RG316 vs RG174: Flexibility, Loss & Lab Selection

Nov 26,2025

When should you choose RG316 over RG174, and vice versa?

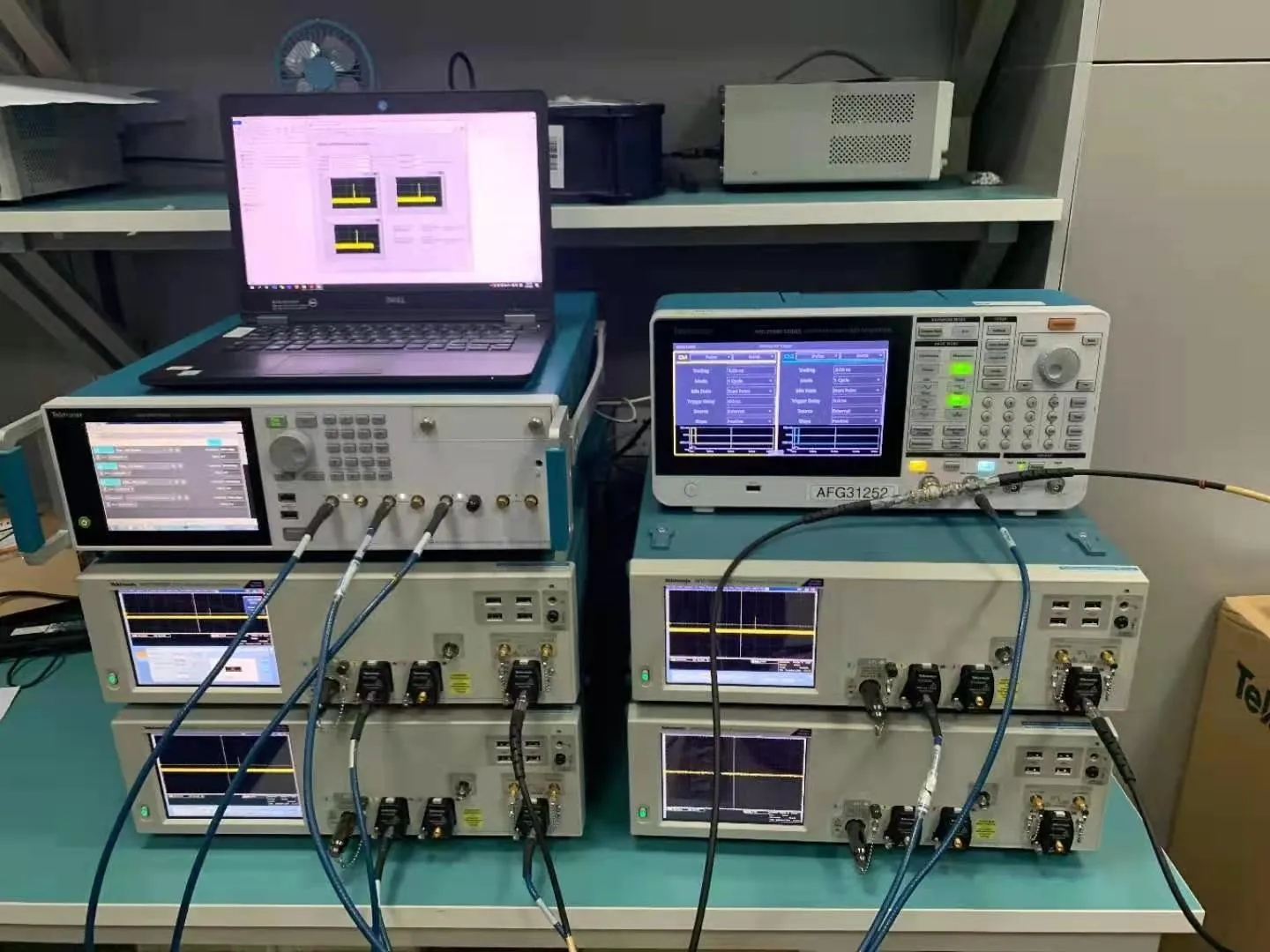

Figure is located at the beginning of the document, and its context emphasizes that the choice between RG316 and RG174 defines signal chain performance. This figure materializes this decision process into a rigorous product inspection phase. It depicts an engineer using equipment like a VNA to perform physical measurements on samples of both cables. By comparing their performance data, it provides an objective, data-driven basis for the selection, reflecting TEJTE's empirical and data-driven engineering approach.

