RG316 vs RG174: Loss, Power & Best Uses

Sep 16,2025

Which cable gives you lower loss at your frequency?

This image is a detailed datasheet for RG316 cable, listing its key characteristics: construction (silver-plated copper inner conductor 7x0.175mm, PTFE dielectric 1.53mm, silver-plated copper braid outer conductor 1.95mm, brown FEP jacket 2.50mm), electrical properties (impedance 50Ω, capacitance 106pF/m, delay 4.7ns/m, withstand voltage 2000Vrms, velocity of propagation 70%, temperature rating 150°C), mechanical properties (min bend radius 15mm, max tensile strength 3.4kg, weight 17g/m), and most importantly, the attenuation (dB/m) and power handling (W CW) values at different frequencies (100 MHz to 6000 MHz). This table provides the baseline for parameter comparison with RG174.

This image is the specifications table for RG174 coaxial cable, detailing its construction (bare copper inner conductor Φ0.16mm, PE dielectric Φ1.5mm, bare copper braid 64x0.09 Φ1.9mm, black PVC jacket Φ2.85mm), key electrical characteristics (impedance 50Ω, capacitance 96pF/m, velocity of propagation 66%, peak power 2.1kW, operating temperature -2070°C, min bend radius 28mm), and other parameters (e.g., screening attenuation ~90dB, VSWR <1.3 @5-3000MHz). This table provides all the basic technical data needed for comparison with RG316, highlighting RG174's softer PVC jacket, lower cost, but higher attenuation and lower temperature rating.

Compare attenuation at 900 MHz, 2.4 GHz, 5.8 GHz (RG316 vs RG174)

Looking at datasheet values (often summarized in an RG316 loss chart or attenuation table) helps set expectations before installation:

- RG174 attenuation: about 0.43 dB/m at 900 MHz, typically 0.76–1.0 dB/m at 2.4 GHz, and 1.3–1.9 dB/m at 5.8 GHz.

- RG316 cable: roughly 0.88 dB/m at 900 MHz, 1.46 dB/m at 2.4 GHz, and 2.15 dB/m at 5.8 GHz.

| Frequency | RG174 Attenuation (dB/m) | RG316 Attenuation (dB/m) | Typical Use |

|---|---|---|---|

| 900 MHz | ~0.43 | 0.88 | GSM, LTE links |

| 2.4 GHz | ~0.9 | 1.46 | Wi-Fi routers, IoT boards |

| 5.8 GHz | ~1.5-1.9 | 2.15 | FPV drones, video systems |

This chart directly compares the attenuation performance (in dB/m) of both RG174 and RG316 cables at the frequencies of 900 MHz, 2.4 GHz, and 5.8 GHz. The chart clearly shows that RG174 has lower attenuation values than RG316 at these common frequencies (e.g., ~0.9 dB/m for RG174 vs 1.46 dB/m for RG316 at 2.4 GHz). This image is a key visual for the core comparison in the document, emphasizing that while RG174's raw attenuation data appears better, cable choice also depends on shielding, temperature stability, etc.

Estimate total path loss for your length and connectors

Cable loss numbers by themselves don’t tell the whole story. In practice, every connector and adapter adds its own penalty, and when you put them together, those small values can add up. That’s why engineers often look beyond a simple RG316 loss chart or RG174 attenuation table and calculate the total path loss of the system.

The main contributors are easy to remember:

| Factor | Typical Value | What it Means in Practice |

|---|---|---|

| Cable attenuation | Varies with frequency (e.g., 0.9 dB/m for RG174 at 2.4 GHz) | Base loss per meter |

| Connector loss | ~0.15 dB each | Two SMA connectors add ~0.3 dB |

| Adapter loss | ~0.3 dB each | One SMA-to-BNC adds ~0.3 dB |

Example calculation:

- A 1 m RG174 cable at 2.4 GHz (≈0.9 dB/m) with two SMA connectors and one adapter ends up at about 1.5 dB total.

- A 1 m RG316 cable under the same setup (≈1.46 dB/m) pushes the total closer to 2.1 dB.

On paper, RG174 still looks like the lighter option. But if you’ve ever seen a Wi-Fi link drop or an FPV video feed flicker under heat, you’ll know why many engineers pick RG316 anyway. Its double-braid shielding cuts interference, and the PTFE dielectric keeps the system consistent over temperature cycles. For purchasing teams, TEJTE’s RF coaxial cable guide is a useful reference when evaluating loss budgets before ordering.

Will RG316 or RG174 handle your bend radius and heat better?

