SMA Connector Guide: Types, Specs & How to Choose

Sep 29,2025

How do I choose the right SMA connector?

Selecting the right SMA connector isn’t just a matter of matching thread sizes. Engineers and buyers usually look at impedance, voltage rating, frequency range, and mechanical durability before making a decision. Understanding the different sma connector types—male, female, jack, plug, PCB-mounted, or even waterproof models—helps avoid costly mistakes later on.

TEJTE’s SMA series covers 0–18 GHz, with designs tested to handle 335V rms working voltage and 1A current capacity. Many models also reach ≥500 mating cycles, making them reliable for consumer networking gear as well as aerospace equipment. It’s this blend of frequency stability and durability that separates a robust connector from a disposable one.

Connector types: SMA Male, SMA Female, SMA Jack, SMA Plug

- SMA Male Connector – has external threads and a center pin. You’ll see it most often on assemblies such as RG316 SMA cables.

- SMA Female Connector – designed with inner threads and a receptacle socket. TEJTE uses gold-plated beryllium bronze contacts, ensuring ≤5 mΩ resistance and long-term corrosion resistance.

- SMA Plug – often interchangeable with “male” in datasheets. It’s the movable half that fits into the jack.

- SMA Jack – the fixed part, mounted to panels or PCBs. A straight SMA-KE jack withstands 1000V rms and operates from -65°C to +165°C, making it suitable for industrial or medical devices where conditions are less forgiving.

Use cases: PCB, antennas, adapters

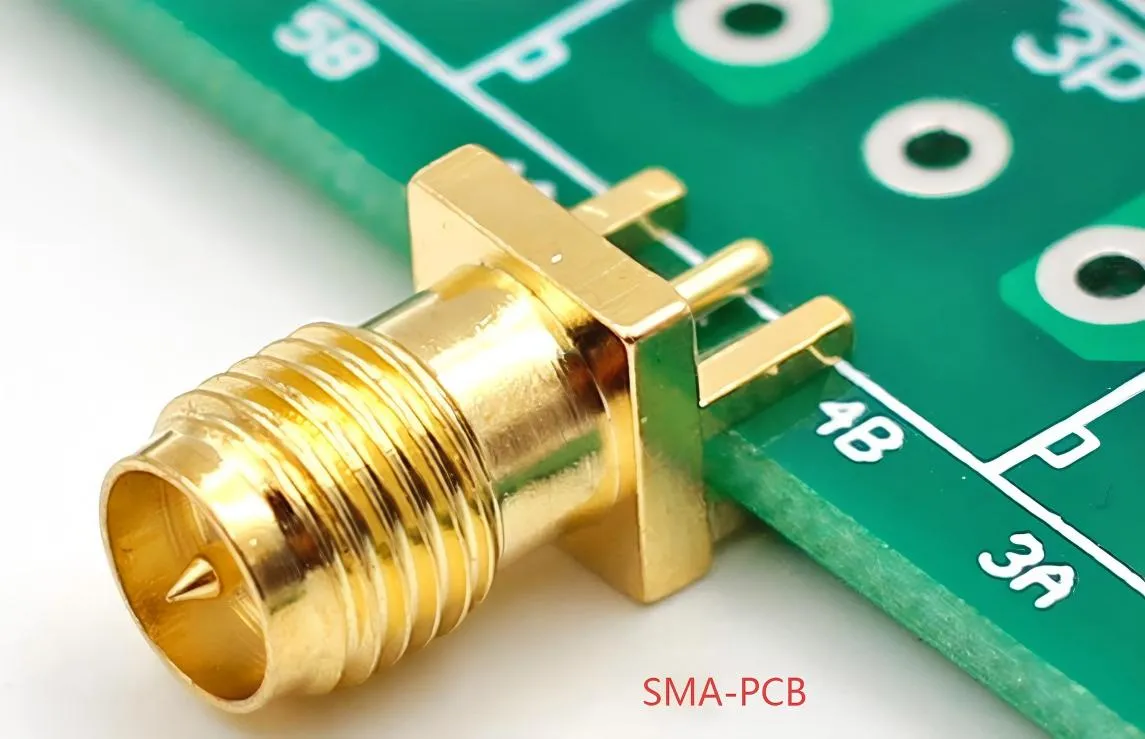

It visually presents the SMA PCB connectors used in compact circuit layouts. The document notes that right-angle jacks make routing easier when vertical clearance is tight, such as TEJTE's SMA-KWE right-angle jack, which achieves ≤0.15 dB insertion loss at 6 GHz, ensuring stable performance without taking up too much room.