Short bench jumpers vs ultra-flexible leads in tight enclosures

The context for Figure emphasizes that flexibility often wins for tight enclosures or IoT boards. The RG174 cable, with its 2.85 mm PVC jacket and PE dielectric, bends effortlessly. This figure visually displays the layers that make up the RG174 cable, explaining its flexibility suited for short SMA pigtails, but with the trade-off of higher loss and limited thermal endurance.

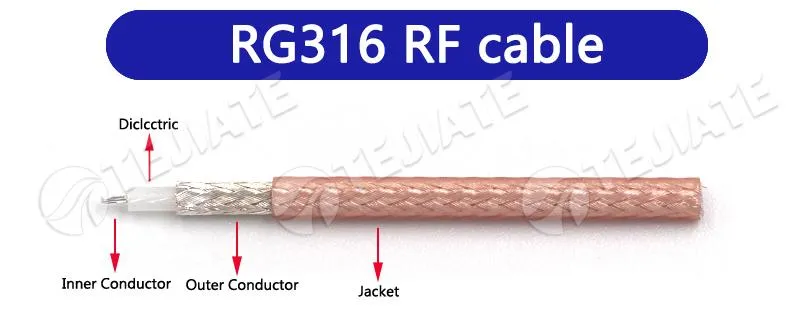

The context for Figure contrasts RG316 with RG174, stating that RG316 cable feels slightly firmer but handles repeated motion without deformation. Its silver-plated strands and PTFE core maintain stable impedance. This figure clearly shows the physical construction of RG316, explaining why it's favored in bench jumper assemblies and modular test rigs.

By contrast, RG316 cable (2.5 mm OD, PTFE dielectric, FEP jacket) feels slightly firmer but handles repeated motion without deformation. Its silver-plated strands and PTFE core maintain stable impedance even after hundreds of re-bends. That’s why it’s favored in bench jumper assemblies and modular test rigs.

In TEJTE’s lab, most engineers start with 0.3 m – 0.6 m RG316 jumpers for 2.4 GHz or 5 GHz setups, while RG174 still finds use in ultra-short Wi-Fi harnesses where space matters more than attenuation.

For engineers planning custom assemblies, see TEJTE’s detailed note on SMA extension cable length and loss considerations—it covers how cable type interacts with return-loss budgets and mechanical routing.

Typical bands: 900 MHz / 2.4 GHz / 5 GHz quick picks

Both RG174 and RG316 behave predictably below 1 GHz. But once you move into higher bands, dielectric loss dominates. At 900 MHz, RG174 averages 0.68 dB/m, while RG316 sits around 0.88 dB/m—a small difference. At 2.4 GHz and above, however, RG174 climbs to 1.47 dB/m, while RG316 maintains roughly 1.46 dB/m, and RG316D (the double-shielded version) stays closer to 1.2 dB/m.

That marginal improvement matters when you’re chasing stability above 5 GHz or running sensitive receivers with minimal SNR margin. RG316D also adds dual silver braids for >90 dB shielding attenuation—helpful around switching regulators or mixed-signal boards.

Will your loss at frequency push you off RG174?

