SMA Extension Cable: RG316 vs RG316D, Loss & Ordering

Sep 28,2025

Shopping for a SMA extension cable isn’t as simple as picking a random length off the shelf. In RF systems, performance, durability, and flexibility all matter, and skipping the details often leads to headaches later.

You’ll hear people casually refer to these assemblies as SMA jumper cables or SMA patch cables, but those names hide important distinctions. In a 50 ohm coax setup, every connector and every centimeter of coax counts. A mismatched run can add unexpected SMA cable loss, sometimes just 1–2 dB at Wi-Fi or LTE bands. That may not sound like much, yet it can be the difference between a strong, clean link and a connection that drops every hour.

From my own experience, one of the most common mistakes is underestimating RG316 attenuation. A short extension might look harmless, but at 2.4 GHz or higher, losses pile up quickly. I’ve seen field teams blame antennas or routers, only to later discover the culprit was an overlong cable.

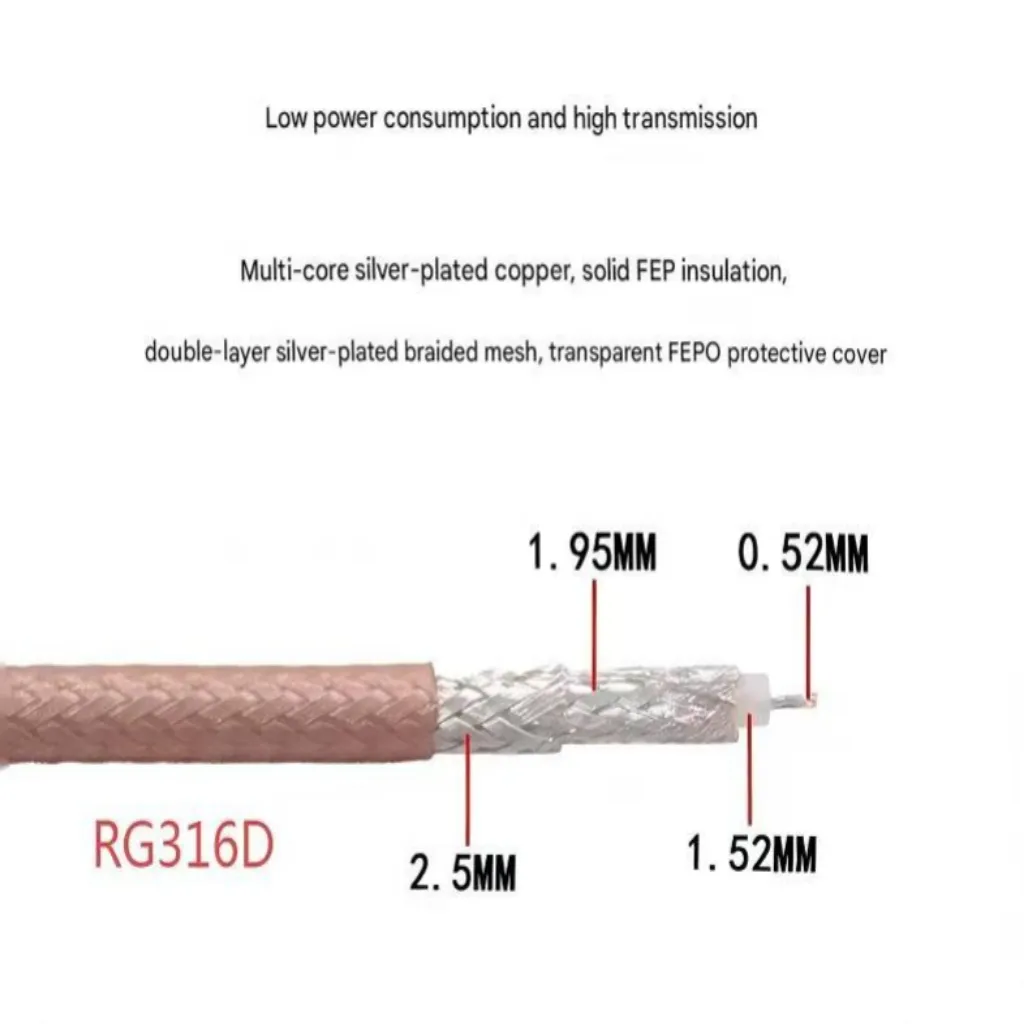

visually demonstrates the internal construction of the RG316 cable. It helps readers understand the layered materials (from outside to inside: jacket, shield, dielectric, conductor), which is crucial for evaluating its electrical performance (e.g., attenuation) and mechanical properties (e.g., flexibility).

