RG316 Cable: Specs, Loss & SMA Assembly

Oct 15,2025

Introduction

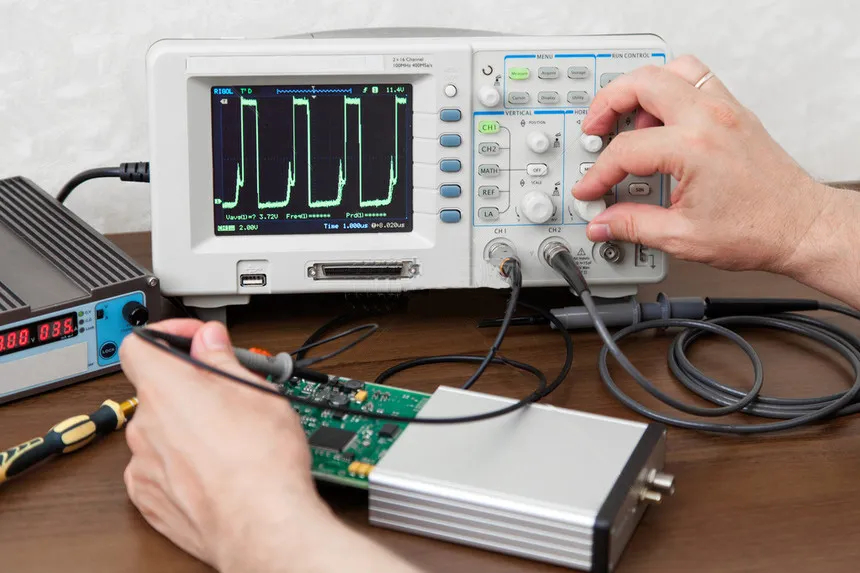

The image shows RG316 cable used inside routers, IoT gateways, and UAV telemetry systems. Its compact size, PTFE dielectric, and silver-plated copper braid allow flexible routing under harsh conditions.

In compact RF builds—from small Wi-Fi routers and IoT gateways to UAV telemetry—RG316 cable has become an engineer’s quiet favorite. Its slim 2.5 mm outer diameter, PTFE insulation, and silver-plated copper braid make it perfect for tight spaces and harsh conditions where larger coax types like RG58 or LMR-200 simply won’t fit.

But a smaller cable always comes with trade-offs: higher attenuation, lower power, and stricter length limits. This guide dives into those details—how RG316 compares with RG58, how long it can realistically run before losses dominate, and how much power it can safely handle.

If you’re wiring SMA to SMA cables or SMA extension cables, these numbers will save you a lot of time and troubleshooting later.

Should you pick RG316 or RG58 for this run?

Both RG316 and RG58 are 50 ohm coax cables, compatible with standard SMA connectors. Yet they serve different roles once deployed.