Attenuation trend: thinner cable → higher dB/m at 2.4 / 5 GHz

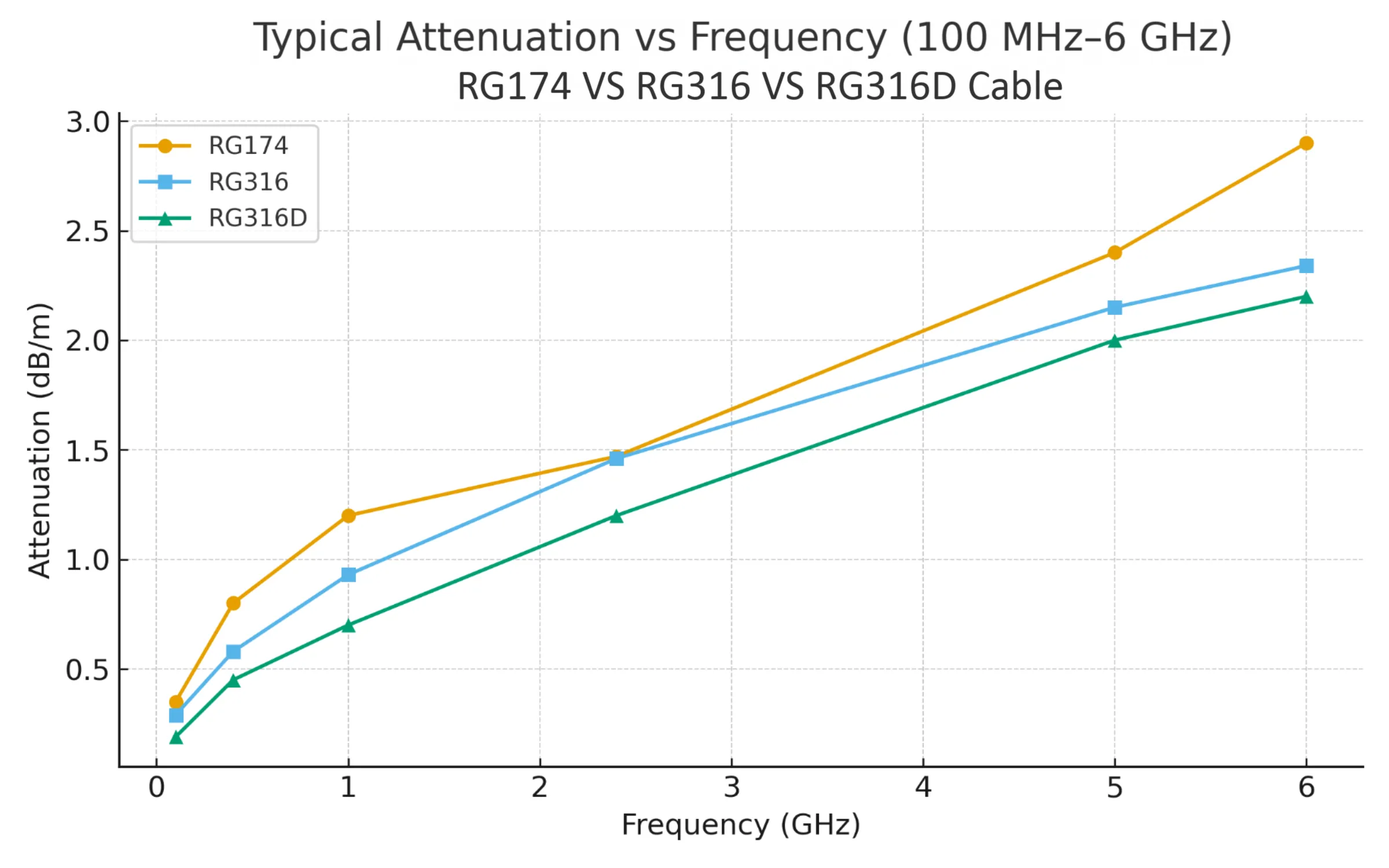

The context for Figure states that loss climbs quickly with frequency, and thinner cables pay the price. The graph clearly depicts the attenuation curves: RG174 dissipates energy faster, while RG316 and RG316D perform better. This figure provides key data for engineers to budget link loss based on operating frequency.

Loss climbs quickly with frequency, and thinner cables pay the price. RG174, with its small conductor and polyethylene dielectric, dissipates energy faster as frequency rises. The data tell the story clearly: at 2.4 GHz, attenuation is about 1.47 dB/m, and at 5 GHz it exceeds 2 dB/m. By comparison, RG316 remains near 1.46 dB/m at 2.4 GHz and 2.15 dB/m at 5 GHz, while RG316D holds the line closer to 2.0 dB/m.

In practice, a 2-meter RG174 jumper at 5 GHz can consume 3 dB more signal than an equivalent RG316D—half your transmitted power. For a short link between a radio and a test instrument, that might decide whether a device passes certification.

This is why TEJTE recommends engineers budget for both cable attenuation and interface losses early. Even a single SMA connection adds 0.05 – 0.20 dB insertion loss at 1 GHz, scaling nearly linearly with frequency. Multiply that by multiple adapters, and the loss snowballs.

Two-adapter chain vs one short jumper: keep interfaces minimal

A cleaner connection path nearly always beats stacking adapters. Instead of linking analyzers through multiple couplers, swap them for one short RG316 jumper—you’ll cut reflections, stabilize VSWR, and improve repeatability.

In field troubleshooting, TEJTE engineers often trace erratic readings back not to cables but to a chain of mismatched connectors. Simplifying the interface count restores phase consistency immediately.

For a closer look at this principle, the article SMA to BNC cable vs adapter matching guide demonstrates how each junction adds incremental loss and mismatch that accumulate silently in RF benches.

Do bend radius and jacket choices change long-term reliability?

