RF Connector: Install, Clean & Waterproof

Oct 20,2025

Preface

This image shows a real-world application example of N-type connectors on an outdoor base station or antenna mast. The image clearly shows how the N-type connector (likely models such as N-KK or N/SMA-KKF) is used to connect the antenna to the feeder cable. Its rugged metal shell, threaded coupling method, and potentially included waterproofing components (e.g., O-rings, flange) visually demonstrate its design for harsh outdoor conditions like rain, UV radiation, and temperature cycling, ensuring long-term stability and IP67-level sealing reliability for the RF link outdoors.

Every RF build—whether it’s a 5G base station, a Wi-Fi access point, or a radar node—depends on something easy to overlook: the RF connector.

It doesn’t blink or hum, but it decides how cleanly power moves through your 50-ohm coax cable. A connector that’s slightly loose, or one that’s overtightened, can eat several decibels of signal before the antenna ever sees it.

Over the years, we’ve seen this in real projects at TEJTE—installations using SMA-KKY, N/SMA-KKF, and N-KK couplers running from DC to 6 GHz. What failed first was rarely the material. It was usually technique: strip lengths off by half a millimeter, torque skipped, or an O-ring left out on a humid day. So, this guide takes what those experiences taught and turns them into practical notes—how to identify connector types, install them right, and keep them sealed and clean so they last outdoors.

How do you determine the exact RF connector type on your device?

This image is a close-up physical photo of an SMA connector, clearly showing its typical physical characteristics: 1/4-36 UNS thread, 6.35mm hex nut, gold-plated center pin, and likely PTFE insulator. This image helps users accurately identify the SMA interface and establish a visual connection with the specific models mentioned in the document (e.g., TEJTE's SMA-KKY double-female coupler), understanding its compact size and precision interface characteristics suitable for frequencies from DC to over 6 GHz.

This image shows the physical appearance of a BNC connector. It highlights the connector's signature bayonet-style (quick-lock) coupling mechanism, which makes it popular in scenarios requiring frequent mating/demating, such as test benches. The image likely indicates its approximate dimensions (~38.5mm long, ~8.37mm inner bore), helping users distinguish it from threaded connectors like SMA, TNC, or N-type.

This image is a physical photo of a TNC connector. It shows the similar external geometry of TNC compared to BNC, but the key difference is its use of a threaded coupling mechanism instead of a bayonet. This threaded design provides a more stable connection, especially in vibrating environments, and allows TNC performance to extend to higher frequencies than BNC. The image helps users correctly identify TNC interfaces in the field or during design.

This image shows the physical appearance of an N-type connector. Through comparison with connectors like SMA or standalone presentation, it highlights the N-type's significantly larger physical size (e.g., ~11.3mm outer thread diameter, 5/8-24 UNEF threads) and more robust construction. This visually explains why N-type connectors are more suitable for high-power applications, base station feeders, and harsh outdoor environments requiring IP67 waterproofing (e.g., using TEJTE's N/SMA-KKF waterproof flange model), with performance often covering DC to 11 GHz.

Start by looking closely at the center pin and the thread. The difference between SMA, RP-SMA, N-type, TNC, and BNC is small to the eye but critical in the field.

You’ll notice that:

- SMA connectors use a ¼-36 UNS thread, a 6.35 mm hex, and a gold-plated pin. The TEJTE SMA-KKY double-female coupler measures about 22.2 mm long and maintains ≤ 1.2 VSWR.

- N-type connectors—like the N/SMA-KKF waterproof flange—are much larger, with 5/8-24 UNEF threads and 18 mm flange spacing.

- TNC connectors share BNC geometry but lock by screw, not by bayonet.

- BNC connectors (≈ 38.5 mm long, 8.37 mm inner bore) twist-lock quickly for test benches.

If you’re unsure, grab a digital caliper. Typical outer thread diameters: SMA ≈ 4.3 mm, N-type ≈ 11.3 mm, BNC ≈ 5.1 mm. Even a 0.2 mm mismatch can cause cross-threading or poor electrical contact.