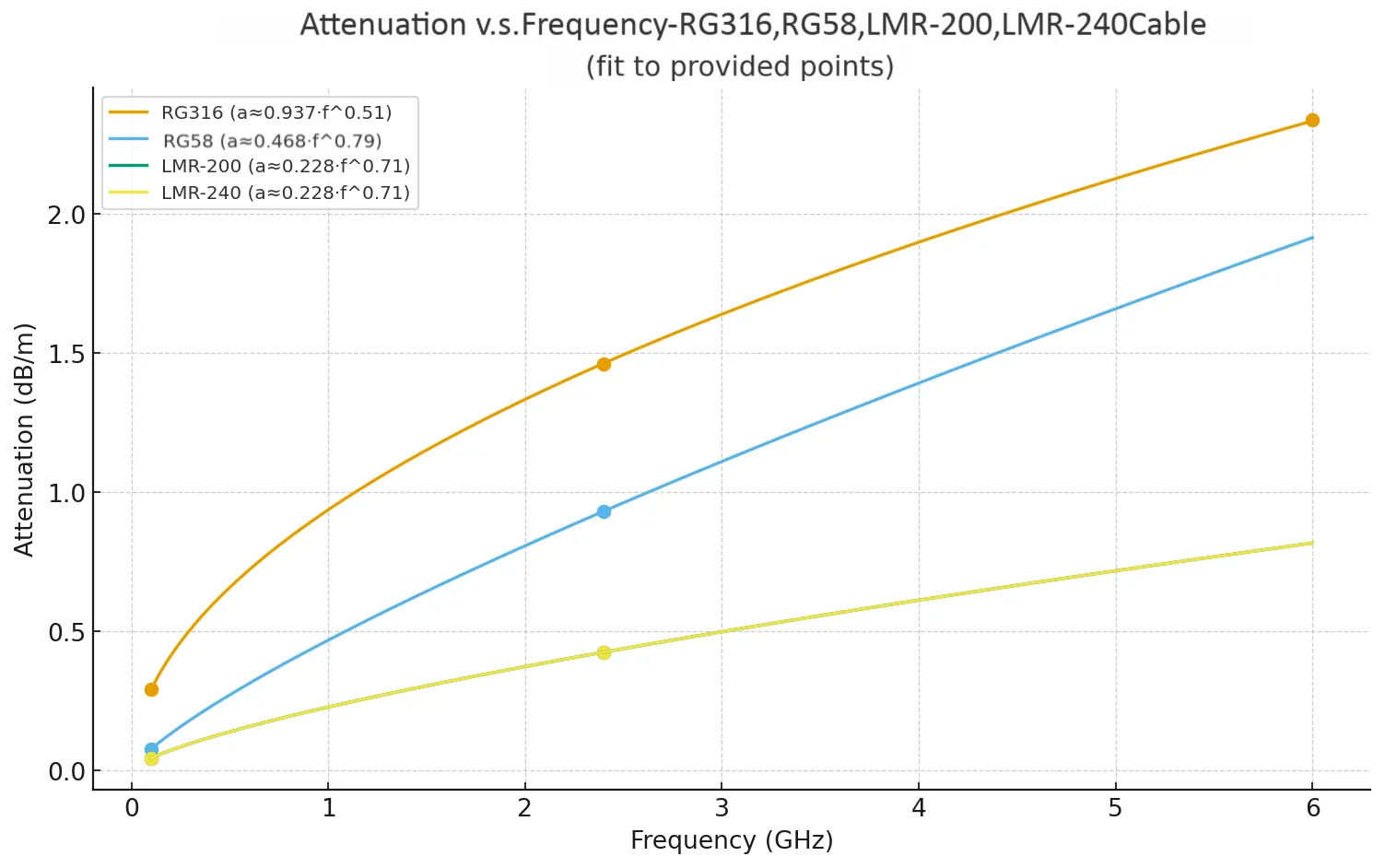

Below is a direct comparison including LMR-200 and LMR-240, which many engineers consider “next-step” upgrades.

| Parameter | RG316 | RG58 | LMR200 | LMR240 |

|---|---|---|---|---|

| Impedance (Ω) | 50 | 50 ± 2 | 50 | 50 |

| Outer Diameter (mm) | 2.50 | 5.0 | 5.0 | 6.1 |

| Attenuation @ 100 MHz (dB/m) | 0.29 | 0.0766 | 0.044 | 0.044 |

| Attenuation @ 2.4 GHz (dB/m) | 1.46 | 0.932 | 0.425 | 0.425 |

| Temperature Range (°C) | -45 ~ +150 | -20 ~ +70 | -20 ~ +80 | -20 ~ +80 |

| Min. Bend Radius (mm) | 15 | 50 | 25 | 30.5 |

| Power @ 2.4 GHz (W) | 78 | 93 | 230 | 250 |

The table compares TEJTE’s standard RG316 with thicker RG58 and low-loss LMR cables. It highlights that RG316 offers extreme flexibility but higher attenuation (1.46 dB/m @2.4 GHz), while LMR240 minimizes loss for outdoor runs.

