SMA Adapter: Practical Selection & Ordering Guide

Oct 1,2025

Introduction

serving as the opening graphic. It shows a physical example of a typical SMA Female to BNC Male adapter, used to connect devices with SMA male ports to instruments with BNC female ports. The document emphasizes that SMA adapters are "the bridge" between test instruments, radios, and antennas, and their correct selection is critical to system performance.

If you’ve worked with RF gear long enough, you know that the wrong connector can ruin a setup. Sometimes it’s just a bit of extra loss, other times it’s a complete mismatch that stops the system cold. That’s why sma adapters are more than “small accessories” — they’re the bridge between test instruments, radios, and antennas.

On the bench, they help you jump from an SMA male connector to a BNC port in seconds. In the field, they make rugged connections to N-type interfaces on outdoor radios. And in custom projects, you may need a flange-mount design with an IP67-rated O-ring to keep moisture out. One of our own SMA to BNC adapters is only 28.4 mm (1.118 inches) long, yet it still handles DC up to 12 GHz reliably. It’s a reminder: even small hardware decisions can have a big impact.

So before you order, it’s worth looking at loss, gender, angle, and impedance. The right choice saves troubleshooting later.

How do I confirm the lowest-loss adapter path?

serving as a visual aid during the discussion of impedance matching (50Ω vs 75Ω). It generically shows the form of an SMA to BNC adapter, leading into the detailed discussion about correctly matching impedance (50Ω to 50Ω is ideal) and the potential performance degradation (e.g., increased return loss, reduced gain) if mismatched

also appearing during the discussion of the lowest-loss path, as an alternative to SMA to BNC. The document explains that for outdoor radios or high-power setups, the connection is usually N female, which makes an SMA to N-type adapter the smarter path. This image shows this adapter suitable for more demanding applications.

Every time you add an sma adapter to the chain, you introduce loss. On paper, it’s often just 0.1–0.2 dB per stage up to 6 GHz. In reality, stack a few couplers together, and suddenly your link margin has shrunk. That can mean retries in Wi-Fi, dropped packets in IoT, or ghosting in analog video.

If your gear ends with a BNC female port, a sma to bnc adapter is the simplest bridge. For outdoor radios or high-power setups, the connection is usually N female, which makes a sma to n-type adapter the smarter path.

