RC Snubber for 12 V: Relay & Motor Damping

Dec 04,2025

Preface

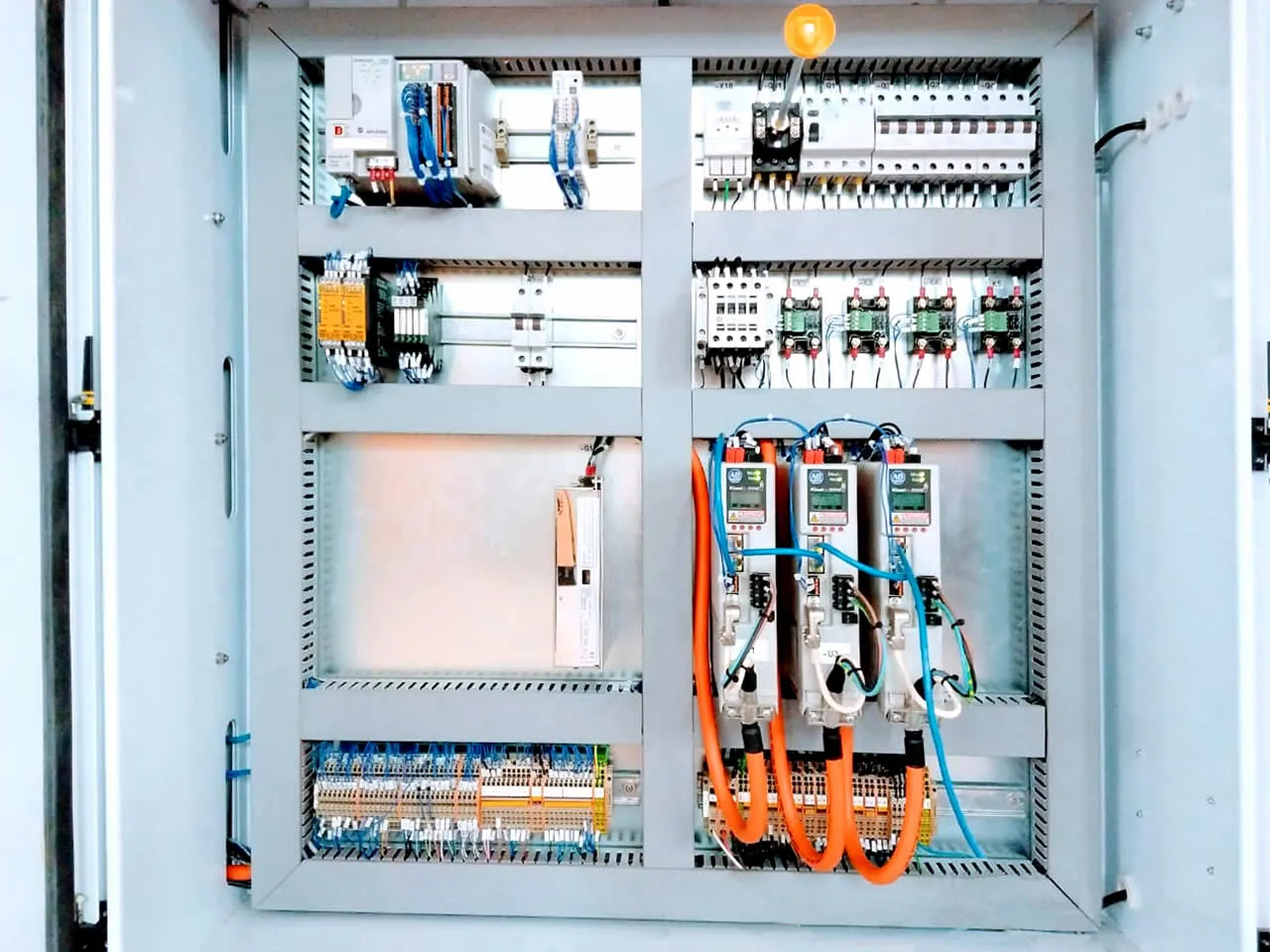

Figure is the visualization of the document's "problem statement." Through an illustration that may include arcing flashes, oscilloscope spike waveforms, or damaged contacts, it transforms the abstract concept of "inductive voltage spikes" into a concrete, tangible engineering challenge. This graphic aims to immediately resonate with readers, especially engineers who have struggled with relay contact damage or EMI issues, laying the groundwork for introducing the RC snubber as a "smarter alternative."