Minimum bend radius vs jacket and braid design

- RG174 cable: outer diameter about 2.85 mm, minimum bend radius ~28 mm. Its PVC jacket and single copper braid make it flexible and easy to snake through crowded housings.

- RG316 cable: outer diameter around 2.5 mm, bend radius ~15 mm. Thanks to PTFE dielectric and an FEP jacket, it resists kinks and keeps impedance stable during sharp turns.

In small IoT boxes, RG174 often feels easier to route. But if you’ve ever chased a stubborn VSWR problem on an SDR or drone harness, you’ll appreciate how RG316 keeps impedance steady even when bent tighter. That extra stability avoids hours of troubleshooting later.

Temperature rating and insulation (PTFE/FEP vs PE/PVC)

- RG174 cable: rated for -20 °C to +70 °C. Adequate for indoor routers and light-duty runs.

- RG316 cable: rated for -55 °C to +150 °C. Its PTFE dielectric and FEP jacket allow it to survive outdoor sun, soldering heat, or even near engine bays.

That’s a huge margin. For office Wi-Fi or simple indoor IoT gear, RG174 is fine. But in outdoor networks, automotive electronics, or aerospace devices, RG316’s higher temperature tolerance is worth the extra cost. It’s one reason both are popular 50 ohm coax cable types, but they serve very different environments.

Do you need more power handling or tighter routing?

- RG174 cable: uses a bare copper conductor with a single braid. It’s light and flexible, but the power rating is modest. It works fine for GPS receivers, small Wi-Fi dongles, or IoT modules running at low wattage.

- RG316 cable: built with a silver-plated copper conductor and double shielding. It can safely handle around 78 W at 2.4 GHz and 52 W at 6 GHz, while keeping VSWR stable. The extra shielding also protects against EMI, which becomes critical in labs or noisy RF environments.

That’s why you’ll often see SMA-to-SMA RG316 jumpers on SDR test benches or in professional setups. They offer confidence that the signal won’t drift under load.

When flex cycles matter more than raw attenuation

There are still cases where RG174 cable makes sense. Its softer PVC jacket tolerates repeated bending better, so it holds up in handheld radios or portable gear that gets coiled and uncoiled daily. In contrast, RG316 cable shines in permanent installs where performance stability is more important than daily flexibility.

A practical tip: if your cable will be moved often, RG174 is usually the safer pick. If it’s staying in place and handling higher power or higher frequencies, RG316 earns its keep.

How should you choose connectors and lengths today?

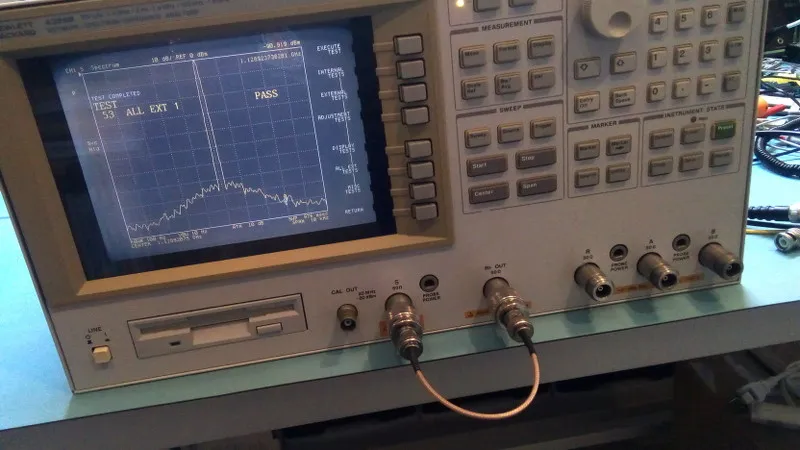

This image underscores the importance of verifying performance in a controlled environment. It connects the theoretical specs from the datasheets to practical, measurable quality assurance, ensuring the cable will perform as expected in the final application.

SMA vs RP-SMA vs BNC vs MMCX vs U.FL on RG316/RG174

- SMA and RP-SMA: Common on routers, SDR boards, and lab equipment. Both RG174 and RG316 terminate cleanly with SMA, but RG316’s tougher FEP jacket holds up better outdoors.

- BNC: Used in SDI video and test gear. Here, RG316 often outperforms RG174 thanks to its double shielding, which keeps signals clean.

- MMCX and U.FL: Space-saving connectors for small modules. RG174’s softer jacket makes it easier to route in compact housings, though impedance consistency is less stable under strain.