For visual reference, the SMA Connector Guide on TEJTE’s site shows the dielectric and polarity layout of SMA vs RP-SMA. Many technicians check that before ordering or re-terminating cables.

How do you install RF connectors safely on 50-ohm coax?

Good installation is equal parts patience and precision. Each 50 ohm coax cable—whether RG58 or RG316—has its own stripping dimensions, ferrule sizes, and torque ranges. Stick within those specs and your setup will hold a VSWR under 1.2, even after months of use. Most field technicians learn this the hard way: one sloppy strip or uneven crimp can cause reflection spikes that no analyzer will forgive.

For RG58 (Ø 5.0 mm PVC jacket, 50 Ω):

• Strip 6.5 mm jacket / 3.5 mm braid / 1.5 mm dielectric

• Crimp hex size 5.41 mm

• Torque 0.45 N·m (SMA bulkhead nut) / 1.36 N·m (N-type body)

• VSWR ≤ 1.20 to 3 GHz

• Attenuation 7.66 dB @ 100 MHz → 105.2 dB @ 3 GHz (100 m)

• Temp –20 ~ +70 °C | Min bend radius 50 mm

For RG316 (Ø 2.5 mm FEP jacket, 50 Ω):

• Strip 5.0 / 3.0 / 1.0 mm

• Crimp hex 3.96 mm

• Torque 0.25 N·m on SMA body

• Attenuation 0.29 dB/m @ 100 MHz → 2.34 dB/m @ 6 GHz

• Temp –55 ~ +150 °C | Bend radius ≥ 15 mm

Before sealing, always test continuity—don’t just assume it’s fine. A single stray braid touching the center pin can spike your return loss above 1.3 VSWR. When dealing with compact outdoor radios, many engineers choose N/SMA-KKF waterproof flanges (50 Ω, DC–6 GHz, ≤ 1.2 VSWR, 500 cycles) paired with RG316 50 ohm coax cable for tight IP67 housings—small, rugged, and dependable in humidity.

If you’re running longer links or chasing every decibel at higher bands, check TEJTE’s RF Cable Loss Guide to learn how length, temperature, and connector type shift attenuation across 2.4 / 5 / 6 GHz. It’s one of those details seasoned RF engineers never skip.

How do you assemble SMA RF connectors without damaging pins?

These tiny connectors reward a steady hand. An SMA pin bent by 0.1 mm can throw off matching at 6 GHz. When fitting SMA-KKY or SMA-KWE connectors, use an ESD strap and a torque wrench—no guesswork.

Typical sequence:

- Strip the coax, leaving ≈ 1 mm of exposed conductor.

- Crimp or solder the pin—crimp for RG316, solder for PCB types.

- Slide ferrule and seat body; the dielectric should sit flush.

- Torque 0.25–0.30 N·m for RG316 / ≈ 0.45 N·m for RG58.

- Check pin height (0–0.3 mm above dielectric) and continuity.

In TEJTE’s internal tests, gold-plated SMA pins showed < 0.05 dB insertion-loss drift after 500 mating cycles when cleaned with IPA and lint-free swabs. PTFE insulators hold impedance stable through 0–18 GHz, and nickel-plated brass housings resist oxidation. For outdoor links, nickel or stainless versions with O-rings—like those used in N/SMA-KKF—are the safest choice for long-term moisture defense.

For multi-port setups mixing SMA and N-type bulkheads, the N-type Connector Guide covers how to keep sealing consistent when jumpers transition between formats.

Should you crimp, clamp, compression or solder — how do you choose?

Different attachment methods exist for one reason: installation speed versus long-term reliability. Crimp, clamp, compression, and solder joints each suit a different environment.

Crimp connectors are the go-to for fast field work. Once the cable is stripped to its proper dimensions — 6.5 / 3.5 / 1.5 mm for RG58, or 5.0 / 3.0 / 1.0 mm for RG316 — a calibrated die creates a uniform hex grip. A clean crimp ensures 360° braid contact and repeatable 50-ohm impedance. We’ve seen SMA-KWE and SMA-KKY crimp joints keep return loss under –25 dB up to 6 GHz when the ferrule is fully seated.

