RF Connector Selection Guide: What You Need to Know

July 25,2025

An example of a common RF connector (BNC) attached to a coaxial cable. Choosing the correct connector ensures optimal signal transfer and system performance.

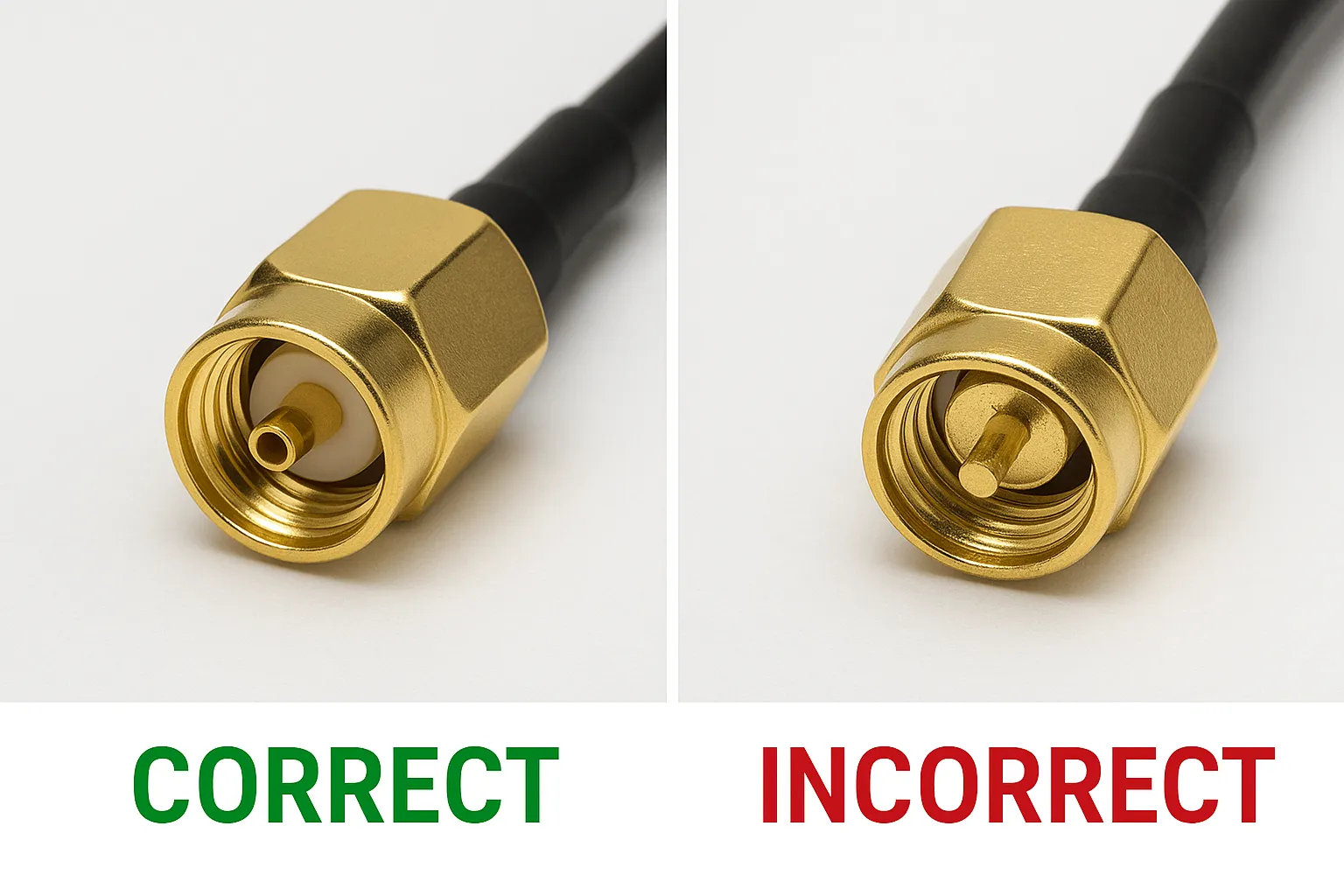

This image highlights the performance degradation caused by using the wrong type of RF connector, compared to a correctly matched one.

Ask any RF engineer, and they’ll tell you—choosing the wrong connector can quietly sabotage even the best-designed system. From a rooftop antenna on a rural home to a dense 5G node in a city, radio frequency connectors often become the weakest link if not properly selected.

