4.3-10 vs 7/16 DIN (L29): Power, PIM & Torque Compared

Aug 28,2025

Introduction

In the world of RF infrastructure, a few connector names always rise to the top: 7/16 DIN (L29) and 4.3-10. Both are low PIM connectors designed to keep multi-carrier signals clean, and both are engineered for outdoor telecom use. Yet they serve slightly different roles.

If you’re an RF engineer, a tower technician, or even a procurement manager tasked with choosing between them, you’ve probably asked: Which connector should I pick? 7/16 DIN or 4.3-10?

Clean studio shot showing a compact 4.3-10 connector next to a larger 7/16 DIN (L29), highlighting their size difference and coupling styles.

The short answer:

- Stick with 7/16 DIN (L29) when you need very high power handling, as in broadcast towers or older macro sites.

- Choose 4.3-10 when you’re deploying LTE or 5G gear, where port density, compact size, and easy torqueing matter more.

- Use adapters carefully during migration, but remember: every junction adds potential PIM.

This article breaks down the comparison across size, torque, power, PIM, outdoor sealing, cable pairing, adapters, and lifecycle cost, finishing with a buyer’s checklist and FAQs.

What Is a 7/16 DIN (L29) Connector?

The 7/16 DIN connector—also known as the L29 connector or simply DIN 7/16—is a large, threaded DIN coaxial connector widely used in high-power telecom and broadcast systems. Its designation comes from its geometry: a 7 mm inner contact and a 16 mm outer insulator.

Studio photo comparing L29 / 7/16 DIN male (plug) and female (jack). Useful for the Form Factors section to clarify gender naming in DIN coaxial connectors.

Key Attributes

- Power handling: Exceptional, often exceeding 1 kW, thanks to its broad contact area.

- PIM performance: Extremely low, making it reliable for multi-carrier GSM/LTE base stations.

- Torque: Requires a 25–30 N·m torque wrench to guarantee stable mating.

- Size: Rugged and durable, though its larger body reduces port density compared with newer alternatives.

- Use cases: Common on rooftop antennas, broadcast towers, outdoor feeder lines, and surge protectors.

For decades, this connector has served as the workhorse of RF infrastructure, especially in installations where low PIM and high power are non-negotiable.

What Is a 4.3-10 Connector?

The 4.3-10 connector is a compact, next-generation RF interface developed to meet the needs of LTE and 5G networks. It belongs to a family of low PIM connectors, designed specifically to minimize passive intermodulation in multi-carrier environments.

Clean side-by-side photo highlighting the male center pin and the female receptacle of 4.3-10 connectors, suitable for high-density panels.

Key Attributes

- Size: Much smaller than the older 7/16 DIN, allowing for higher port density on modern radios and antennas.

- Torque flexibility: Available in three coupling types—screw (5–8 N·m), hand-screw, and push-pull—making installation faster and less prone to errors.

- PIM performance: Excellent, often specified at ≤ -155 to -160 dBc, ensuring stable performance even in dense LTE/5G deployments.

- Applications: Common in LTE eNodeBs, 5G gNodeBs, small cells, and DAS (Distributed Antenna Systems).

- Weatherproofing: Built with O-rings and compatible sealing kits to achieve IP67-level outdoor protection.

Because it is both a compact connector and a low PIM connector, the 4.3-10 has rapidly become the preferred choice for new 4G and 5G infrastructure, balancing mechanical convenience with outstanding RF performance.

