4.3-10 vs N-Type Connector: Size, Torque & PIM Compared

Aug 29,2025

Introduction

This image sets the stage for comparing 4.3-10, designed for dense 5G radios, with the rugged N-Type, long trusted in telecom since the 1940s.

Ask any RF engineer and they’ll tell you: connectors aren’t just small pieces of hardware, they’re decision points that ripple through your entire project. They affect signal quality, PIM risk, port density, and how quickly a crew can finish an install. Two names in particular come up often—the 4.3-10 connector and the N-Type connector.

If you’re weighing 4.3-10 vs N connector, chances are you’re either upgrading a legacy site or building out LTE/5G gear. The choice isn’t trivial. The 4.3-10 is today’s compact, low PIM connector for high-density radios, while the N-Type is a rugged veteran, trusted since the 1940s for medium-power links and test setups.

Here’s the bottom line up front:

- Pick 4.3-10 for modern LTE/5G deployments where space and port count matter.

- Stick with N-Type when you need a proven threaded connector for medium-power outdoor or lab applications.

The rest of this article digs deeper—size, torque, power handling, PIM, weatherproofing, adapters, and lifecycle costs—and closes with a decision matrix and FAQs to help you choose the right fit.

What Is a 4.3-10 Connector?

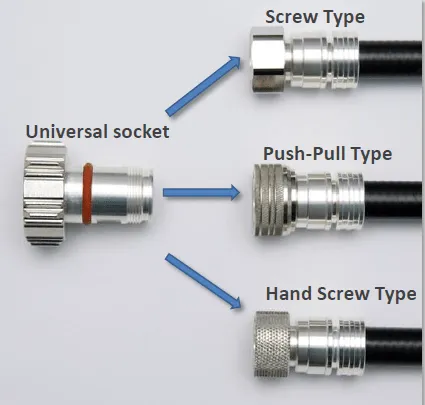

The image highlights how 4.3-10 supports multiple coupling types and delivers low PIM, making it a standard for LTE/5G, DAS, and small cells.

The 4.3-10 connector is relatively new compared to classics like the N-Type. It was designed with one thing in mind: make LTE and 5G radios easier to deploy and maintain without sacrificing RF performance.

Instead of sticking to a single coupling method, the 4.3-10 offers three:

- Screw type tightened with about 5–8 N·m of torque,

- Hand-screw that you can finger-tighten,

- Push-pull for quick connect/disconnect without tools.

This flexibility has been a game-changer on dense tower panels. You can fit more ports in less space, cut down installation time, and reduce the chance of torque errors that cause passive intermodulation (PIM).

In terms of performance, the 4.3-10 is built as a low PIM connector, with specs often listed at ≤ -155 to -160 dBc. That’s why you’ll find it standard on 5G gNodeBs, LTE base stations, DAS systems, and even small cells.

This image demonstrates the built-in sealing features of 4.3-10, ensuring IP67 outdoor performance for rooftop and tower deployments.

What Is an N-Type Connector?

The image highlights the versatility of N-Type, balancing medium power, threaded durability, and dual 50/75Ω versions used across telecom and broadcast.

What makes it stand out is its versatility. N-Type connectors are available in both 50 Ω and 75 Ω versions. The 50-ohm type is what you’ll see in telecom and wireless equipment, while 75 ohms shows up in broadcast and cable TV networks. Mixing them is a common rookie mistake—it leads to mismatched impedance and reflections.

From a power standpoint, N-Type sits in the middle ground. It’s not a monster like the 7/16 DIN, but it comfortably supports medium-power applications such as rooftop repeaters, outdoor antennas, or test gear in an RF lab. One thing installers appreciate is the light torque requirement—only about 1.3–1.5 N·m. That makes it quick to work with, though you do have to be careful: under-tightened threads can raise PIM levels. Many field crews hand-snug them and move on, which usually works but isn’t best practice for critical low-PIM sites.

Durability is another reason the N connector is still here after 80 years. The threaded design holds up in wind, rain, and daily handling. You’ll see N connectors everywhere: GPS antennas, WiFi gear, DAS hubs, military radios, and outdoor telecom links.

So while newer designs like the 4.3-10 are taking over dense 5G deployments, the N-Type remains a versatile workhorse, still one of the most widely used threaded RF connectors today.

