RG316 vs RG58: Loss & Power Comparison Guide

Sep 17,2025

This diagram breaks down the components of the RG316 cable, emphasizing its silver-plated copper conductor, PTFE (Teflon) dielectric for stable high-frequency performance, and FEP jacket that offers a wide temperature range and flexibility for tight spaces.

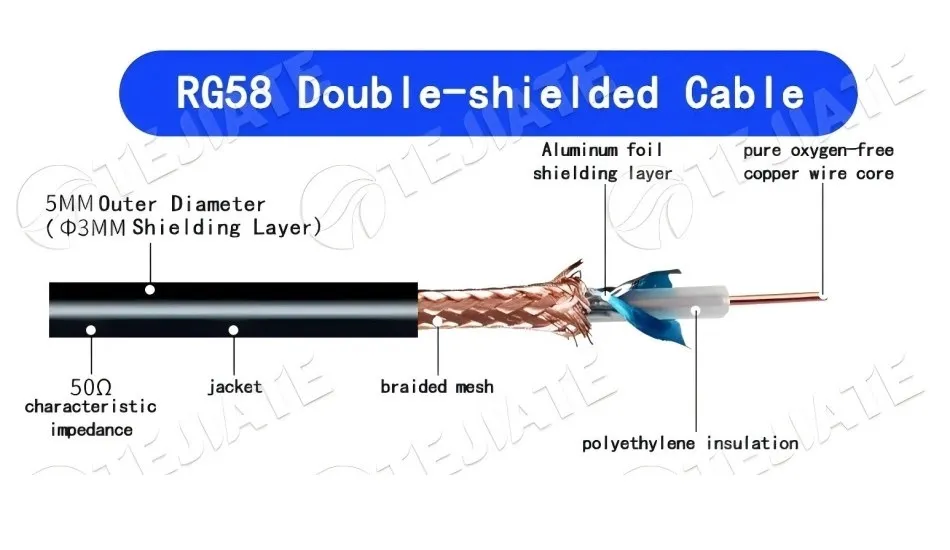

This diagram illustrates the robust construction of the RG58 cable, highlighting its oxygen-free copper core, polyethylene insulation, double braided shielding, and PVC jacket, which contribute to its lower attenuation and higher power handling capabilities.

For many RF buyers and engineers, the choice often narrows to RG316 vs RG58 when selecting a 50 ohm coax cable. Both have been widely used in telecom, antenna systems, and test labs for years, but they’re not interchangeable. RG58 cable is bulkier and supports higher power with lower attenuation, while RG316 is slimmer, easier to route, and frequently chosen for compact enclosures or high-frequency jumpers.

Because both options are readily available and support customization at TEJTE, the real question isn’t about supply—it’s about fit. You’ll need to weigh loss, diameter, bend limits, power handling, and connector compatibility before making a purchase.

Tip from experience: don’t assume one cable can serve all purposes. A 5-meter GPS antenna cable leans toward RG58 to keep loss manageable, but inside a router where space is tight, RG316 is the only realistic option.

Which cable delivers lower loss at your band?

Compare attenuation at 150 MHz / 900 MHz / 2.4 GHz / 5.8 GHz (RG316 vs RG58)

| Frequency | RG316 Attenuation (dB/m) | RG58 Attenuation (dB/m) |

|---|---|---|

| 100 MHz | 0.19 dB/m | 0.077 dB/m |

| 400 MHz | 0.50 dB/m | 0.212 dB/m |

| 900 MHz | ~1.0 dB/m (interpolated) | 0.432 dB/m |

| 1500 MHz | ~1.5 dB/m (est.) | 0.696 dB/m |

| 2500 MHz | ~1.9 dB/m (est.) | 0.932 dB/m |

| 3000 MHz | 2.0 dB/m | 1.052 dB/m |

What stands out is that RG58 coaxial cable consistently carries less attenuation, especially beyond 1 GHz. At 2.4 GHz, rg316 loss nearly doubles the dB per meter compared to RG58. That might be fine in a 10 cm jumper, but over multiple meters in a Wi-Fi feedline or GPS antenna cable, those extra dB quickly become critical.

