50 ohm coax cable: selection, driving & loss

Oct 17,2025

Should you choose 50 Ω or 75 Ω for this link?

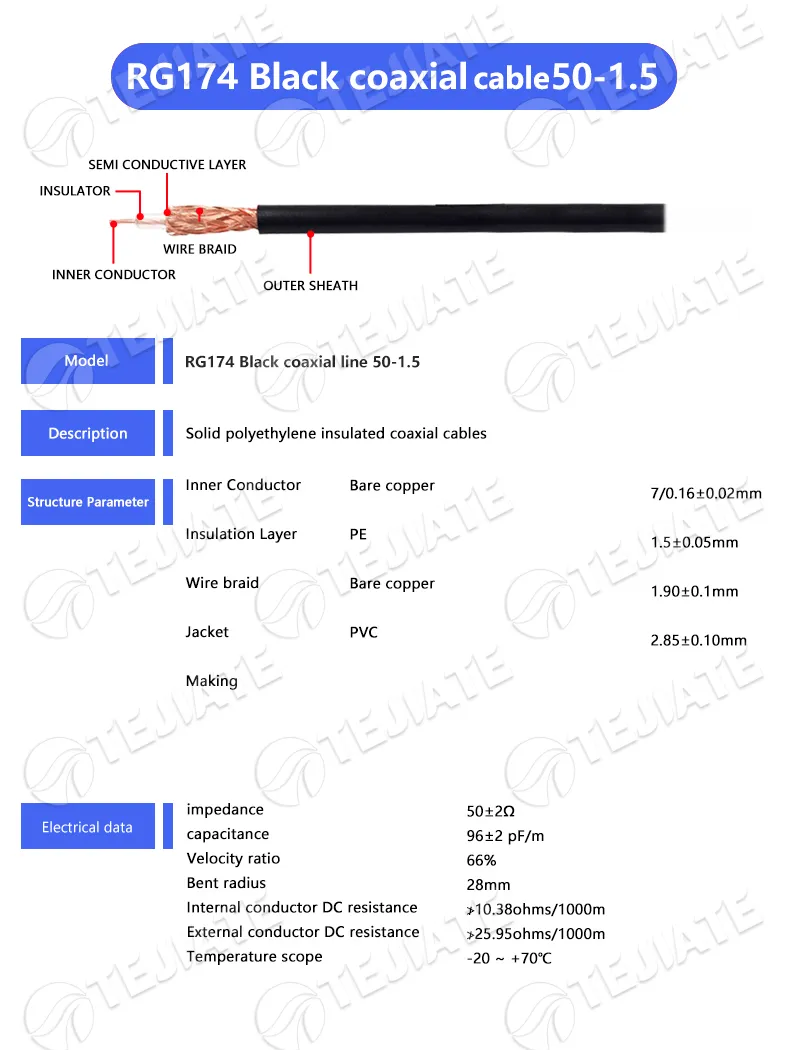

This image is a technical illustration or cross-section photograph that breaks down the components of RG174 coaxial cable, the "workhorse of consumer Wi-Fi setups" as described. It visually details the layers listed in the spec table: 1) The central Bare Copper Conductor (7 strands of 0.16mm). 2) The white PE (Polyethylene) Insulation layer. 3) The Bare Copper Braid shield. 4) The outer Black PVC Jacket. This helps users understand the materials and construction that define the cable's flexibility, electrical properties (50 Ω impedance, ~0.82 dB/m loss at 2.4 GHz), and its limitations (higher loss at 5 GHz).

If you’ve ever mixed up 50 ohm coax cable with a 75-ohm TV lead, you know how invisible this mismatch looks until the spectrum analyzer shows the spike.

The difference isn’t cosmetic — it’s physics.

A 50-ohm line represents a compromise between power handling and minimum loss for radio-frequency transmission lines.

In contrast, 75 ohm coax optimizes voltage standing wave ratio for long video or data runs with lower current.

In professional RF systems — routers, 4 G / 5 G modems, test benches, or IoT radios — equipment ports are almost always rated at 50 Ω.

That’s why most assemblies on TEJTE’s RF Cable hub are built around this standard.

Using the wrong impedance creates reflection (VSWR ↑) and degrades the signal chain.