PCB integration – In compact circuit layouts, board space is always a concern. This is where sma pcb connectors stand out. Right-angle jacks make routing easier when vertical clearance is tight. TEJTE’s SMA-KWE right-angle jack, for example, withstands 1000V rms and achieves ≤0.15 dB insertion loss at 6 GHz, ensuring stable performance without taking up too much room.

Antennas – Many WiFi, LTE, and GPS devices rely on SMA female ports, so pairing them with the correct sma male connector cable preserves the 50Ω impedance across the system. For outdoor installs—think 5G modules on rooftops or IoT gateways exposed to the elements—using an IP67-rated sma waterproof connector is not optional, it’s essential. Without sealing, even a week of humidity can degrade performance. For more antenna-related insights, see TEJTE’s WiFi antenna guide.

Adapters – Different systems don’t always share the same interface. That’s why sma connector types also include adapters—bridging SMA with BNC, N-type, or TNC connections. TEJTE offers SMA to BNC adapters and other couplers that let engineers connect mismatched systems quickly, without redesigning entire cable runs.

What are the differences between SMA connectors?

SMA Male vs SMA Female connection types

- SMA Male Connector (plug) – includes the center pin and external threads. It’s normally mounted on cables, making it more prone to wear or bent pins if handled roughly.

- SMA Female Connector (jack) – has a socket and internal threads, often fixed to boards or equipment housings. TEJTE’s sma female connectors use gold-plated brass housings with beryllium bronze sockets, offering ≥5000 MΩ insulation resistance and ≥500 mating cycles for consistent, long-term use.

SMA Plug vs SMA Jack performance comparison

- SMA Plug (male) – usually cable-mounted, making it the “moving half” of the connection. Because of frequent connect/disconnect cycles, it tends to wear faster.

- SMA Jack (female) – panel- or PCB-mounted, better at resisting vibration or mechanical stress in industrial environments.

corresponding to the introduction of the SMA-KE straight jack. The document states that this connector operates across DC-6 GHz with a VSWR of 1.10:1, proving its reliability in RF communication boards, test instruments, and rugged systems.

Electrically, both maintain the required 50Ω impedance when properly matched. TEJTE’s SMA-KE straight jack operates across DC–6 GHz with a VSWR of 1.10:1, proving its reliability in RF communication boards, test instruments, and rugged systems.

For more context, TEJTE’s male vs female guide provides diagrams and real-world examples to avoid confusion in connector selection.

How do I check the impedance and frequency of SMA connectors?

Impedance standards: 50Ω vs 75Ω

- 50Ω SMA connectors – standard in RF communication, IoT modules, and lab instruments. TEJTE’s common sma connector types for RG316 and RG174 assemblies maintain this impedance, supporting broadband wireless and measurement needs.

- 75Ω SMA connectors – found mainly in video and broadcast applications.

Even though 50Ω and 75Ω screw together physically, mixing them creates reflection and mismatch losses. That means degraded throughput and potential device malfunction. For a deeper explanation, see TEJTE’s RF coaxial cable guide, which details how impedance affects system reliability.

Frequency matching: DC–6 GHz vs higher frequencies

- Standard SMA models – perform reliably up to 6 GHz, covering WiFi, LTE, and Bluetooth.

- Extended-range SMA connectors – precision-machined with PTFE insulation, stable up to 18 GHz.

- Stainless steel SMA for RG405 – designed for aerospace; rated at ≤1.25 VSWR with shielding effectiveness ≥100 dB @ 1 GHz.

Specification snapshot

| Parameter | Value |

|---|---|

| Frequency Range | DC-6 GHz |

| Withstand Voltage | 1000 V rms |

| Insertion Loss | ≤0.15 dB @ 6 GHz |

| Mechanical Durability | ≥5000 cycles |

| Insulation Resistance | ≥5000 MΩ |

What dimensions and specs should I consider when selecting SMA connectors?

Standard dimensions for various applications: straight, threaded, right angle

showing the SMA-KWE right-angle connector. The document emphasizes that right-angle SMA connectors are widely used where vertical clearance is tight. The SMA-KWE right-angle jack measures 23 mm in total length with a 17 mm tooth, and maintains ≤0.15 dB insertion loss @ 6 GHz, making it compact but high performing.