Practical note: at 150 MHz, either cable performs adequately. But once you move into the microwave bands, RG58 often becomes the safer pick if loss budget is tight.

Do you need more power handling or a smaller OD?

rg58 diameter vs RG316 OD → thermal margin & current density

- RG58: 5.0 ± 0.1 mm OD, PE dielectric, oxygen-free copper conductor

- RG316: 3.0 ± 0.05 mm OD, PTFE dielectric, silver-plated copper conductor

That 2 mm difference in diameter might not look like much on paper, but in practice it changes everything. RG58’s larger cross-section spreads current density, which reduces heating and provides better thermal stability. RG316’s slim profile, on the other hand, makes it the clear winner when you’re routing through 3 mm panel cutouts or crowded RF housings.

Tip from the field: if your design team has already cut small feedthrough holes, don’t waste time trying RG58—it simply won’t fit. RG316 is the only option unless you retool the chassis.

rg58 max power / power handling vs thin-coax limits

| Cable | Max Power (30 MHz, CW) | Notes |

|---|---|---|

| RG58 | ~1.8 kW | Suitable for high-power transmit setups |

| RG316 | ~200 W (limited by OD & heat) | Best for short jumpers or low-power gear |

This image depicts a typical real-world use case for RG58 cable: connecting an outdoor GPS or cellular antenna to an amplifier or receiver. Its superior power handling and lower loss per meter make it the preferred choice over thinner cables like RG316 for runs of several meters, especially in demanding outdoor environments where durability is key.

Will bend radius and temperature constraints force your choice?

Minimum bend guidance & flex cycling

- RG58 coaxial cable: minimum bend radius ~50 mm

- RG316 cable: minimum bend radius ~13 mm

That difference is striking. Push RG58 into a tighter curve and you risk crushing the dielectric, creating micro-cracks, or even spiking return loss. RG316, by contrast, is designed for tight bends and repeated flexing, which is why it’s common in compact RF boards and inside router housings.

Tip from hands-on installs: engineers often underestimate how much repeated bending affects cable life. RG316 holds up better when cycled through flexing tests, while RG58 tends to stiffen and fail sooner if bent aggressively.

Jacket/insulation notes impacting high-temperature installs

This educational diagram breaks down the fundamental components common to all coaxial cables discussed (RG316, RG58, LMR). Understanding the role of each layer—such as the dielectric material (PE vs. PTFE) affecting loss and frequency range, and the shielding affecting EMI protection—is crucial for making an informed choice between them based on application requirements.

- RG58: PVC jacket, operating range –20 °C to +70 °C

- RG316: FEP jacket with PTFE dielectric, rated –55 °C to +255 °C

Here the contrast is even clearer. RG58 works well indoors, in telecom racks, or in lab test setups. But once it’s outdoors in direct sunlight, near engines, or exposed to industrial heat, its PVC jacket won’t last. RG316, with its wide thermal range, keeps performing where RG58 simply can’t.

Pro tip: when sourcing coax for high-heat or outdoor environments, always check the jacket rating. Saving a little on RG58 may look attractive upfront, but a cracked sheath six months later will cost far more in downtime and replacements.

How does frequency range affect your decision above 150 MHz?

Practical rg58 frequency range vs rg316 frequency range ceilings

- RG58 cable: practical cutoff around 1.5–3 GHz, depending on construction quality. Many datasheets list 1.5 GHz as the stable ceiling, while higher-grade versions can sometimes stretch closer to 3 GHz.

- RG316 cable: rated up to 6 GHz, thanks to its PTFE dielectric and precision tolerances.

What this means in practice: RG58 handles HF, VHF, and UHF with no issue, but it’s less reliable once you enter the 2.4 GHz or 5.8 GHz range. RG316, while more lossy, maintains impedance and VSWR performance where RG58 begins to fall short.

Lesson from the field: many engineers working with SDRs or Wi-Fi modules at 2.4 GHz eventually switch to RG316, not because it’s lower loss—it isn’t—but because RG58 can’t keep return loss under control at those higher frequencies.