From my own experience, it’s not unusual to see RG174 cables used in low-cost IoT builds, while RG316 cables dominate in SDR labs or outdoor gear. The same connector can behave very differently depending on which coax it’s crimped to.

10 cm vs 30 cm vs 1 m jumpers—when to pick which

- 10 cm jumpers: Great for short board-to-panel runs. At this length, the loss is negligible for either cable.

- 30 cm jumpers: Common in FPV drones. At 5.8 GHz, RG316’s 2.15 dB/m spec gives more stable video than RG174’s variable 1.5–1.9 dB/m.

- 1 m or longer: This is where losses add up. For Wi-Fi or GPS, RG316 is more reliable long-term. RG174 should generally be kept under 0.5 m if operating above 2 GHz.

If you’re unsure, TEJTE’s RF coaxial cable guide offers a useful side-by-side breakdown. Many purchasing teams use such references when deciding which jumper lengths meet their target loss budgets.

Selection Checklist

- Frequency

- Length

- Power level

- Minimum bend radius

- Connector pair (SMA, BNC, U.FL)

- Environment (temperature, outdoor/indoor)

- Target loss

A quick rule: if your calculated loss is at least 1 dB below the system’s budget and the bend radius fits the spec, RG316 is the safer choice. Otherwise, consider RG174 for cost-sensitive builds or move up to thicker lines like RG58.

When should you pick RG58 or RG178 instead?

“Thicker-for-power” (RG58) and “thinner-for-space” (RG178) decision notes

- RG58: About 5 mm in diameter, double-shielded, and rated for peak power up to 1.8 kW. It operates reliably to 15 GHz, with attenuation around 7.66 dB/100 m at 100 MHz and 105.2 dB/100 m at 3 GHz. That’s far lower than RG174 or RG316 over longer runs, which makes RG58 a go-to for base stations or lab equipment. The compromise is size: its 50 mm bend radius means you won’t be squeezing it into a tiny enclosure.

- RG178: Much slimmer than RG174, bending to about 5 mm. That flexibility is useful in aerospace, drones, or IoT boards where space is critical. The downside? Higher attenuation than both RG174 and RG316, so it’s only suitable for very short jumpers.

Typical crossover points for Wi-Fi/GPS/FPV/SDI

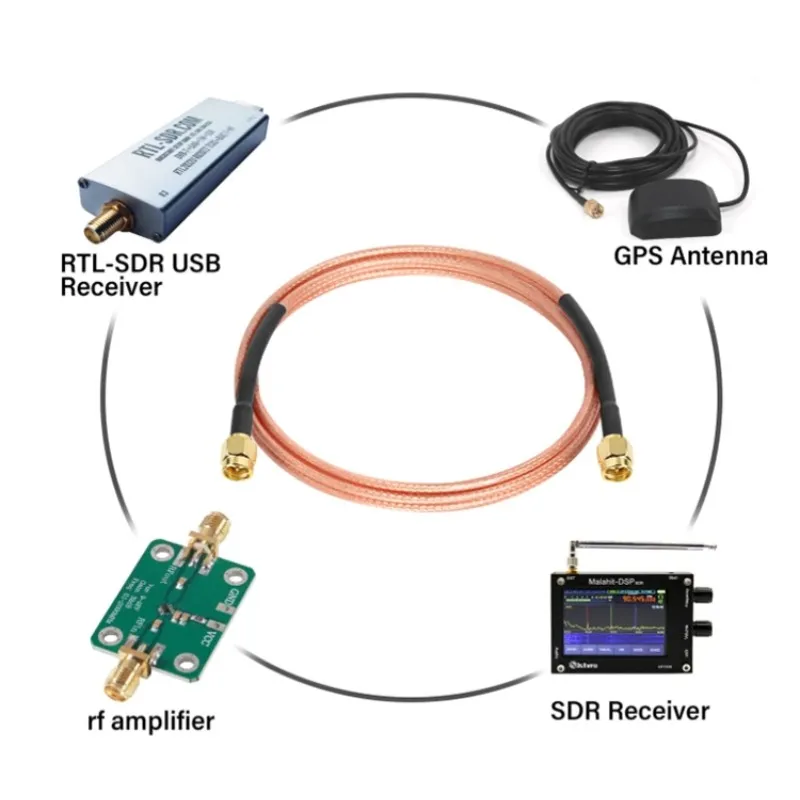

This photo exemplifies the typical use case for RG174: short, low-power, indoor connections where flexibility and low cost are paramount. It's commonly found connecting antennas to boards in routers, dongles, and IoT sensors.

