12V 2A Power Supply: NCP1207BDR2G Repair Guide

Nov 29,2025

What fails first in a 12V 2A flyback SMPS on the bench?

Figure is likely a schematic or annotated physical board diagram aiding engineers in quickly locating and identifying the vulnerable components described in the document, thereby improving repair efficiency.

Every engineer who has opened a 12V 2A power supply knows that what fails first isn’t always the controller itself. In most cases, you’ll see a silent chain of degradation — one part at a time.

Electrolytic capacitors dry out first, startup resistors drift, and then the MOSFET goes short. It’s a pattern as old as offline SMPS repair itself.

When a 12V 2A flyback converter (typically a 24 W design) lands on your bench with no output, here’s what’s worth checking before you even touch the IC:

- Electrolytic aging:

The high-voltage bulk capacitor (usually 400 V, 33–68 µF) is the first to suffer under continuous ripple. ESR doubles every few thousand hours at 70 °C.

- Repair tip: Replace with a 105 °C low-ESR type, even if capacitance still measures “okay.”

- Startup resistor drift:

The startup path feeding the NCP1207’s VCC pin often uses a 330 kΩ–560 kΩ resistor. Over years, its value climbs due to film cracking. That means the controller never reaches its 11 V startup threshold.

- MOSFET shorts:

Drain-to-source failure kills both primary energy and the controller IC.

- Always verify with a ring tester or DMM diode mode before assuming the IC is dead.

- Optocoupler / TL431 loop:

Feedback paths often drift because of solder fatigue or cracked secondary traces. This makes the supply overshoot, triggering hiccup protection.

- RCD snubber overheating:

Perhaps the most common “invisible killer.” Once leakage energy rises and the snubber cap (Csnub) ages, the RCD clamp runs hotter.

- You’ll notice brown board marks near the snubber diode, even when the rest looks fine.

Field note: In a recent batch of repairs at TEJTE’s lab, nearly 40% of 12 V 2 A flybacks that failed had nothing wrong with the controller — only RCD dissipation creeping past 0.5 W due to capacitor loss.

How do you confirm it’s a flyback and map the primary/secondary?

Before diving into replacement, you must be certain that the unit is indeed a flyback topology, not a forward or quasi-resonant variant.

A simple visual and electrical map can save you hours.

Practical probing note:

When tracing the primary, keep your oscilloscope earth-isolated or use a differential probe. A direct ground clip on the MOSFET drain can vaporize your probe tip faster than you can blink.

The transformer secondary usually carries about 14–16 VDC rectified, giving a regulated 12 V output after load.

If you confirm these signatures, you’re indeed repairing an offline flyback converter, exactly the use case for the NCP1207BDR2G controller used in TEJTE’s archived 12 V/2 A reference design.

UC3842 vs. NCP1207: where do startup current and VCC supply differ?

When comparing legacy controllers like UC3842 to modern low-power designs like NCP1207, two specs define the difference:

startup current and VCC window. They’re small numbers on paper, but they determine if your supply will wake up — or stay dead.

Key Electrical Comparison

| Parameter | UC3842 | NCP1207BDR2 | Difference & Implication |

|---|---|---|---|

| Startup current (typ.) | 0.5 mA | 0.15 mA | 3× lower → smaller startup resistor dissipation |

| VCC (start / stop) | 16 V / 10 V | 11 V / 7.8 V | Lower startup voltage means faster activation |

| Max frequency (Fsw) | 100 kHz | Up to 200 kHz | Smaller transformer possible |

| OCP / OTP / OVP | External sense | Integrated protections | Improved reliability for repair retention |

| Topology | PWM (fixed) | Current-mode flyback | Smoother transient response |

The NCP1207 series, designed by onsemi, integrates protection that UC3842 lacks — including over-current, overload, over-temperature, and over-voltage control.

That’s why it remains one of the most reliable chips for small AC/DC flyback designs up to 30 W, even though the line has now moved to EOL (End of Life).

If your old UC3842-based board keeps blowing startup resistors, swapping to NCP1207BDR2G can cut dissipation by up to 80%.

Its 10.6–20 V operating VCC window allows smaller bias capacitors and lower stress during cold starts.

TEJTE note: The chip’s internal architecture supports up to 200 kHz switching frequency without internal FETs (external switch design). That makes it perfect for designs where isolation is mandatory but cost remains tight.

