which SMA male-to-female do you actually need?

Decide by endpoint genders and ports (router, SDR, panel)

This image serves as a fundamental reference, visually demonstrating the key differences between standard SMA and Reverse Polarity (RP-SMA) connectors: Male has a center pin and external threads, Female has a center hole and internal threads, while RP-SMA reverses the center contact (pin/hole) configuration. It helps users avoid common connector confusion and mismating.

The first thing you’ll want to do is look closely at the ports you’re connecting.

- Routers and Wi-Fi cards often come with RP-SMA female jacks, so you’ll need an adapter with an SMA male end to complete the link.

- SDRs and RF instruments usually carry SMA female jacks, meaning a male-to-female coupler is required.

- For enclosures, a bulkhead feedthrough adapter is usually the cleanest choice, tightened with a nut and sealed with an O-ring for stability.

Quick tip from the field: always confirm both the thread direction and the pin/hole layout. Mistaking an RP-SMA hole for an SMA pin is one of the most common slip-ups. A 10-second check can save you a return.

If you need a visual guide, TEJTE’s SMA connector breakdown shows exactly how SMA and RP-SMA ports differ.

Straight inline vs bulkhead feedthrough vs right-angle: when to pick each?

Not every installation is the same, so the adapter shape matters.

- Straight inline types are simple and work best in test setups or when space isn’t tight.

- Bulkhead feedthrough adapters, such as TEJTE’s SMA-J and SMA-K series, are designed for enclosure walls. With standard thread lengths of 8 mm, 11 mm, or 13 mm, they match common panel thicknesses and ensure a proper fit.

This image shows the physical product of the specific model SMA-JW-3 right-angle adapter. In context, it is used to illustrate how right-angle adapters solve clearance issues inside enclosures and to highlight its performance parameters (e.g., insertion loss <0.15 dB @ 6 GHz, VSWR ≤1.20) and durability features (beryllium bronze sockets, Teflon insulation).

“Gender changer” vs “extension”: what’s the practical difference?

A gender changer (M-M or F-F) is used when your cables both end with the same gender, while an extension adapter (M-F) simply brings the port outward without changing its type.

For example:

- Two male-ended cables? You’ll need an F-F gender changer.

- Port recessed inside a housing? A male-to-female extension makes the port accessible without stressing the connector.

This image displays an SMA female-to-female gender changer (or coupler). In context, it is used to explain the practical difference between a "gender changer" (like F-F or M-M) and an "extension/adapter" (M-F), where the former is used to connect cables/ports of the same gender rather than simply extending or re-orienting a port.

This image displays an SMA male-to-male gender changer. Along with Figure 4, it further illustrates the concept and application scenarios of gender changers (connecting two ends of the same gender) and warns that mixing up types can lead to bent connectors or stripped threads.

Do SMA and RP-SMA adapters affect signal?

VSWR & insertion-loss targets for M-to-F (typical ≤0.2 dB @ 2.4 GHz)

Good SMA adapters are rated for:

- Frequency range: DC–6 GHz up to DC–18 GHz, depending on model

- VSWR: ≤1.05 for straight types, ≤1.20 for right-angle

- Insertion loss: ≤0.15 dB at 6 GHz

Take TEJTE’s SMA-JW-3 as an example. It uses a gold-plated brass housing, beryllium bronze contacts, and Teflon insulation. With 500+ mating cycles and insertion loss below 0.15 dB @ 6 GHz, it balances durability and RF performance.

RP-SMA to SMA: when a short pigtail is safer than a hard adapter

Here’s a common mistake: hanging a heavy antenna directly on an RP-SMA port with a rigid adapter. Over time, the stress loosens the jack or even cracks the PCB.

In these cases, a short coax pigtail (for example, RG316 or RG178) is a smarter pick. Yes, a 20 cm RG316 adds about 0.45 dB @ 2.4 GHz and 0.85 dB @ 5.8 GHz, but it protects the port from damage.

You’ll find ready-made solutions like this in TEJTE’s RF adapter cable lineup, which includes SMA to RP-SMA pigtails designed for routers and FPV gear.

Mounting through a panel? How long should the bulkhead thread be?

This is likely a schematic diagram showing a cross-section of a bulkhead adapter passing through a panel, annotating panel thickness, washer, nut, O-ring compression, and required thread engagement length. It visually explains the rule-of-thumb formula provided in the text (Required_thread ≥ Panel_thickness + Washer_thickness + Nut_engagement + O_ring_compression + Safety_margin) to help users select the correct thread length (e.g., 8/11/13/17/21 mm).

