MMCX Connector Guide for RF Modules & SMA Links

Jan 25,2025

Figure 1 is used to introduce the core value proposition of MMCX connectors—they are not chosen because they are the “best” connector in isolation, but because they fit the narrow intersection of constraints like size, frequency, serviceability, and mechanical tolerance that many compact RF products face.

When does an MMCX connector become the right choice?

Figure 2 aims to map MMCX connectors to specific typical use cases, emphasizing their suitability in dense enclosures requiring detachable coax interfaces, with limited internal volume and short RF paths.

In most RF projects, connector decisions arrive late. By the time an engineer starts debating whether to use an SMA, MMCX, or U.FL interface, the RF module is already selected, the enclosure outline is fixed, and the antenna strategy is mostly settled. At that point, the connector is no longer a blank-slate decision—it is a constraint-solving exercise.

This is exactly where the mmcx connector earns its place.

MMCX is rarely chosen because it is “the best” connector in isolation. It is chosen because it fits a narrow intersection of size, frequency, serviceability, and mechanical tolerance that many compact RF products eventually land in.

Map typical RF modules and use cases to MMCX

You’ll most often encounter an mmcx connector on RF modules that sit inside dense enclosures but still require a detachable coax interface. These are not edge cases; they describe a large portion of modern wireless hardware.

Typical examples include Wi-Fi and Bluetooth modules in industrial gateways, sub-6 GHz cellular modems in IoT devices, radio links inside drones, compact wearable electronics, industrial vision cameras, and vehicle-mounted communication subassemblies. In all of these products, the RF path is short, the internal volume is limited, and the antenna or test interface cannot be permanently soldered to the PCB.

MMCX fits this scenario well. It is small enough to live on crowded boards, yet robust enough to survive repeated lab handling. Unlike ultra-miniature connectors, it tolerates side loading and re-mating far better. And unlike full-size SMA, it does not demand excessive board edge space or tall keep-out zones.

If your RF module is already locked in and you need a detachable coax interface without redesigning the entire layout, MMCX often becomes the pragmatic choice rather than a theoretical one.

Compare MMCX against SMA, MCX, and U.FL in real products

From a purely mechanical perspective, SMA connectors are stronger and easier to torque. From a purely size-driven perspective, U.FL connectors are smaller. MMCX sits between these extremes, and that middle ground matters in real hardware.

Compared with SMA, MMCX consumes far less PCB area and vertical height. That difference alone can determine whether a module fits inside an enclosure or not. SMA also tends to force antenna connections to the board edge, whereas MMCX can be placed deeper inside a layout with a short pigtail leading outward.

Compared with MCX, MMCX offers similar electrical performance in a smaller footprint. In practice, MCX is often passed over simply because MMCX achieves the same goals while freeing additional space for components or shielding.

Compared with U.FL, MMCX trades absolute miniaturization for durability. U.FL connectors work well when they are connected once and left alone. MMCX connectors tolerate repeated mating, cable movement, and rework with far fewer surprises. That difference becomes obvious during debugging and field servicing.

At a system level, the mmcx connector is best understood not as a “small SMA,” but as a connector that exists specifically to bridge compact RF modules to flexible coaxial interconnects without sacrificing usability.

How should you pair an MMCX connector with MMCX cable and RG316 coaxial cable?

Selecting the connector is only half the decision. The cable that follows it often has more influence on real-world performance than engineers expect.

A common failure pattern looks like this: the mmcx connector is carefully chosen and reviewed, while the coax is treated as interchangeable. In reality, the connector and cable behave as a single RF structure, especially at multi-GHz frequencies.

Match RF band, power, and loss budget before choosing cable

Figure 3 appears in the section discussing cable selection, emphasizing that the connector and cable behave as a single RF structure, especially at high frequencies, and that cable choice significantly impacts performance and should not be treated as interchangeable.

The first filter is frequency. At sub-1 GHz, most short coax assemblies behave acceptably. At 2.4 GHz, losses and impedance discontinuities begin to matter. By 5 GHz and above, even a few centimeters of coax can measurably affect link margin.

Power is usually not the limiting factor in MMCX-based systems. Loss, repeatability, and mechanical stability are far more critical.

Figure 4, in context, illustrates that RG316 coaxial cable is often the default or baseline choice for MMCX cable assemblies due to its flexibility, heat resistance, and durability, particularly suited for industrial and automotive environments.