This image represents the application of RG316 in scenarios that demand higher reliability. Its superior shielding and temperature resistance make it the cable of choice for professional labs, outdoor wireless links, automotive systems, and drone video transmitters where RG174 might fail.

- Wi-Fi (2.4 GHz): If your jumper is longer than 30 cm, choose RG316 or RG58. RG174 works only for short pigtails.

- GPS (1.575 GHz): Indoors, RG174 is fine. Outdoors or in heat, RG316 or RG58 are far more reliable.

- FPV drones (5.8 GHz): RG316 is still the preferred choice. RG174 drops too much signal beyond ~20–30 cm, while RG178 is reserved for tiny internal links.

- SDI video (BNC coax): RG58 dominates in professional video setups because of its lower attenuation. RG316 can be used for short SDI jumpers, but RG174 usually won’t pass the quality bar.

Procurement teams often compare these families directly—RG58 vs RG174 vs RG316—to align cable choice with both performance and budget. For a structured breakdown, TEJTE’s RF coaxial cable comparison guide provides detailed attenuation charts and practical selection notes.

Can your build pass acceptance checks before buying?

Pre-buy acceptance criteria & spec verification

| Cable | Frequency | Max Length | Max Total Loss | Min Bend Radius | Temp Range | Connector Type | Pass/Fail Notes |

|---|---|---|---|---|---|---|---|

| RG174 | 2.4 GHz | ≤0.5 m | ≤0.8 dB | 28 mm | -20 to +70 °C | SMA / RP-SMA | Short GPS pigtails |

| RG316 | 5.8 GHz | ≤1.0 m | ≤2.1 dB | 15 mm | -55 to +150 °C | SMA / BNC | FPV drones, Wi-Fi |

| RG58 | 2.4 GHz | ≤5.0 m | ≤2.5 dB | 50 mm | -20 to +70 °C | SMA / N-Type | Base stations |

| RG178 | 5.8 GHz | ≤0.2 m | ≤0.6 dB | 5 mm | -40 to +85 °C | U.FL / MMCX | Ultra-short only |

A simple pass/fail matrix like this makes it easier to filter out cables before samples are even ordered. For example, a buyer sourcing a 1 m jumper at 5.8 GHz can immediately see that RG174 won’t meet spec, while RG316 is acceptable. Longer indoor runs may shift the choice to RG58.

From experience, skipping this step often leads to wasted cycles—installations fail, then teams scramble to reorder. Adding acceptance criteria upfront is cheaper and faster. For connector-level checks, TEJTE’s SMA connector guide can help confirm proper gender and interface matching before purchase.

How do you test and maintain your coax to keep loss stable?

Quick continuity/return-loss checks and handling best practices

- Continuity test: A quick multimeter check before installation ensures the conductor and shield are intact. Skipping this step is a common rookie mistake.

- Return-loss or SWR test: A handheld VNA or SWR meter will quickly show mismatches. For Wi-Fi or GPS runs, keep VSWR below 1.5. If you see higher, look for a pinched bend or loose connector.

- Handling tip: Never clamp coax cables with hard zip ties. It may seem harmless at first, but you’ll distort the dielectric and increase local attenuation. Velcro straps or cushioned clips are safer.

For those new to RF builds, TEJTE’s RF coaxial cable guide offers a solid overview of why impedance stability matters.

Storage, strain relief, and re-termination tips

- Storage: Coil cables loosely into 20–30 cm loops. Over-tight coils will deform the dielectric over time.

- Strain relief: Use heat-shrink boots or proper clamps where cables exit panels. This prevents stress on SMA or BNC ends, especially for RG316 SMA jumpers in lab setups.

- Re-termination: If a connector corrodes or loosens, don’t patch it—re-crimp. A fresh connector restores shielding and impedance control.

These small practices often make the difference between a stable GPS link and one that fails after the first hot summer. In my own projects, I’ve seen inexpensive RG174 cables last much longer simply because they were coiled gently and protected from strain.

FAQs

Is RG316 better than RG174 at 2.4 GHz for Wi-Fi modules?

Generally yes. Even though an RG316 cable shows slightly higher datasheet loss, its PTFE dielectric and double shielding make performance more stable under heat and bends. That’s why many 50 ohm coax cable jumpers for routers and SDR modules are made with RG316 instead of an RG174 cable.

How much loss should I expect from 1 m of RG174 at 5.8 GHz?