In every 12 V control cabinet—whether automotive or industrial—the real enemy of longevity isn’t always heat.

It’s that sharp inductive kick that comes the instant a relay or motor winding is switched off.

What looks like a harmless 12 V circuit can generate spikes exceeding 100 V, enough to pit relay contacts, disturb sensors, or radiate bursts into CAN and LIN buses.

A freewheel diode is the traditional fix, but it comes with side effects: slower release, sluggish timing, and lingering current.

When precise actuation or EMI compliance matters, an RC snubber becomes the smarter alternative.

This article walks through when and how to use it, how to size the components, and what to watch for in layout and validation—based on hands-on testing and the design principles shared in TEJTE’s 12 V protection hub.

When should you choose an RC snubber instead of a freewheel diode?

The freewheel diode clamps the voltage across a coil to roughly one diode drop.

It’s simple and cheap, but it slows the magnetic collapse, delaying relay release by several milliseconds.

An RC snubber, by contrast, lets the voltage rise moderately—perhaps 30 V to 60 V—while absorbing energy through the resistor–capacitor network.

That balance yields faster release and cleaner waveforms with less ringing.

If you’ve seen contact arcing, EMI bursts, or inconsistent release timing, those are textbook symptoms telling you the diode alone isn’t enough.

Many teams running life tests on 12 V relays discovered that switching to an RC network reduced EMI by >10 dB µV and improved lifetime by nearly 2×.

The same applies to brushed DC motors: snubbers can keep commutation spikes from coupling into logic supplies.

Map the symptom: relay bounce, EMI, arcing, or slow release?

| Symptom | Typical Cause | Recommended Suppression |

|---|---|---|

| Contact arcing on opening | Inductive discharge | RC snubber across contacts |

| EMI or sensor glitch | Fast dv/dt from coil | RC snubber or RC + TVS diode |

| Slow release timing | Diode clamp holds current | Replace with RC network |

| Audible relay bounce | Coil overshoot / vibration | RC with slightly larger C |

| MCU reset near relay | Ground bounce / radiation | Tight layout + RC close to coil |

Compare effects on release time vs. voltage spike vs. EMI

| Suppression Method | Peak Voltage Impact | Release Time | EMI Suppression | Heat Dissipation Path |

|---|---|---|---|---|

| Freewheel diode | ~ 0.7 V above supply | Slow (× 5-10) | Medium | Diode junction loss |

| Zener diode | Vz + Vf | Moderate | Good | Zener junction |

| RC snubber | Configurable 10–50 V | Fast | Excellent | Resistor element |

| TVS diode | 30-40 V clamp | Fastest | Excellent | TVS silicon |

If the relay’s release delay hurts logic sequencing or PLC timing, go for an RC snubber.

For severe arcing or transient-energy spikes, add a TVS diode as a parallel clamp—TEJTE’s automotive TVS overview explains why low-clamping types make sense in 12 V nodes.

How do you size R and C for a 12 V coil or motor node?

Sizing isn’t guesswork; it’s about matching the energy in the coil to what the snubber can safely dissipate.

Start from what you can measure—coil inductance, spike current, and allowable voltage swing—and then iterate on the bench.

Start from wiring / coil inductance and target ring-down time

Measure or estimate the total inductance L_equiv, including harness parasitics.

Small automotive relays sit around 30–150 mH; wiper or seat motors closer to 100–400 µH.

A ring-down time τ of 50–100 µs usually balances quick release with controlled EMI.

Estimate C ≈ (I_spike · dt) / ΔV; set R ≈ √(L / C) for critical damping

[ C_{\min} \approx \frac{I_{\text{spike}} · dt}{\Delta V_{\text{target}}} ]

[ R_{\text{target}} ≈ \sqrt{\frac{L_{\text{equiv}}}{C_{\min}}} ]

Example calculation

A 40 mH relay coil carrying 0.15 A, target ΔV = 40 V, desired decay = 100 µs:

(C_{\min} = (0.15 × 100 × 10^{-6}) / 40 = 375 nF);

(R ≈ √(0.04 / 3.75 × 10^{-7}) ≈ 325 Ω).