For short internal runs, mmcx cable assemblies using thin, flexible coax are often sufficient. They minimize strain on the connector and simplify routing in tight spaces. When temperature resistance, chemical stability, or long-term reliability is required, rg316 coaxial cable becomes a common default. Its PTFE dielectric and braided shield make it suitable for industrial and automotive environments where PVC-based cables may degrade over time.

Rather than assuming one cable fits all, it’s better to treat the cable as a design variable tied directly to frequency band and allowable loss.

Size pigtail length and bend radius for compact RF modules

Figure 5 emphasizes the importance of mocking up cable routing early using real assemblies and introduces the conservative engineering rule: minimum bend radius should be ≥ 5-10 times the cable outer diameter to maintain impedance stability and long-term reliability.

Internal pigtails have a tendency to grow during development. An extra few centimeters make assembly easier, then quietly become permanent. That additional length rarely comes without cost.

Longer pigtails increase insertion loss and raise the risk of tight bends near the connector body. Both issues tend to surface late, often after the enclosure is finalized.

A conservative engineering rule still holds:

Minimum bend radius ≥ 5–10× the cable outer diameter, depending on whether the bend is static or subject to motion. Staying above this range helps maintain impedance stability and long-term reliability.

In compact RF modules, it is often worth mocking up the cable routing early using real assemblies. CAD models do not capture how coax behaves once compressed between shields, covers, and neighboring components.

Use an MMCX interconnect selection matrix before you place a PO

Before purchasing locks in connectors and cables, formalizing the interconnect decision prevents quiet assumptions from becoming expensive changes later.

Below is an example of an MMCX interconnect selection matrix used at the module level:

| Parameter | Example |

|---|---|

| Application | Industrial Wi-Fi Gateway |

| RF band | 2.4 GHz |

| Max frequency | 6 GHz |

| Link type | Bidirectional |

| Target VSWR | ≤ 1.5:1 |

| Max link loss allowed | 1.2 dB |

| Connector position | On-board |

| Mount type | SMT |

| Connector gender | MMCX jack |

| Cable type | rg316 coaxial cable |

| Pigtail length | 10 cm |

| External interface | sma coax cable |

| Environment | Indoor industrial |

| Required mating cycles | ≥ 300 |

Loss estimation can be kept simple:

Total_Loss_dB = Cable_Loss_dB_per_m × Length_m + N_connectors × 0.05

And verified against the budget:

Total_Loss_dB ≤ Max_Link_Loss_Allowed_dB

This kind of matrix is not bureaucracy. It creates a shared technical reference that aligns RF, mechanical, and purchasing teams before a part number ever appears on a PO.

Plan SMA transitions from MMCX without wrecking VSWR or loss

Decide between an MMCX to SMA adapter and an MMCX pigtail

Figure 6 illustrates the physical form of the first of two dominant design patterns: the “adapter approach.” This approach favors flexibility for testing and reconfiguration but introduces an additional interface with small insertion loss and a mechanical joint that can loosen over time.

Figure 7 represents the second “fixed pigtail approach.” This approach is electrically cleaner with fewer mating surfaces and is mechanically more robust, but it reduces flexibility once assembled. The text notes that many teams use adapters during development and transition to fixed pigtails in production.

Two patterns dominate real designs.

The first uses an on-board MMCX connector paired with a plug-in mmcx to sma adapter. This approach favors flexibility. It allows engineers to swap test cables easily and reconfigure setups without touching the PCB. The trade-off is an additional interface, which introduces small but measurable insertion loss and another mechanical joint that can loosen over time.

The second approach uses a fixed MMCX-to-SMA pigtail. Electrically, this is cleaner. There are fewer mating surfaces and fewer opportunities for impedance mismatch. Mechanically, it reduces the chance of accidental side loading during cable swaps. The downside is reduced flexibility once the assembly is built.

In practice, many teams use adapters during development and transition to fixed pigtails in production. The key is to treat this as a deliberate design decision rather than an afterthought.

Coordinate SMA coax cable outside the enclosure with internal MMCX pigtails

A common and effective structure pairs MMCX and rg316 coaxial cable inside the enclosure with sma coax cable outside. Internally, flexibility and temperature tolerance matter most. Externally, durability, standardization, and compatibility with antennas and instruments take priority.