“Low-band (≤150 MHz) vs 2.4/5.8 GHz” crossover choices

At ≤150 MHz, the choice is easy: RG58 wins almost every time. It carries less attenuation, supports higher power, and has no cutoff issues.

Once you move into 2.4 GHz and above, the balance shifts. RG316 cable, despite its higher attenuation, can still deliver usable performance and stable impedance where RG58 struggles.

For a deeper breakdown of how dielectric and shielding affect high-frequency stability, see our RF coaxial cable guide, which explains why some cables age more gracefully in demanding bands.

What connectors and jumper lengths should you buy today?

sma to sma rg58, bnc to bnc rg58 sdi, gps antenna cable rg58

This image serves as a reference for the different connector interfaces available for terminating coaxial cables. The choice of connector (e.g., SMA, BNC, N) is crucial for ensuring compatibility with equipment and maintaining signal integrity, as discussed in the document's sections on cable assemblies.

- SMA to SMA RG58: common in RF test benches, where low insertion loss matters more than compact size.

- BNC to BNC RG58 SDI: a standard choice in video transmission. RG58 coaxial cable supports the impedance needed for SDI signals at short to medium distances, though longer runs may demand RG59 or LMR195.

- GPS antenna cable RG58: frequently used outdoors, where a few extra meters won’t push loss beyond budget but robustness is still essential.

All of these are available as stock products or custom coax cable assemblies. If you need SMA bulkhead or BNC feedthrough jumpers, TEJTE’s RF adapter and cable line can provide assemblies from 10 cm short jumpers up to multi-meter antenna leads, all tested before shipment.

When a thin jumper helps: short RG316 (e.g., 10 cm / 1 m) for U.FL to SMA

Not every job suits RG58. Inside routers, LTE gateways, or compact RF modules, U.FL to SMA pigtails built with RG316 cable are far more practical. Its 13 mm bend radius and slim OD let it snake through tight housings without stressing connectors.

Practical takeaway: never order just by cable type. Always specify the connector pair, jumper length, and environment. It’s the only way to avoid mismatched assemblies that quietly eat into your signal budget.

Should you step up to LMR alternatives instead?

rg58 vs lmr195 for lower loss & higher power margin

RG58 vs LMR195 is the classic upgrade path. Both have an outer diameter of about 5 mm, but the build is not the same. LMR195 uses a foam dielectric and stronger shielding, which delivers roughly 30–40% less attenuation per meter, particularly above 1 GHz. For outdoor antenna runs longer than 3–5 m, this difference can be the deciding factor in keeping your link within spec.

Procurement insight: many teams stick with RG58 because it’s familiar and cheap, but once the run length goes past a few meters at Wi-Fi or LTE bands, LMR195 often reduces maintenance calls and improves system stability—making it the more cost-effective choice in the long run.