Size, Density & Torque Compared

The most obvious difference in N connector vs 4.3-10 comparisons comes down to size and torque.

- 4.3-10: A smaller body (roughly 20 mm) makes it easier to fit dozens of ports on compact radio heads. The screw version needs 5–8 N·m of torque, while the push-pull version skips torque wrenches entirely. For rooftop crews, this means faster installs and fewer errors.

- N-Type: Slightly larger at about 22 mm, and threaded only. Torque is minimal—around 1.3–1.5 N·m—so tightening is easy. But the lighter clamping force means you’ve got to double-check connections if you’re targeting low PIM performance.

Quick Mechanical Snapshot

| Feature | 4.3-10 Connector | N-Type Connector |

|---|---|---|

| Body size | Small, ~20 mm | Medium, ~22 mm |

| Coupling types | Screw / Hand-screw / Push-pull | Threaded only |

| Typical torque | 5–8 N·m (screw type) | 1.3–1.5 N·m |

| Port density | High (compact radios) | Medium (fewer ports) |

| Mating cycles | High, vendor dependent | Medium-high, vendor dependent |

Power Handling & PIM Performance

4.3-10 Connector

N-Type Connector

Quick Comparison

| Metric | 4.3-10 Connector | N-Type Connector | Field Note |

|---|---|---|---|

| Power Handling | Medium-High (40–200 W) | Medium (common RF loads) | 7/16 DIN still wins for >1 kW |

| PIM (typical) | ≤ –155 to –160 dBc | Vendor-dependent, often higher | Installation makes the difference |

| VSWR / Return Loss | Excellent | Excellent | Both stable if cables are good |

Outdoor Use & Weatherproofing

4.3-10 Connector

N-Type Connector

Weatherproofing Checklist

- Clean connector surfaces and threads.

- Verify O-rings are intact and lightly lubricated.

- Wrap self-amalgamating tape, overlapping by half width.

- Add heat-shrink tubing for UV protection.

- Use a boot or cap to block water entry.

- Recheck torque after first major weather cycle.