They might seem like a small part, but these connectors directly influence how well high-frequency signals travel. Poor compatibility or mismatched impedance can lead to disruptions that aren’t always easy to trace.

Instead of simply listing specs, this guide aims to help you think practically. What are RF connectors really doing in your setup? Which specs actually matter for your use case? By walking through real-world factors and examples, you’ll be able to choose a connector that holds up—technically and commercially.

Understanding RF Connectors

What is an RF Connector?

Ever tried plugging something in and it just didn’t feel right?

That’s not just a bad fit—it might be the wrong connector altogether.

In the world of radio frequencies, RF connectors are the specialized hardware that makes sure your coaxial cable isn’t just connected—but properly shielded.

They’re different from your everyday plugs.

These connectors preserve impedance, block signal loss, and keep reflections in check, especially when you’re dealing with high-frequency signals.

Here are a few names you’ll run into (and probably already have):

• BNC – quick to snap on, quick to pull off

• SMA – tiny but built for GHz action

• N-Type – robust, often used outdoors

• TNC – got threads, perfect for shaky setups

So where do they show up?

If it sends a signal wirelessly—think towers, satellites, broadcast vans, or radars—there’s likely an RF connector somewhere inside, doing quiet but critical work.

Why the "Right" Connector Actually Matters

Let’s get real: choosing poorly here doesn’t just lower performance. It can quietly wreck everything.

Think about this:

You’ve got power, the gear is on… but the signal’s dropping.

That could be impedance mismatch, reflections, or worse—VSWR through the roof.

It’s not always about numbers.

Even a technically “correct” connector might be physically off—too loose, too tight, or simply incompatible with your gear’s port layout.

Watch out for these deal-breakers:

• Signal fades out too fast? Might be high insertion loss

• Getting weird reflections? Check impedance balance

• Broken cable tip? That’s mechanical mismatch

• Outside install? You’ll want weather resistance, no question

TL;DR?

The “right” RF connector isn’t just about specs—it’s about long-term reliability, from military comms to 5G.

Common Types of RF Connectors and Applications

RF connectors come in a variety of form factors and performance ratings. Here we highlight some of the most common connector types, along with typical usage scenarios and characteristics:

Various popular RF connectors (from largest to smallest): N-type, PL-259 (UHF), TNC, BNC, SMA, SMB, MCX, and others. Each connector type has specific applications and frequency limits.

- BNC Connector:

- Compact, with a bayonet-style lock—just push and twist.

- Used heavily in CCTV, lab oscilloscopes, and ham radios.

- Works up to ~4 GHz, and comes in 50Ω or 75Ω versions.

- Why BNC? Because you don’t need tools. Plug in, twist, test, done.

- SMA Connector:

- Threaded, tight, and tiny—that’s SMA.

- Ideal for Wi-Fi, cellular, GPS, and RF test equipment.

- Operates comfortably up to 18 GHz, sometimes even 26.5 GHz with precision variants.

- Always 50Ω, unless you’re dealing with RP-SMA, its polarity-flipped cousin (watch out for this).

- N-Type Connector:

- Rugged, threaded, and surprisingly capable.

- Handles higher power and resists the elements.

- Supports frequencies to ~11 GHz, sometimes 18 GHz.

- You’ll spot these on base station antennas, radars, and satellite dishes.

- Internal seals make them weatherproof warriors.

- TNC Connector:

- Think BNC, but screwed on, not twisted.

- Less wobbly, more stable at higher frequencies—up to ~11 GHz.

- Found in military comms, aerospace, and WLAN devices.

- Typically 50Ω, with some 75Ω options around.

- SMB & SMC Connectors:

- SMB: Snap-on, smaller than SMA. Easy to connect, supports up to ~4 GHz.

- SMC: Similar look, but with a threaded fit—goes up to ~10 GHz.

- Preferred in compact RF modules, medical devices, and tight circuit boards.

- MCX & MMCX Connectors:

- These are micro connectors, perfect for tiny gadgets.

- Both go up to ~6 GHz, and MMCX allows 360° rotation once locked in—handy for reducing cable stress.

- Seen in GPS receivers, drones, handheld trackers, and more.

- F-Type Connector:

- Found on cable boxes, TVs, and set-top antennas.

- 75Ω impedance, threaded coupling, and runs up to ~1 GHz.

- The cable’s center wire becomes the connector pin—simple and cost-effective.