What is the practical difference between 50 ohm and 75 ohm coax cable?

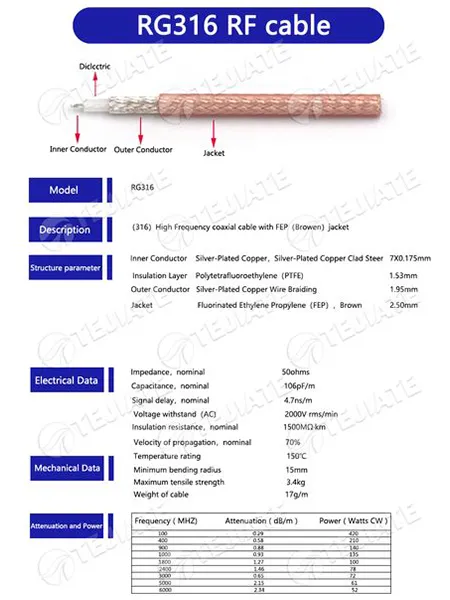

This image appears at the beginning of the document during the comparison with RG174, used to visually show the physical form of RG316 cable. Combined with the text, RG316, thanks to its PTFE insulation and silver-plated braid, offers a smaller minimum bend radius (15mm) and higher operating temperature (up to 150°C), making it suitable for scenarios demanding high reliability and heat resistance, such as aerospace and lab instruments.

A 50 Ω line carries more current at the same voltage, allowing higher power before dielectric breakdown.

A 75 Ω line has thinner insulation and lower capacitance (≈ 67 pF/m vs 100 pF/m), making it ideal for long video or CATV paths.

Your RG58 cable (50 Ω, 96 pF/m) uses a solid PE dielectric for robustness; your RG316 cable (50 Ω, 106 pF/m, PTFE insulation) sacrifices some loss to gain flexibility and 150 °C rating.

Both are clearly different from 75 Ω types such as RG6.

What happens if you substitute 75 Ω for 50 Ω in Wi-Fi / ham / test chains?

At first glance, everything “works.”

Yet, every transition from 50 Ω equipment to 75 Ω cable and back reflects about 5.6 % of the wave, or roughly –26 dB return.

That small mismatch can grow catastrophic at 5 GHz and above, especially when cables or connectors accumulate tolerances.

For precise chains — for example, a SMA to SMA cable linking a 5.8 GHz antenna to an analyzer — staying at 50 Ω is non-negotiable.

How much loss will your 50 ohm coax add at the planned length?

Even a perfect impedance match can’t escape attenuation.

RF energy fades as heat through the conductor and dielectric.

The shorter the cable and the lower the frequency, the smaller the loss — but above 2 GHz, details matter.

TEJTE’s lab data for its RG316 cable shows ≈ 1.46 dB/m @ 2.4 GHz and 2.34 dB/m @ 6 GHz (25 °C).

RG58 cable measures ≈ 24.8 dB/100 m @ 900 MHz and 43.2 dB/100 m @ 1 GHz.