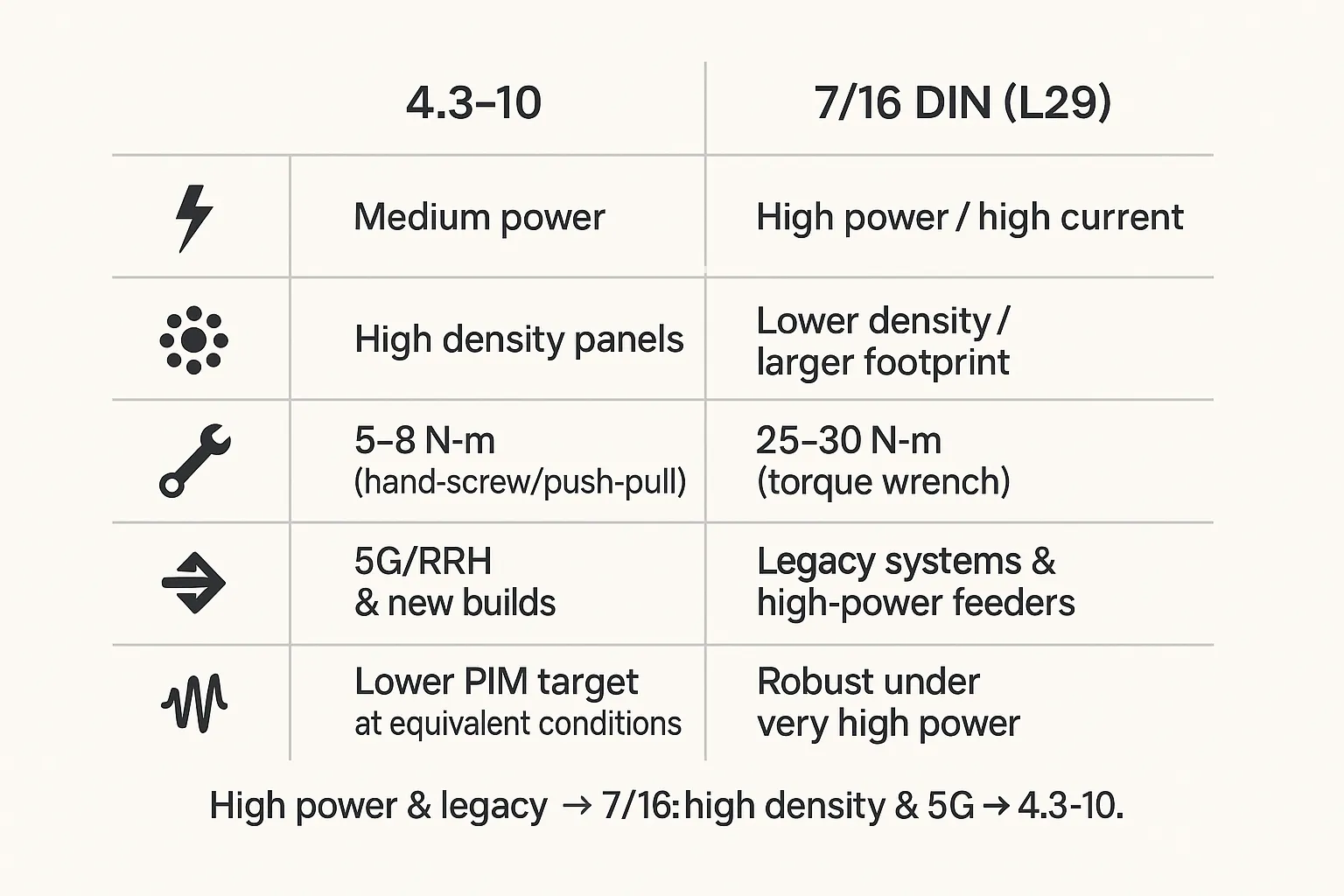

Size, Density & Torque Compared

One of the biggest differences between these two connectors is physical size and the torque required during installation.

- 7/16 DIN (L29): Large body diameter (~29 mm), requiring 25–30 N·m torque. Solid, but space-hungry.

- 4.3-10: Smaller body (~20 mm), torque as low as 5–8 N·m, and optional push-pull coupling that saves time and avoids over-torquing.

Quick Mechanical Comparison

| Feature | 7/16 DIN (L29) | 4.3-10 Connector |

|---|---|---|

| Body Size | Large, 29 mm | Smaller, ~20 mm |

| Coupling | Threaded only | Screw / Hand-screw / Push-pull |

| Typical Torque | 25–30 N·m | 5–8 N·m (screw type) |

| Port Density | Low | High (more ports per panel) |

| Mating Cycles | ~500 | Higher (depends on vendor, often >500) |

Power Handling & PIM Performance

When comparing 7/16 DIN vs 4.3-10, one of the most critical questions is: How much power can each connector handle, and how clean is the signal path?

7/16 DIN (L29)

- Built for very high power. It can safely manage hundreds of watts, even exceeding 1 kW in broadcast environments.

- Its large contact surfaces minimize resistive heating, keeping performance stable during continuous high loads.

- PIM performance is typically excellent—around ≤ -155 dBc, provided installation is done with proper torque.

4.3-10 Connector

- Designed for medium to high power, typical in LTE and 5G systems. While it doesn’t match 7/16 DIN’s extreme capacity, it easily handles the 40–100 W per port typical of modern base stations.

- Mechanical stability and optimized inner/outer conductor design give it low PIM performance, often ≤ -160 dBc.

- Its lighter torque requirement helps reduce the risk of improper tightening, a common cause of PIM spikes.