Specification Summary (from TEJTE verified database)

| Attribute | Description |

|---|---|

| Manufacturer | TEJTE / onsemi |

| Type | Offline flyback controller (no internal switch) |

| Operating VCC Range | 10.6 V – 20 V |

| Switching Frequency | Up to 200 kHz |

| Protection Features | Current limit, overload, over-temp, over-voltage |

| Package | 8-SOIC (7 leads, 3.9 mm width) |

| Temperature Range | -40 °C ~ +125 °C (Tj) |

| RoHS / REACH | Compliant (MSL 1, unlimited shelf life) |

| Topology | Isolated flyback |

| Lifecycle | Obsolete / Not for new designs |

| Typical Use Case | 12 V 2 A / 24 W AC-DC supply |

| Datasheet Reference | NCP1207A-D (onsemi, Rev. 2024) |

Field insight:

If your VCC never crosses 11 V but the bulk cap charges normally, your startup resistor is too large for the NCP1207’s lower Istart.

Try dropping resistance by ~15%, ensuring the VCC capacitor is ≥22 µF / 25 V low-ESR. This small tweak often revives “dead” 12 V 2 A bricks instantly.

Can an NCP1207B drop into a 24 W design safely?

Figure is crucial for controller replacement, helping engineers confirm pin compatibility and understand potential circuit adjustments needed, such as gate resistor modifications.

When maintaining legacy 12 V 2 A power supplies, engineers often wonder whether the NCP1207B can be used as a drop-in replacement for older controllers.

The answer is mostly yes — but only if you check a few critical details first.

Start by comparing pin maps. The NCP1207BDR2G keeps the standard SOIC-8 footprint (7 active pins) used by UC3842-class controllers, so mechanical fit isn’t an issue.

But electrical parameters tell a more nuanced story:

| Parameter | NCP1207BDR2G | Typical 12 V / 2 A Flyback Target |

|---|---|---|

| Power Class | 24 W (max) | 12 V × 2 A = 24 W |

| Switching Frequency | 65 – 200 kHz programmable | 80 – 120 kHz common region |

| VCC Operating Range | 10.6 – 20 V | 12 – 15 V bias normal |

| Protection Features | OCP / OTP / OVP built-in | External OCP only on older designs |

The controller handles the 24 W band comfortably if thermal paths are clean and snubber loss remains below 0.5 W. A proper heatsink or enlarged copper pour around the MOSFET helps maintain loop stability at full load.

Pro note: When replacing an obsolete controller, always measure the gate-drive rise time on the scope. The NCP1207B’s softer drive edge reduces EMI but may require a slightly lower gate resistor (22 Ω → 15 Ω).

While onsemi officially lists the device as EOL (End of Life), you can still find small-batch spares on TEJTE’s component page or refer to the company’s SMPS repair guide for verified alternatives.

How to size and cool the RCD snubber without killing efficiency

If your RCD snubber is too aggressive, efficiency dies. If it’s too light, your MOSFET dies. The balance defines a long-life SMPS repair.

A good starting point is estimating clamp loss with the standard formula:

PRCD≈21CsnubVclamp2fsw

At 200 kHz, even a small 680 pF snubber at 100 V clamp dissipates ≈ 0.7 W. Use this value to check your thermal headroom.

| Parameter | Recommended Range | Note |

|---|---|---|

| Clamp Voltage (Vclamp) | ≤ 80 % of MOSFET Vds max | Protect device margin |

| Snubber Cap (Csnub) | 470 pF – 1 nF typ. | Adjust for ring damping |

| Resistor (Rsnub) | 47 – 100 kΩ / 1 W | Limit average loss < 0.5 W |

| Diode (Dsnub) | UF4007 / FR107 class | Fast recovery (< 75 ns) |

| ΔT thermal limit | < 40 °C (steady 1 h) | Per TEJTE thermal tests |

Field insight: If your RCD network runs hot but output is stable, increase the resistor by 20 % and monitor drain-ring amplitude on the scope. You want a single ring decay within two cycles — that marks the sweet spot between efficiency and MOSFET stress.

TEJTE’s lab often uses this rule: for a 24 W flyback, keep total RCD loss under 3 % of output power (≈ 0.7 W). Beyond that, heat propagates to the controller and reduces reliability.

For reference, see our RCD snubber heat control article for extended examples and oscilloscope captures.

Should you migrate to a newer QR flyback controller instead?