- Other specialized connectors:

- UHF (PL-259) – Old-school, mostly for HF/VHF radio (<300 MHz).

- 7/16 DIN – Massive, made for high-power transmitters.

- QMA – A quick-lock version of SMA, no screwing.

- 2.92mm, 2.4mm, 1.85mm – Precision-grade, reaching up to 67 GHz+, for lab-grade microwave systems.

Applications Recap: Each connector type is chosen based on the application’s needs. For example, BNCs in test labs and video links, SMA for high-frequency radio modules, N-type for outdoor antenna feeds, and F-type for TV cables. Understanding the context in which a connector is used will guide you toward the appropriate type.

Key Factors to Consider When Choosing an RF Connector

Now that we know the common connector styles, let’s discuss how to actually choose the right one for your project. This decision should be guided by several key factors and requirements:

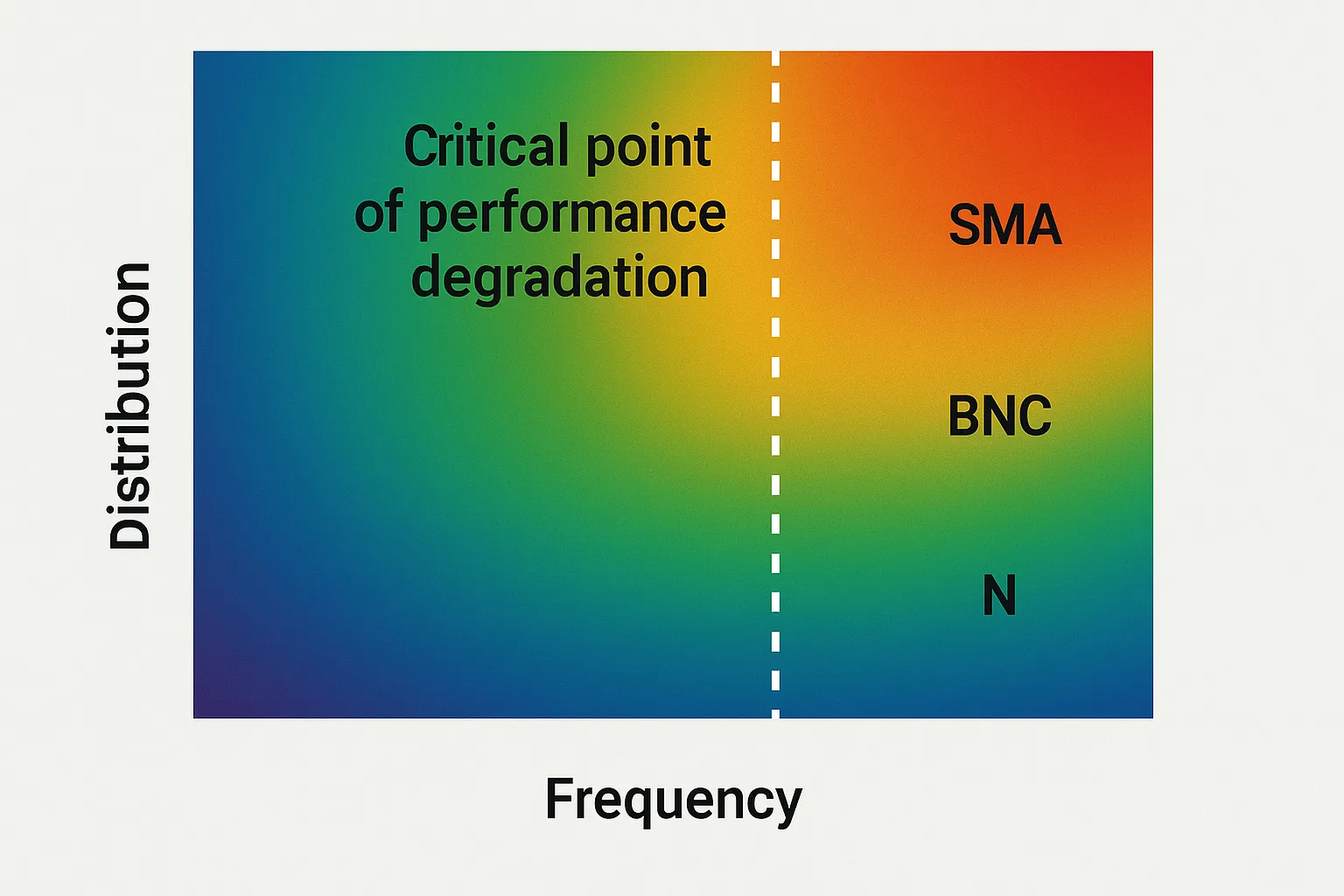

1. Frequency Range vs. Real-World Performance

Start with Frequency—Always

RF isn’t forgiving. Use a connector outside its comfort zone, and your signal starts falling apart—like sending a whisper through a megaphone tuned for shouting.