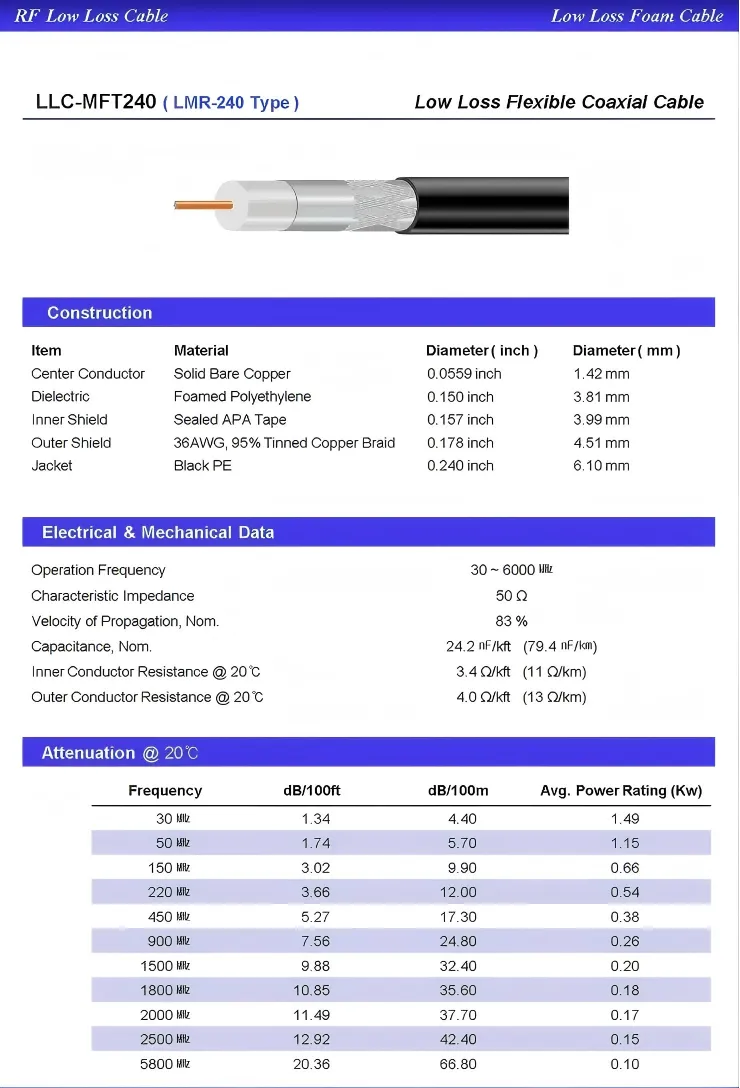

Low-loss upgrades such as LMR-200 and LMR-240 cut that dramatically thanks to their foam PE core and dual shielding.

Quick heuristics at 2.4 / 5 / 6 GHz (including connector loss)

| Cable Type | Attenuation @ 2.4 GHz | Attenuation @ 5 GHz | Loss @ 1 m | Loss @ 5 m | Loss @ 10 m | Typical Connector Ends |

|---|---|---|---|---|---|---|

| RG316 Cable (PTFE + FEP Jacket) | 1.46 dB/m | 2.15 dB/m | 1.66 dB | 7.7 dB | 15.2 dB | SMA-SMA / SMA Ext |

| RG58 Cable (PE Jacket) | 0.43 dB/m | 0.66 dB/m | 0.63 dB | 3.5 dB | 7.0 dB | SMA-N / N-N |

| LMR-200 (Foam PE) | 0.22 dB/m | 0.35 dB/m | 0.42 dB | 2.1 dB | 4.4 dB | N to SMA |

| LMR-240 (Foam PE) / Outdoor | 0.18 dB/m | 0.30 dB/m | 0.38 dB | 1.9 dB | 3.8 dB | N to SMA / Outdoor |

So a 10 m RG316 run at 5 GHz delivers barely 30 % of the source power.

When in doubt, step up to LMR-240 or shorten the path.

What is the dB loss of a 50-ft 50 Ω coax cable at common bands?

The image shows TEJTE’s LMR240 coaxial cable, featuring a solid copper conductor, foam PE dielectric, and double-shielded braid for excellent signal retention. It’s ideal for long-run antenna feeders, ensuring minimal loss at 2.4/5 GHz and outdoor durability under UV exposure.

The image presents TEJTE’s LMR200 coax cable, built with a stranded copper core and PE foam dielectric. It provides low attenuation (≈0.27 dB/m @2.4 GHz) while retaining bend flexibility, making it an excellent choice for router-to-antenna or CPE installations.

For a typical 50-ft (≈ 15.24 m) length:

- RG316 Cable: ≈ 32 dB @ 2.4 GHz → unusable for high power links.

- RG58 Cable: ≈ 9.5 dB @ 2.4 GHz — acceptable for short outdoor feeder.

- LMR-200: ≈ 3.4 dB @ 2.4 GHz — a good balance for AP or ham mast.

- LMR-240: ≈ 2.7 dB @ 2.4 GHz — ideal for base-station or long run.

(Internal reference: see SMA Extension Cable: Length, Signal Loss & Outdoor Setup for extended loss tests and outdoor routing tips.)

In the real world, each connector or coupler adds 0.1 – 0.3 dB, and UV exposure or tight bends can increase loss over time.