Choose standard 330 Ω + 390 nF rated > 50 VDC film or X7R capacitor.

| Parameter | Symbol / Formula | Example Value |

|---|---|---|

| Coil inductance | L | 40 mH |

| Coil current | Ispike | 0.15 A |

| Target voltage swing | ΔV | 40 V |

| Decay time | dt | 100 μs |

| Calculated Cmin | I × dt / ΔV | 375 nF |

| Calculated R | √(L/C) | ~ 325 Ω |

Verify power in R: P_R(rms) under worst-case switching

Each turn-off dissipates ≈ ½ L I² joules.

For this example: 0.5 × 0.04 × 0.15² = 0.45 mJ per event.

At 10 Hz switching, average ≈ 4.5 mW—negligible—but instantaneous pulse may hit 0.1 W.

Check both pulse energy and RMS power against the resistor’s surge spec.

Thick-film 1206 parts > 1 J pulse rating or carbon-film axials handle this easily.

For automotive nodes, consider AEC-Q200 resistors from the same family used in TEJTE’s crimp connector guide to ensure vibration endurance matches the wiring harness.

Where exactly should the snubber be placed to minimize loop inductance?

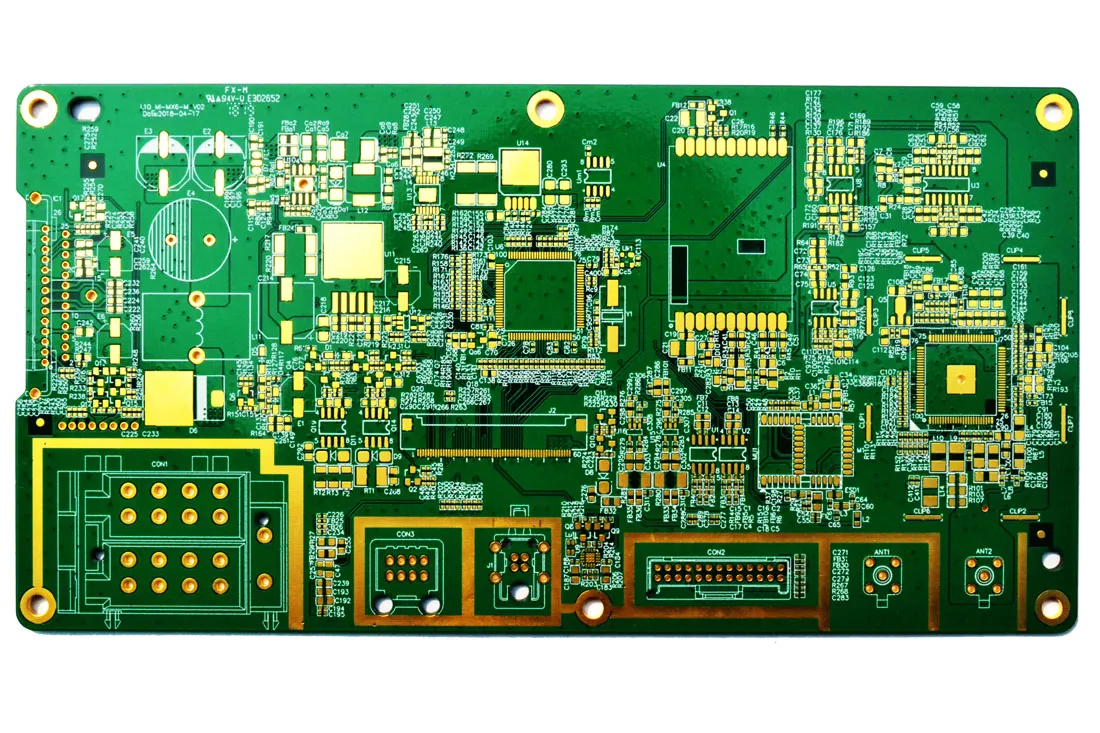

Figure is a core instructional graphic on the practical application of RC snubbers. Correct placement is crucial for their effectiveness. This figure visualizes the options described in the text—"across contacts," "across coil," "across switch"—helping engineers make correct layout decisions based on the specific phenomenon to be suppressed (e.g., contact arcing, coil inductive spike, switch protection). The principles of "short leads" and "low loop inductance" emphasized in the diagram are key to ensuring the snubber works effectively at high frequencies.

A snubber only works if it’s close to where the energy lives.

Long leads or remote mounting defeat its purpose.

The loop area between the coil, driver, and snubber defines how well the circuit handles high-frequency currents.