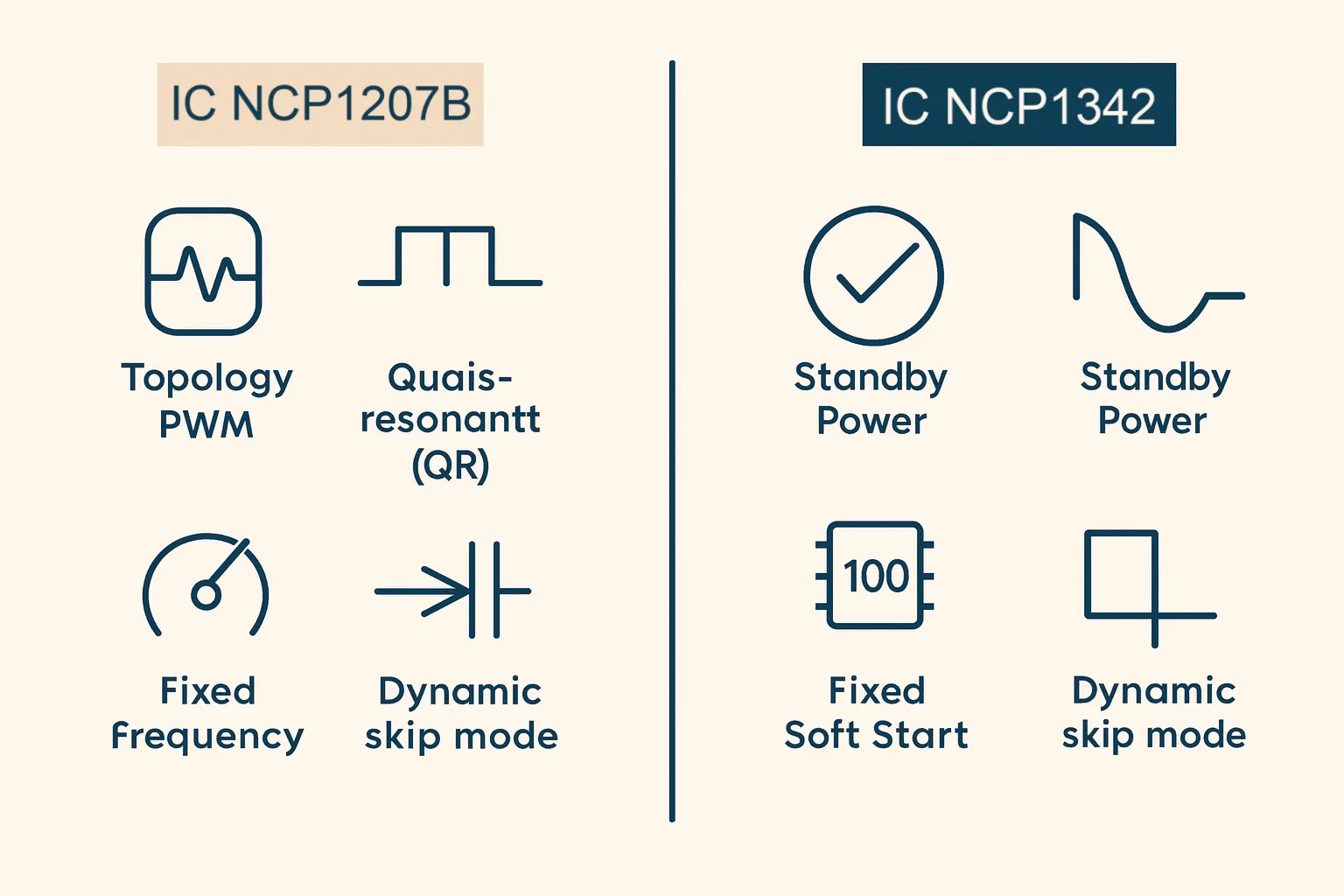

Figure visually demonstrates the technological evolution and performance improvements from traditional PWM to more efficient quasi-resonant topology, providing a visual reference for design upgrade decisions.

| Feature | NCP1207B | NCP1342 | Design Impact |

|---|---|---|---|

| Topology | Fixed-frequency PWM | Quasi-resonant (QR) | Lower switching loss |

| Valley Lockout | - | Yes | Prevents false valley firing |

| Standby Power | < 300 mW | < 100 mW | Meets new DOE standards |

| Istart / UVLO start | 0.15 mA / 11 V | 0.2 mA / 9 V start | Requires slightly tighter bias |

| Fsw Range | 65 – 200 kHz | 40 – 130 kHz QR adaptive | May require snubber re-tune |

| Soft-Start / Burst | Fixed soft start | Dynamic skip mode | Better light-load behavior |

Migration Checklist for NCP1207 to NCP1342

| Parameter | Check Condition | Guideline |

|---|---|---|

| Vcc(on/off) | New ≤ old + 5 % / off ≥ old - 5 % | Startup compatibility |

| Istart | ≤ 0.2 mA | Adjust Rstart if too large |

| Fsw_range | Overlap > 50 % | Keeps transformer within core limits |

| Valley_lockout | Enabled | Avoid noise trigger |

| Burst/skip | Smooth transition | No audible chirp |

| OCP_sense | Pin match ok | Verify sense resistor value |

| Gate_R | Tune 15-33 Ω | Balance EMI vs. speed |

| Soft-start | No overshoot > 10 % | Observe on scope |

| RCD_re-tune | △T < 40 °C steady | Thermal margin kept |

| EMI_margin | > 3 dB from limit | Final compliance headroom |

Field note: TEJTE engineers found that when migrating from NCP1207 to NCP1342, the snubber resistor often needed a 10–15 % increase to compensate for lower peak voltage in valley switching. Failing to adjust can lead to ringing visible at the drain node.

