SMA Coax Cable for RF Jumpers and Antennas

Jan 15,2025

Introduction

This opening graphic establishes the core problem addressed by the guide. It likely uses a visual metaphor, such as a small SMA cable being added as an afterthought to a complex, seemingly complete RF system diagram. The image emphasizes that while SMA cables are physically small and often specified after major components are finalized, underestimating their role can lead to subtle but significant performance issues and margin erosion later in the product lifecycle.

The sma coax cable is rarely treated as a design decision. In most RF projects, it appears after the antenna has been selected, after the radio has already passed early testing, and after the enclosure layout feels mostly settled. At that point, the cable is expected to behave like a neutral link—short, passive, and unlikely to influence system performance in any meaningful way. That assumption holds just long enough to become dangerous.

On a workbench, early measurements often look fine. The radio locks, sensitivity is acceptable, and throughput meets expectations. Problems tend to surface later, when something small changes. A bulkhead connector is added. The antenna is moved outside the enclosure. A different jumper is used during final validation. The system still works, but margins feel thinner. Results become harder to reproduce. Engineers start questioning the RF design itself, even though nothing fundamental has changed. In many of those cases, the sma coax cable is part of the shift, not because it is defective, but because its role was underestimated.

This article looks at SMA-terminated coax where it actually operates: short RF jumpers, antenna leads, and transition points between subsystems. It does not attempt to re-explain coaxial theory or long feeder behavior. If that broader context is needed, the Coaxial Cable Ultimate Guide already covers it. The focus here stays narrow and practical, centered on how SMA cables behave once they are part of real hardware.

Where does sma coax cable actually sit in your RF chain?

Map every segment that really needs sma coax cable

This instructional diagram provides a practical methodology. It likely depicts a step-by-step breakdown of a typical RF signal path, visually highlighting the short transition segments (e.g., board-to-bulkhead, bulkhead-to-external port) where SMA cables are appropriate and necessary. The graphic reinforces the guide's advice to consciously separate these compact, frequently mated jumper segments from longer feeder runs, which require different cable and connector strategies.

A useful way to reduce SMA-related problems is to stop thinking in terms of “the RF cable” and instead trace the signal path step by step. Start at the RF chip or module. Follow the route through any internal jumper, into a panel or bulkhead connector, and then out to an antenna or test instrument. In most designs, only those short transition segments truly require sma coax cable.

These segments share the same constraints. They are mechanically exposed, often close to enclosure boundaries, and frequently subject to handling or rework. That is where SMA connectors make sense. They are compact, repeatable, and designed for frequent mating. What they are not designed for is acting as a substitute for a proper feeder cable over longer distances or solving routing problems created elsewhere in the design.

Trouble usually starts when convenience replaces intent. A long SMA jumper is used because it fits through an opening. A thick RG cable is pulled inside an enclosure because redesign feels risky. The immediate problem disappears, but mechanical stress and RF inconsistency quietly take its place. Teams that avoid these issues tend to be explicit about where SMA is mandatory and where it is merely available.

Separate sma cable, sma rf cable, and sma coaxial cable in practice

In day-to-day conversation, terminology is loose. In documentation and purchasing, it cannot be. When engineers say sma cable, they often mean a finished jumper with SMA connectors already installed. Sma rf cable usually refers to intent, not construction: a cable suitable for RF use that happens to terminate in SMA. Sma coaxial cable is broader still and is sometimes used to describe raw coax plus connectors, sometimes a completed assembly.

The ambiguity becomes a problem when those terms are copied directly into a BOM. A line item that simply reads “SMA cable, 1 m” leaves room for multiple interpretations. Different coax families may meet that description while behaving very differently at frequency. Connector variants may match mechanically but differ in loss, durability, or mating life.

A more reliable approach is to treat sma coaxial cable as a specification container rather than a product name. Define the coax family, the connector genders, the form factor, and the acceptable tolerances. The language becomes less elegant, but the result aligns far better with design intent.