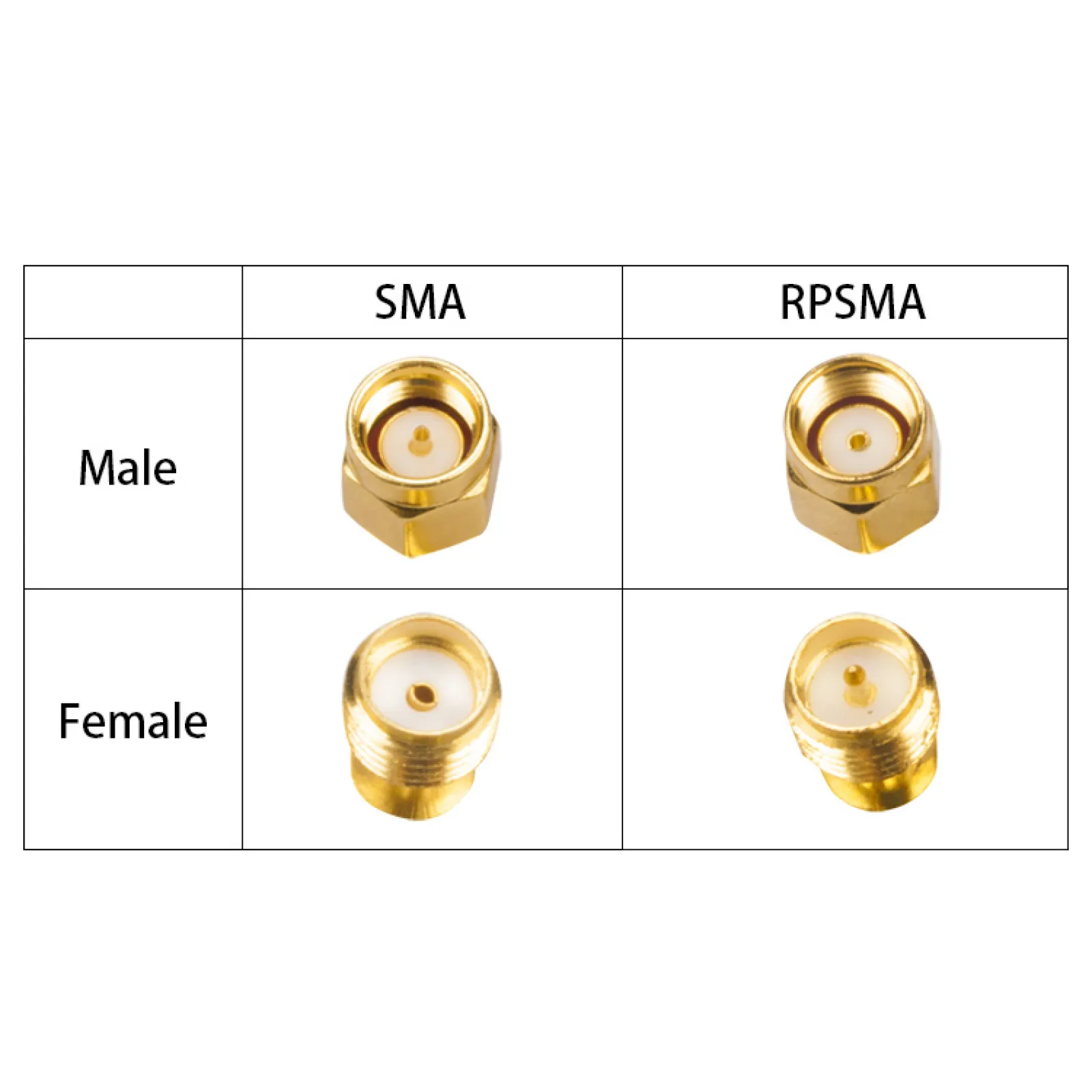

The tricky part is spotting RP-SMA. From the outside it looks just like SMA. Many Wi-Fi routers use RP-SMA connectors for antenna, so if you don’t check the center contact, you’ll likely order the wrong adapter.

SMA/RP-SMA vs BNC/N (gender/polarity/locking)

- SMA: Male = pin, Female = socket. Threaded, reliable.

- RP-SMA: Reverse pin/socket, common in wireless gear.

- BNC: Bayonet style, fast connect/disconnect, 50 Ω or 75 Ω.

- N-Type: Bigger, threaded, rated up to 18 GHz, good outdoors.

When to choose SMA to BNC vs SMA to N

- SMA to BNC adapter: Great for labs and scopes where you need speed.

- SMA to N-type adapter: Better for rugged setups, telecom, and outdoor use where VSWR and durability matter.

In short: if it’s convenience, go BNC. If it’s ruggedness and high-frequency stability, go N-type.

Which gender combo guarantees plug-and-play? or SMA to TNC is smarter

Nothing slows down an install faster than discovering the genders don’t match. If your device has an SMA female, you’ll need an SMA male on the adapter side. Sounds obvious, but with RP-SMA and cross-standards in the mix, mistakes happen.

Here’s a simple connection matrix built on common SKUs and field use:

Connection Matrix — Device A/B to Recommended SKU to Need for M-F adapter/jumper

titled "Connection Matrix". It is a simplified selection guide table that, based on the port types of Device A and B (SMA M/F, RP-SMA M/F), recommends the correct adapter SKU and indicates if an SMA male-to-female adapter is needed. The document emphasizes that gender mismatch is one of the most common slowdowns during installation, and this matrix aims to help users avoid such errors.

| Device A (Port) | Device B (Port) | Recommended Adapter | Need SMA Male to Female Adapter? |

|---|---|---|---|

| SMA-M | BNC-F | SMA-M to BNC-F Adapter | No |

| SMA-F | BNC-F | SMA-F to BNC-F Adapter | No |

| RP-SMA-F | SMA-M | RP-SMA-F to SMA-M | Yes, if polarity differs |

| SMA-M | N-F | SMA-M to N-F Adapter | No |

| SMA-F | SMA-F | SMA-F to SMA-F Coupler | Sometimes to use SMA male to female adapter |

Avoiding RP-SMA mismatches

- RP-SMA female: has a pin in the middle.