Take BNC: reliable up to ~4 GHz. But put it in a 10 GHz system?

You’re inviting impedance mismatch, reflection, and loss to the party.

Each connector has a ceiling—cross it, and performance drops off a cliff.

That’s why you must check the max frequency rating (a.k.a. cutoff frequency).

How to Choose Smartly

If your system runs at 10 GHz, don’t pick a 10 GHz-rated connector—choose one with headroom.

- It’s not just about the fundamental frequency, either. Consider harmonics, especially for high-speed or modulated systems.

Connector Frequency Capabilities (Examples):

| Connector Type | Typical Max Frequency (GHz) | Notes on Usage |

|---|---|---|

| BNC | ~4 GHz | 50 Ω or 75 Ω; quick bayonet lock; used in video, tests. |

| TNC | ~11 GHz | Threaded BNC variant; better at higher freq, rugged. |

| SMA | ~18 GHz | Precision threaded; common for microwave modules. |

| N-Type | ~11 GHz | Large threaded; high power; often outdoor use (weatherproof). |

| MCX / MMCX | ~6 GHz | Snap-on micro connectors; used in compact devices (GPS, etc.). |

| SMB | ~4 GHz | Snap-on subminiature; quick connect in tight spaces. |

| SMC | ~10 GHz | Threaded subminiature; secure connection for small devices. |

| F-Type | ~1 GHz | 75 Ω threaded; for TV cable and satellite feeds. |

| 7/16 DIN | ~7.5 GHz | Very high power; used in cellular base stations. |

Pushing Limits = Poor Results

Working too close to the max rating?

Expect high VSWR, signal fade, and unexpected losses.

Treat that frequency cap not as a goal—but as a hard warning.