Performance Snapshot

| Metric | 7/16 DIN (L29) | 4.3-10 Connector | Notes |

|---|---|---|---|

| Power Handling | Very high (>1 kW possible) | Medium-High (40–200 W typical) | Depends on band & cooling |

| PIM Performance | ≤ –155 dBc | ≤ –155 to –160 dBc | Vendor & torque dependent |

| VSWR / Return Loss | ≤ 1.2 (up to 2.5 GHz) | ≤ 1.2 (up to 3.8 GHz) | Both provide stable matching |

| Multi-carrier Use | Excellent | Excellent | LTE/5G safe with proper install |

Establishing photo of a rooftop sector with panel antennas and an outdoor cabinet. Ideal to introduce weatherproofing and maintenance notes.

Outdoor Use & Weatherproofing

Both DIN 7/16 vs 4.3-10 connectors are meant for outdoor installations, but they rely on proper sealing to achieve their rated performance.

7/16 DIN

- Typically paired with IP67 or IP68-rated sealing kits.

- Its larger body and robust O-rings give it strong resistance to water ingress.

- Field best practice: self-amalgamating tape, heat-shrink tubing, and weather boots layered in sequence.

4.3-10

- Also designed for IP67-level sealing, but with a more compact profile.

- Because of smaller size, installers must be careful about taping and shrinking to avoid gaps.

- Many vendors provide pre-sealed jumpers with integrated boots, reducing installation variability.

Weatherproofing Checklist

- Clean connector ends before mating.

- Ensure O-rings are intact and lubricated.

- Wrap with self-amalgamating tape, overlapping by half width.

- Apply heat-shrink tubing for UV protection.

- Add a weatherproof boot for long-term outdoor use.

- Inspect after heavy rain or seasonal temperature shifts.