When using a panel-mounted SMA, grounding deserves special attention. A poorly bonded SMA bulkhead can negate careful internal RF design by introducing reference discontinuities and unintended radiation paths.

For a broader discussion on SMA cabling practices and loss planning, see the related guide on designing SMA coax cable links correctly.

Avoid hidden ground and reference issues at the transition

Many unexpected VSWR issues trace back to grounding rather than connector quality. The MMCX launch references the PCB ground plane. The SMA bulkhead references the enclosure. If those references are not tied together with low impedance, the transition behaves like an RF discontinuity.

Short ground paths, solid metal-to-metal contact, and intentional bonding between PCB and enclosure matter far more than connector brand or plating finish.

How do you keep MMCX connector reliability under repeated mating?

Most mmcx connector failures don’t look like failures at first.

The RF link still works. Return loss still looks “acceptable.” Then a technician touches the cable, or the enclosure is opened one more time, and something shifts. Sensitivity drops slightly. Throughput becomes inconsistent. Nothing is obviously broken, which makes the problem harder to trace.

That’s usually the moment teams realize MMCX reliability is not an electrical problem. It’s a mechanical one.

Treat mating cycles, retention force, and cable strain as design inputs

Data sheets love round numbers. Hundreds of mating cycles. Stable impedance. Defined retention force. All true—under controlled conditions.

In real products, MMCX connectors rarely see purely axial mating. Cables pull sideways. Technicians disconnect them at odd angles. Assemblies vibrate. The connector survives, but the effective mating life quietly shrinks.

Teams that have been burned by this once tend to change their approach. They stop treating mating cycles as a theoretical spec and start treating them as a budget. If the product will be serviced weekly, they assume the lower end of the rated cycle count. If the cable exits sideways, they assume additional wear.

Strain relief becomes a design feature, not an afterthought. Even a simple anchor point a few centimeters away from the connector can dramatically reduce long-term damage. The goal is not to eliminate movement, but to control where that movement goes.

Design PCB footprints and keep-outs around MMCX connector

Many MMCX problems are designed into the board layout.

The footprint itself is rarely the issue. Most engineers follow the recommended land pattern. The trouble starts around it. Tall components placed too close. Shield cans that force the cable into a tight bend the moment it leaves the connector. Ground copper that looks fine electrically but offers little mechanical support.

Over time, these small compromises add up. The connector sees micro-movements during temperature changes or handling. Solder joints fatigue. Contact pressure changes just enough to show up at higher frequencies.

Leaving generous keep-out space around an mmcx connector feels wasteful during layout. It almost never feels wasteful later, when the product survives repeated rework without RF drift.

Validate reliability with simple but realistic abuse tests

You don’t need an elaborate qualification plan to learn something useful.

A handful of basic tests usually reveal the weak points fast: repeated plug-and-unplug cycles with light side load, gentle cable tugging, then a few thermal cycles followed by another round of mating. Measure again. Compare results.

If performance changes, it will show up here—long before a formal test report would have flagged it. These tests are crude on purpose. They resemble what actually happens on benches, in vehicles, and in the field.

For general background on connector mechanics and common RF interface failure modes, the overview on radio-frequency connectors is a helpful reference—not because it gives design rules, but because it frames the problem space accurately.

Document MMCX connector specs so purchasing can order the right parts

A surprising number of MMCX-related issues start nowhere near the RF lab. They start in purchasing.

MMCX connectors from different vendors look interchangeable. Many of them are interchangeable. But “mostly compatible” is not the same as “safe at scale.”

Build a module-level interconnect table instead of scattered notes

Scattered documentation is the enemy here. A comment in a schematic. A note in an email. A memory that lives in one engineer’s head.

A simple module-level interconnect table works better. It lists every mmcx connector, what it connects to, what frequency it carries, and which cable and adapter combinations are approved. Nothing fancy. Just explicit.

When designs move between teams—or survive longer than the original engineers expected—this table becomes the single source of truth that prevents quiet substitutions.

Align part numbers across connectors, cables, and adapters

MMCX plug versus jack. Straight versus right-angle. These mistakes happen constantly, and they are rarely caught in schematic review.

Locking part numbers together as a set helps. If a board uses a specific mmcx to sma adapter, that adapter should appear alongside the connector and cable in the BOM. Not implied. Explicit.