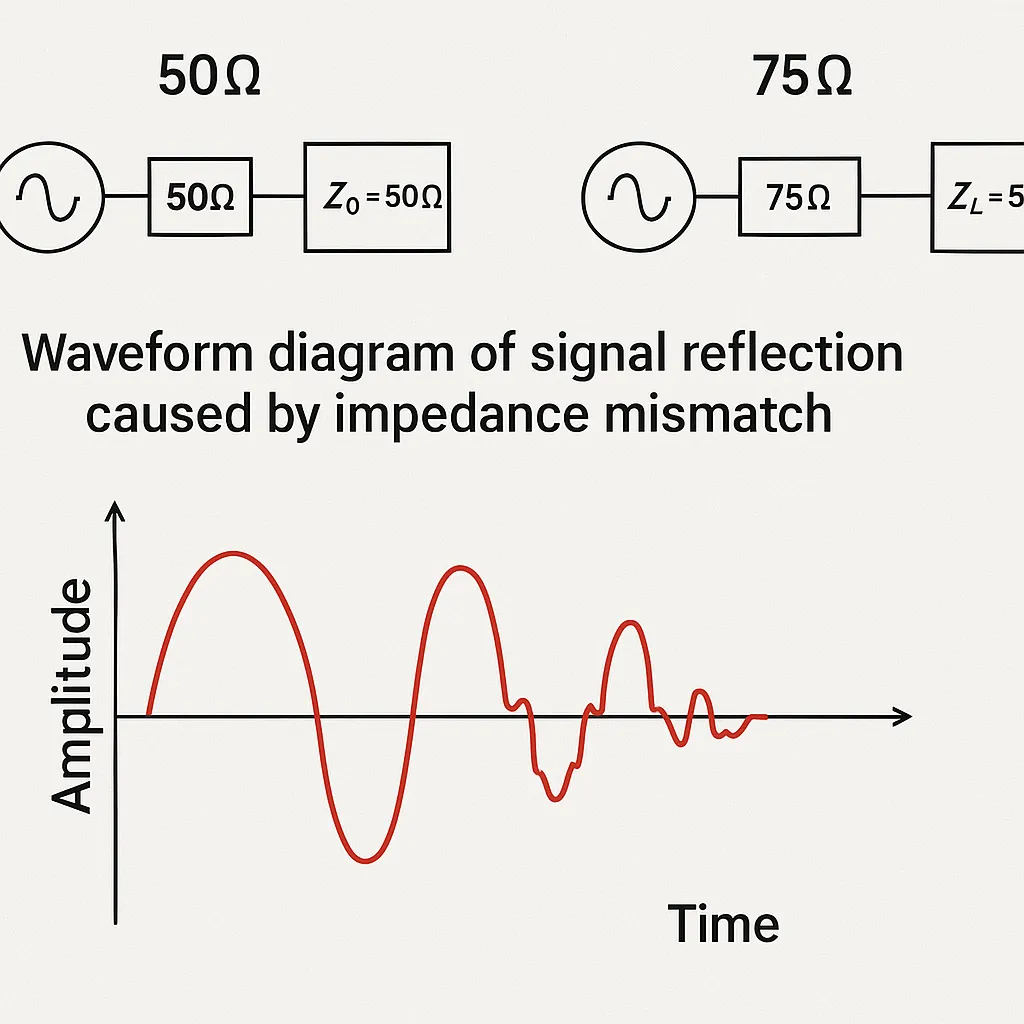

Impedance Compatibility (50 Ω vs 75 Ω)

This chart compares the characteristics of 50Ω and 75Ω RF connectors, where 50Ω is preferred for high power and 75Ω for video signal clarity.

Mismatch = Trouble

- Think impedance like a language—if one side speaks 50Ω and the other speaks 75Ω, you’ll get miscommunication… in the form of signal reflections.

- SMA, N, TNC and friends? That’s your 50Ω crew—ideal for Wi-Fi, radios, cellular, and RF test gear.

- On the flip side: F-type, Belling-Lee, and some BNC connectors are 75Ω, built for TVs, satellite dishes, and video feeds.

Don’t Mix Without a Plan

If your setup is 50Ω end-to-end, don’t sneak in a 75Ω BNC just because it “fits” physically.

Looks are deceiving—electrically, it’s a mismatch.

Same goes for TV or video systems:

Stick with 75Ω cables and connectors throughout.

Watch for These Gotchas

Some connector types have both versions!

BNC and SMB are classic culprits—you’ll find 50Ω and 75Ω variants that look nearly identical.

Always check the labeling or datasheet, not just the shape.

Unless you’ve got a matching pad, transformer, or impedance adapter, mixing them can wreck your signal—especially at higher frequencies.

Simple Rule of Thumb

- 50Ω goes with 50Ω. 75Ω stays with 75Ω.

- Mixing? Only with proper matching. No exceptions.

3. Mechanical Form Factor: Size, Mounting & How It Fits

Consider size, mounting style, and mating requirements. The physical design of the connector must suit your application’s constraints:

Size & Space Constraints

Space is precious.

Try fitting an N-type connector into a smartwatch PCB? Not happening.

In compact builds, connectors like MMCX or U.FL might be your only option.

But they’re not rugged—great for one-time assembly, not for constant plugging.

SMA, on the other hand, is much sturdier—ideal when repeated mating is expected.

Tip: Match size to both available space and mechanical durability needs.

Cable Type Compatibility

Coaxial cables aren’t universal.

Whether it’s RG-6, RG-58, or RG-174, the connector must match the diameter and build.

Example:

• RG-6 → use F-type or 75Ω BNC

• RG-174 → go with SMA or MCX variants

The fit isn’t just about size—it’s about pin diameter, ferrule match, and termination method (solder vs. crimp).

Tip: Always double-check that your chosen connector supports your cable’s physical specs.

Cable Type Compatibility

Coaxial cables aren’t universal.

Whether it’s RG-6, RG-58, or RG-174, the connector must match the diameter and build.

Example:

• RG-6 → use F-type or 75Ω BNC

• RG-174 → go with SMA or MCX variants

The fit isn’t just about size—it’s about pin diameter, ferrule match, and termination method (solder vs. crimp).

Tip: Always double-check that your chosen connector supports your cable’s physical specs.

Mounting Style: PCB, Panel, or Inline?

Need to pass the connector through a case wall?

That’s where bulkhead connectors shine.

Building a radio board? Then it’s PCB-mounted—options include edge-launch, end-launch, or right-angle types.

If it’s an inline cable-to-cable connection, pick a straight or right-angle variant accordingly.