Identify the main scenarios for sma antenna cable

This image categorizes the common applications where SMA antenna cables are critical. It likely uses icons or simple drawings to represent scenarios like a short cable from a router to an external antenna, connections in compact access points, and jumper cables on a lab bench linking instruments. The graphic underscores that despite being short, these cables operate in demanding environments requiring consistent performance across temperature, mating cycles, and physical routing changes.

The term sma antenna cable shows up repeatedly in a small set of use cases. One is the short run between a Wi-Fi router or IoT module and an external antenna, typically under a meter and often routed through a panel. Another is compact infrastructure hardware such as access points or small cells, where SMA offers a workable balance between size and RF capability. The third is the lab environment, where SMA jumpers connect instruments, loads, attenuators, and reference antennas.

In all of these cases, the cable length is short, but expectations are high. The jumper is expected to behave consistently across temperature changes, repeated mating cycles, and small routing adjustments. That combination is what makes sma antenna cable choices more sensitive than their size would suggest.

How do you match sma coax cable type to frequency and power?

Compare common coax families behind sma rf cable

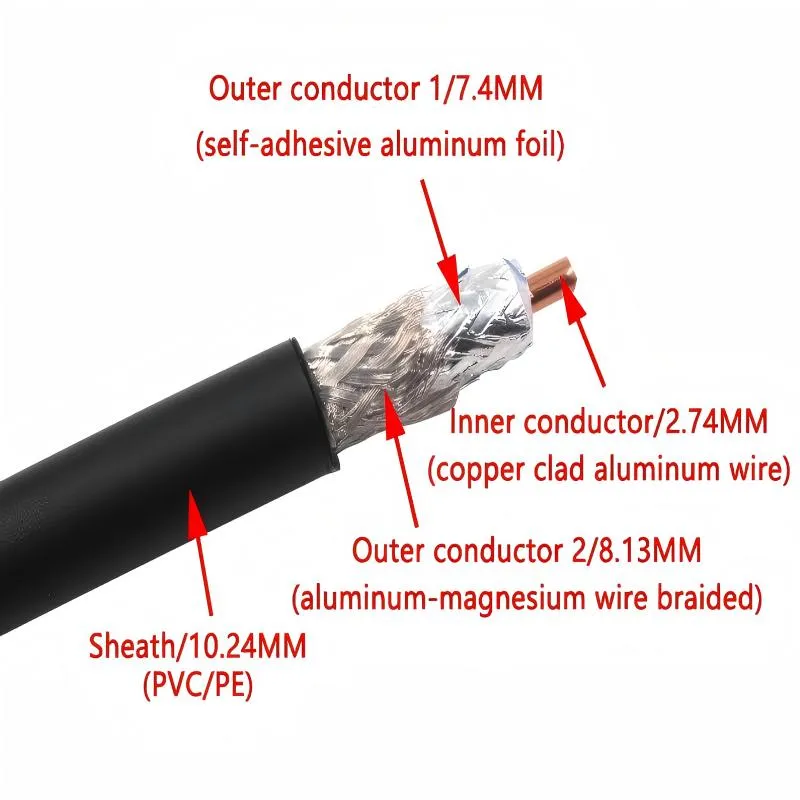

An SMA connector defines the interface. It does not define performance. The electrical behavior of any sma rf cable is dominated by the coax behind the connector. In practice, most SMA assemblies are built on a familiar set of coax families, each with its own compromises.

RG174 is thin and easy to route, which makes it attractive in tight spaces, but its attenuation rises quickly as frequency increases. RG316 improves thermal stability and high-frequency behavior through its PTFE dielectric and plated conductors. LMR-100 reduces loss further while remaining relatively compact. LMR-195 pushes attenuation lower again, but stiffness and bend radius become more noticeable.

From a distance, these all look like interchangeable SMA jumpers. Electrically, they are not. This is why experienced teams tie SMA jumper selection back to a broader RG and LMR comparison rather than treating SMA cables as generic accessories. For that wider comparison, the RG Cable Guide is often the starting point.

Choose cable families for sub-GHz, 2.4 GHz, and 5–6 GHz bands

Different frequency ranges expose different weaknesses. Below 1 GHz, short RG174 jumpers are often acceptable, particularly when flexibility matters more than absolute loss. The attenuation exists, but it rarely dominates the link budget. At 2.4 GHz, margins tighten. RG316 or LMR-100 is commonly chosen for sma coax cable to keep loss under control without making routing unnecessarily difficult.