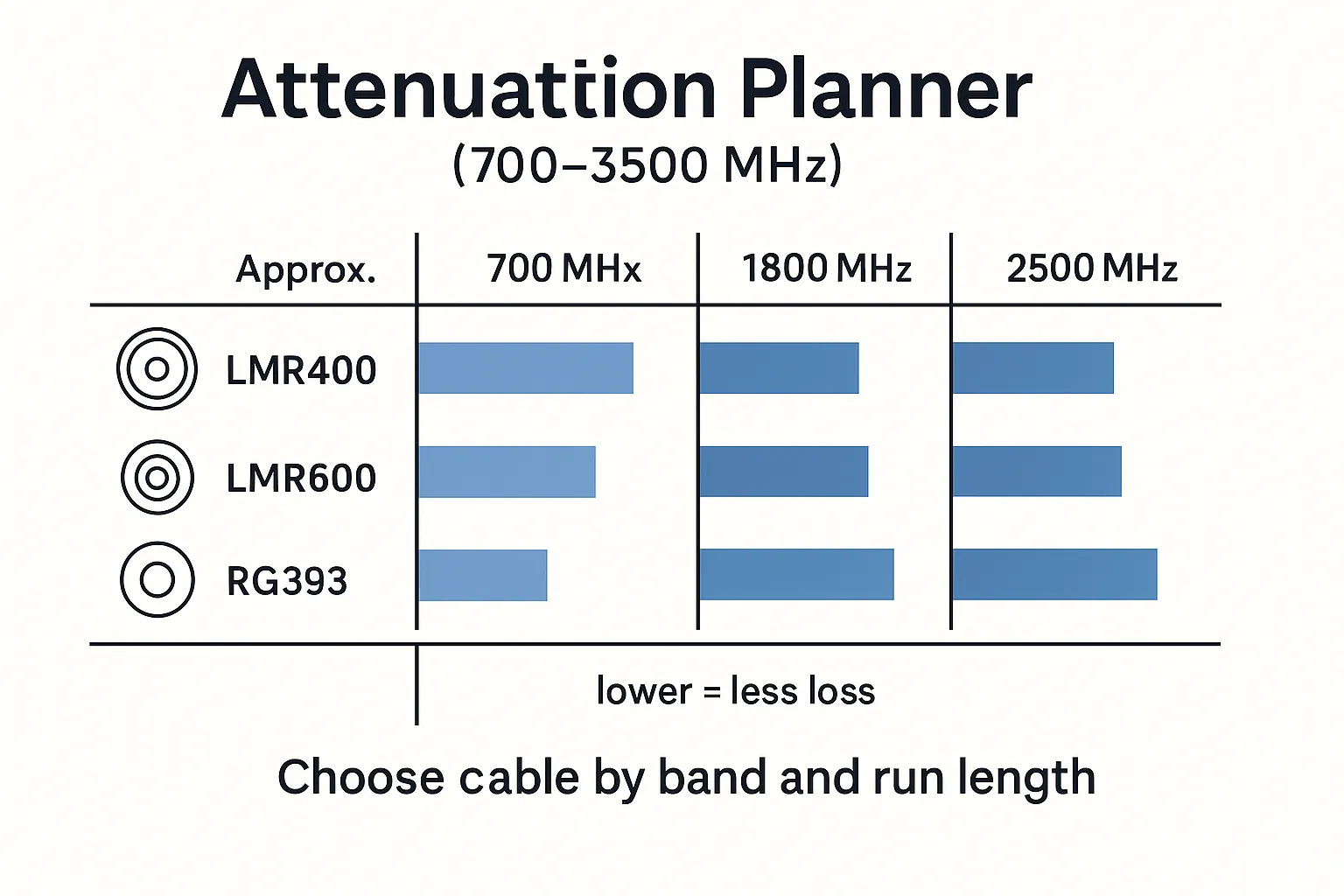

Cable Pairing & Attenuation Planning

No connector performs in isolation—it must be matched with the right coaxial cable for the run.

With 7/16 DIN (L29)

- Commonly paired with LMR600 or even larger feeder cables for long outdoor runs.

- Used in broadcast and high-power macro sites where attenuation must be kept to a minimum.

With 4.3-10

- Frequently paired with LMR400 or LMR600 in 4G/5G base stations.

- For cabinet jumpers, RG393 or other flexible coax is used.

- Compact size makes it easier to manage in DAS (Distributed Antenna Systems) and small-cell deployments.

Attenuation Planning Table

Minimal, brand-neutral infographic listing typical dB/100 ft values for common cables at key bands.

| Frequency (MHz) | Cable Type | Loss per 100 ft | Best Use Case |

|---|---|---|---|

| 900 | LMR-400 | ~3.9 dB | Mid-length rooftop feeders |

| 1800 | LMR-600 | ~4.4 dB | Long macro-site feeders |

| 2400 | RG-393 | ~6.7 dB | Short cabinet jumpers |

| 3500 | LMR-600 | ~6.8 dB | 5G mid-band rooftop runs |

Tip from field practice: Always check the minimum bend radius for each cable. Kinking a feeder raises VSWR, which can undo the low-PIM advantage of these connectors.

Adapters & Migration Paths

During real-world network upgrades, operators often need to connect old gear with DIN 7/16 ports to new radios that use 4.3-10 connectors. This is where adapters come in.

Common Adapter Types

- 7/16 DIN ↔ 4.3-10 – the most common during LTE-to-5G migration.

- 4.3-10 ↔ N-Type – useful when mixing modern small radios with legacy medium-power gear.

- Gender changers (M-M, F-F) – for correcting mismatched jumpers.

Pros & Cons

- Pros: Allow mixed generations of equipment to work together without replacing entire feeder lines.

- Cons: Each adapter is an extra junction, which introduces small insertion loss and raises PIM risk.

Best Practices

- Use certified low PIM adapters when necessary.

- Keep adapter count to a minimum—prefer direct connections wherever possible.

- Apply correct torque even on adapters. A finger-tight adapter is a PIM generator waiting to happen.

- Always weather-seal adapters outdoors just like native connectors.

Adapter Map

| Adapter Type | Scenario | Caution |

|---|---|---|

| 7/16 DIN → 4.3-10 | Migration from old baseband to new | Check torque compatibility |

| 4.3-10 → N-Type | Connecting to legacy gear | Additional PIM risk |

| Gender Changers | Lab or temporary fixes | Avoid in permanent installs |

Cost & Total Cost of Ownership (TCO)

When considering 7/16 DIN vs 4.3-10, cost is more than just the price tag of the connector. You need to think in terms of total cost of ownership (TCO)—procurement, installation time, maintenance cycles, and long-term reliability.

7/16 DIN (L29)

- Unit Cost: Typically higher due to its larger size and heavier metal content.

- Installation: Requires calibrated torque wrenches and more physical effort. Technicians often spend more time ensuring proper mating and weatherproofing.

- Maintenance: Long-lasting once installed properly, but heavy and harder to work with in dense rack or rooftop environments.

- Best suited for: Broadcast, high-power, and legacy macro sites where robustness outweighs installation speed.

4.3-10 Connector

- Unit Cost: Often lower or comparable, depending on vendor and coupling style.