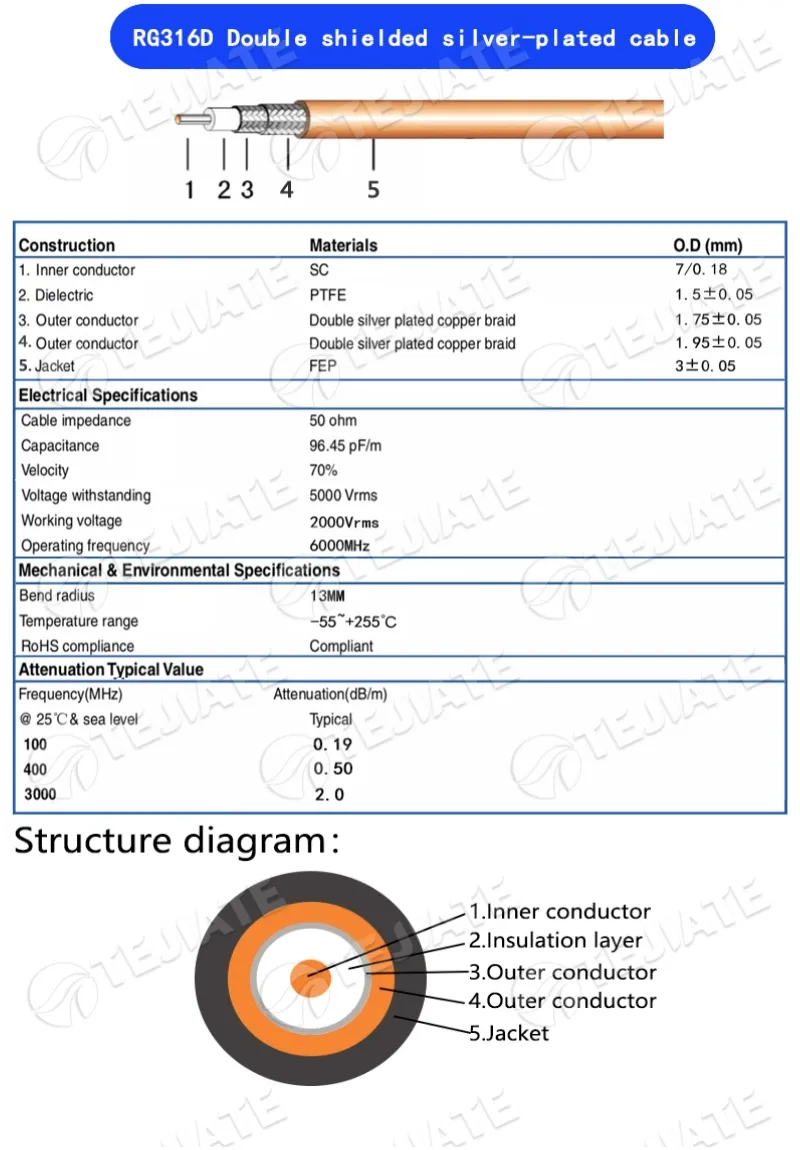

The document states that the key advantage of RG316D is its dual braid shielding, which provides better EMI rejection than RG316 (single braid) and a wider operating temperature range (-55°C to +255°C). The diagram should clearly show its dual-shield structure and slightly larger outer diameter (3.0mm) compared to RG316.

How do I choose between RG316 and RG316D?

Construction & materials (conductor, dielectric, braid, jacket)