Across contacts vs. across coil vs. across the switch

| Placement | Primary Purpose | Design Note |

|---|---|---|

| Across contacts | Quenches arc at mechanical open | Raises contact voltage slightly |

| Across coil | Damps inductive kick + ringing | Standard for relay / solenoid |

| Across switch transistor | Protects MOSFET / BJT from spike | Place directly across transistor |

Mount the RC right at the connector or transistor pins—not centimeters away on the PCB.

Short tracks (< 20 mm) and solid ground planes cut loop inductance dramatically.

Harness effects and ground reference consistency

Vehicle harnesses add ≈ 0.2 µH per meter, enough to resonate with the snubber cap if grounds differ.

Always tie the RC return to the same ground as the coil driver.

On metal chassis, use ring terminals and serrated washers to keep contact resistance < 50 mΩ — a simple detail that often drops radiated noise by 3 – 5 dB µV.

Will an RC snubber fix arcing without slowing release too much?

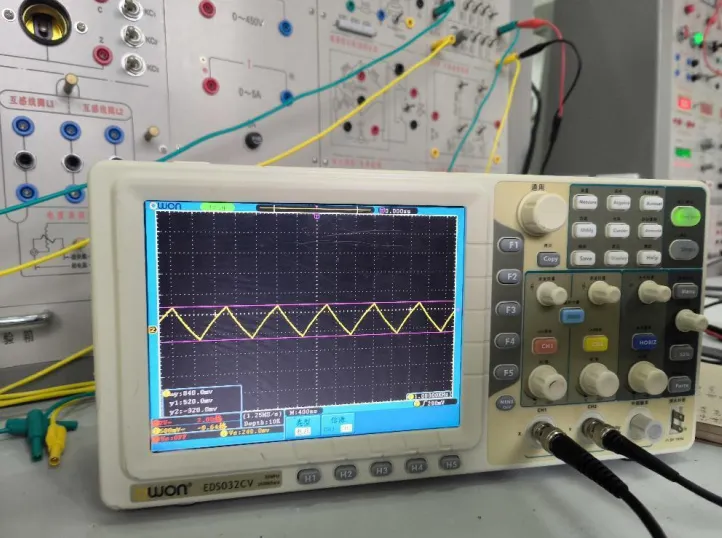

Figure is a quantitative tool for engineering trade-off decisions. It transforms the characteristics of different suppression solutions (peak voltage, release time) into directly comparable visual evidence. Through this graph, engineers can clearly see how the RC snubber strikes a balance between the “low-voltage clamp but slow release” diode solution and the “high voltage but extremely fast release” unprotected solution, thereby understanding its core value of “balancing fast release with good EMI suppression.” This graph is key to understanding the working principle and selection basis of RC snubbers.

Relays and contactors have a tricky balance: the faster they open, the more likely they arc.

Add a diode, and the current takes too long to decay—no arc, but release slows.

An RC snubber lives in the middle ground.

It allows a higher voltage to appear (unlike a freewheel diode) but still damps the high-frequency oscillations that ignite arcs or radiate EMI.

When a coil is switched off, the voltage across it reverses polarity as its magnetic energy collapses.

A plain diode short-circuits this event.

An RC snubber, on the other hand, forms an energy reservoir where the capacitor takes the initial hit, and the resistor bleeds it off in a few microseconds.

The result: voltage peaks stay below insulation limits, yet the current collapses fast enough for crisp release.

| Suppression method | Voltage limit (12 V coil) | Effect on release time | Arcing mitigation |

|---|---|---|---|

| Freewheel diode | ~13 V | Very slow | Excellent |

| Zener clamp | ~Vz + 0.7 V | Medium | Good |

| RC snubber | 30-60 V adjustable | Fast | Excellent |

| TVS diode | 35-45 V | Fastest | Excellent but higher cost |

Compare to freewheel diode, Zener clamp, and TVS diode

A freewheel diode is ideal for energy return into the coil but delays contact opening.

A Zener diode clamps at a fixed threshold and works well where space is tight.

A TVS diode responds fastest but wastes more heat and costs more.

The rc snubber combines moderate voltage with flexible damping; if the coil current or inductance changes, it remains stable.

It’s also bidirectional—handy in H-bridge motor drivers where polarity reverses, something a diode cannot handle.

When safety regulators demand consistent arcing suppression without risking slow actuation, RC networks often meet both targets.

For high-energy cases—like starter solenoids—a hybrid (diode + RC or diode + Zener) can deliver the best compromise.