At lower frequencies or short indoor runs, RG316 cable performs impressively for its size. But attenuation rises quickly beyond 2 GHz—1.46 dB/m @ 2.4 GHz and 2.34 dB/m @ 6 GHz—so long feedlines should use RG58 or LMR200 instead.

Where RG316 truly excels is flexibility and endurance: the PTFE dielectric tolerates 150 °C, and its 15 mm bend radius allows tight routing inside housings or drones. In many designs, engineers use RG316 inside the device and transition to RG58 outside for the main antenna line.

You can see extended comparisons of loss and shielding in TEJTE’s RG316 vs RG58 analysis, which also covers connector matching and outdoor sealing.

How long can RG316 be before loss breaks your link budget?

The image illustrates the layered construction of TEJTE’s RG316 coaxial cable — featuring a silver-plated copper inner conductor, solid PTFE dielectric, tinned copper braid, and a brown FEP jacket. This structure offers high temperature tolerance (–65°C to +165°C) and stable 50-ohm impedance.

| Frequency (MHz) | α(f, RG316) (dB/m) |

|---|---|

| 900 | 0.88 |

| 1800 | 1.27 |

| 2400 | 1.46 |

| 5000 | 2.15 |

| 6000 | 2.34 |

Loss_total = α × L + Σ Loss_connectors

In many SMA extension cable assemblies—like a RG316 SMA-M to SMA-F 1 m patch lead—you’ll find optimal results under 1.5 m for stable throughput.

FPV builders often trim 20 cm just to recover 0.3 dB of SNR. That’s how sensitive high-band systems are to cable length.

Will RG316 handle your power—how do you check rating safely?

| Frequency (MHz) | Attenuation (dB/m) | Rated Power (W) |

|---|---|---|

| 100 | 0.29 | 420 |

| 400 | 0.58 | 210 |

| 900 | 0.88 | 140 |

| 1000 | 0.93 | 135 |

| 1800 | 1.27 | 100 |

| 2400 | 1.46 | 78 |

| 5000 | 2.15 | 61 |

| 6000 | 2.34 | 52 |

Derating tips for real installations:

- Subtract 20–30 % capacity if ambient > 60 °C or cable bundled.

- Deduct ~10 % per additional adapter or coupler.

- Half-duty (50 %) modes regain ~10–15 % margin.

If your application exceeds 80 W @ 2.4 GHz or 60 W @ 5 GHz, it’s safer to move up to LMR-200 or LMR-240. These thicker 50 ohm coax cables deliver < 0.5 dB/m loss and stay cool above 200 W.

When testing, always measure return loss (S11) under nominal power. If the cable sheath feels hot after a few minutes, you’re at the thermal limit. For long-term reliability, design around 70 % of rated power rather than the absolute maximum.

Do you need M-M, M-F or U.FL / RP-SMA ends for this build?