- Straight SMA connectors – best for inline panel or PCB connections. TEJTE’s SMA-KE straight jack measures 13.5 mm in length with an 8 mm tooth size, tolerates 1000V rms, and supports -65°C to +165°C operating ranges.

- Right-angle SMA connectors – widely used where vertical clearance is tight. The SMA-KWE right-angle jack measures 23 mm in total length with a 17 mm tooth, and maintains ≤0.15 dB insertion loss @ 6 GHz, making it compact but high performing.

- Threaded bulkhead connectors – lock in place with nuts and washers, ensuring vibration resistance for automotive, aerospace, or heavy machinery setups.

If you’re not sure which layout works best, TEJTE’s SMA right-angle adapter guide provides examples of when angled connectors outperform straight versions.

Compatibility between connectors and cables

| Cable Type | Recommended SMA Connector | Frequency Range | Key Notes |

|---|---|---|---|

| RG174 | Standard crimp SMA | DC-3 GHz | Very flexible, but higher loss |

| RG316 | Straight or right-angle SMA | DC-6 GHz | Strong shielding, tight bend radius |

| LMR-200 | Bulkhead SMA connector | DC-6 GHz | Low loss, weather-resistant jacket |

serving as a physical reference in the "Compatibility between connectors and cables" section. It clearly shows the integration state of SMA connectors (likely through-hole mounted SMA jacks) on an electronic circuit board (PCB). This installation method provides a robust mechanical connection and a reliable electrical path for RF signals, and is a typical application in compact designs like wireless communication modules and IoT devices. The document previously notes that connector selection (e.g., straight or right-angle) and installation method are critical for spatial layout and signal integrity in PCB integration.

How do I properly crimp SMA connectors?

SMA Crimping Standards

| Field | Recommended Standard |

|---|---|

| Tool Type | Ratcheted hand crimper (manual) or pneumatic (automatic) |

| Crimp Depth | 2.5–3.0 mm depending on connector series |

| Conductor Strip Length | 3.0–3.2 mm (inner conductor) |

| Dielectric Cut | Flush cut, no nicking |

| Ferrule Crimp | Hex crimp, uniform, no visible gaps |

Step-by-step procedure

- Strip the coax cable – expose the inner conductor (~3.0 mm) and dielectric carefully. A clean cut prevents micro-cracks in the PTFE insulation.

- Insert the conductor – slide it into the connector pin. Depending on the design, soldering may be optional.

- Position the ferrule – pull it over the cable braid to secure shielding.

- Seat the connector body – make sure the pin is fully inserted and aligned.

- Crimp the ferrule – use the correct die size to form a tight, uniform hex crimp (2.5–3.0 mm).

- Inspect visually – check that the braid isn’t loose and the pin is centered.

- Test electrically – confirm continuity with a multimeter, and check there’s no short between pin and shell.

For more examples of crimped assemblies in practice, see TEJTE’s SMA adapter options, where connectors are often paired with flexible cables like RG316 and RG174.

What are the common mistakes when selecting SMA connectors?

It shows a typical application of SMA connectors in an antenna base. The document discusses common selection mistakes in this section, such as confusing standard SMA with RP-SMA polarity and underestimating environmental requirements outdoors leading to performance degradation.

Verifying connector polarity (straight vs reverse polarity)

A common error is confusing standard SMA with RP-SMA (reverse polarity). Both use the same thread, but the center pin/socket arrangement is swapped. For example, an RP-SMA male has a socket instead of a pin, which won’t mate properly with a standard SMA female. Mixing the two is a classic source of frustration in WiFi antenna projects.

Practical note: always check the datasheet images or pin diagrams. More than one technician has ordered “SMA male connectors” only to discover they needed RP-SMA for the router port. TEJTE’s male vs female guide illustrates these subtle but costly differences.

Outdoor and waterproof considerations

Another frequent oversight is underestimating the environment. Standard connectors may perform perfectly indoors but fail quickly outdoors. Moisture creeps into the threads, corrosion sets in, and insertion loss rises sharply.

For antennas mounted on rooftops or 5G small cells, you’ll need an sma waterproof connector. TEJTE’s IP67-rated versions include silicone rubber seals, gold-plated contacts, and have been tested to ≥5000 MΩ insulation resistance and 1000V rms withstand voltage. These features aren’t luxuries—they’re survival requirements in harsh weather.