Mixed strategies: diode + Zener, diode + RC, contact capacitor

Sometimes one technique alone isn’t enough.

Adding a Zener clamp parallel to a diode gives a “two-stage” discharge: gentle current decay until the voltage hits V_z, then quick field collapse.

The diode + RC option works when you must both protect the transistor and soften contact transients—common in automotive body controllers.

Mechanical switches may also use a small “contact capacitor” (100 nF–470 nF film) directly across contacts, supplementing the main snubber near the coil.

A practical wiring tip: keep any RC or diode pair twisted with the coil leads to minimize radiated loop area.

Long untwisted runs often produce the very EMI you thought you’d eliminated.

What component classes and ratings do you pick for reliability?

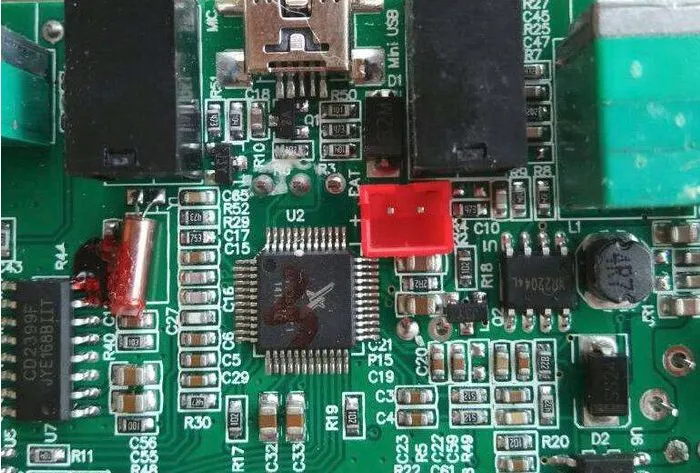

Figure elevates the design from “theoretically feasible” to “long-term reliable.” It reminds engineers that a snubber is not a “passive afterthought” but a power component that needs to withstand surge, temperature, and vibration stresses. By displaying components that meet automotive-grade standards, this figure conveys the materials science and quality management knowledge required to ensure circuit longevity in harsh environments. It is a crucial step in translating a lab design into a mass-produced product.

A reliable rc snubber doesn’t just survive—it must age gracefully under temperature, surge, and vibration.

That means treating it like a power component, not a passive afterthought.

C: Film vs. MLCC; AEC-Q200 parts for automotive harness

For capacitance values below 1 µF, X7R MLCCs in 0805 or 1206 are tempting, but beware of DC bias derating.

A 470 nF MLCC rated 50 V may lose 40 % at 12 V DC bias.

If your space allows, polypropylene or polyester film capacitors handle surge current and temperature cycling far better.

| Cap type | Surge robustness | Temp range | Typical use |

|---|---|---|---|

| X7R MLCC (1206) | Medium | -55 to 125 °C | Compact modules |

| PP film radial | High | -40 to 125 °C | Relay / motor snubbers |

| PPS film SMD | High | -40 to 150 °C | Automotive modules |

Always choose AEC-Q200-qualified capacitors for in-vehicle harnesses.

They resist solder-joint fatigue from engine-bay vibration.

You can cross-check this selection logic against TEJTE’s battery terminal connector article — the same automotive reliability principles apply to both copper lugs and RC networks.

R: Surge rating, pulse energy, anti-sulfur thick film

The resistor sees repetitive high-energy pulses.

Pick parts with high pulse tolerance and low drift.

For 12 V snubbers, metal-film axials or anti-sulfur thick-films in 1206 or 1210 sizes perform best.

Carbon composition types can still shine when you need extreme surge resistance.

Guidelines:

- Surge rating ≥ 1 J (10 ms pulse) for contact suppression.

- Tolerance ≤ 5 %, tempco < 200 ppm/°C to keep damping predictable.

- Conformal coating or silicone encapsulation if humidity is high.

In humid automotive environments, sulfur-containing exhaust fumes can corrode resistor terminations, causing > 20 % value shift after 1 khr exposure.

Anti-sulfur designs prevent this drift.

Their long-term stability directly influences the damping ratio ζ = R / 2 √(L / C) that governs spike decay.

Can a Schottky or fast-recovery rectifier outperform RC in your case?

Not always, but the comparison is worth a look.

For switching transistors that already include a clamp diode, upgrading it can improve behavior nearly as much as adding an RC.