Clamp connectors come in handy where rework is expected. They use a screw sleeve that presses the braid mechanically—ideal in lab setups or when multiple tests are run on the same coaxial cable.

Compression types (rare on RF) seal well but require more force; they’re common in broadcast coax like 75 Ω F-series rather than 50 Ω RF lines.

Then there’s soldering—slow but rock-solid. It’s the method for PCB or semi-rigid builds. The TEJTE SMA-KWE solder version for PCB boards, rated 0-18 GHz and 50 V DC, maintains stability where vibration or temperature swing would loosen a crimp.

So, when should you avoid screw-on or hand-tight connectors? Indoors, on low-frequency test benches, they’re fine. Outdoors, vibration and moisture can loosen them over time. For any permanent mount, torque it to spec—0.45 N·m for SMA, 1.36 N·m for N-type—and verify the O-ring seats evenly.

For more structural details on torque and flange hardware, the RF Connector Product Page lists the mating dimensions used in TEJTE’s SMA and N-type series.

Should you use N-type or PL-259/SO-239 for this run?

Different attachment methods exist for one reason: installation speed versus long-term reliability. Crimp, clamp, compression, and solder joints each suit a different environment.

Crimp connectors are the go-to for fast field work. Once the cable is stripped to its proper dimensions — 6.5 / 3.5 / 1.5 mm for RG58, or 5.0 / 3.0 / 1.0 mm for RG316 — a calibrated die creates a uniform hex grip. A clean crimp ensures 360° braid contact and repeatable 50-ohm impedance. We’ve seen SMA-KWE and SMA-KKY crimp joints keep return loss under –25 dB up to 6 GHz when the ferrule is fully seated.

Clamp connectors come in handy where rework is expected. They use a screw sleeve that presses the braid mechanically—ideal in lab setups or when multiple tests are run on the same coaxial cable.

Compression types (rare on RF) seal well but require more force; they’re common in broadcast coax like 75 Ω F-series rather than 50 Ω RF lines.

Then there’s soldering—slow but rock-solid. It’s the method for PCB or semi-rigid builds. The TEJTE SMA-KWE solder version for PCB boards, rated 0-18 GHz and 50 V DC, maintains stability where vibration or temperature swing would loosen a crimp.

So, when should you avoid screw-on or hand-tight connectors? Indoors, on low-frequency test benches, they’re fine. Outdoors, vibration and moisture can loosen them over time. For any permanent mount, torque it to spec—0.45 N·m for SMA, 1.36 N·m for N-type—and verify the O-ring seats evenly.

For more structural details on torque and flange hardware, the RF Connector Product Page lists the mating dimensions used in TEJTE’s SMA and N-type series.

What should you use to waterproof RF connectors outdoors?

Moisture doesn’t shout—it sneaks in quietly. A single drop creeping into the thread or braid gap can corrode contacts, drive VSWR up, and ruin a link that otherwise looked perfect on paper. For anyone working outside, choosing the right IP67 waterproof connector matters more than the cable itself.

Here’s the proven sealing sequence field engineers trust:

- Butyl rubber tape — the first barrier. Stretch it firmly over the mated joint until it self-fuses into a dense seal.

- UV-resistant PVC tape — the outer armor, shielding the butyl from sunlight and physical wear.

- Heat-shrink boot or rubber cap — the final touch, keeping the ends sealed and preventing wicking along the braid.

At TEJTE’s outdoor test site, the N/SMA-KKF IP67 waterproof connector passed 24-hour immersion tests while maintaining ≤ 1.2 VSWR from DC to 6 GHz. Even after 500 mating cycles and repeated –45 °C to +125 °C temperature swings, the O-rings and flange threads held tight without leakage. Some technicians add a thin coat of silicone grease on O-rings—a small trick that helps prevent cracks during winter maintenance.

When installing bulkhead connectors, follow the proper tightening order: body → washer → panel nut. Then create a gentle “drip loop” in the cable so rainwater can’t flow straight to the connector. It’s a detail easy to skip but essential for long-term reliability.