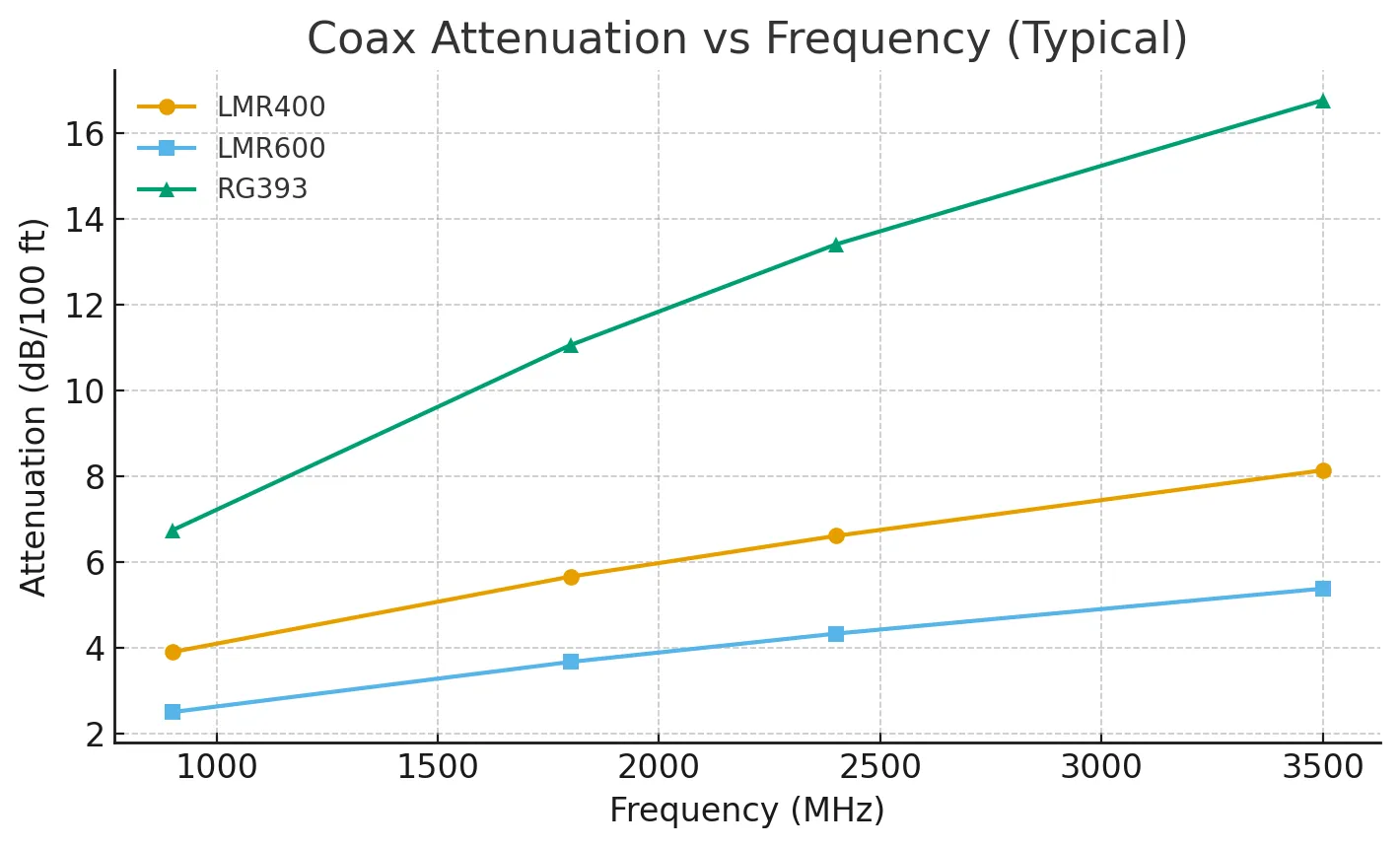

Cable Pairing & Attenuation Planning

Minimal line chart showing typical attenuation (dB/100 ft) versus frequency for three telecom coaxial cables—LMR400, LMR600, and RG393—at 900, 1800, 2400, and 3500 MHz. Helps plan feeder length and cable selection.

4.3-10 Connector Pairing

N-Type Connector Pairing

Attenuation Snapshot

| Frequency (MHz) | Cable Type | Loss / 100 ft | Typical Use |

|---|---|---|---|

| 900 | LMR-400 | ~3.9 dB | Mid-length rooftop feeders |

| 1800 | LMR-600 | ~4.4 dB | Long feeder runs in macro sites |

| 2400 | RG-393 | ~6.7 dB | Cabinet jumpers |

| 3500 | LMR-600 | ~6.8 dB | 5G mid-band rooftop links |

Adapters & Migration Paths

The image highlights common 4.3-10 to N adapters, widely used in LTE-to-5G upgrades, enabling reuse of existing feeders while maintaining low PIM.

Common Adapter Types

- 4.3-10 ↔ N-Type: By far the most common during LTE-to-5G upgrades.

- Gender changers (M-M, F-F): Handy in labs but risky outdoors.

- 50 Ω ↔ 75 Ω N-Type: Sometimes needed for video/telecom crossover, but impedance mismatch can cause serious reflections.

Pros & Cons

- Pros: Save cost by reusing existing feeders; no need to rip out everything during migration.

- Cons: Each adapter adds another junction, which means slight insertion loss and higher PIM risk.

Best Practices

- Choose certified low PIM adapters.

- Keep the adapter count to an absolute minimum—prefer direct runs.

- Always torque to spec (5–8 N·m for 4.3-10 screw; ~1.5 N·m for N-Type).

- Apply the same sealing steps as you would for a normal connector.

Adapter Map

| Adapter Type | Scenario | Watch Out For |

|---|---|---|

| 4.3-10 → N-Type | Migration from old feeders to new radios | Extra junction = PIM risk |

| 4.3-10 M-M / F-F | Lab testing or temporary patching | Not for long-term installs |

| N-Type 50 Ω ↔ 75 Ω | Broadcast vs telecom crossovers | Impedance mismatch = reflection |

Cost & Total Cost of Ownership (TCO)

4.3-10 Connector

- Unit price: Usually similar to or slightly higher than N connectors, depending on coupling type (screw, hand-screw, push-pull).

- Install time: Faster. Push-pull and hand-screw versions cut down wrench work, which saves minutes per port. On a radio with 16 ports, that time adds up.