At 5–6 GHz, assumptions break faster. Loss accumulates quickly, connector quality becomes visible in measurements, and adapter stacks start to matter. In this range, engineers typically shorten jumpers aggressively, move toward LMR-195, and remove any interface that does not serve a clear purpose. These are not strict rules, but patterns that show up repeatedly across real systems.

Balance flexibility, loss, and power rating in sma coaxial cable

Every sma coaxial cable decision trades one constraint against another. Thinner cables bend easily and reduce mechanical stress on connectors, but they dissipate more RF energy and tolerate less power. Thicker cables preserve signal integrity and power margin, but resist tight routing and transmit mechanical loads directly to connectors and solder joints.

Problems arise when teams try to optimize all three simultaneously. Designs that hold up over time usually start by identifying which constraint cannot move. If enclosure space is fixed, loss must be managed elsewhere. If link margin is tight, mechanical convenience has to give way. Once that priority is clear, the cable choice tends to follow naturally.

How can you estimate loss for any sma coax cable run?

Define a practical loss model for typical sma coax cable types

For short runs, nobody I know calculates loss from first principles. Not for sma coax cable. It is not worth the time. Too many unknowns dominate anyway. Cable routing changes after layout freeze. Assemblies come from different vendors. Connectors get reused more than planned.

What actually happens is simpler. Someone picks a loss-per-meter number that roughly matches the frequency band and the cable family. That number is treated as “good enough.” Then a fixed penalty is added for every SMA interface in the path. The goal is not accuracy. The goal is direction.

Most teams assume around a tenth of a decibel per SMA interface when things are clean. More if the cable lives on a bench and gets mated every day. The exact value is rarely debated. Consistency matters more than correctness. Once a team agrees on a rule, comparisons become possible.

This model survives because it answers the real question. Not “what is the loss,” but “is this cable choice obviously eating margin.”

SMA Coax Cable Loss & Length Budget Sheet

This is a detailed product photo focusing on the SMA connector itself, specifically the male variant. It serves as a reference point within the guide's discussion about connector genders, variants, and the importance of specifying details. The image highlights the mechanical construction (threads for mating, center contact) that defines the interface, reminding engineers that the “SMA” in “SMA coax cable” refers to this precise component, whose quality and compatibility directly impact performance.

This product photo showcases LMR-400, a specific type of low-loss coaxial cable often mentioned as an upgrade path for longer or higher-frequency SMA jumper runs where standard RG316 loss becomes prohibitive. The image likely emphasizes its relatively thick and stiff construction compared to RG174/RG316, visually explaining the trade-off between lower attenuation and reduced flexibility/routing ease discussed in the guide.

Some teams formalize the above into a small worksheet. Others just keep it in their heads. The better ones write it down.

Inputs stay minimal on purpose. Frequency. Cable family. Total length. Number of SMA interfaces. An allowed loss number taken from the system budget, not invented for the jumper itself.

Internally, each cable family is assigned a rough attenuation value for the relevant band. Nothing fancy. Total loss is treated as cable loss plus a fixed connector term. No correction factors. No false precision.

The output is binary in spirit, even if numbers are shown. Either the jumper is comfortably inside budget, or it is not. If it is not, nobody tweaks decimals. The response is structural. Shorten it. Change the cable family. Remove adapters. These steps recover real margin. Everything else is noise.

This way of thinking matches how jumper-level decisions usually relate back to larger coax planning, as outlined in references like the RG Cable Guide. Relative behavior matters more than exact values.

Use length tiers to derisk sma antenna cable choices

In practice, many engineers skip calculations entirely for very short runs. They use length tiers instead. For sma antenna cable under roughly half a meter, most RG316 or LMR-100 jumpers behave predictably enough that loss is rarely the limiting factor. Mechanical fit matters more.

Between about half a meter and a couple of meters, assumptions start to fail. Connector quality begins to show. Assembly variation becomes visible. This is where teams are more likely to check numbers instead of trusting intuition.