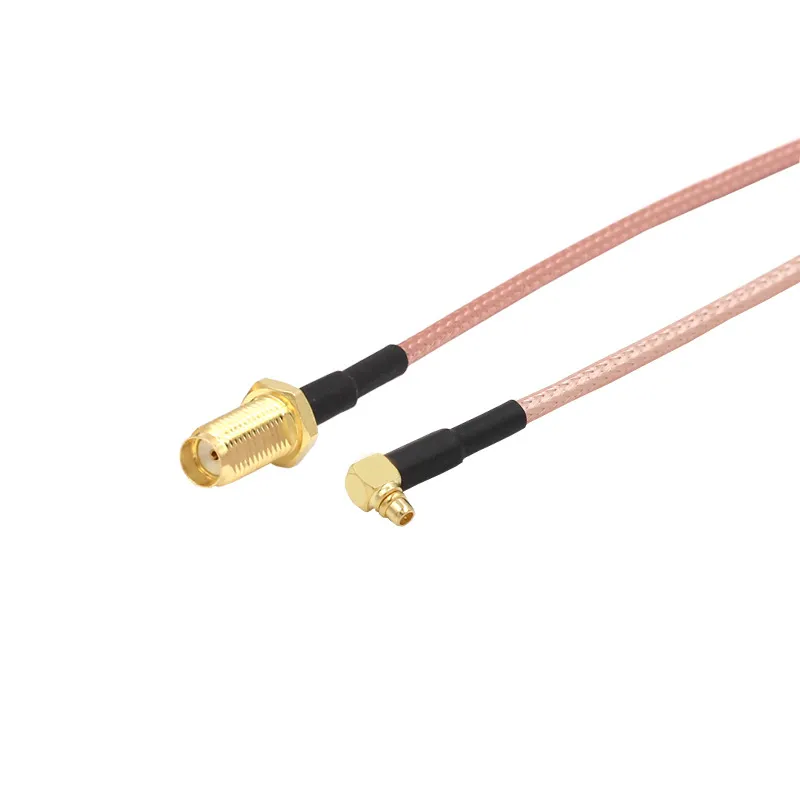

Images help too. Purchasing teams are often more confident when they can visually confirm what “right-angle MMCX jack” actually means in context.

Share connector and cable BOM views with test & manufacturing teams

Test and manufacturing teams handle MMCX interfaces more than anyone else. They know which connectors loosen, which cables kink, and which assemblies are awkward to work with.

Sharing interconnect documentation early gives these teams a chance to flag issues before production locks in. It also avoids a common trap: building test fixtures around assumptions that don’t survive contact with real hardware.

What do 2025 miniature RF connector trends mean for MMCX connector users?

Follow the growth of the MMCX connector and miniature RF connector markets

Compact RF modules are not slowing down. They’re spreading—into industrial equipment, vehicles, infrastructure, and consumer products that previously never needed high-frequency links.

In that environment, the mmcx connector benefits from being neither extreme nor obsolete. It’s not the smallest option available, but it remains one of the most workable choices when products need both compactness and repeated access.

The broader miniature RF connector space reflects the same tension: smaller form factors, higher frequencies, and higher expectations for consistency.

Connect MMCX connector decisions to broader RF interconnect trends

Across RF interconnect systems—connectors and cable assemblies alike—the trend is not toward eliminating interfaces, but toward controlling them better. Mechanical robustness, manufacturing repeatability, and high-frequency behavior are increasingly treated as a single design problem.

Engineering organizations such as the IEEE regularly frame RF interconnect challenges in this combined electrical-mechanical context. That perspective aligns well with how MMCX connectors succeed—or fail—in real products.

Watch how audio, vision, and test equipment adopt MMCX connector

MMCX is also showing up in places that are not traditionally “RF hardware.” Detachable cabling in in-ear monitors, compact industrial cameras, and modular test setups increasingly uses MMCX-style interfaces.

These products value serviceability and density more than brute strength. If your design lives in a similarly constrained environment, those industries offer a realistic preview of how MMCX connectors behave over time.

Turn this guide into a repeatable MMCX connector checklist

Most MMCX-related mistakes are not exotic. They’re repetitive. The same assumptions show up again and again, usually because nobody wrote them down the first time.

A checklist doesn’t make a design perfect. It makes the same mistake harder to repeat.

Capture the minimum questions to ask in every new design

Before placing an mmcx connector on a board, it helps to pause and answer a short set of questions—out loud, not implicitly.