- Maintenance: Easier in high-density racks. Less torque also means fewer stripped threads.

- Lifecycle: Favored in LTE/5G rollouts where downtime penalties are high and speed is everything.

N-Type Connector

- Unit price: Often lower, and widely available.

- Install time: Simple, but each connector still requires threading and rechecking torque.

- Maintenance: Durable, but bulkier in dense panels. Under-tightening is common if crews rush.

- Lifecycle: Still strong in medium-power, cost-sensitive builds. Spare parts are everywhere, which lowers replacement cost.

TCO Snapshot

| Factor | 4.3-10 Connector | N-Type Connector | Field Note |

|---|---|---|---|

| Unit Price | Medium-High | Low-Medium | Vendor & style dependent |

| Install Speed | Fast (push-pull / hand-screw) | Slower (threaded only) | Adds up on multi-port radios |

| Maintenance | Easy, fewer errors | Robust but easy to under-torque | Torque discipline matters |

| Spare Parts | Readily available, newer | Abundant worldwide, legacy | N-Type spares are everywhere |

| Lifecycle Value | Strong for LTE/5G | Strong for legacy/medium-power | Depends on site type |

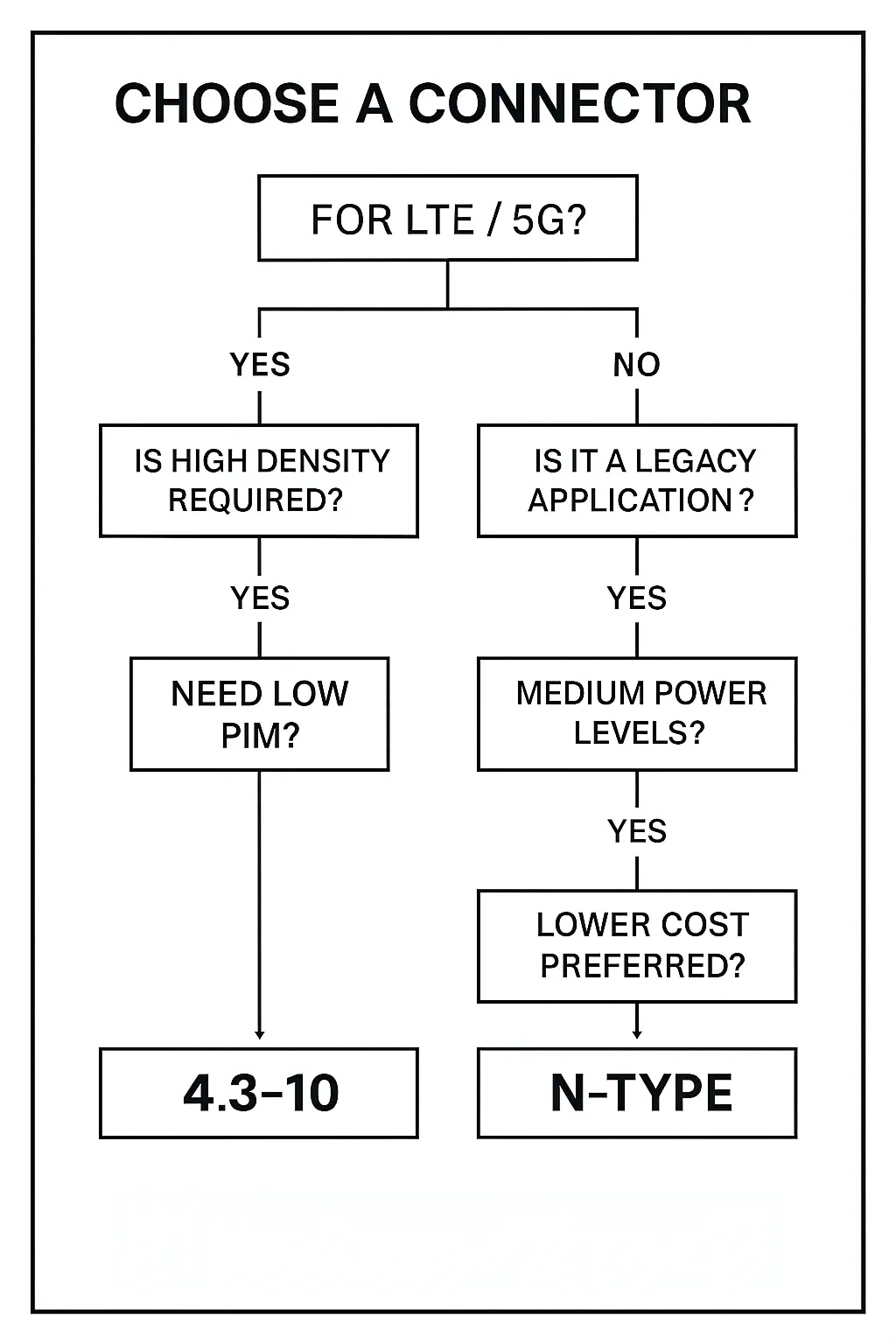

Buyer’s Decision Matrix

This decision matrix visually summarizes when to pick 4.3-10 for LTE/5G or N-Type for legacy, helping buyers and engineers plan upgrades.

Choose 4.3-10 if:

- You’re building or upgrading LTE/5G networks.

- Port density and rack/tower space are limiting factors.

- You want low PIM connectors that can handle dense multi-carrier traffic.

- Fast install/maintenance time is worth more than a few dollars saved per connector.

Choose N-Type if:

- You’re maintaining or expanding legacy systems.

- Power needs are moderate, not kilowatt-level.

- Budget is tight and spare parts availability matters.

- The environment is rugged but not ultra-high density.

Migration?

Buyer’s Checklist

- Define power level (medium vs high).

- Check frequency band and PIM targets.

- Evaluate site density—high-density radios = 4.3-10.

- Confirm torque/installation practices available to your crews.

- Plan for weather sealing regardless of connector type.

- Factor in lifecycle cost, not just upfront spend.

(Insert Image 10: Decision flow diagram—Power → Density → PIM Target → Torque/Tools → Final Choice: 4.3-10 or N-Type)