And one more rule many forget—avoid stacking adapters outdoors. Each extra joint becomes a new place for moisture to creep in. Instead of chaining multiple couplers, use a short SMA to N adapter cable like RG316 or LMR-240. It gives you one clean interface, better strain relief, and far lower reflection loss under real weather conditions.

For additional sealing components, you can check TEJTE’s RF Waterproofing Kit page, which lists butyl tapes, silicone boots, and IP-rated gaskets used in our outdoor assemblies.

How do you clean RF connector ends without lowering return loss?

Cleaning isn’t glamorous, yet it saves more systems than any firmware patch. Even microscopic dust can alter impedance. Before connecting, always check both male and female ends.

- Use IPA (> 90 %) on lint-free swabs to remove oxidation.

- For tighter interfaces like SMA and TNC, a soft contact-cleaner pen can lift residues the swab misses.

- Dry fully—don’t blow with compressed air; it can drive debris deeper.

- Visually inspect the dielectric. If it’s discolored or cracked, replace the part.

After cleaning, confirm electrical integrity. Set a DMM to continuity: center-to-center should read < 1 Ω, center-to-body should be open. Any resistance drop indicates partial shorting.

Re-mate and measure return loss on a handheld analyzer—stable readings within ± 0.1 dB mean the interface is solid.

During one internal test, cleaned SMA-KKY couplers kept insertion loss within 0.05 dB variance across 500 re-mating cycles, while uncleaned ones degraded by 0.3 dB after just 50.

For extended guidance on verifying continuity and signal stability, TEJTE’s RF Cable Loss Guide also outlines post-installation testing under 2.4 / 5 / 6 GHz bands.

Can you repair or re-terminate a damaged RF connector?

Sometimes yes—but only if the damage is limited to the cable end, not the connector body. Bent pins, loose ferrules, or water-ingress corrosion can often be fixed by cut-back and re-crimp, though it depends on the coax type and the connector material.

When repair is worth trying:

- The connector plating is intact (no flaking).

- Center pin is slightly off but not snapped.

- The braid still has enough length for a full 360° crimp.

Steps:

- Cut off the damaged section, then re-strip the cable to factory spec (6.5 / 3.5 / 1.5 mm for RG58, 5.0 / 3.0 / 1.0 mm for RG316).

- Replace with a new SMA-KWE or N/SMA-KKF connector of the same impedance (50 Ω).

- Crimp or solder as originally installed.

- Verify continuity and return loss ≤ –25 dB at 6 GHz.

If the center pin is fully bent or the dielectric fractured, don’t force it—cut and replace. Reusing distorted bodies usually leads to intermittent VSWR drift once vibration or humidity sets in.

Acceptance checklist before returning the line to service:

- Continuity: < 1 Ω center-to-center, open center-to-shell.

- Pin height: 0 – 0.3 mm above dielectric.

- Braid coverage: 360° visible contact.

- Pull strength: ≥ 30 N for RG316, ≥ 60 N for RG58.

- Spot-check return loss: –25 dB min @ 3 GHz.

In practice, it’s usually cheaper to cut and re-terminate short jumpers than to try re-centering pins. Long feedlines, however, benefit from a careful re-crimp if the connector body is still usable.

For a practical look at connector durability after hundreds of mating cycles, the SMA Connector Guide includes TEJTE’s internal 500-cycle VSWR test results.

Do you need a one-shot spec to order the right parts?

RF Connector Install & Torque Matrix

| Connector Family | Cable Type | Attachment | Strip Lengths (mm) | Hex Size (inch) | Torque (N·m) | Waterproof Kit | Acceptance Standards | Suggested TEJTE P/N |

|---|---|---|---|---|---|---|---|---|

| SMA / RP-SMA | RG316 | Crimp | 5 / 3 / 1 / — | 0.156" (3.96 mm) | 0.25 / — | Yes (boot + tape) | Pin height 0-0.3 mm / pull ≥ 30 N | SMA-KKY / SMA-KWE |

| SMA / RP-SMA | RG58 | Crimp | 6.5 / 3.5 / 1.5 / — | 0.213" (5.41 mm) | 0.45 / — | Optional | VSWR ≤ 1.20 @ 3 GHz | SMA-KWE |

