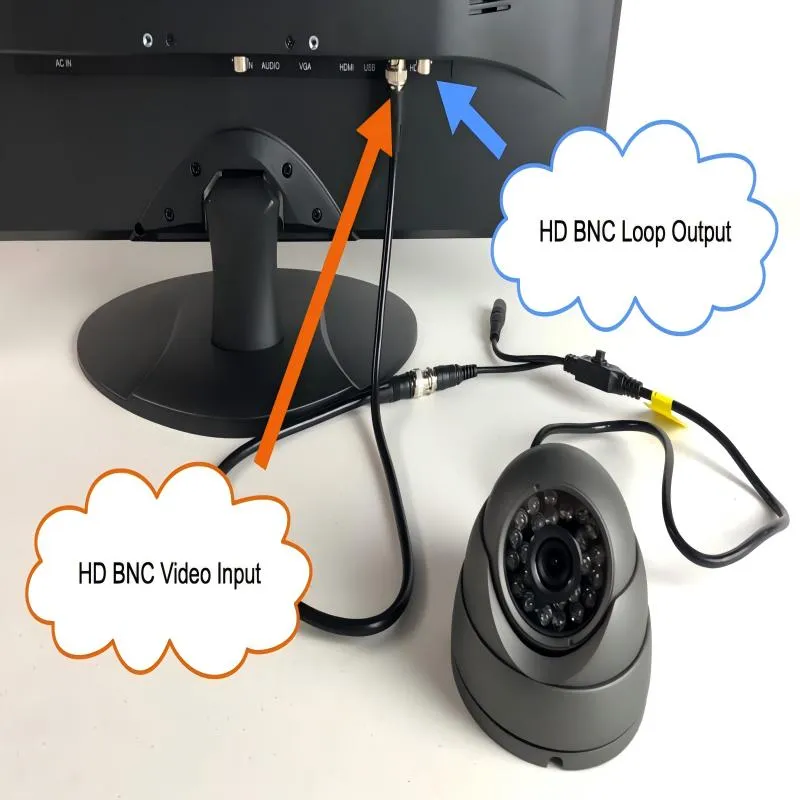

75 Ohm BNC Cable Planning for HD Video Systems

Video systems rarely fail in obvious ways. A camera still powers on, a monitor still shows an image, and basic checks pass during installation. Yet weeks or months later, picture quality begins to drift. Edges soften, brief dropouts appear, or sync instability shows up only under motion or load. In many real-world installations, the root cause is not the camera, recorder, or display. It is the 75 ohm BNC cable quietly sitting between them, operating just outside its safe margin.