- SMA female: has a hole in the middle.

That quick check avoids most Wi-Fi adapter mix-ups.

Should I pick straight or right-angle for my layout?

Pros/cons on handhelds, enclosures, racks

- Straight SMA: Cleanest electrical path, lowest loss.

- Right-angle SMA: Saves space, helps in tight enclosures or gear with limited clearance.

Take the earlier 28.4 mm SMA-to-BNC coupler as an example. In open layouts, it’s perfect. But in a dense rack, a right-angle part prevents stress on the cable and connector.

Torque/strain and reliability

appearing during the discussion of "Torque/strain and reliability". It shows a flange-mount SMA adapter. The document points out that for outdoor gear, a flange-mount adapter with an IP67 O-ring is even better, as it adds weather sealing and mechanical relief, preventing fittings from loosening or ports from being damaged over time due to stress.

How do I match 50 Ω/75 Ω, and what if I don’t?

Impedance matching isn’t a textbook detail; it’s what keeps your link stable. Most 50 ohm sma cables are designed for RF and wireless systems, while many BNC connectors in video broadcasting are 75 Ω. Plugging them together works physically, but electrically you create reflections.

Imagine sending a clean 2.4 GHz Wi-Fi signal through a 50-to-75 mismatch. The result? Return loss increases, part of the power bounces back, and your device compensates with retries. In analog video, you’ll see snow or ghosting. In data networks, bit error rates go up.

Pairing rules and common symptoms of mismatch

- 50 Ω SMA to 50 Ω BNC to Safe, low-loss.

- 50 Ω SMA to 75 Ω BNC to Works, but reflections rise.

- 50 Ω SMA to N-type (50 Ω) to Stable, often preferred in telecom gear.

As a quick field rule: if your device specifies 50 Ω, don’t casually bridge into 75 Ω unless you’re measuring baseband signals. A better alternative is using purpose-built adapters or short jumpers — for example, see our detailed guide on 50 Ohm Coax Cables for SMA which compares RG174, RG316, and LMR-200 for loss and impedance.

If you’re troubleshooting:

- Snowy video or ghosting to usually impedance mismatch.

- Higher BER (bit error rate) to also impedance mismatch.

- Loss of effective gain to reflected energy instead of clean forward transmission.

So while mismatches won’t fry your equipment, they definitely degrade performance.

What loss/VSWR should I expect from cascaded adapters?

One adapter adds a little loss. Two, maybe 0.3–0.4 dB. By the time you chain four or five, you’ve wasted a whole dB — and worsened VSWR. In many wireless setups, that’s the tipping point between stable and unstable.

That’s why cascaded adapters need careful calculation. Below is a quick estimator for insertion loss and VSWR at common bands.

Cascade Estimator — Total_IL≈n×IL_stage; RL to |Γ| to VSWR

| Frequency (MHz) | Stages (n) | IL_stage (dB) | Total IL (dB) | Typical VSWR |

|---|---|---|---|---|

| 900 | 3 | 0.15 | 0.45 | 1.05–1.1 |

| 2400 | 4 | 0.20 | 0.80 | 1.1–1.2 |

| 5800 | 5 | 0.25 | 1.25 | 1.2–1.3 |

From practice, we recommend no more than 3 rigid couplers at 2.4 GHz. Beyond that, use a sma jumper cable or sma extension cable. Flexible jumpers cut loss and reduce stress.

This is why in our blog Understanding RF Cables: The Ultimate Guide, we point out that short, high-quality coax assemblies outperform stacked adapters almost every time.

When a short jumper outperforms a hard coupler

Rigid adapters are fine for test benches or temporary setups. But in permanent installs, a short jumper does two things at once:

- Keeps the total loss lower than cascaded couplers.