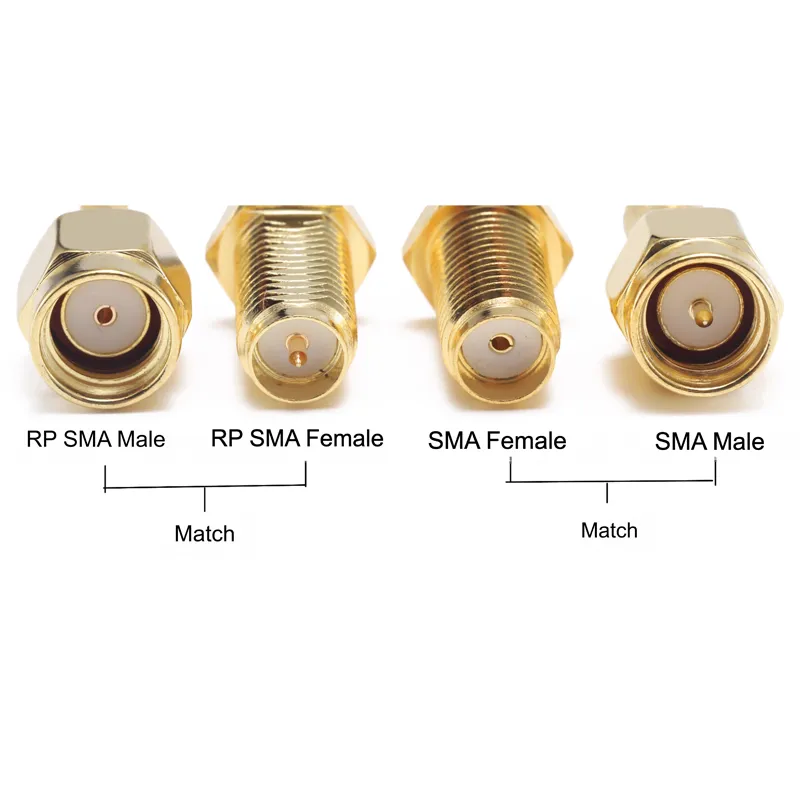

The image shows standard SMA-M (male), SMA-F (female), and RP-SMA variations. Matching both thread type and polarity ensures continuity between router, test instruments, and antennas.

Connector gender and polarity mistakes are still one of the most common causes of wasted builds.

A quick scan of TEJTE’s SMA connector guide will remind you:

- SMA-M (male) = inner pin + outer thread

- SMA-F (female) = inner receptacle + outer nut

- RP-SMA (reverse-polarity) = pin/receptacle swapped

For module-to-antenna wiring, match gender + polarity, not just thread type.

A Wi-Fi router using an RP-SMA jack requires an RP-SMA plug, while test instruments normally use standard SMA male ports.

If you mix the two, the pin won’t mate, and signal continuity breaks even though the threads fit.

Different assembly styles solve different tasks:

| Configuration | Typical Use | Notes |

|---|---|---|

| SMA-M to SMA-M jumper | Bench testing or coupler link | short flexible SMA jumper cable |

| SMA-M to SMA-F extension | Router / panel pass-through | ideal for outdoor SMA extension cable |

| U.FL to SMA-F pigtail | loT board to chassis antenna | miniature connector, < 1.13 mm coax |

| RP-SMA variants | Wi-Fi, GSM modules | match router polarity exactly |

When ordering TEJTE parts, look for suffixes like -JJ, -JF, or -KWE – they encode male/female and thread type.

If your design is space-constrained, right-angle SMA types such as SMA-JW reduce strain and fit flush against PCBs or panels.

Fast gender / polarity ID and common router patterns

A quick field tip:

- Consumer routers to RP-SMA female on chassis.

- Test gear to SMA female panel port.

- Antenna to SMA male connector.

So a male-to-female RG316 extension bridges both worlds neatly.

To verify polarity, check for the presence of a center pin before tightening.

Reversing the threads under power can permanently deform the dielectric and introduce > 1 dB mismatch loss.

Pick SMA jumper cable vs pigtail vs panel feed-through

- Choose pigtails (U.FL to SMA) for internal RF modules, typically 10–30 cm.

- Use jumpers (SMA-M to SMA-M) between instruments; they handle repeated cycles (> 500).

- For enclosures, the panel feed-through SMA bulkhead provides sealing with nuts + washers and can be upgraded to IP67 boots – see TEJTE’s SMA bulkhead guide.

How do you terminate and strain-relieve RG316 to SMA cleanly?

Termination quality defines cable life and return-loss performance.

RG316’s PTFE dielectric can cold-flow if overheated, so precise stripping and torque control are essential.

Cable prep, crimp hex sizes, pin height and torque order (ESD safe)

Use a sharp coax stripper preset to 3 layers:

- Strip 5 mm jacket to expose braid.