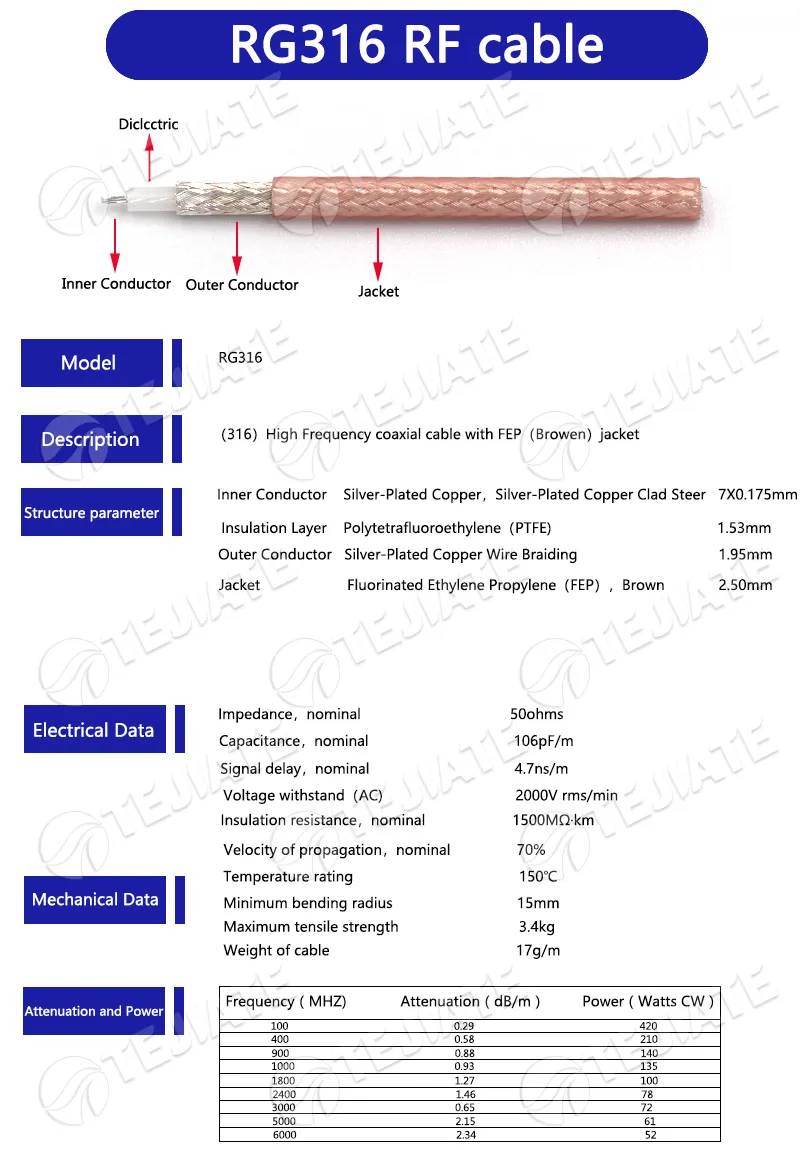

Provides a detailed cutaway view and tabulated specifications for the RG316 cable, including its inner conductor, dielectric, shielding, jacket materials, impedance, capacitance, attenuation values at various frequencies, power handling, mechanical data like bend radius, and temperature rating.

- RG316 cable

- Inner conductor: silver-plated copper or copper-clad steel, 7 × 0.175 mm

- Dielectric: PTFE, Ø 1.53 mm

- Braid: silver-plated copper, Ø 1.95 mm, ~95% coverage

- Jacket: FEP, brown, Ø 2.50 mm

- Typical attenuation: 0.88 dB/m @ 900 MHz, 1.46 dB/m @ 2.4 GHz, 2.34 dB/m @ 6 GHz

Illustrates the superior construction of RG316D cable, highlighting its dual silver-plated copper braid shielding, key electrical parameters (impedance, capacitance, voltage withstand), mechanical specs (tighter bend radius of 13mm, wider temperature range up to 255°C), and typical attenuation values compared to RG316.

- RG316D cable

- Inner conductor: silver-plated copper, 7/0.18 mm

- Dielectric: PTFE, Ø 1.5 mm

- Dual braids: two layers of silver-plated copper, Ø 1.75 + 1.95 mm

- Jacket: FEP, Ø 3.0 mm

- Typical attenuation: 0.50 dB/m @ 400 MHz, 2.0 dB/m @ 3 GHz

The key difference is shielding. RG316 has a single braid, while RG316D doubles it. That extra shield improves EMI rejection and helps reduce overall SMA cable loss, especially in noisy lab environments or industrial sites packed with RF sources. The tradeoff? RG316D is bulkier and less flexible, making it harder to route inside compact housings.

If you’re setting up a test bench with multiple SMA patch cables, RG316D might save you from unexpected interference creeping into your measurements. On the other hand, RG316 often wins in device integration where tight bends are required. From experience, I’ve learned that engineers who underestimate RG316 attenuation at higher frequencies often regret not running the quick math first.

For buyers comparing assemblies, TEJTE’s RF connector and cable range includes both RG316 and RG316D options, making it easier to align performance with cost and application needs.

alongside the "RG316 Cable" heading. It shows the actual appearance of this brand's RG316 cable for user identification and reference during procurement and installation. The document notes that RG316 is more flexible and suitable for compact spaces.

The document emphasizes that the key difference of RG316D is its dual braid shielding, which provides better EMI rejection but makes it bulkier and less flexible. The picture shows its physical form.

Numbers on a datasheet can look neat, but in practice they don’t always tell the full story. RG316 cable has a minimum bend radius of about 15 mm, while RG316D coax can bend slightly tighter at 13 mm. That difference might not sound like much, yet in a crowded housing, it can be the detail that keeps a cable intact rather than fractured at the braid.

Temperature ratings widen the gap even more. RG316 handles −55 °C to +150 °C, which is already respectable for Wi-Fi or LTE applications. But RG316D stretches the range to −55 °C to +255 °C, a serious advantage in outdoor enclosures exposed to sun, or in defense systems tested under extreme heat cycles.