- Protects the device’s SMA port from torque.

That’s why many integrators default to jumpers once the path needs more than one conversion.

How do I ensure outdoor/motion reliability?

O-rings, caps, bulkheads, corrosion considerations

- Sealing: Bulkhead adapters with O-rings are the standard choice for outdoor enclosures. Models rated IP67 keep out dust and water, making them essential for rooftop and pole-mounted installs.

- Caps: A simple dust cap with a gasket protects unused ports during transport or when the site isn’t fully wired.

- Materials: Stainless steel shrugs off corrosion in salty air but adds cost and weight. Brass with gold plating is lighter and cheaper, though it won’t survive as long in harsh climates. Nickel plating sits in the middle — a compromise many integrators choose.

If your project involves using an sma connector for antenna in outdoor gear, don’t skip waterproofing. We once saw a Wi-Fi gateway installed on a water tower where plain brass couplers were used with no caps. Within a year, corrosion crept in and signal quality dropped sharply. Switching to stainless steel bulkhead SMA-BNC adapters with IP67 O-rings solved the problem — they’ve since gone through three winters without issue.

Practical scenarios where IP67 really matters

- Rooftop cellular antennas: O-ring bulkheads stop leaks during storms.

- Vehicle-mounted radios: IP67 adapters handle vibration plus rain splash at highway speeds.

- Outdoor Wi-Fi hotspots: Dust sealing prevents gradual loss of performance in desert or industrial zones.

appearing when emphasizing the importance of waterproofing for outdoor antenna connections. It shows a physical SMA Male Antenna Connector. The document uses a case study to illustrate that using plain brass couplers with no caps outdoors leads to corrosion and signal quality drop within a year, highlighting the importance of selecting waterproof adapters (e.g., IP67 rated) for outdoor antenna connections.

Do I need an adapter, or an extension/jumper instead?

Decision tips and wiring sketches

- Use an adapter: Best for quick lab setups or when you need to swap connections often.

- Use an extension cable: When space is tight and you want to move the stress point away from the device port.

- Use a jumper cable: When you’d otherwise cascade multiple rigid couplers.

For instance, a 28.4 mm SMA-to-BNC coupler is fine in an open rack. But if you add another conversion, you’ll already hit ~0.3 dB of loss. At that point, a sma jumper cable will give you cleaner performance and protect your SMA port from torque.

Lab test vs long-term deployment

- In lab work, rigid couplers are efficient. You don’t worry about vibration or moisture, and quick swaps matter more than strain relief. In long-term deployments — like rooftop radios or IoT base stations — jumpers and sealed bulkhead adapters are far more reliable. For a deeper dive into these trade-offs, see our blog RF Cables and More: The Ultimate Guide.

What specs must I submit before ordering?

- RF adapters are small, but orders can go wrong if details aren’t clear. Vendors like TEJTE support customization, yet the outcome depends entirely on what you provide up front. A half-complete spec sheet almost always leads to delays.

Interface, gender, angle, impedance, band, materials/plating

Before you click “order,” make sure these basics are written down:

- Interface type: SMA, RP-SMA, BNC, N-type, etc.

- Gender: male/female — double check the center pins; it’s where most mistakes happen.

- Angle: straight or right-angle, depending on your layout.

- Impedance: 50 Ω or 75 Ω.

- Frequency band: DC–6 GHz, 2.4 GHz Wi-Fi, or 5.8 GHz ISM, whichever applies.

- Materials and plating: stainless steel for corrosion resistance, brass with gold plating for lighter setups, nickel when you want balance between cost and durability.

For example, if you’re sourcing a flange-mount BNC-SMA adapter with IP67 sealing, it’s not enough to say “bulkhead version.” The drawing usually calls out panel cutout Ø23.7 mm, screw hole spacing 12.7 mm / 18.5 mm, and 1/4-36UNS-2A threads. Miss one of those, and the part may not fit your chassis. Trust me, I’ve seen installers file out panels in the field just to make things work — not ideal.

QC and traceability docs

A serious supplier should also provide:

- Lot numbers tied to raw materials for full traceability.