FAQs

Q1. What’s the main difference between 4.3-10 and N connector?

The 4.3-10 is compact, supports high port density, and was designed as a low PIM connector for LTE/5G. The N-Type is older, medium-power, threaded, and widely used in legacy and lab systems.

Q2. Is 4.3-10 better for 5G?

Yes. Its size, low PIM performance, and push-pull option make it the preferred choice for 5G radios and antennas.

Q3. Can I still use N-Type in modern networks?

Absolutely. For medium-power, cost-sensitive links, N-Type remains reliable. But if you’re deploying dense multi-carrier 5G radios, 4.3-10 is the smarter pick.

Q4. Do adapters increase PIM?

They can. Every adapter adds another junction. Always use certified low PIM adapters, torque correctly, and keep the adapter count as low as possible.

Q5. What torque values should I follow?

- 4.3-10 Screw: ~5–8 N·m

- N-Type: ~1.3–1.5 N·m

- For hand-screw or push-pull 4.3-10, follow vendor guidelines.

Q6. Are both waterproof?

Yes, both can reach IP67 rating with proper sealing (tape, shrink, boots). The connector itself doesn’t guarantee waterproofing—the field sealing process does.

Q7. Is the N-Type part of the DIN coaxial connector family?

Yes, historically it’s considered one of the threaded DIN coaxial connectors, though in practice most people just call it “N connector.”

Conclusion

So, 4.3-10 vs N-Type—who wins?

- For LTE and 5G networks, 4.3-10 is the clear choice. It saves space, reduces PIM, and speeds up installs.

- For legacy and medium-power builds, N-Type still earns its keep. It’s cost-effective, durable, and easy to source worldwide.

- During migration, you’ll likely need 4.3-10 to N adapters—but remember, fewer junctions mean fewer PIM headaches.

Both connectors have carved their niches. Knowing when to use each ensures your site runs cleaner, lasts longer, and costs less to maintain.

Explore Further

If this breakdown of N connector vs 4.3-10 helped, you might also like:

Your Project Toolbox

At TEJTE, we deliver certified low PIM 4.3-10 and N-Type connectors, plus weather-sealed jumpers for LTE/5G upgrades. If you’re migrating from N-Type to 4.3-10, ask us about one-box kits with adapters and cables tailored to your site.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.