| N-type | RG58 | Clamp | 6.5 / 3.5 / 1.5 / — | 0.324" (8.23 mm) | 1.36 / 1.36 | Yes (O-ring + butyl) | IP67 pass / 500 cycles | N/SMA-KKF |

| TNC | RG316 | Crimp | 5 / 3 / 1 / — | 0.156" (3.96 mm) | 0.25 / — | Optional | Continuity < 1 Ω | N/TNC-JK |

| BNC | RG58 | Crimp | 6.5 / 3.5 / 1.5 / — | 0.213" (5.41 mm) | 0.45 / — | Optional | Pull ≥ 60 N | BNC-J-1.5N |

Do you need a quick decision guide from identification to install?

RF Connector Decision Tree

Input: port gender (M/F), presence of center pin, dielectric shape, thread diameter, environment (indoor / outdoor).

Output: recommended connector family × attachment method × waterproof option + matching cable and part number.

| Port Gender | Has Pin | Thread @ Panel (mm) | Environment | Recommended Connector | Attachment | Suggested Cable | Waterproof | Suggested P/N |

|---|---|---|---|---|---|---|---|---|

| Female hole | No | ≈ 4.3 | Indoor | SMA | Crimp | RG316 | Optional | SMA-KKY |

| Female hole | No | ≈11.3 | Outdoor | N-type | Clamp | RG58 | Yes | N/SMA-KKF |

| Male pin | Yes | ~ 4.3 | Outdoor | RP-SMA | Crimp | RG316 | Yes | SMA-KWE |

| Male pin | Yes | ≈ 11.3 | Outdoor | N-type | Clamp | LMR-240 | Yes | N-KK |

| Bayonet | Yes | ≈ 5.1 | Indoor | BNC | Crimp | RG58 | No | BNC-J-1.5 |

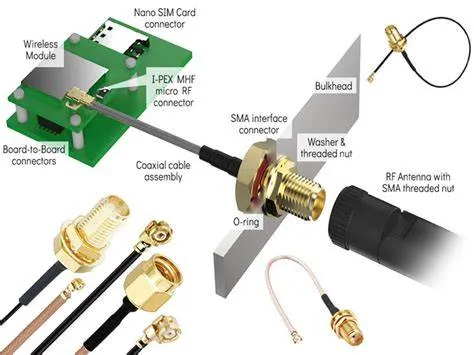

This image is a collection photo comparing physical samples of various common RF connectors (e.g., SMA, BNC, TNC, N-type). Placing the different connectors side-by-side, it visually demonstrates their significant differences in size, thread type (or bayonet), and center contact structure. This visual comparison helps engineers, technicians, or purchasers quickly identify equipment port types, understand the compactness of SMA, the ruggedness of N-type, the quick-lock feature of BNC, and the threaded coupling of TNC, thereby selecting the correct connector and corresponding cable assembly (e.g., RG316, RG58) for specific applications (e.g., test benches, outdoor base stations, indoor routers).

Use caliper or thread gauge for accuracy; select connector matching impedance and mount style.

This matrix and decision tree form the core of TEJTE’s internal “quick-spec” tool for RF assembly teams. They combine the torque and seal data from field measurements with inventory part mapping, so engineers can go from visual ID to orderable SKU in minutes.

For a more complete discussion on loss budgeting and installation verification after assembly, see the RF Cable Loss Blog — it ties these connector choices to overall system performance.

Frequently Asked Questions

How do I determine whether my port is SMA, RP-SMA, N-type or TNC without damaging it?

You can identify the connector type safely using just eyesight and a caliper—no tools that risk scratching threads.

Start by looking at the center pin: if the female port has a visible pin, it’s RP-SMA; if not, it’s a standard SMA. N-type connectors are larger, typically with a 5/8-24 UNEF thread, while TNC shares the same geometry but uses a threaded coupling rather than a bayonet.

Measure outer thread diameters: about 4.3 mm for SMA, 11.3 mm for N-type, and 5.1 mm for BNC/TNC. When in doubt, refer to TEJTE’s SMA Connector Guide, which includes visual pin and thread diagrams for quick reference.