- Trim 2.5 mm dielectric to reveal center conductor.

- Tin lightly if solder-pin SMA; for crimp pins, keep bare.

Crimp hex: use 1.72 mm (0.068 in) die for RG316 ferrules.

Recommended torque on SMA nut ≈ 0.45 N·m (4 lbf·in).

Over-tightening distorts threads and detunes impedance.

Many technicians now follow TEJTE’s SMA crimp connector workflow – it lists correct strip lengths and visual pass criteria.

Quick acceptance: continuity + spot return-loss / VSWR checks

After assembly, perform:

- DC continuity (should read < 1 Ω between pins, open between shield and pin).

- Spot VSWR check at operating band (≤ 1.25 @ 6 GHz is excellent).

- Flex test around the strain-relief zone; no flicker in continuity means good crimp.

For production runs, TEJTE recommends sample testing with network analyzers at 2.4 and 5 GHz to catch any connector misalignment early.

Will your routing survive tight bends and vibration?

Minimum bend radius vs repeated flex; tie-downs and grommets

RG316’s mechanical flexibility is one of its biggest assets – minimum bend radius 15 mm (static) and about 25 mm (dynamic).

Still, repeated flexing near the connector weakens the braid.

Always secure the cable with a nylon tie or adhesive mount 5–10 mm behind the connector boot.

In vibrating systems like drones or automotive IoT, soft grommets or silicone strain boots significantly reduce fatigue.

A tight 90° bend is acceptable once, but not as a permanent loop.

Drone / FPV & compact enclosures: right-angle relief options

The image shows TEJTE’s SMA-JW right-angle male connector, often paired with short RG316 jumpers in drones and routers. Its compact geometry enhances reliability and minimizes bending near ports.

FPV pilots often choose right-angle SMA connectors to keep antennas clear of propellers.

TEJTE’s SMA-JW series (male right-angle) minimizes height and improves mechanical reliability.

For cramped enclosures, combine short RG316 jumpers (0.1 – 0.2 m) with 90° connectors to maintain signal integrity without forcing the cable.

Even small layout adjustments—like routing along a bulkhead—can extend service life by thousands of cycles.

Order in one pass: which RG316 cable spec matches your use case?

Engineers often juggle too many part codes when sourcing RF jumpers.

To simplify, TEJTE organizes each RG316 SMA assembly by connector ends, frequency rating, and verified loss per meter.

Use the Spec-to-Order Matrix below as a practical checklist.

| Ends | Frequency (GHz) | Length Options (m) | Est. Loss (dB) | Min Bend Radius (mm) | Power Hint | Suggested TEJTE P/N |

|---|---|---|---|---|---|---|

| SMA-M to SMA-M | 2.4 / 5 / 6 | 0.1 – 2.0 | 1.46 × L + 0.2 | 15 / 25 | OK ≤ 1 m @ 2.4 GHz | RG316-JJ-Series |

| SMA-M to SMA-F (extension) | 2.4 / 5 | 0.3 – 3.0 | 1.46 × L + 0.3 | 15 / 25 | OK ≤ 2 m; >2 m use RG58 |

RG316-JF-Extension |

| U.FL to SMA-F (pigtail) | 2.4 / 5 | 0.05 – 0.3 | 1.46 × L + 0.2 | 10 / 20 | OK short internal use | UFL-SMA Pigtail RG316 |

| RP-SMA variants | 2.4 | 0.1 – 1.5 | 1.46 × L + 0.3 | 15 / 25 | OK < 1.5 m | RP-SMA Series |

Formula: Loss_total = α(f, RG316) × L + Σ Loss_connectors (0.1–0.3 dB per end)

Each part passes 100 % VSWR (< 1.25 @ 6 GHz) and insulation resistance > 1500 MΩ·km.