Related reading: TEJTE shares real-world antenna practices in the WiFi antenna guide, showing how connector choice impacts both indoor and outdoor system stability.

How do SMA connectors perform in antennas and communication devices?

Antenna-SMA connector matching requirements

It shows a specific connector from TEJTE's antenna-grade SMA series. The document states that this series supports DC-6 GHz for standard applications and up to 18 GHz for specialized systems, all while maintaining ≤0.15 dB insertion loss and ≥5000 MΩ insulation resistance, and that an IP67 sma waterproof connector is the safer choice for outdoor antenna installations.

Most antennas—whether WiFi, LTE, or GPS—are designed with SMA female connectors. To keep the impedance at 50Ω, these must be paired with sma male connectors of equal quality. TEJTE’s antenna-grade SMA series supports DC–6 GHz for standard applications and up to 18 GHz for specialized systems, all while maintaining ≤0.15 dB insertion loss @ 6 GHz and ≥5000 MΩ insulation resistance.

For outdoor antenna installations, such as pole-mounted 5G modules or weather stations, an IP67 sma waterproof connector is the safer choice. Equipped with silicone seals and gold-plated contacts, they prevent corrosion even after prolonged exposure to rain or humidity.

Applications in wireless communication systems

- WiFi routers & access points – use SMA female ports for detachable antennas, giving flexibility in coverage upgrades.

- 4G/5G modules – rely on SMA for consistent RF links in both consumer and industrial equipment.

- GPS receivers – compact SMA jacks help maintain low noise and accurate positioning.

- IoT devices – miniature boards often integrate sma pcb connectors, ensuring reliable wireless connectivity even in dense layouts.

For broader antenna-related insights, see TEJTE’s WiFi antenna guide, which explains how connector choice interacts with different frequency bands and device types.

How do I assess the quality and reliability of SMA connectors before purchase?

Quality certifications and brand selection

A reliable connector should meet RoHS standards at minimum, and for demanding applications, MIL-grade testing is a strong signal of durability. TEJTE’s SMA line is validated for consistent electrical performance, making them suitable for network communication boards, RF measurement instruments, and even medical devices.

Performance figures speak louder than claims. For instance, TEJTE’s SMA-KWE right-angle jacks deliver ≤0.15 dB insertion loss at 6 GHz and endure ≥5000 mating cycles, ensuring they remain stable even after heavy use.

Related insight: the RF connector selection guide explains how connector quality directly influences overall system stability.

Verifying materials and manufacturing process

- Brass with gold plating – balances conductivity and resistance to corrosion.

- Stainless steel housings – ideal for outdoor or aerospace use, offering higher tensile strength.

- PTFE dielectric – ensures stability across wide temperature ranges (-65°C to +165°C).

For antenna systems exposed to the elements, using an sma waterproof connector is essential. TEJTE’s IP67-rated designs include silicone rubber seals and gold-plated contacts, tested to withstand 1000V rms and maintain ≥5000 MΩ insulation resistance. Without these protections, even a small amount of moisture can degrade performance quickly.

How do I order SMA connectors from TEJTE?

Choosing the connector type, length, and custom requirements

- Pick the connector version you need: male, female, jack, or plug.

- Decide on orientation—straight or a sma right angle connector, depending on your layout.

- Match the connector to your coaxial type: RG316 or RG174 sma coaxial cable assemblies are common for compact wireless projects, while LMR-series works best for outdoor installations.

- For board-level designs, consider sma pcb connectors with through-hole or surface-mount options.

- Customization is available: tooth length, plating finish (gold, nickel, silver), logo engraving, and even small-batch runs for specialized antenna systems.

Lead time and after-sales support

- Quotation – provided quickly once connector type and cable requirements are confirmed.

- Lead time – typically 7–15 days, depending on order size and customization.

- Prototype sampling – available for validation before mass production.

- After-sales service – includes technical support and replacement if any manufacturing defects are found.

To streamline your process, you can order SMA connectors for custom solutions directly, or explore SMA coaxial cable assemblies suited for high-frequency performance.

FAQ

What is the difference between SMA male and SMA female connectors?

How do I choose the right SMA connector for my antenna system?

What are the common mistakes when selecting SMA connectors for RF applications?

How do I crimp an SMA connector correctly?

What materials should I consider when purchasing SMA connectors for outdoor use?

Can I use a right-angle SMA connector for tight spaces?

How do I verify the quality of SMA connectors before purchasing?

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.