Tip: Pick a mounting style that integrates smoothly into your enclosure or board layout.

Mating Interface: Gender & Polarity

Sounds obvious, but… male doesn’t connect to male.

And reverse polarity can trip you up.

Standard rule:

• Male has a center pin, often with external threads

• Female has a receptacle, threads inside

Watch out for RP-SMA (reverse polarity SMA), used in Wi-Fi gear.

Looks identical until you realize the center pin is missing or reversed.

Tip: Never guess polarity—always confirm via datasheet or visual check.

Coupling Mechanism: How It Locks

Different connectors connect… differently:

- Screw-on → SMA, N, TNC

• Bayonet (twist-lock) → BNC

• Snap-on → SMB, MCX, MMCX

• Push-pull or quick-lock → QMA, FME

If your setup will vibrate or move, stick to threaded or locking types.

For quick swaps (like lab work), snap-on or bayonet saves time.

Tip: Balance ease-of-use with mechanical reliability.

4. Power Handling & Voltage: Can Your Connector Take the Heat?

RF Power – Don’t Let Your Connector Melt

Power = heat. Heat = risk.

Running 100W or more? That little MMCX probably isn’t going to survive.

Larger connectors like N-type or 7/16 DIN are built for the job.

The 7/16 DIN can handle kilowatts—which is why you’ll find it on cell towers and broadcast stations.

Key point: As frequency goes up, power-handling drops.

Losses increase, and heat builds faster. Always check the rated RF power at your actual working frequency.

Using an undersized connector = signal drop, heat, maybe even meltdown.

Voltage Rating – Not Just About RF

Some connectors are built to handle voltage, not power.

Example:

• MHV → good for ~1.6 kV

• SHV → safe up to ~5 kV

You’ll find these in lab environments—like photomultiplier tubes or high-voltage power supplies.

Regular connectors (like SMA or BNC) handle hundreds of volts max, not kilovolts.

If your system deals with peak voltage spikes, don’t overlook the voltage rating even if RF power is low.

What About Current? (Especially for DC or Low-Freq)

Sometimes a coax carries more than RF—maybe DC bias or low-frequency signals.

In such cases, the question becomes:

Can the center conductor handle the current?

Example: a 1.5 mm² copper wire typically handles 10–16 A, depending on conditions.

That doesn’t mean your connector can.

Check not just the wire size—but the connector’s pin diameter, contact material, and thermal rating.

Power/Voltage Checklist

- Match connector to RF power at real frequency

- For high-voltage use, use rated high-voltage types like SHV

- Carrying DC current? Confirm pin size & material specs

- When in doubt—check the datasheet

5. Environmental & Durability Concerns: Not All Connectors Like Rain

Indoors or Out in the Wild?

Connectors hate weather—unless built for it.

Outdoors? You’ll want weatherproof designs like N-type, 7/16 DIN, or ruggedized SMA with O-rings and seals.

Got an antenna on the roof?

Then you better use a connector that can withstand water, UV, dust, and daily temperature swings.

Or at the very least, wrap it tight with weatherproofing tape.

Tip: If it’s going outside, treat it like a roof tile—not just an electronic part.

How Often Will You Plug It?

Some connectors are made to mate and unmate. Others… not so much.

BNC and SMA are good for hundreds of cycles.

Great for test gear, labs, or anything that gets reconfigured a lot.

But U.FL? 10–30 plug-ins. That’s it.

Designed for permanent internal use, not daily abuse.

What’s the workaround?

Use a pigtail: U.FL inside, SMA bulkhead on the outside—saves wear on the tiny guy.

Tip: If you’ll be unplugging often, don’t rely on micro-connectors alone.

Got Vibration? Secure It

- In cars, planes, or machines, things shake—and connectors can come loose.

- That’s why threaded connectors (like SMA, TNC) or locked designs (like bayonet or latch mechanisms) are better.

- Also add strain relief—because tugged cables = broken joints.

Poor mechanical security is a silent failure waiting to happen.

Heat, Rust & Other Enemies

Not all connectors like it hot.

Some plastic insulators deform or degrade at elevated temps.

Standard materials: brass, stainless steel, gold/nickel plating, PTFE/Teflon insulators.

Marine or corrosive use? Choose corrosion-resistant plating—stainless + special coatings recommended.

Tip: Check temperature and corrosion ratings like you would for fasteners or enclosures.