All assemblies use silver-plated 7×0.175 mm center conductors, FEP jacket (-45 ~ 150 °C), and brass-gold-plated SMA contacts for corrosion resistance.

Estimate loss and margin before you cut the cable?

Cable trimming without calculations often backfires.

A 10 cm mistake can shift signal-to-noise by nearly 0.3 dB at 5 GHz.

Use the Quick Loss & Margin Calculator below to size your run correctly before fabrication.

| Input Parameter | Symbol / Unit | Example Value |

|---|---|---|

| Frequency | f (GHz) | 2.4 / 5 / 6 |

| Cable Length | L (m) | 1.5 |

| Attenuation Factor | α(f, RG316) (dB/m) | 1.46 @ 2.4 GHz : 2.34 @ 6 GHz |

| Connectors + Adapters | Σ Loss (dB) | 0.2 × 2 = 0.4 |

| Old SNR Margin | SNR_old (dB) | 25 |

| Output Total Loss dB | α × L + Σ Loss | 1.46 × 1.5 + 0.4 = 2.59 dB |

| Output SNR new | SNR_old - Loss dB | 22.4 dB |

If Loss_dB > 3 dB, shorten the cable or upgrade to LMR-200 or LMR-240.

These achieve roughly 0.4 dB/m @ 2.4 GHz—about three times less than RG316—making them ideal for outdoor or long-distance antenna feeds.

Field engineers typically keep a 20 % margin under the loss ceiling; this cushions SNR drift caused by humidity or connector aging.

If you use TEJTE’s RF attenuator guide, you can combine cable and attenuator loss into one consolidated link budget.

FAQ

1. How much power can RG316 safely carry compared with RG58 on 2.4 / 5 GHz?

At 25 °C continuous-wave, RG316 handles ≈ 78 W @ 2.4 GHz and ≈ 61 W @ 5 GHz, while RG58 supports ≈ 93 W and ≈ 77 W respectively.

Always derate 20–30 % for enclosed or high-ambient setups.

2. Which cable is better for higher power—RG58 or RG316—and when should I move to LMR-200 / 240?

3. How do I connect RG316 to a FrSky RX (or similar RC receiver) without tearing pads?

Pick a U.FL to SMA pigtail with gentle strain relief and anchor it 5 mm behind the U.FL jack.

TEJTE’s U.FL to SMA installation guide shows proper bend angles and tie-points.

4. What is RG316 commonly used for, and when should I avoid it for long outdoor runs?

RG316 is ideal for short jumpers, internal modules, and high-temp areas (−45 ~ 150 °C).

Avoid runs > 2 m in open air; UV and moisture raise loss and aging.

For outdoor applications, use RG58 coax or LMR-series with PVC jackets.

5. How do I use RG316 for RX antennas while meeting bend-radius limits on drones?

Keep bends > 15 mm radius (static) and 25 mm (dynamic).

Secure the cable with tie-points or flex boots to prevent micro-fracture at the crimp.

Refer to TEJTE’s SMA right-angle guide for tight enclosure layouts.

6. Is there a “low-loss RG316,” or should I switch cable type past a certain length?

So-called “low-loss RG316” variants exist with denser braids, but physics still limits attenuation to ≈ 1.3 dB/m @ 2.4 GHz.

Beyond 1.5 m, it’s more efficient to move to LMR-200 or LMR-240.

7. What quick checks confirm my new RG316 lead won’t hurt return loss or SNR?

The image presents TEJTE’s full coaxial cable range — RG174 for compact devices, RG316 for flexible high-temperature applications, and LMR-series (LMR200, LMR240, LMR400) for low-loss outdoor communication setups. All maintain 50Ω impedance and wide frequency coverage up to 6 GHz.

Run a continuity test (< 1 Ω pin-to-pin), then measure VSWR (< 1.25 @ 6 GHz).

Visually inspect crimps and braid integrity.

TEJTE’s SMA inspection guide lists pass/fail criteria for production QC.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.