That’s why installers often prefer pre-terminated SMA to SMA cable assemblies from TEJTE with FEP jackets — they survive heat and bending without drift.

Can your source drive a 50 Ω coax directly (LVCMOS, LVC245A, drivers)?

Driving a 50 ohm coax cable isn’t just about voltage; it’s about current.

A 3.3 V digital output feeding a 50 Ω load demands I = V / R = 3.3 / 50 ≈ 66 mA.

That’s already double what a standard LVCMOS gate can source (usually ±24 mA).

Without a buffer or resistor network, the edge will distort and ring back along the cable.

How much current is required to drive 50 ohm coax cable?

| Source Voltage | Load (50 Ω) | Required Current | Typical Driver Capability |

|---|---|---|---|

| 1.8 V logic | 50 Ω | 36 mA | Too high for direct CMOS drive |

| 3.3 V logic | 50 Ω | 66 mA | Requires buffer or line driver |

| 5 V TTL | 50 Ω | 100 mA | Needs RF amp or video driver |

You’ll need a dedicated line driver (LVDS buffer or video amplifier) or insert a series resistor (≈ 25 Ω) to split the impedance.

Otherwise, reflections will create overshoot and false triggers beyond 100 MHz.

Can LVCMOS / LVC245A gate drive 50 Ω coax without a buffer or matching?

Not reliably.

The LVC245A can sink ≈ 24 mA max, so even a 1.2 V swing into 50 Ω is borderline.

If you must interface directly, limit the length (< 30 cm) or add a resistor divider network to soften edges.

In high-frequency paths (> 100 MHz), it’s safer to use a small RF buffer such as a 74ABT or dedicated op-amp driver.

Otherwise, the line becomes a ringing antenna instead of a transmission path.

Tip from field use: engineers often add a DC block capacitor and place the driver near the coax entry to reduce stub effects. It’s a simple fix that improves return loss by > 3 dB.

Which connector family fits your 50 Ω run — SMA-SMA or N to SMA?

This image shows a TEJTE SMA male-to-male RF cable assembly, commonly used to connect lab equipment, routers, or IoT modules. Such cables use flexible 50-ohm coax like RG316 or RG58, support frequencies up to 6 GHz, and offer low loss and easy routing.

This image shows an N-type to SMA connector combination, suitable for outdoor environments requiring higher power handling and better weather/UV resistance. These connectors are typically used with low-loss 50-ohm cables like LMR-200 or LMR-240 to ensure stable signal integrity in harsh conditions.

Choosing connectors isn’t just about what fits the panel hole.

Every RF chain has to maintain the 50 ohm impedance right through the connectors.

Most indoor test setups and Wi-Fi modules use SMA to SMA cable assemblies, while outdoor routers and base stations often adopt N-type to SMA combinations for weatherproof durability.

On TEJTE’s RF connector series, SMA is favored for compact 6 GHz links; the N-type connector handles higher power and better sealing.

Both mate directly to the RG58, RG316, LMR-200, and LMR-240 families you provided — each designed for 50 Ω characteristic impedance.

What type of connector is used on 50 ohm coax cables for indoor / outdoor use?

- Indoor (lab, router, IoT):

• SMA male–male or SMA male–female extension cables (see TEJTE’s SMA extension guide)

• RG316 or RG58 preferred — flexible and easy to route

- Outdoor (masts, antennas, base stations):

• N to SMA assemblies on LMR-200 or LMR-240 — double-shielded for UV resistance

• Optional IP67 boots or torque nuts from TEJTE accessories

When to choose SMA-SMA vs SMA extension vs N to SMA lead?

This image shows a TEJTE N-type to SMA connector assembly with LMR-240 low-loss 50-ohm coaxial cable. This combination is designed for outdoor and high-power applications. The LMR-240 cable uses foam PE insulation and dual shielding, offering attenuation as low as 0.18 dB/m at 2.4 GHz, and includes weather-sealing features for long-term reliability in harsh conditions.

If your device ports face each other on a bench, a short SMA-SMA RG316 cable is perfect — low loss and super flexible.

For stacked modules or tight enclosures, use a SMA extension cable (SMA male to female) to reduce mechanical stress.