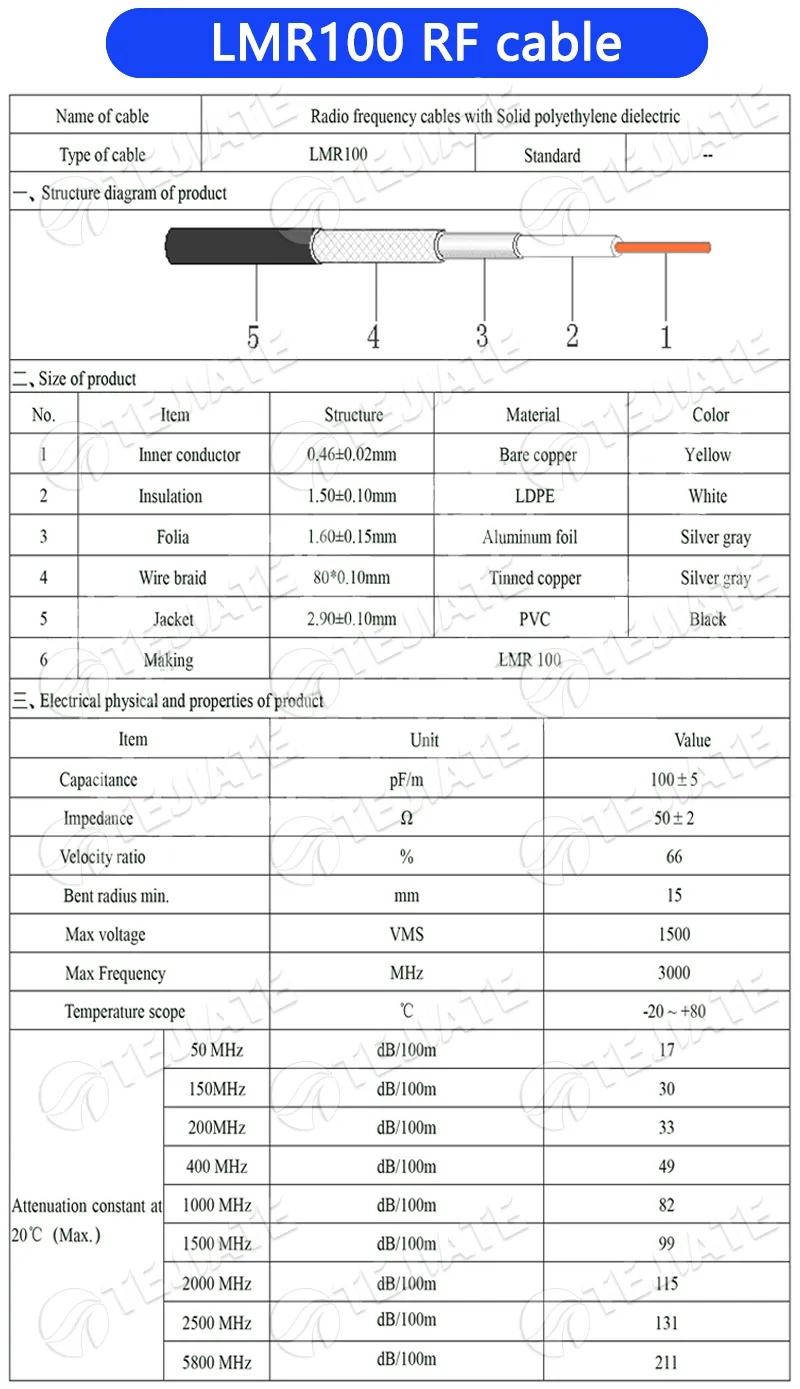

rg316 vs lmr100 when thin + lower loss is required

This figure presents the LMR100 cable as a potential alternative, providing its structural details and key electrical parameters like impedance, attenuation values across frequencies, and temperature range. It allows for a direct comparison with RG316 and RG58, highlighting its position as a lower-loss option similar in size to RG316.

When space is limited but RG316 cable introduces too much attenuation, LMR100 becomes an attractive alternative. It’s nearly the same thickness as RG316, yet the improved dielectric cuts down loss significantly. For IoT gateways, SDR test setups, or embedded boards where size and signal budget both matter, LMR100 often hits the sweet spot.

For a broader comparison beyond just RG316 vs RG58, check our comprehensive RF cable guide. It breaks down where LMR, RG174, and other specialty cables fit into real-world sourcing decisions.

Can your build pass pre-buy acceptance checks?

Spec verification & acceptance limits

| Cable | Frequency | Max Length | Max Total Loss | Min Bend Radius | Temp Range | Connector | Pass/Fail Rule |

|---|---|---|---|---|---|---|---|

| RG58 | ≤1.5 GHz | ≤10 m | <5 dB | ≥50 mm | -20 °C to +70 °C | SMA/BNC | Fail if loss >5 dB or bends <50 mm |

| RG316 | ≤6 GHz | ≤1 m | <3 dB | ≥13 mm | -55 °C to +255 °C | SMA/U.FL | Fail if jacket cracks during heat cycling |

This photo illustrates the ideal application environment for RG316 cable. It is commonly used for short jumpers inside routers, connecting GPS modules to PCBs with U.FL connectors, or in FPV drone systems for video transmission where its small bend radius and stable performance at high frequencies (up to 6 GHz) are critical advantages, even though its attenuation per meter is higher than RG58.