- Incoming QC reports to confirm material quality.

- Final inspection logs for mechanical fit and plating.

- Electrical test data (continuity, VSWR, return loss) — even a simple sweep helps.

One small note: mechanical dimensions may have a ±0.1 mm tolerance. That’s normal in machining, and usually the electrical performance is what matters most. Still, if your build is tight, let the supplier know the maximum panel tolerance you can accept.

How do I accept incoming adapters quickly?

Visual/mechanical/electrical checks

| Category | What to Check | Why it Matters |

|---|---|---|

| Visual | Thread quality, plating uniformity | Prevents mis-mates, corrosion later |

| Marking | Impedance stamp, batch/lot code | Traceability, easier recall if needed |

| Mechanical | Coupling torque, thread tightness | Ensures stable fit, no wobble |

| Electrical | Continuity, insulation, return loss | Finds hidden RF failures |

Common defects & practical fixes

- Loose threads to reject outright, don’t try to “tighten” by hand.

- Peeling or patchy plating to often a sign of poor base metal, better to reject.

- Pin off-center to reject; trying to force it will damage both sides.

One thing to keep in mind: mechanical dimensions usually carry a ±0.1 mm tolerance. That’s perfectly normal in CNC machining and doesn’t affect electrical performance. Still, if your panel cutouts are tight (for example, Ø23.7 mm bulkhead holes), check that tolerances don’t stack up across multiple units. A quick gauge test is often enough.

From our own shipments, even high-quality lots sometimes include 1–2% off-spec pieces. That’s why a quick acceptance routine is worth the time. For more detail on inspection workflows, see our SMA Connector Guide: Types, Specs & How to Choose.

Conclusion

Picking the right sma adapter isn’t just about finding something that threads on. It’s about considering the signal path, the environment, and the way your hardware will be used day after day. A wrong choice can mean extra insertion loss, mismatched impedance, or even premature port damage.

For bench testing, a sma to bnc adapter usually covers the basics. When you’re deploying outdoors — especially if you’re pairing an sma connector for antenna with radios or IoT gateways — a flange-mount bulkhead with IP67 sealing is the safer investment. And once you find yourself stacking couplers, it’s smarter to swap them out for a sma extension cable or sma jumper cable, both of which reduce torque and improve reliability.

At TEJTE, we’ve also learned that no two projects are exactly the same. That’s why we support multiple customization levels: from small changes like plating or logo, to full drawing-based builds, to sample duplication, and even fully tailored adapters. Clear specs up front save time and eliminate rework later.

FAQs

Do SMA and RP-SMA adapters noticeably affect signal at 2.4 GHz?

Yes. Each adapter adds around 0.1–0.2 dB insertion loss. At Wi-Fi bands, stacking more than three can reduce stability. If you need more flexibility, a sma jumper cable is a better option.

Which gender combo do I need if my device port is SMA-Male?

You’ll need an adapter with an SMA-Female on that side. For instance, an SMA-M to BNC-F if your instrument has a BNC port.

When is a right-angle SMA adapter better than a straight coupler?

Right-angle versions are handy in tight spaces — racks, handhelds, or small enclosures. But they do add strain on ports. For permanent setups, use a short extension cable instead.

Can I mate a 50 Ω SMA to a 75 Ω BNC input without damage?

It won’t damage the hardware, but mismatches increase reflections. Expect snowy video, higher error rates, or lower gain. For clean performance, stick with matched impedance.

Should I use a metal coupler or a short SMA jumper to reduce loss?

Two rigid couplers are fine. Beyond that, a sma extension cable or jumper is usually better — you’ll reduce loss and protect the SMA port from torque.

What acceptance checks should I run on new adapters?

Always check the threads and plating visually, confirm the fit mechanically, and run a quick electrical test for continuity and return loss. Our SMA Connector Guide covers this in more detail.

How do I avoid RP-SMA mix-ups when buying adapters for Wi-Fi gear?

Check the center conductor:

- RP-SMA female has a pin.

- SMA female has a hole.

That one glance can save you from ordering the wrong part.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.