Beyond that range, SMA often stops being the right transport solution. At longer distances, designs usually switch to a thicker feeder and leave SMA only at the termination. That change simplifies both RF behavior and mechanical stress, even if it complicates routing.

How do connector genders and variants impact sma coax cables?

Plan male–male vs male–female sma jumper roles

This is a crucial instructional image aimed at preventing a common and costly mistake. It clearly illustrates the polarity reversal between standard SMA (male has a center pin, female has a socket) and Reverse Polarity SMA or RP-SMA (male has a socket, female has a pin). The guide uses this to warn against the “quick fix” adapter traps, as mechanically mating these different standards can create an electrical short or open circuit, severely degrading performance even if the threads fit.

Connector gender is often inherited, not chosen. Instruments are female. Bulkheads are female. The default sma coax cable becomes male–male without discussion.

In a lab, that is fine. Cables are consumables there. In finished hardware, the situation is different. Repeated torque on a fixed connector is a common failure mode. Extending that connector outward with a male–female jumper reduces risk with almost no RF penalty.

Teams that think about this early tend to use fewer adapters later. That alone improves robustness.

Avoid RP-SMA and “quick fix” adapter traps in the chain

SMA and RP-SMA look close enough to cause mistakes. Threads engage. Something connects. The pin mismatch hides until measurements look odd.

Adapters feel harmless. Each one adds a little loss and a little mismatch. Mechanically, it adds leverage. One adapter is rarely a problem. Several in a row often are.

Replacing an adapter stack with a dedicated sma male to sma female cable usually removes multiple variables at once. Fewer interfaces. Shorter path. Less mechanical stress. The fix is boring. It works.

Document connector details in every sma coax cable spec

Many issues trace back to vague specs. “SMA both ends” is not enough once a cable is installed. Gender, polarity, straight versus right-angle bodies, bulkhead threads—these details matter later, even if they feel tedious during design.

Teams that treat sma coax cable as a defined component usually write both ends explicitly. That habit reduces procurement errors and avoids field fixes that introduce adapters nobody wanted.

How should you route and secure sma coax cables inside hardware?

Respect bend radius and strain limits for flexible sma rf cable

Most SMA cable failures are mechanical. Tight bends near the connector body. Repeated flex at the same spot. Constant preload from forced routing. Flexible sma rf cable tolerates movement, not abuse.

Designs that survive vibration give the cable room. They do not force alignment. Sharp corners near connectors are avoided whenever possible.

Place anchors and strain reliefs along sma coax paths

Strain relief rarely shows up in performance plots, but it shows up in failure reports. Anchors near connectors redirect force away from solder joints and threads. Short support sleeves reduce local bending stress.

These details matter most where free cable meets fixed structure. Ignore those points and intermittent faults become likely.

Keep sma coax cable away from hot or noisy components

Routing choices affect aging. Heat accelerates dielectric degradation. Noise couples where it is allowed to. Sma coax cable routed near converters, amplifiers, or motor wiring will age differently than cable routed through quiet space.

Where distance is limited, grounded metal partitions or continuous ground planes help. These decisions rarely pay off immediately. They matter later.

What industry trends are reshaping sma coax cable demand?

Track growth in global RF interconnect and cable assemblies

From an engineering perspective, market numbers rarely change design decisions. What they do change is availability, lead time, and how standardized certain components become. Sma coax cable sits in a category that has quietly benefited from sustained growth in RF interconnect demand.

As wireless infrastructure expands and test complexity increases, short precision jumpers are used in higher volumes, not lower. More radios per enclosure, more bands per device, more test points per board. Each of those trends favors compact, repeatable interconnects rather than long bespoke cable runs.

What matters more than the headline figures is how this growth pushes suppliers toward tighter tolerances and broader standard offerings. SMA jumpers that once felt “custom” are now treated as semi-standard items. That shift reduces friction for engineering teams but also increases the importance of specifying details clearly. When everything is available, ambiguity becomes the real risk.

See how 5G, IoT, and small cells favor compact SMA-based jumpers

High-power macro systems moved away from SMA long ago. What brought SMA back into focus is the opposite end of the spectrum. Small cells, distributed radios, and dense IoT hardware prioritize size, modularity, and ease of replacement. In those environments, SMA remains a practical compromise.