Once the line goes outdoors or above 2 m, switch to N to SMA LMR-240 assemblies to gain a few dB and UV safety.

How do you install 50 Ω coax connectors without hurting return loss?

Installing connectors is where good RF design meets hand skill.

A perfect 50 ohm coax cable can turn into a 25 Ω nightmare if the center pin is mis-aligned or the shield is poorly crimped.

The goal is to maintain a uniform geometry from dielectric to connector body.

How to install 50 ohm coax connectors (tools, torque, ESD)

Installing a connector on a 50 ohm coax cable looks simple until you’ve done a few dozen by hand.

Tiny deviations — a braid trimmed too short, a pin pressed too deep — can change return loss by several dB.

Patience matters as much as torque.

- Prepare the cable carefully. Strip the jacket, braid, and dielectric exactly to spec.

For RG316 cable, the inner conductor is 7 × 0.175 mm silver-plated copper — avoid nicking any strand or you’ll weaken the joint.

- Slide the boot and ferrule onto the cable before you crimp.

It sounds obvious, but even seasoned technicians occasionally forget, forcing a full redo.

- Insert the center pin until it sits flush. Solder only if required; the PTFE insulation of RG316 can handle up to 150 °C, but prolonged heating still risks creeping.

- Crimp the ferrule using the correct die size.

TEJTE recommends 1.37 mm for RG316 ferrules, ensuring even compression without crushing the dielectric.

- Tighten the connector to exactly 0.8 N·m using a calibrated

SMA torque wrench.

Overtightening can cause microscopic cracks that later appear as high VSWR.

Always torque in one clean motion — no “double clicks.”

- Seal and relieve strain.

Apply a heat-shrink boot or an IP67-rated cover such as TEJTE’s

SMA waterproof boot.

This keeps moisture and vibration from degrading the braid contact over time.

ESD precautions:

Ground the cable braid to chassis before connecting to sensitive modules or LNAs.

A small static snap can silently destroy a front-end FET — something you might only discover after hours of calibration.

A simple wrist strap or ESD mat is cheap insurance.

Can you mix 50 Ω and 75 Ω using matching sections?

Mixing different impedances is sometimes unavoidable — for instance, when a lab instrument (50 Ω) feeds a monitor circuit (75 Ω).

In those cases, a quarter-wave matching section can bridge the gap over a narrow band.

It’s an old but still elegant RF trick.

What is the formula to make a 50 Ω link using lengths of 75 Ω and 50 Ω coax?

The core formula is:

[ Z_\text{match} = \sqrt{Z_{01} \times Z_{02}} = \sqrt{50 × 75} ≈ 61.2 Ω ]

Use a λ/4 segment of ≈ 61 Ω cable between the two lines at your target frequency.

If such a cable isn’t available, you can approximate it by modifying the dielectric or combining short sections of RG58 and RG6.

λ is given by c / (f × VF), where c ≈ 3×10⁸ m/s and VF is the velocity factor of your cable (0.66 for RG58, 0.70 for RG316, 0.80 for LMR-200 / 240).

| Input Fields | Example Values | Output / Remarks |

|---|---|---|

| System Zo1 | 50 Ω | Standard RF equipment |

| Load Zo2 | 75 Ω | Video front-end or TV module |

| Frequency f | 2.4 GHz | Wi-Fi band |

| VF (Velocity Factor) | 0.70 (RG316) | Depends on dielectric |

| → Calculated Z match | 61.2 Ω | Target impedance for λ/4 section |

| → λ/4 Length | c / (4 × f × VF) ≈ 0.0429 m | ≈ 4.3 cm segment @ 2.4 GHz |

| Bandwidth note | ±5 % around f | Narrow-band solution only |

This matching section reduces reflection to below -25 dB around its center frequency.

For wide-band applications, it’s better to replace the 75 Ω segment entirely with a 50 Ω line.

Which 50 Ω cable family should you pick — RG58, RG316 or LMR-200/240?