Which crimp hex sizes and strip lengths should I use for SMA on RG316 vs RG58?

Follow standard dimensions to maintain a 50-ohm match:

- RG316: strip 5.0 / 3.0 / 1.0 mm, crimp hex 3.96 mm, torque 0.25 N·m

- RG58: strip 6.5 / 3.5 / 1.5 mm, crimp hex 5.41 mm, torque 0.45 N·m

Always confirm braid contact covers 360° before crimping. TEJTE’s SMA-KKY and SMA-KWE connectors use these dimensions for consistent VSWR ≤ 1.20 up to 6 GHz. Using non-matching strip lengths can shift impedance, especially on flexible cables like RG316.

What should I apply to waterproof outdoor connectors, and in what order?

This diagram details the typical application and sealed installation method of an IP67 waterproof RF connector (e.g., the TEJTE N/SMA-KKF waterproof flange model mentioned in the document) on outdoor equipment (e.g., enclosures, junction boxes). The image likely breaks down components such as the connector body, O-ring(s), sealing washer, flange, and lock nut, illustrating how they work together to form an effective seal on the equipment panel, preventing the ingress of moisture and dust. The diagram may also indicate the correct installation sequence and torque requirements, emphasizing the importance of following these steps to achieve long-term reliable operation and maintain low VSWR performance in damp, rainy, or otherwise harsh outdoor environments.

For outdoor runs or antenna mounts, use three layers of defense:

- Butyl rubber tape (primary seal)

- UV-resistant PVC tape (outer wrap)

- Heat-shrink boot or silicone cap (final closure)

Connectors like N/SMA-KKF and N-KK are designed for IP67 sealing when wrapped this way. Before sealing, ensure torque is correct and O-rings are lightly greased with silicone. Avoid stacking multiple adapters outdoors; a single SMA-to-N pigtail reduces leakage points. More waterproofing options can be found on the RF Accessory Page.

How do I clean oxidized SMA or N-type ends without worsening return loss?

Use high-purity IPA and lint-free swabs—never sandpaper or abrasive cloths.

Apply a small amount of IPA, rotate the swab gently inside the connector, then let it air-dry. For persistent oxidation, use a contact-cleaner pen designed for RF interfaces. After cleaning, test continuity: center-to-center < 1 Ω, and open to shell. Stable return loss within ±0.1 dB after re-mating confirms the connector is ready for service. TEJTE’s SMA-KKY couplers showed <0.05 dB change after 500 cleanings when IPA and lint-free swabs were used.

Can I repair a slightly bent SMA center pin, or should I re-terminate the cable?

Will stacking SMA-to-SMA adapters hurt VSWR more than using one N to SMA pigtail?

What quick acceptance checks confirm my new RF run is good?

After completing installation and sealing:

- Measure continuity with a DMM (center < 1 Ω, center-to-shell open).

- Check return loss or VSWR using a portable analyzer—anything ≤ 1.20 indicates proper matching.

- Inspect pin height (0–0.3 mm above dielectric).

- Perform a light pull test (≥ 30 N for RG316, ≥ 60 N for RG58).

- Visually confirm full braid contact and clean threads.

These checks take less than two minutes and prevent the most common field failures—loose crimps, moisture ingress, or cross-threaded fittings.

For post-install signal verification and attenuation testing, you can refer to TEJTE’s RF Cable Loss Guide, which details how to measure and budget cable loss across 2.4 / 5 / 6 GHz frequencies.

Conclusion

RF connectors might look simple, but they’re precision mechanical devices that decide whether your signal path is solid or unstable.

Whether you’re using a compact SMA connector, a weather-sealed N-type, or a quick-lock BNC, clean installation, correct torque, and proper waterproofing matter more than any other variable. With tested TEJTE parts such as SMA-KKY, N/SMA-KKF, and BNC-J-1.5, and correct practices for RG58 and RG316 coaxial cables, you can achieve consistent, low-loss connections in any RF environment—from indoor routers to outdoor base stations.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.