Min bend ≈ 10×OD near boots; avoid hinge-line kinks

Mechanical stress quietly kills more jumpers than electrical overload. As a rule of thumb, maintain a bend radius of at least ten times the outer diameter (10×OD)—that’s roughly 28 mm for RG174, 25 mm for RG316, and 30 mm for RG316D. Anything tighter risks shield fatigue and micro-fractures that shift impedance over time.

In TEJTE’s reliability testing, repeated sub-radius bends led to VSWR drift beyond 1.3:1 after just a few hundred cycles. The damage was invisible but measurable. The best workaround is mechanical—route cables away from hinge points and use right-angle SMA connectors or strain relief boots where motion is unavoidable.

PTFE dielectric, FEP jacket; when to step up to RG316D (double shield)

Material composition makes or breaks a cable’s lifetime. RG174’s PVC jacket and PE core limit it to about +70 °C, making it suitable only for light-duty or temporary setups. RG316, built with a PTFE dielectric and FEP jacket, stays reliable up to +150 °C, even under constant flexing. When the temperature climbs higher or when the electromagnetic environment gets noisy, RG316D becomes the clear upgrade—it combines dual silver braids with a thicker FEP shell for exceptional shielding and mechanical stability.

To put the differences in perspective, here’s how the three families compare in real operation:

| Cable Type | Jacket Material | Temperature Range (°C) | Min Bend Radius (mm) | Shielding Structure |

|---|---|---|---|---|

| RG174 | PVC | -20 ~ +70 | 28 | Single bare copper braid |

| RG316 | FEP | -55 ~ +150 | 25 | Single silver-plated braid |

| RG316D | FEP (dual-braid) | -55 ~ +255 | 30 | Double silver-plated braid |

The practical takeaway is simple: when your environment runs hot, moves often, or sits close to digital noise sources, RG316D pays for itself in reliability.

In TEJTE’s long-term bench testing, technicians found that cables following these material and bend limits maintain their VSWR ≤ 1.3:1 even after thousands of flex cycles. Push them tighter than the 10×OD guideline, and micro-fractures start appearing near the connector boots—usually invisible until a measurement suddenly drifts.

If your project involves continuous movement or exposure to switching power stages, it’s safer to choose RG316D from the start. It saves the headache of chasing random mismatch errors later on.

For designers dealing with sealed or outdoor panels, see TEJTE’s practical note on SMA feedthrough mounting and IP sealing. It details how shield continuity and torque balance directly affect long-term RF performance.

Can you keep power & VSWR safe on short jumpers?

De-rate with frequency, ambient temperature, and VSWR

Power handling scales inversely with both frequency and standing-wave ratio (VSWR). At 100 MHz, RG316 cable can handle about 420 W, but that number drops to 78 W at 2.4 GHz and barely 61 W at 5 GHz. The loss mechanism isn’t just heat—it’s dielectric breakdown and current crowding in the braid.

RG174, though thicker in jacket, handles less continuous power (≈2.1 kW peak, but much less CW) because of its PVC dielectric losses and lower thermal stability. Once temperature climbs above 70 °C, attenuation increases sharply, and impedance begins to drift. For longer or high-power test lines, RG316D is a safer choice; its dual silver braid and PTFE/FEP structure maintain VSWR ≤ 1.3 up to 6 GHz.

In practice, derating can be estimated using the rule:

PowerDerateFactor ≈ (1 – (ambient – 25)/80) / VSWR

That gives you a quick sanity check—if you’re running near +70 °C at a 1.5:1 VSWR, expect about a 40 % reduction in power capacity.

Heat rise and connector torque: right-angle vs straight tips

Temperature rise also depends on connector geometry. Right-angle SMA connectors create slight resistive losses due to longer current paths, typically adding 0.05–0.1 dB at high frequencies. But the trade-off is worthwhile in confined spaces, where straight connectors tend to kink cables and introduce repeatability errors.

TEJTE’s internal reliability studies show that proper torque control—around 0.45 N·m for SMA types—prevents both mechanical fatigue and micro-gap oxidation that lead to drift. If your setup involves frequent mating cycles, it’s better to use RG316D with nickel-plated SMA connectors for consistent return-loss performance.

For extended outdoor links or enclosure penetrations, the comparison in SMA to N adapter outdoor transition guide discusses how proper connector geometry preserves VSWR and waterproof integrity at once.

What connector options map cleanly to each cable family?