At 12 V, the game is about Qrr and leakage more than breakdown voltage.

Schottky rectifier vs. fast-recovery diode: Vf, leakage, Qrr, EMI

| Parameter | Schottky diode | Fast-recovery diode |

|---|---|---|

| Forward drop (Vf) | 0.3 – 0.45 V | 0.9 – 1.1 V |

| Reverse leakage (12 V, 125 °C) | Higher (μA range) | Lower |

| Reverse recovery (Qrr) | ~ 0 nC | 10 – 40 nC |

| EMI generation | Minimal | Moderate |

| Thermal stability | Good ≤ 150 °C | Better ≤ 175 °C |

A Schottky rectifier virtually eliminates reverse-recovery spikes that plague slower diodes.

That’s why modern control boards often use them at the transistor node while still keeping an RC snubber across the relay coil.

Together they reduce both dv/dt and di/dt, keeping logic lines clean.

For detailed part families like CFP2-HP low-Vf Schottkys, check the product update summary later in this article.

12 V reverse-polarity protection: losses vs. robustness

Many 12 V controllers include reverse-polarity protection using a diode in series or across the supply.

Replacing it with a low-Vf Schottky can cut 0.4 V loss, reducing dissipation by ≈ 0.8 W at 2 A load.

Yet, Schottkys leak more and have lower surge voltage tolerance.

For harsh automotive environments, fast-recovery rectifiers rated ≥ 60 V and AEC-Q101 qualified often outlive pure Schottkys.

When efficiency dominates—say, in DC motors or ECU modules—Schottky wins.

Where robustness against load dumps matters, choose fast-recovery types with proper RC snubber support to tame switching noise.

How do you validate the snubber on the bench?

After calculation and simulation, nothing beats a scope trace.

Real harnesses and relays behave worse than models—wires flex, grounds drift, contacts carbonize.

Proper measurement techniques separate “good enough” from “production-ready.”

Scope setup: ground spring, coax tip, bandwidth ≥ 200 MHz

The easiest way to ruin your data is to probe with a long ground clip.

Always use a ground spring or coaxial probe tip to minimize loop area.

At 12 V systems, ringing often sits in the 10–50 MHz range; a 200 MHz or higher bandwidth scope reveals overshoot clearly.

Trigger on the transistor gate or coil voltage and capture the entire release event.

For repetitive test cycles, record 1000 turn-off waveforms and average them to remove noise.

A cleanly damped RC snubber waveform should show less than two visible oscillations and a smooth decay within 100 µs.

If oscillations persist or spikes exceed 50 V, revisit the R:C ratio or layout.

Pass/fail: overshoot, ringing Q, contact burn marks, temperature rise

| Metric | Target | Test Method |

|---|---|---|

| Overshoot voltage | ≤ 50 V (typ. 12 V system) | Scope capture |

| Ringing decay (Q) | < 1.5 cycles @ 50 % amplitude | Waveform analysis |

| Relay release delay | < 10 ms extension vs no-snubber | Timer / camera |

| Contact surface | No visible pitting after 10 k ops | Microscope check |

| Snubber temperature ΔT | < Tj max – 20 °C | Thermocouple / IR cam |

Engineers often forget the temperature check.

A resistor dissipating just 50 mW average can still hit 90 °C in a small sealed module.

After 10 minutes of continuous switching at rated duty, verify that the combined P_R + P_C losses keep the board below safe limits.

What’s changing in suppression components this year? (Industry updates)

Component technology for transient suppression is evolving fast.

Manufacturers now push higher energy density into smaller packages, crucial for 12 V and 48 V vehicle platforms.

Automotive TVS updates (Littelfuse 2025)

Sep 2 2025 — Littelfuse SZSMF6L Series

A 600 W SOD-123FL TVS designed for automotive 12 V/EV subsystems.

It combines low clamping voltage (< 25 V @ 10 A) with high surge endurance, targeting relay and solenoid nodes once reserved for 400 W SMAJ devices.

This new footprint fits tightly packed PCBs where RC snubbers coexist with silicon clamps.

Miniaturized Schottky trend (Nexperia Nov 2025)

Nexperia expanded its CFP2-HP line of low-Vf planar Schottky rectifiers, replacing traditional SMA/B/C footprints.

Thermally enhanced copper-clip construction yields 2× better RθJA, making them ideal for dense 12 V ECU boards.

For engineers migrating away from through-hole clamps, these devices simplify the BOM while maintaining AEC-Q101 reliability.