Special Environments = Special Specs

- Military or aerospace? Now you’re talking MIL-spec, NASA-rated, or low-outgassing components.

- Precision lab gear? You might want sexless connectors like APC-7 to eliminate wear asymmetry.

- These aren’t just “fancy” options—they’re often mission-critical.

Bottom Line: Will It Survive?

- Outdoors? Seal it.

- Mating often? Use durable types.

- High-vibe? Thread it and strain-relieve it.

- Harsh heat or salt air? Use the right metals.

- Mission-critical? Go military-grade or precision.

6. Quality, Availability & Cost – Choose with Confidence

Quality Matters – Especially at High Frequencies

Not all connectors are created equal.

At microwave and RF levels, even small manufacturing tolerances can affect impedance continuity and signal integrity.

That’s why it’s important to stick with reputable manufacturers—like Amphenol, TE Connectivity, Molex… or trusted specialists like TEJTE.

TEJTE provides ISO-certified RF connectors and cable assemblies, complete with testing reports and performance guarantees, suitable for telecom, industrial, and custom integration needs.

Tip: Look for connectors with MIL-STD or ISO certifications if your application demands stability and verified performance.

Availability – Can You Source It When You Need It?

Common types (like SMA, BNC, N-type) are easy to find.

Rare or proprietary connectors might be obsolete, backordered, or MOQ-restricted.

TEJTE solves this with flexible sourcing: we offer both standard off-the-shelf connectors and custom OEM/ODM manufacturing, including small-batch prototyping with rapid turnaround.

Don’t let sourcing become the bottleneck in your RF project lifecycle.

Cost – Balance Price with Performance

RF connectors range from under $1 (F-type, basic BNC) to over $50+ (precision-grade microwave connectors).

For low-volume or prototyping, it may be worth spending slightly more for a trusted standard type—like a TEJTE SMA connector that ensures consistent performance.

For high-volume production, every cent counts—but quality still matters on critical RF paths.

And don’t forget the hidden cost of tooling:

Crimp-type connectors require specialized tools. If that’s not in your setup, TEJTE offers fully assembled RF cable kits, pre-tested and ready to use.

Serviceability & Long-Term Standardization

Think beyond the lab. If your product will be maintained in the field, choose a widely-used connector like SMA—users can easily find extensions or replacements.

Using obscure or proprietary connectors can make future maintenance difficult.

With TEJTE, you can standardize around proven types, while still having the option to custom-brand, label, or tailor to specific housing or mating requirements.

Why TEJTE?

“TEJTE offers ISO-certified RF connectors, cable assemblies, and antenna solutions. From rapid prototypes to high-volume OEM/ODM production, we provide reliable, customizable, and cost-effective RF components backed by technical expertise.”

Conclusion: Choosing the Right RF Connector – It’s All in the Details

Choosing an RF connector isn’t just about one spec—it’s about fit, function, and future-proofing.

Here’s a quick wrap-up checklist:

Start with the specs:

Know your system’s frequency, power, and impedance.

• High frequency? Go SMA or N.

• High power? Look at N or 7/16 DIN.

• 75Ω system? F-type or 75Ω BNC.

Check physical constraints:

• Tight on space? Go micro (MCX, MMCX).

• Need panel mount? Try bulkhead SMA or BNC.

• Mating interface must match your cable/device layout.

Consider the environment:

• Outdoor? Use weatherproof models.

• Frequent plug/unplug? Pick connectors rated for it.

• Vibration? Threaded or locking types win.

Verify datasheets and margins:

Don’t just go by the name—read the actual frequency rating, VSWR, and mating cycles.

Think ahead – assembly, sourcing, and scaling:

• Can you terminate it reliably?

• Do you have the tools?

• Will replacements be available 6 months from now?

A Reliable Connector = A Reliable System

A solid choice avoids signal loss, mechanical failures, and future headaches.

A bad one? It might pass a test—only to fail in the field.

The connector isn’t just hardware—it’s the keystone of RF performance.

Need Help? Ask the Experts – Like TEJTE

Not sure what to choose? TEJTE’s engineering team is here to help.

Whether you need off-the-shelf connectors, custom cable assemblies, or application-specific solutions, we’ve got you covered.

Check out:

- tejte.com/about/certificates/ – View our certificates

- tejte.com/custom-made – Explore tailored OEM/ODM services.

- tejte.com/products – Browse ready-to-use RF components.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.