Rule-of-thumb formula & screw stack (panel + washer + nut + O-ring)

Use this calculation as a quick guide:

Required_thread ≥ Panel_thickness + Washer_thickness + Nut_engagement + O_ring_compression + Safety_margin

- O_ring_compression is usually 0.5–1 mm

- Safety_margin is about 1 mm

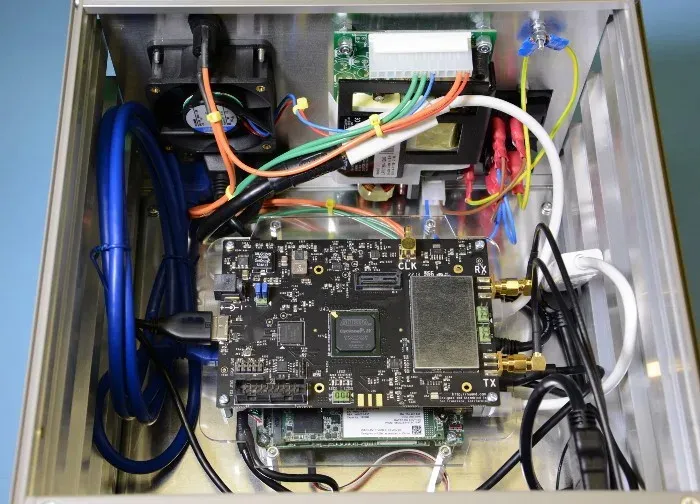

This image is likely a collage or scene showing the use of SMA adapters (possibly specifically bulkhead feedthrough or right-angle types) in various application scenarios such as base stations, PCs, test instrumentation, and telecommunications equipment. It aims to illustrate the versatility and importance of adapters in different contexts.

Standard thread lengths (8/11/13/17/21/33 mm) mapped to panel thickness

| Panel Thickness (mm) | Recommended Thread (mm) | Example TEJTE Part |

|---|---|---|

| 1-3 | 8 mm | SMA-J bulkhead (Part No. 08195) |

| 3-5 | 11 mm | SMA-J-1.5 (Part No. 35041) |

| 5-7 | 13 mm | SMA-JB2 stainless (Part No. 35042) |

| 7-11 | 17 mm | SMA-K-4 feedthrough (Part No. 54255) |

| 11-15 | 21 mm | Custom extended type |

| >15 | 33 mm | Deep-mount specialty |

Need a right-angle turn? Use a 90° adapter or a right-angle cable?

Tight-clearance cases where 90° M-to-F is fine

When you’re dealing with modules pressed against a panel wall, a 90° inline adapter solves the problem quickly. High-quality parts, like TEJTE’s SMA-JW series, maintain insertion loss under 0.15 dB @ 6 GHz and VSWR ≤1.20, which is more than good enough for Wi-Fi and LTE bands.

For quick installs or places where vibration isn’t severe, this option works perfectly.

When to prefer RG316/RG178 right-angle pigtail to reduce stress

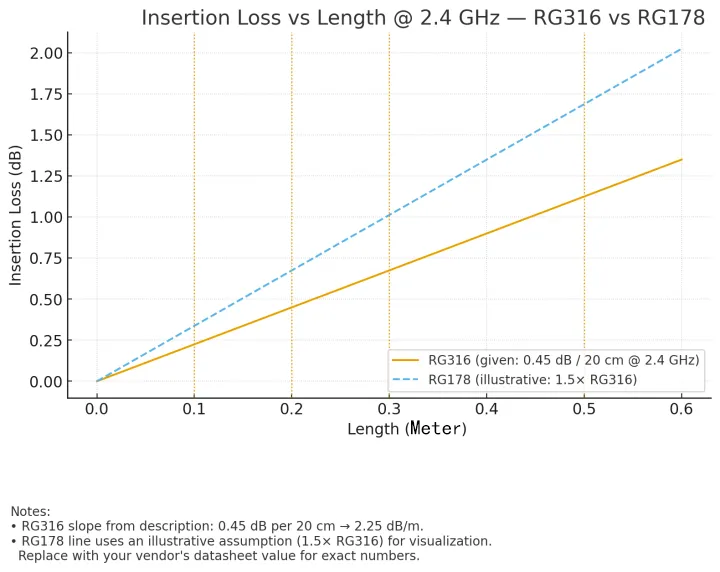

This line chart plots the loss trend for RG316 and RG178 cables at 2.4 GHz, with length (meters) on the X-axis and insertion loss (dB) on the Y-axis. In context, it is used to quantitatively compare the loss difference between using a rigid right-angle adapter versus using a flexible right-angle pigtail solution (e.g., ~0.45 dB loss for 20 cm RG316), aiding engineers in making trade-off decisions between solving space constraints and minimizing signal loss/mechanical stress.

But if you expect repeated handling, vibration, or heavier antennas, rigid right-angle adapters can turn into levers, putting stress on PCB-mounted jacks. In those cases, a short coax pigtail is far safer.

- RG316 (2.5 mm OD): ~0.45 dB loss per 20 cm at 2.4 GHz

- RG178 (1.8 mm OD): even thinner, useful where flexibility matters most

By using a pigtail, the stress is absorbed by the cable, not your device’s connector. TEJTE details these trade-offs in the SMA adapter cable guide, where straight, bulkhead, and right-angle options are compared side by side.

How do you keep 50 Ω and frequency headroom?

50 Ω only: avoid mixing 75 Ω video parts in RF chains

Many low-cost “SMA-like” connectors on the market are actually 75 Ω video parts. Plugging one into your 50 Ω SMA chain might not matter at low MHz, but once you climb into gigahertz frequencies, mismatch shows up as high VSWR, reduced bandwidth, and even extra heat.