Such progress means the practical boundaries between diode clamps and rc snubbers blur:

you can now build mixed solutions that fit even in micro-relays and power distribution modules.

Build a safe snubber in 2 minutes

This mini-calculator summarizes all sizing logic from the article.

You can recreate it in any spreadsheet or embedded configurator.

Input parameters

| Symbol | Description | Unit |

|---|---|---|

| Vbus | Supply voltage | V |

| Lequiv | Equivalent inductance (coil + wiring) | μH |

| Ispike | Peak current at switch-off | A |

| ΔVtarget | Allowed voltage rise | V |

| dt | Desired energy decay time | μs |

| fsw | Switching frequency | Hz |

| Ta | Ambient temperature | °C |

| Acu | Copper area for dissipation | cm² |

Calculation formulas

Cmin≈ΔVtargetIspike⋅dt

[ R_{\text{target}} \approx \sqrt{\frac{L_{\text{equiv}}}{C_{\min}}} ]

EC=21C(ΔVtarget)2;PC≈EC⋅fsw

PR(rms)≈RVR2;ΔT≈(PR+PC)θJA

Pass / Fail Rule:

if ΔT + Ta < Tj max – 20 °C and waveform overshoot ≤ ΔV_target → PASS,

else increase C or select higher-rated R/C package.

Output example

| Parameter | Value | Comment |

|---|---|---|

| Crec | 390 nF X7R 50 V | AEC-Q200 |

| Rrec | 330 Ω 1 J pulse | Thick-film anti-sulfur |

| EC (per switch) | 0.31 mJ | Stored energy |

| P_total avg | 4.2 mW @ 10 Hz | Safe margin |

| ΔT_est | +28 °C @ θJA = 120 °C/W | PASS |

This quick tool helps engineers verify that the snubber will survive repetitive duty without overheating.

For production documentation, always pair numeric checks with oscilloscope proof.

Device example

- RC Network: CDE QAS Automotive RC Snubber (AEC-Q200), 100 nF – 470 nF, 250 VDC.

- Suppression Diode: Combine with Schottky or TVS diode for hybrid protection chains on 12 V coils.

These component classes are standard in relay harnesses, solenoid drivers, and DC-motor control boards.

FAQ

Does an RC snubber slow relay release less than a freewheel diode?

Usually yes. Because voltage can rise moderately, current decays faster—release time improves 40–60 % versus a pure diode clamp.

How do I pick C and R without a full harness model?

Start from the observed spike current and ring frequency; use the formulas above, then fine-tune ±20 % on the bench.

Should the snubber go across contacts, the coil, or the switch?

Place it across the energy source: contacts for arcing, coil/switch for inductive kick and EMI.

When is a TVS better than an RC snubber?

When spikes are rare but high energy, and you need instant clamping without current recycling.

A TVS acts faster and simplifies wiring, though it can’t damp ringing like RC does.

Film cap or MLCC for a 12 V snubber?

Film types handle pulses and temperature cycling better. X7R MLCCs fit tight spaces if bias derating is verified.

Can a low-Vf Schottky replace the RC entirely?

It reduces spikes but extends release. Combine with Zener or RC for balanced speed and EMI.

How do I know the snubber isn’t overheating?

Compute P_R and P_C, then run a 10-minute hot test. Ensure ΔT + Ta < Tj max – 20 °C; if not, increase component size or rating.

Closing Remarks

Figure is the ultimate embodiment of the document's integration of theory and practice. It brings together all the previous calculations, component selections, and layout recommendations into the final, actionable verification step. The professional instruments and standardized operations (e.g., using a ground spring) in the scene emphasize the impact of measurement techniques on result credibility. This figure aims to motivate engineers to close the design loop, ensuring through hands-on testing that the RC snubber is not only feasible on paper but also reliable in practical applications for protecting circuits, thereby avoiding future field failures.

A 12 V rc snubber isn’t just a capacitor and resistor —it’s a reliability decision.

Selecting the right values protects contacts, shrinks EMI, and keeps control systems predictable even as components age.

On today’s tight automotive boards, a well-tuned snubber can replace complex shielding work and prolong relay life by years.

For engineers expanding 12 V or 24 V actuator lines, carry forward the same discipline used in power-MOSFET designs:

measure, simulate, then verify.

The few minutes spent tuning R and C on the bench will save months of field failures later.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.