This image showcases the flexibility of RG58 cable in professional and commercial applications through its compatibility with multiple connector types. It is commonly terminated with SMA connectors for RF test equipment and WiFi systems, BNC connectors for video surveillance and SDI broadcast equipment, and larger N-type connectors for base stations and high-power applications. The choice of connector is critical for ensuring impedance matching, mechanical stability, and environmental sealing, all of which are key strengths of the robust RG58 platform.

Procurement tip: always request sample lengths before a big buy. Running a quick sweep test or return-loss check in your own setup is far cheaper than discovering a mismatch after hundreds of assemblies are delivered.

For a closer look at how connector quality can impact return loss, see our SMA connector guide.

How do you test and avoid extra loss after installation?

Quick return-loss/continuity checks, strain-relief, re-termination tips

- Continuity & impedance check – A quick scan with a handheld analyzer will confirm whether your 50 ohm coax cable has proper termination or hidden faults. Skipping this step often leads to hours of chasing “mystery” signal issues.

- Return-loss sweep – Kinks or sloppy terminations show up as VSWR spikes. This is especially important with RG316, which bends more easily but punishes over-bending with unstable impedance.

- Strain relief – Always use clamps, grommets, or tie-downs. RG58’s stiffness lets it take more pulling force, while RG316 can fatigue if it hangs loose or unsupported.

- Re-termination caution – Each additional connector adds roughly 0.1–0.2 dB. Too many reworks and the margin you planned for is gone.

Practical advice: for outdoor antenna runs, sealing connectors with heat-shrink tubing and weatherproof tape often doubles the cable’s life. A few extra minutes during install can turn a 2-year service cycle into a 10-year one.

For a step-by-step approach to link validation, see our GPS antenna cable guide, which walks through real-world loss calculations combining coax attenuation and connector impact.

FAQs

Is RG58 truly lower-loss than RG316 at 150 MHz, and by how much per meter?

Yes. At 150 MHz, RG58 attenuation is about 0.11 dB/m, while RG316 attenuation is closer to 0.15–0.19 dB/m. The gap looks small at low bands, but it keeps widening as frequency rises.

How does RG58 power handling change for short vs long runs at 2.4 GHz?

On short jumpers, RG58 power handling is strong enough to support tens of watts. Over long runs, attenuation becomes the bigger limitation—signal loss, not overheating, is usually what kills performance.

If my design needs tight bends, will RG316’s smaller OD reduce return-loss spikes?

Yes. With its 13 mm bend radius, RG316 cable bends cleanly in tight enclosures. RG58, with a much larger bend limit, often fails in the same scenario.

What’s the practical frequency ceiling where RG316 starts to outperform RG58?

Above about 2.4 GHz. RG58 can push to 3 GHz in some builds, but impedance stability suffers. RG316, rated to 6 GHz, stays usable even if each meter costs you more in dB.

For BNC-SDI video, does RG58 meet length/loss limits or should I pick another coax?

For short SDI runs, BNC to BNC RG58 is fine. For longer video links, buyers usually shift to RG59 or LMR195 to keep attenuation within limits.

When the target link budget is fixed, how do I pick between RG316 and RG58 using total-loss math?

Use the standard calculation: Total Loss = Attenuation × Length + Connector/Adapter losses. If your total is over budget, shorten the run, move to RG58, or step up to an LMR alternative.

Under outdoor heat, does jacket/insulation choice favor RG58 or RG316 for longevity?

Absolutely. RG58’s PVC jacket tops out around +70 °C. RG316’s FEP/PTFE design handles up to +255 °C, which is why it’s trusted in aerospace and automotive.

Conclusion

Neither cable is “better” in every case. RG58 is the workhorse for longer, lower-frequency runs where low loss and higher power handling matter. RG316 wins when the environment is hotter, the space is tighter, or the frequency is higher.

For sourcing, TEJTE’s coaxial assemblies can deliver both types as custom coax cable assemblies, cut to spec and tested before shipment—removing guesswork from the procurement process.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.