The context for Figure revolves around choosing connector options for each cable family. It emphasizes that selecting the right connector involves mechanical stress, direction, and mating reliability. The shown SMA Jumper is a typical termination for RG316 cable assemblies used on test benches. The context stresses defining gender and orientation clearly to avoid RP-SMA mix-ups and to prevent cable twisting during assembly.

Figure is located in the "connector options" section, complementing or contrasting with the jumper in Figure 5. The preceding discussion emphasizes minimizing interfaces, stating a clean path beats stacking adapters. Adapter chains add reflections, VSWR issues, and hurt repeatability. This figure visually presents the adapter, reminding engineers that while sometimes necessary, each extra interface adds loss and mismatch, and should be minimized by using short jumpers instead.

Choosing the right connector isn’t just about matching gender—it’s about mechanical stress, direction, and long-term mating reliability. Each cable family has typical pairings that simplify assembly and testing.

SMA male to SMA female directioning without RP-SMA mix-ups

Most RG316 cable assemblies terminate with SMA male to SMA female ends for test bench use. This avoids confusion with RP-SMA connectors, common on consumer Wi-Fi devices but electrically incompatible. In TEJTE’s build guides, all RF jumpers are tagged with direction arrows to eliminate reversed mating.

When specifying connectors for manufacturing, define both the gender and orientation clearly—e.g., SMA-male (straight) to SMA-female (right-angle). If the system includes panel exits, use bulkhead connectors on the fixed side so you don’t twist the cable during assembly.

Bulkhead/feedthrough pairings for panel exits

For enclosures or rack panels, feedthrough connectors simplify cable routing and preserve shielding continuity. A SMA feedthrough jack, mounted properly with an O-ring seal, allows you to pass a signal through a metal wall without exposing the inner conductor to EMI or moisture.

This configuration is especially effective when combining RG316D inside the cabinet and RG174 externally for flexible leads. It keeps internal loss low and provides easy field servicing. TEJTE’s field teams often use this combination in small network analyzers and RF test racks—internal high-performance cables, external flexible tails.

More guidance on mounting torque, gasket compression, and IP-rated transitions is covered in the SMA feedthrough panel installation guide.

How do you predict insertion loss & check fit in two minutes?

RG316 vs RG174 Quick Selector

| Input / Parameter | Symbol | Example | Notes |

|---|---|---|---|

| Frequency | f | 2400 MHz | Wi-Fi band |

| Length | L | 0.5 m | Total jumper |

| Cable family | — | RG316 | 50 Ω |

| Outer diameter | OD | 2.5 mm | Used for bend check |

| Interfaces count | N | 2 | SMA ends |

| Interface loss | IL_if | 0.10 dB | Typical per connector |

| VSWR | — | 1.2 | Measured |

| Ambient temp | T | 40 °C | Lab environment |

| Loss budget | LB | 1.5 dB | Design target |

| Return loss target | RL_t | 20 dB | Acceptable match |

Core Equations

cable_loss_dB = α(f) × L

interface_loss_dB = N × IL_if

ρ = (VSWR – 1)/(VSWR + 1)

mismatch_loss_dB = -10·log10(1 – ρ²)

IL_total = cable_loss_dB + interface_loss_dB + mismatch_loss_dB

ReturnLoss = 20·log10((VSWR + 1)/(VSWR – 1))

For the above case:

- RG174 → cable_loss = 1.47 × 0.5 = 0.74 dB

- RG316 → 1.46 × 0.5 = 0.73 dB

- RG316D → 1.20 × 0.5 = 0.60 dB

Total estimated loss (including connectors) ≈ 0.9 dB for RG316D versus 1.1 dB for RG174.

Return-loss ≈ 20.8 dB → PASS.

Pass/Fail Decision

If IL_total ≤ LB and ReturnLoss ≥ RL_t, the design passes. Otherwise, the selector suggests shorter length, fewer connectors, or upgrading to RG316D.

| Result | Cable Loss (dB) | IL Total (dB) | Return Loss (dB) | Verdict |

|---|---|---|---|---|

| RG174 | 1.1 | 1.3 | 20.8 | Borderline |

| RG316 | 0.73 | 1.0 | 21.0 | Good |

| RG316D | 0.60 | 0.9 | 21.5 | Best |

Practical insight

This quick check helps engineers decide within minutes which cable to order—no software needed. The same logic is embedded in TEJTE’s internal selection worksheets for lab jumpers and modular RF test harnesses.

When uncertainty remains, start with RG316D; it provides a safety margin in both loss and mechanical reliability.