Compare RG58 vs RG316 vs LMR-200/LMR-240 by loss & bend

| Cable Type | Attenuation @ 2.4 GHz | Attenuation @ 5 GHz | Outer Diameter (mm) | Min Bend Radius (mm) | Typical Use |

|---|---|---|---|---|---|

| RG316 Cable (PTFE + FEP jacket) | 1.46 dB/m | 2.34 dB/m | 2.5 | 15 | Tight spaces / test patch |

| RG58 Cable (PE jacket) | 0.43 dB/m | 0.66 dB/m | 5.0 | 50 | General indoor/outdoor |

| LMR-200 (Foam PE dual shield) | 0.22 dB/m | 0.35 dB/m | 5.0 | 25 – 50 | Outdoor feedline < 10 m |

| LMR-240 (Foam PE dual shield) | 0.18 dB/m | 0.30 dB/m | 6.1 | 30 – 60 | Long runs / base station |

The numbers tell the story. RG316 cable is the most flexible, handling sharp bends in lab setups or IoT modules. RG58 cable balances cost and ruggedness but adds noticeable loss above 3 GHz. When signal integrity matters, LMR-200 and LMR-240 — both 50 Ω low-loss cables — are the clear winners, offering less than half the attenuation of RG58.

For visual comparison, see TEJTE’s RF Coaxial Cable Guide for loss curves and application maps.

Temperature rating and jacket choice for rooftops / vehicles

Material dictates survivability. RG316 uses PTFE insulation and FEP jackets rated up to 150 °C — it won’t soften in summer enclosures. RG58 relies on solid PE and PVC, comfortable between –20 °C and +70 °C, fine for indoor use but prone to UV aging. LMR-series cables extend to 80 °C and employ black PVC jackets with UV inhibitors for rooftops and vehicle masts.

A small detail, often missed: bend radius. LMR-200’s static radius of 25 mm allows gentle routing along masts without micro-cracks. Over-bent RG58 sections can easily detune impedance and increase VSWR.

When your deployment mixes indoor and outdoor sections, splice RG316 jumpers inside the box and transition to LMR-240 outside — both available pre-terminated from TEJTE’s RF Cable Products.

Order in one pass: which 50 Ω coax SKU maps to your use case?

Planning a signal chain is like mapping a road trip — you don’t just choose “a cable,” you choose the path your signal must survive.

This is where practical data meets real deployment.

The following 50-Ω Coax Selection Matrix translates TEJTE’s verified attenuation and mechanical parameters into ready-to-order combinations.

| Use Case | Recommended Cable Family | Frequency (GHz) | Length Options (m) | Est. Loss (dB)* | Connector Ends | Temperature / UV | Power Handling (W) | Shield Type | Suggested TEJTE P/N |

|---|---|---|---|---|---|---|---|---|---|

| Router / Wi-Fi AP feedline | LMR-200 | 2.4 / 5 GHz | 1 / 3 / 5 m | 0.4-2.0 | SMA-SMA | -20 ~ 80 °C / UV Y | ≈ 100 W @ 2.4 GHz | Dual (Foil + Braid) | LMR200-SMA-3M |

| Test bench / instrumentation | RG316 Cable | 1 – 6 GHz | 0.1 / 0.3 / 1 m | 0.1-2.3 | SMA-SMA / SMA Ext | -55 ~ 150 °C | ~ 50 W @ 2.4 GHz | Single Braid | RG316-SMA-0.3M |

| Ham radio / lab setup | RG58 Cable | 0.1 – 3 GHz | 1 / 3 / 5 / 10 m | 0.4-7.0 | N to SMA / BNC | -20 ~ 70 °C / UV Y | ~ 120 W @ 2.4 GHz | Foil + 16×CCA Braid | RG58-N-SMA-5M |

| Outdoor mast / base station | LMR-240 | 2.4 / 5.8 GHz | 5 / 10 / 30 m | 1.9-3.8 | N to SMA | -20 ~ 80 °C / UV Y | ≈ 150 W @ 2.4 GHz | Dual (Al + Tinned Cu) | LMR240-N-SMA-10M |

| loT module interconnect | RG316 Cable | 2.4 GHz | 0.08 / 0.15 / 0.25 m | < 0.4 | SMA Male to U.FL | -55 ~ 150 °C | ≈ 25 W @ 2.4 GHz | Single Braid | RG316-SMA-UFL-0.15M |

- Formula: Loss_total = α(f, cable) × L + ΣLoss_connectors (0.1–0.3 dB each)

Every number here comes from TEJTE’s own test bench data — not from catalog averages.