- Installation: Faster and easier, especially with hand-screw or push-pull options. Reduced torque means less risk of over- or under-tightening.

- Maintenance: Easier re-torque and replacement in compact radio units. High port density reduces rack/tower space requirements, lowering long-term site cost.

- Best suited for: LTE and 5G deployments where compact size, easy handling, and cost efficiency are priorities.

TCO Comparison

| Factor | 7/16 DIN (L29) | 4.3-10 Connector | Notes |

|---|---|---|---|

| Unit Price | Higher | Lower / Comparable | Varies by vendor |

| Install Effort | High (torque wrench, heavy) | Low–Medium (5–8 N·m or tool-less) | Labor cost impact |

| Maintenance | Stable but heavy | Easier, compact | Field friendly |

| Port Density | Low | High | More ports per radio |

| Lifecycle Value | Strong in high-power | Strong in LTE/5G | Context dependent |

Buyer’s Decision Matrix

Selecting between DIN 7/16 vs 4.3-10 doesn’t have to be complicated. Here’s a practical decision matrix to guide your choice.

A simple matrix graphic mapping use cases: power level, port density, torque tools, and migration needs.

Quick Guidelines

- Choose 7/16 DIN (L29):

- Extremely high-power broadcast or RF combining systems.

- Legacy sites already equipped with DIN 7/16 feeders.

- Harsh outdoor conditions where mechanical robustness is paramount.

- Choose 4.3-10 Connector:

- LTE/5G macro and small-cell deployments.

- High port density radios requiring compact interfaces.

- Sites where maintenance speed and low torque matter.

- Adapters:

- Use only as temporary or migration solutions.

- Select certified low PIM connectors to minimize risk.

Buyer’s Checklist

- Power Requirement → kW-level? Stick to 7/16 DIN. For standard LTE/5G loads, 4.3-10 is enough.

- Port Density → More radios = more ports. 4.3-10 is compact, DIN 7/16 is not.

- Torque & Tools → DIN requires torque wrench; 4.3-10 can be tool-less.

- Migration Needs → If mixing, budget for adapters but minimize their use.

- Weatherproofing → Both can reach IP67/68, but installation practices matter more than spec sheets.

- Lifecycle Costs → Factor in labor, downtime, and spare parts, not just purchase price.

FAQs on 7/16 DIN vs 4.3-10

Q1. What’s the difference between 4.3-10 and 7/16 DIN?

4.3-10 is smaller, lighter, and requires less torque, making it ideal for LTE/5G high-density radios. 7/16 DIN is larger and designed for very high power, common in broadcast and legacy macro sites.

Q2. Is 4.3-10 better for 5G?

Yes. Its compact size and low PIM performance make it the preferred connector for 5G radios and antennas.

Q3. When should I keep using 7/16 DIN (L29)?

Stick with DIN if you’re handling very high power (>1 kW), managing broadcast towers, or maintaining legacy feeder systems.

Q4. Do adapters increase PIM?

Yes. Every extra junction adds insertion loss and can create passive intermodulation. Use certified low PIM connectors and limit adapter use to transitional scenarios.

Q5. What torque should I use?

- 7/16 DIN: ~25–30 N·m

- 4.3-10 Screw: ~5–8 N·m

- Hand-screw/Push-pull: Follow vendor instructions; ensure fully seated.

Q6. Are both waterproof?

Both can achieve IP67/68 when properly sealed with tape, shrink, and weather boots. The connector alone isn’t enough—installation quality is crucial.

Q: Is the 7/16 DIN considered a DIN coaxial connector?

A: Yes, the 7/16 DIN is part of the larger DIN coaxial connector family, widely used in telecom and broadcast systems.

Conclusion

So, which connector should you use—7/16 DIN vs 4.3-10?

- If you’re running legacy high-power or broadcast gear, the DIN 7/16 (L29) still delivers unmatched robustness.

- For new LTE and 5G rollouts, the 4.3-10 connector wins on size, port density, and ease of maintenance.

- In mixed environments, minimize adapters but select certified low PIM connectors when you must.

Both connectors have their place. Understanding where each shines ensures you get reliable, long-lasting RF performance without unnecessary headaches.

Explore Further

If this guide helped you weigh DIN 7/16 vs 4.3-10, here are related resources for deeper insights:

Your Project Toolbox

For engineers sourcing hardware, explore these product categories:

At TEJTE, we deliver low-PIM 7/16 DIN and 4.3-10 solutions, pre-torqued and weather-sealed for field reliability. Whether you’re upgrading or migrating, our team can help build the right kit for your site.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.