TEJTE’s SMA-K and SMA-J stainless steel series are built to maintain 50 Ω ±2 Ω up to 6 GHz, with isolation resistance ≥5000 MΩ and contact resistance ≤3 mΩ (inner). These specs ensure your system doesn’t just work on paper—it keeps running reliably in the field.

If you’re interested in the deeper theory, TEJTE’s RF cable guide explains why impedance consistency is crucial across coax, connectors, and adapters.

Pick DC–6/10/18 GHz ratings; fewer joints → less loss

When buying SMA to SMA adapters, check the frequency rating.

- DC–6 GHz: covers Wi-Fi, LTE, GPS, and GSM

- DC–10 GHz: adds X-band applications

- DC–18 GHz: the premium range, often stainless steel or precision brass

Every joint adds mismatch and insertion loss. A single male to female coupler is fine, but stacking two or three adapters in line can cost you >0.5 dB at 5.8 GHz. For high-frequency work, one good adapter always beats a daisy-chain.

Can you extend a run with M-to-F or should you order a cable?

Pick DC–6/10/18 GHz ratings; fewer joints → less loss

Loss budget examples at 2.4 GHz & 5.8 GHz (adapter vs 20 cm RG316)

| Option | Extra Loss @ 2.4 GHz | Extra Loss @ 5.8 GHz |

|---|---|---|

| 1× M-F adapter | ~0.15 dB | ~0.25 dB |

| 20 cm RG316 extension cable | ~0.45 dB | ~0.85 dB |

Adapters give you lower loss, but cables provide flexibility and strain relief.

TEJTE’s SMA extension cables are built with RG316, RG402, or RG174, and maintain VSWR ≤1.05 (straight) while handling 500+ mating cycles. You can find them in the RF adapter cable section if you need reliable ready-made options.

Reliability: torque, thread wear, and strain relief

Torque and wear are often overlooked. SMA threads are small; over-tightening, especially on brass-nickel finishes, shortens lifespan. For long-term reliability:

- Follow torque specs of 0.56–0.79 N·m (5–7 in-lbf)

- Use stainless steel parts if you expect frequent cycles

- Add strain relief via cable instead of rigid stacking

For more context on field use, the SMA bulkhead connector guide explains how thread length, O-rings, and materials affect installation durability.

What specs must be on your PO to avoid returns?

One of the most common causes of returned SMA adapters is vague purchase orders. Leaving out details like thread length or finish opens the door to mismatched parts. A good PO should act like a checklist—simple, complete, and unambiguous.

In RF supply, engineers often ask for “an SMA male to female adapter,” but without specifying whether it’s inline, bulkhead, or right-angle, suppliers may ship the wrong type. The result? Lost time, rework, and sometimes damaged ports.

By writing down the critical specs from the start—impedance, frequency range, thread length, plating, and sealing—you’ll avoid surprises and ensure consistency across batches.

PO Spec Checklist

| Field | Choices / Notes |

|---|---|

| Interface | SMA male → SMA female / RP-SMA |

| Form factor | Inline / Bulkhead feedthrough / Right-angle |

| Bulkhead | Thread length (8/11/13/17/21/33 mm), O-ring (Yes/No) |

| Frequency rating | DC-6 / 10 / 18 GHz |

| Impedance | 50 Ω only |

| VSWR (straight) | ≤1.05 typical |

| VSWR (angle) | ≤1.20 typical |

| Finish/material | Brass-nickel / Brass gold-plated / Stainless |

| Contact resistance | Inner ≤3 mΩ / Outer ≤2.5 mΩ |

| Insertion loss | ≤0.15 dB @ 6 GHz |

| Quantity/pack | pcs / sets |

| Environment | Indoor / Outdoor (sealed with silicone O-ring) |

| Notes | Torque spec 0.56-0.79 N·m, RoHS/REACH compliance |

FAQs

Do SMA and RP-SMA adapters affect signal?

Is a male-to-female adapter the same as a “gender changer”?

When should I choose a right-angle M-to-F instead of a straight one?

Which bulkhead thread length works for my panel?

Use the formula:

Required_thread ≥ Panel_thickness + Washer + Nut_engagement + O_ring + 1 mm margin

Then pick the next closest standard length (8 / 11 / 13 / 17 / 21 / 33 mm). For example, TEJTE’s SMA-JB2 stainless bulkhead with 13 mm thread handles thicker housings and maintains insulation resistance ≥5000 MΩ.

Can I stack two M-to-F adapters to “extend” a cable?

What torque should I use on SMA?

Will a 75 Ω video part work in a 50 Ω RF chain?

Wrapping up

Whether you need a straight coupler, a panel-mount feedthrough, or a right-angle SMA adapter, the key is to match not only gender but also mechanical fit and electrical specs. By applying the PO checklist and avoiding common pitfalls, you’ll reduce downtime and keep your RF system stable.

For more practical comparisons, check TEJTE’s SMA to BNC adapter guide or the N-Type to SMA adapter overview. These cover cross-family conversions and waterproofing, completing the picture of how sma adapters fit into real-world setups.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.