In the lab, attenuation readings typically stay within ±0.5 dB of these values, even after repeated flexing.

That consistency is what lets integrators plan link budgets confidently instead of guessing.

FAQs

What is the formula for building a 50-Ω section using 75-Ω and 50-Ω coax (quarter-wave matching)?

Use Z_match = √(Z₁ × Z₂) and λ = c / (f × VF).

At 2.4 GHz with VF = 0.70 (RG316), the λ/4 segment is roughly 4.3 cm, giving about a 61 Ω match.

That’s enough to keep reflections below –25 dB within ±5 % bandwidth — narrow, but clean.

How much current is required to drive a 50-Ω coax, and why do 3.3 V digital drivers struggle?

A 50 Ω load at 3.3 V pulls about 66 mA.

Most LVCMOS devices can’t source more than 24 mA, so edges flatten and ringing appears.

A small line driver or a 25 Ω series resistor usually cures it.

Can LVCMOS or LVC245A drive a 50-Ω coax directly?

Not reliably.

They weren’t built for RF current.

Use an LVDS or op-amp buffer if your signal runs above 100 MHz — otherwise you’re just driving an antenna.

What’s the real-world difference between 50 Ω and 75 Ω coax, and when is mixing risky?

75 Ω lines have lower capacitance, good for long video or CATV runs.

Mixing them with 50 Ω equipment causes roughly a 5 % reflection (–26 dB), which becomes visible past 2 GHz.

For RF work, stay with 50 Ω types like RG316 cable or LMR-200.

How much dB loss should I expect from a 50-ft run at 2.4 / 5 GHz with common connectors?

Based on TEJTE’s data: RG316 ≈ 32 dB, RG58 ≈ 9.5 dB, LMR-200 ≈ 3.4 dB, LMR-240 ≈ 2.7 dB,

plus another 0.3 dB for connectors.

If your link margin is tight, shorten the line or upgrade to LMR-240.

Which connector family fits 50-Ω coax for indoor vs outdoor routes (SMA vs N)?

Use SMA connectors indoors for compact setups; they’re easier to route on benches or inside enclosures.

For outdoor or high-power installations, N-type connectors provide a more durable, weather-sealed joint.

Both options are available under TEJTE’s RF Connector Series.

How do I install 50-Ω coax connectors while keeping return loss acceptable?

Follow the same process outlined in TEJTE’s SMA Crimp Connector Guide.

Keep the strip length precise, torque at 0.8 N·m, and check continuity (< 1 Ω).

A clean crimp makes a measurable difference — it’s usually worth the extra two minutes.

Does TEJTE offer custom 50-Ω coax lengths or certified test reports?

Yes.

All TEJTE RG316, RG58, and LMR-series assemblies can be ordered in custom lengths and connector combinations.

On request, TEJTE provides VSWR, insertion-loss, and continuity reports with each batch — useful for OEM or lab validation.

These reports come straight from the same test benches used to generate the attenuation tables above, ensuring traceable data integrity.

Where 50 Ω coax truly matters in real deployment

If you’ve worked around RF systems long enough, you’ll notice one quiet truth — nearly every reliable signal chain still runs on 50 ohm coax cables. From rooftop 5 G antennas to small IoT boards, this standard has stood firm because it simply works. The balance between manageable current and low reflection is something even the best PCB traces struggle to match beyond a few gigahertz.

In the field, a few inches of wrong cable can ruin an entire measurement. I’ve seen setups where a beautifully tuned RF amplifier lost 3 dB of gain just because someone swapped a RG58 jumper for a 75 Ω video lead. And on the flip side, a cleanly terminated LMR-240 cable feeding a mast antenna can maintain signal integrity through months of rain and heat.

That’s also why TEJTE engineers keep refining their RG316, RG58, and LMR-series assemblies — not only for better attenuation, but for long-term consistency. When you order a pre-tested SMA or N-to-SMA line from their catalog, you’re getting the same level of impedance control used in lab-grade test benches. In the end, that’s what keeps your waveform intact and your system predictable, no matter where it’s installed.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.