- What frequency range will this link actually see in the field, not just on paper?

- How often will this connector be mated and unmated after production?

- Is the cable static once installed, or will it move during service or vibration?

- What cable family is assumed, and what happens if purchasing substitutes it?

- Where does the RF reference plane transition—from PCB to enclosure—and is that intentional?

- What external interface follows this MMCX link?

None of these questions are difficult. The problem is that they’re often answered silently and differently by different people. Writing them down forces alignment.

Standardize review items for MMCX connector and cabling

Teams that use MMCX frequently tend to formalize it into design reviews.

During DR or NPI, MMCX-specific review items usually include: connector orientation, keep-out clearance, strain relief strategy, approved mmcx cable or rg316 coaxial cable options, and how the internal link transitions to the external sma coax cable.

Once these items become routine review checkpoints, MMCX stops being a “late surprise” and becomes a controlled design element.

This is especially important when MMCX connects to SMA externally. If you already have internal guidelines for SMA cabling—such as those discussed in SMA RF cable length and loss planning—MMCX decisions should be reviewed against the same loss and grounding expectations.

Keep a running log of field failures related to connectors

Field failures are uncomfortable. They’re also invaluable.

A simple log that tracks connector-related issues—loose MMCX interfaces, damaged cables, intermittent RF behavior—quickly reveals patterns. Often, the same mechanical weakness shows up across different products.

That feedback loop is what turns MMCX from a “known risk” into a managed one. The next design doesn’t start from zero. It starts with evidence.

Frequently asked questions engineers actually ask about MMCX

Is an mmcx connector good enough for 6 GHz Wi-Fi or sub-6 5G modules?

In most cases, yes. Many MMCX connectors are specified well into the multi-GHz range. The connector itself is rarely the limiting factor.

What matters more is the PCB launch, the short coax segment, and how grounding is handled. Treat the mmcx connector and its cable as part of the RF network, not as an ideal interface, and it performs as expected.

Can I mix MMCX connectors from different vendors on the same board and cable assembly?

Mechanically and electrically, it often works. Tolerances, plating thickness, and retention force still vary between vendors.

For prototypes, mixing is usually acceptable. For volume production or safety-critical systems, qualifying a consistent connector-and-cable combination reduces variability that otherwise shows up much later.

How many mating cycles can I realistically expect in the field?

Assume fewer than the headline number if the connector will be handled regularly.

Side loading, angled removal, and cable stiffness all reduce effective life. If your product will be re-patched frequently, design for strain relief and plan around the lower end of the rated mating cycle range.

When should I choose an mmcx to sma adapter instead of a fixed pigtail?

Use a fixed MMCX-to-SMA pigtail when RF cleanliness and long-term stability matter more than flexibility. Use an mmcx to sma adapter when you expect frequent changes in test setups or external cabling.

Many teams use adapters during development and eliminate them in production. That transition is normal—and healthy.

What cable should I specify for high-temperature MMCX pigtails?

rg316 coaxial cable is a common baseline because of its PTFE dielectric and thermal stability. It is not the only option.

In very tight spaces or at higher frequencies, other 50-ohm cables may be more appropriate. RG316 is a starting point, not a rule.

For a broader comparison of 50-ohm cable trade-offs, see discussions such as RG316 vs other compact coax options.

How tight can I bend an MMCX cable assembly without degrading performance?

A conservative rule is to stay above 5–10× the cable outer diameter for static bends, and more for dynamic motion.

Bending tighter may work initially, but it increases the risk of impedance shifts, higher loss, and long-term mechanical fatigue.

Are MMCX connectors robust enough for outdoor or automotive applications?

They can be—if the surrounding design supports them.

The connector alone does not guarantee robustness. Sealing, strain relief, vibration control, corrosion-resistant plating, and validation testing all matter. In harsh environments, treat MMCX as part of a system, not a standalone solution.

Closing perspective

MMCX connectors rarely fail because someone misunderstood their data sheet. They fail because small mechanical assumptions pile up unnoticed.

When used deliberately—paired with the right cable, given room to breathe on the PCB, and documented clearly—an mmcx connector does exactly what it’s meant to do. It bridges compact RF modules to the outside world without forcing a redesign every time requirements shift.

The difference between a clean MMCX design and a fragile one is rarely a single decision. It’s a series of small, explicit choices made early—and remembered later.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.