What recent RF lab trends could change your jumper choice?

Denser Wi-Fi/IoT radios to shorter, cleaner 50-Ω paths

Modern Wi-Fi 6, BLE, and 5G IoT radios operate between 2.4 GHz and 6 GHz, where cable loss becomes a limiting factor. In these setups, the distance between the RF module and the measurement instrument often shrinks below half a meter. That shift favors RG316 cable assemblies—they maintain impedance control and stable attenuation in high-frequency benches where RG174 begins to leak dB.

In TEJTE’s integration projects, engineers routinely replace traditional long RG174 runs with RG316D jumpers inside enclosures. The dual-shield design prevents coupling between adjacent test lines, keeping channel-to-channel isolation above 90 dB even in dense setups.

This trend toward “shorter, cleaner paths” also changes how engineers think about jumper management. Instead of reusing generic coax jumpers, teams now treat them as critical RF components, just like attenuators or terminations.

Lightweight handheld VNAs → more right-angle jumpers to reduce strain

Portable VNAs and handheld analyzers have made field calibration faster—but they also add mechanical strain. When a cable hangs directly from a handheld port, torque can shift the connector alignment and distort readings. Using a right-angle SMA jumper—typically RG316 or RG316D—minimizes leverage and extends both connector and cable lifespan.

TEJTE’s test labs record up to 2× connector cycle life when replacing straight RG174 leads with right-angle RG316D assemblies. The improved torque balance also prevents VSWR spikes during movement, which can otherwise confuse calibration routines.

As RF tools continue to shrink, mechanical design and cable routing are becoming as important as S-parameter accuracy.

Order the exact SKU without back-and-forth

The context for Figure is in the "Order the exact SKU" section, emphasizing specification clarity for fast procurement. The figure shows a specific RG316D jumper model. The context states that ambiguous attributes cause delays. A complete definition includes length, cable family, SMA gender, straight/RA, color, etc. A clear model like the one shown ensures production without confirmation steps, leading to faster bench readiness.

Specify: length, cable family, SMA gender, straight/RA, color

A clear purchase line might read: RG316D-SMA-M/F-0.3 m-RA (FEP jacket, RoHS compliant)

Each token in that description matters. The cable family defines loss and bend radius; SMA gender ensures correct mating; and straight vs right-angle orientation affects both layout and mechanical life. If you’re using mixed configurations—say, an RG316 pigtail inside and RG174 tail outside—document that transition explicitly.

When customers specify full parameters upfront, TEJTE’s production can deliver finished jumpers with no additional confirmation steps. That means faster bench readiness and fewer re-crimps in the lab.

Include docs: RoHS/REACH, torque note, serialization

Every certified coaxial cable jumper leaving TEJTE’s line includes standard documentation: material compliance (RoHS/REACH), connector torque guidance, and serialization for traceability. This ensures that replacement cables later reproduce the same RF behavior without recalibration.

In a controlled test environment, those small administrative details make large differences. They prevent mismatched torque specs, connector oxidation, and unverified replacements that could invalidate previous measurements.

When defining your next rg316 cable assembly, record these attributes as standard line items in your bill of materials. A 30-second clarification in specification often saves hours of troubleshooting after installation.

Frequently Asked Questions

Which cable handles more power on short bench runs to RG58, RG316, or RG174?

Is RG174 “too lossy” for 2.4 GHz and 5 GHz jumpers?

Is there a lower-loss alternative to RG316 for longer paths?

Does a right-angle SMA reduce performance compared with a straight one?

What length should I start with for Wi-Fi or IoT test benches?

Conclusion

The comparison of RG316 vs RG174 ultimately comes down to predictability. Both families serve their purpose: RG174 for flexibility and quick patching, RG316 and RG316D for stability under stress and frequency. The correct choice depends not on price, but on how long you expect your system to stay calibrated and consistent.

For most 2.4 GHz and 5 GHz benches, RG316D remains the practical default—it provides the thermal headroom, shielding, and repeatability modern test setups demand. If weight or routing space are tighter priorities, RG174 still delivers at sub-GHz frequencies.

Across all cases, consistent connector torque, limited interface count, and correct bend management matter more than any cable datasheet number. As TEJTE engineers like to say:“A jumper is small, but it decides whether your 50 ohms stays 50 ohms.”

For engineers designing or maintaining RF benches, TEJTE’s technical library offers deeper reading on related topics such as SMA extension cable design, feedthrough installation, and adapter matching—all written for real-world labs rather than textbook simulations.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.