Plan for about 1.5–1.9 dB per meter, plus another 0.2–0.3 dB from connectors. In FPV systems, that’s enough to noticeably reduce range if the run is longer than 30 cm.

What’s the safe minimum bend radius for RG316 inside compact enclosures?

Around 15 mm. You can bend it tighter, but you risk shifting VSWR. Personally, I leave extra clearance whenever possible, because a pinched bend can cause unpredictable attenuation.

For GPS pigtails, which performs more consistently—RG316 or RG174?

Both can work for short indoor runs. Outdoors or near engine bays, RG316 cables rated at -55 °C to +150 °C are the safer option. By contrast, an RG174 cable rated only to 70 °C can drift out of spec. For more context, see TEJTE’s GPS antenna cable guide.

Does RG316’s higher temperature rating matter for outdoor installs?

Yes. If a cable is exposed to sunlight or engine heat, RG174 tends to degrade quickly. RG316 cables hold their performance in those conditions, which is why they’re often chosen for outdoor Wi-Fi or automotive systems.

Is RG316 suitable for BNC-based SDI runs, or should I consider another coax?

For short SDI jumpers, RG316 is fine. But for long professional video runs, RG58 is usually preferred due to lower attenuation.

If I need both tight bends and low loss, when should I move to RG58 or RG178?

Use RG178 when space is your main constraint and the run is very short. Choose RG58 when you need lower loss over distance and can accept a larger bend radius. RG316 sits between them—compact but still offering stable shielding.

Wrapping up: keeping comparisons practical

At the end of the day, the RG316 vs RG174 debate is less about raw numbers and more about matching cable traits to your project. RG174 bends easily and works in short IoT pigtails; RG316 stays stable in high-frequency, high-temperature, or lab environments. If neither fits, RG58 (for power) or RG178 (for space) fill the gaps.

For buyers, using checklists, acceptance tables, and simple test routines will help avoid costly re-installs. And if you need ready-made assemblies, TEJTE offers custom coaxial cable solutions ranging from SMA-to-SMA jumpers to U.FL-to-SMA GPS cables.

When should you pick RG58 or RG178 instead?

“Thicker-for-power” (RG58) and “thinner-for-space” (RG178) decision notes

- RG58: With a diameter of about 5 mm and double shielding, RG58 supports higher peak power—up to 1.8 kW—and performs reliably up to 15 GHz. Attenuation is 7.66 dB/100 m at 100 MHz and about 105.2 dB/100 m at 3 GHz, much lower than RG174 or RG316 for long runs. The trade-off is space: its 50 mm bend radius makes it unsuitable for cramped builds.

- RG178: Designed for extreme space constraints, RG178 is thinner than RG174 and bends to around 5 mm. The downside is higher attenuation, making it best for short jumpers inside compact IoT or aerospace devices.

Typical crossover points for Wi-Fi/GPS/FPV/SDI

- Wi-Fi routers (2.4 GHz): Use RG316 or RG58 if the jumper exceeds 30 cm; RG174 works only for very short pigtails.

- GPS antenna cables (1.575 GHz): Indoors, RG174 is fine; outdoors, RG316 or RG58 are more durable.

- FPV drones (5.8 GHz): RG316 is the clear choice; RG174 suffers too much loss, and RG178 is only acceptable for ultra-short links.

- SDI video via BNC: RG58 remains the standard for professional video, though RG316 can work for shorter SDI jumpers.

For further detail on where each cable shines, see TEJTE’s RF coaxial cable comparison guide.

Can your build pass acceptance checks before buying?

How do you test and maintain your coax to keep loss stable?

Quick continuity/return-loss checks and handling best practices

- Continuity test: A simple multimeter verifies conductor integrity before install.

- Return loss/SWR test: At Wi-Fi or GPS bands, keep VSWR <1.5 for reliable links. Tools like handheld VNAs are effective for this.

- Handling: Avoid crushing coax under clamps or sharp bends. Both RG174 and RG316 rely on consistent dielectric geometry for impedance stability.

For a more detailed overview of measurement basics, check TEJTE’s coaxial cable testing guide.

Storage, strain relief, and re-termination tips

- Storage: Coil cables loosely in 20–30 cm loops.

- Strain relief: Add heat-shrink or boots where cables exit panels to avoid stress on SMA or RP-SMA ends.

- Re-termination: If connectors degrade, crimp new ones rather than patching. A fresh connector restores shielding and impedance control.

Following these practices ensures that a custom SMA-to-SMA RG316 jumper delivers the same performance after two years as it did the day it was installed.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.