For an overview of this controller family, see QR flyback design notes, which include scope shots and layout tips for 24 W applications.

How do you validate the repair and migration with minimum lab time?

Figure , as a physical display of a modern quasi-resonant controller, appears in the validation section to help engineers accurately identify the device. Migrating from the traditional NCP1207 to this NCP1342 is a critical step in improving power supply efficiency (especially standby power) and reliability. Confirming the correct controller model and proper installation is the foundation for all subsequent validation tests.

A repaired 12 V 2 A power supply might power up fine on your bench — but that doesn’t mean it’s stable.

Validation is where you separate a temporary fix from a reliable redesign. Engineers at TEJTE typically use a three-phase verification loop that requires less than one hour per unit.

Startup sequence

Use a differential probe on the MOSFET drain and a standard probe on VCC.

The waveform should climb smoothly past 11 V (for NCP1207) or 9 V (for NCP1342) before any gate pulse appears.

If you see jitter or double pulses, check your startup resistor or bias capacitor.

Dynamic load test

Step the output from 0 A to 2 A using an electronic load or a simple toggle-resistor array.

Observe the FB pin and Vout ripple. Acceptable transient overshoot is under ±3 %.

If ripple spikes appear, tweak the compensation network (RC loop) rather than the optocoupler.

Thermal steady-state

After 60 minutes at full load, verify that:

- The RCD snubber ΔT < 40 °C

- The MOSFET package stays below 110 °C junction equivalent

- No audible oscillation occurs under no-load mode

If all three conditions hold, your SMPS passes the minimal qualification set TEJTE uses for its AC-DC SMPS repair guide.

Engineer tip: Always re-measure efficiency after migration. A well-tuned offline flyback converter with NCP1342 should reach 83–86 % at 230 VAC in / 12 V 2 A out. Anything lower often points to excessive RCD loss or snubber mis-match.

What recent controller news should repair engineers know?

Keeping up with flyback controller updates saves time when recommending replacements.

As of mid-2025, onsemi continues to maintain its legacy line documentation but actively pushes the newer NCP1342 and NCP13992 families for low-standby applications.

Key bulletins:

- NCP1207A/B datasheet (Rev. 2024) — still downloadable, but all distributors mark the family as Obsolete / Not for New Designs.

Engineers supporting existing 12 V 2 A supplies should build buffer stock for at least three years of service coverage.

- NCP1342 datasheet (Rev. 29, July 2025) — added valley-lockout and frequency-foldback features that make it drop-in friendly for 15 W – 30 W retrofits.

- TEJTE internal evaluation shows up to 10 % efficiency gain in IoT and router adapters when migrating from NCP1207B to NCP1342, with identical transformer geometry.

For repair engineers or OEMs extending product life, monitoring these revisions through TEJTE’s technical blog ensures you stay aligned with current semiconductor lifecycles and sourcing updates.

Bottom line: The 12 V 2 A flyback SMPS isn’t going away soon — it just keeps changing controllers.

The best repair strategy today is to maintain a validated NCP1207BDR2G base design while prototyping an NCP1342 migration board in parallel.

Frequently Asked Questions

Does a 12 V 2 A flyback need a different startup resistor when moving from UC3842 to NCP1207?

Why does my 12V 2A power supply click or tick repeatedly after startup?

That ticking sound usually means the flyback controller is entering protection mode — often due to a leaky RCD snubber diode or a dried-out startup capacitor.

Measure the VCC rail; if it rises and drops cyclically between 7–11 V, your NCP1207BDR2G is resetting on UVLO.

How do I verify my repair without a differential probe?

Use an isolated bench supply and float your oscilloscope ground through an isolation transformer.

Then monitor only secondary-side ripple and thermal performance.

If output voltage remains within ±3 % across 0–2 A load and no audible noise occurs, the SMPS repair is considered stable.

What are the tell-tale signs that my transformer is mismatched for a new controller?

If you see excessive ringing on the drain node or high no-load consumption (>300 mW), the magnetics aren’t tuned to the new switching frequency.

Either lower the switching frequency within 20 % or add a damping RC across the primary

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.