A short sma coax cable allows RF sections to be physically separated without committing to rigid board-to-board interfaces. It also allows late-stage adjustments during tuning and validation. That flexibility matters more in compact systems than in large installations where everything is fixed early.

This is why SMA continues to appear in designs that operate well into the gigahertz range, even when other connector families are technically capable. Convenience and repeatability carry weight.

Understand flexible RF coaxial cable market momentum

Flexible RF coax continues to gain share relative to rigid interconnects. That trend is not driven by performance alone. It is driven by assembly tolerance, field serviceability, and the reality that mechanical constraints shift late in many projects.

Sma coax cable lives squarely in that space. It absorbs small mechanical mismatches without forcing redesigns upstream. As long as systems continue to favor modular RF blocks over monolithic layouts, demand for short flexible jumpers will remain stable.

How can teams standardize sma coax cable choices across projects?

Define a minimum spec template for every sma coax cable

Standardization does not mean locking everything down. It means deciding which variables are allowed to vary. Teams that struggle with SMA issues often have no shared baseline. Every project re-discovers the same questions: which coax, which length, which connector variant.

A minimum template solves that. Impedance and frequency range. Cable family. Nominal length with tolerance. Connector A and connector B, including gender, polarity, and mechanical form. Environmental assumptions such as indoor versus outdoor use and temperature range. Nothing exotic. Just explicit.

Once this exists, deviations become visible instead of accidental.

Build an internal jumper catalog tied to part numbers

After a few projects, patterns emerge. The same lengths. The same connector combinations. The same coax families. Teams that capture those patterns into an internal catalog spend less time arguing about cables and more time validating systems.

An internal catalog does not replace custom assemblies. It reduces how often they are needed. It also creates a shared reference for purchasing and assembly, which lowers the chance of last-minute substitutions.

This approach pairs naturally with broader coax documentation already maintained in resources like the RG Cable Guide and related jumper-specific notes.

Feed sma coax rules back into RF design and purchasing checklists

The final step is procedural. Rules that live only in one article or one engineer’s memory decay quickly. Teams that actually benefit from standardization feed those rules back into checklists used during design reviews and purchasing approvals.

Length tiers. Loss assumptions. Connector documentation requirements. Bend radius guidance. These items do not need to be debated every time. They need to be checked. Over time, this closes the loop between RF design intent and what gets built.

When that loop is closed, sma coax cable stops being a recurring source of late-stage questions and becomes just another predictable part of the system.

Practical FAQs

How short should an sma coax cable be at 6 GHz before loss becomes a serious problem?

Below about 0.3 m, loss is rarely the dominant factor. Around 0.5 m, coax choice and connector quality start to matter. By 1 m, many teams consider stepping up to a lower-loss cable family or rethinking the routing altogether.

Can I mix different sma coax cable types in a single RF path?

Yes, as long as impedance is consistent. Short mixed sections are usually acceptable. What matters is tracking total loss and interface count rather than insisting on uniformity everywhere.

When does it make sense to replace an adapter stack with a dedicated sma coax jumper?

As soon as frequency rises or repeatability matters. Dedicated jumpers reduce interfaces, shorten the path, and remove mechanical leverage introduced by stacked adapters.

How often should sma coax cables in a busy RF lab be replaced or requalified?

There is no fixed interval. Cables that see frequent mating should be treated as consumables. Visible wear, connector looseness, or unexplained measurement drift are practical triggers for replacement.

Is there a practical torque target for tightening SMA connectors on coax jumpers?

Most standard SMA connectors fall in the range of roughly 0.8–1.1 N·m, depending on the connector design. Over-tightening causes as many problems as under-tightening.

What is the best way to label sma coax cables for future troubleshooting?

Label both ends with cable family, length, connector gender, and functional role. Simple identifiers prevent unnecessary swaps during debugging.

How do I quickly tell if a failing RF measurement is caused by the sma coax cable or the DUT?

Swap in a known-good reference cable. If the measurement stabilizes, the jumper is suspect. Many labs keep one or two “golden cables” for exactly this reason.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.