One field note: bending RG316 below its rated radius can quickly add hidden SMA cable loss because the dielectric compresses unevenly. Over time, this worsens RG316 attenuation and leaves you scratching your head over rising VSWR. If you’re wiring up a set of short SMA patch cables on a lab bench, the flexibility of RG316 is welcome. For outdoor antennas in coastal air, though, RG316D paired with stainless connectors gives peace of mind.

A quick takeaway: RG316 bends easier and fits small spaces, but RG316D survives harsher conditions. Matching the cable to your layout isn’t just theory—it can prevent failure months later when a system is already in service.

What length keeps insertion loss within my limit?

Loss Estimator — Fields & calculation

Every extra meter of coax means more SMA cable loss, and ignoring that fact is one of the fastest ways to ruin system performance. The good news? The math isn’t complicated:

Loss_{dB} = \alpha(f) \times L

- f = frequency (MHz or GHz)

- L = length (m)

- α(f) = attenuation at that frequency (dB/m), specific to the cable type

With your measured data:

- RG316 @ 2.4 GHz: α = 1.46 dB/m

- RG316D @ 2.4 GHz: α ≈ 1.20 dB/m (extrapolated from 3 GHz curve)

For example, a 2 m SMA extension cable built with RG316 shows roughly 2.92 dB loss, while the same length in RG316D drops closer to 2.40 dB. That half-decibel might not jump off the page, but in weak-signal GNSS or long-distance IoT deployments, it can be the difference between stable operation and random disconnects. I’ve seen labs chasing “mystery” issues that turned out to be nothing more than underestimating RG316 attenuation over a slightly longer run.

Quick references at 900/2.4/5.8 GHz

| Frequency | Cable type | Loss @1 m (dB) | Max length <1 dB | Max length <2 dB |

|---|---|---|---|---|

| 900 MHz | RG316 | 0.88 | 1.1 m | 2.3 m |

| 900 MHz | RG316D | 0.70 | 1.4 m | 2.8 m |

| 2.4 GHz | RG316 | 1.46 | 0.7 m | 1.4 m |

| 2.4 GHz | RG316D | 1.20 | 0.8 m | 1.6 m |

| 5.8 GHz | RG316 | 2.34 | 0.4 m | 0.9 m |

| 5.8 GHz | RG316D | 2.00 | 0.5 m | 1.0 m |

below the loss reference table. The document suggests after the table that if loss exceeds the 1-2 dB limit, one should switch to a lower-loss option like LMR-200. This image represents that upgrade option.

As a rule of thumb: stay under 1 dB loss if precision matters, allow up to 2 dB in casual Wi-Fi setups. Go beyond that and you should either shorten the run or switch to a lower-loss option such as LMR-200. Remember, adding just one more SMA patch cable or adapter can push you over the line.

A simple tip: when you feel tempted to order “just a bit longer” than needed, check the chart first. It often saves both budget and headaches.

Should I pick straight or right-angle plugs (90°/45°/135°)?

Choosing between a straight SMA extension cable and an angled version isn’t just about space management. The connector geometry influences both stress on the cable and electrical performance. A straight plug minimizes discontinuities, often delivering the lowest VSWR and the most predictable results in long assemblies. That’s why they’re the default choice for test labs and sensitive RF chains.

That said, reality often complicates things. Anyone who has ever tried to squeeze a straight head into a packed chassis knows it can feel impossible. This is where angled plugs—90°, 45°, or even 135°—earn their keep. They redirect the cable path and prevent tight bends that could exceed the rated bend radius. For example, RG316 attenuation worsens if the cable is forced into a bend tighter than 15 mm. RG316D allows 13 mm, but repeated stress still adds up over time.

From experience, angled connectors are also a form of strain relief. Instead of bending the coax right behind the connector, the angle moves that stress point into the body. In portable setups or rigs where cables are plugged in and out daily, this simple change can extend service life dramatically. One engineer I worked with doubled the lifespan of his test harnesses just by switching a few straight heads to right-angle builds.

It’s worth noting that extra geometry does introduce minor mismatch. A single 90° plug usually won’t hurt, but stacking multiple adapters or chaining too many SMA patch cables can create ripple in the return loss. That ripple shows up as unexpected SMA cable loss in sensitive bands like 5.8 GHz. The takeaway? Use right-angle heads where you need them, but don’t build your entire chain from elbows.

For more guidance, TEJTE shares practical examples in its SMA right-angle adapter blog, which covers both mechanical routing and electrical trade-offs.

Do I need stainless-steel heads or brass gold-plated?

Connector materials are often treated as an afterthought, but in practice they can decide how long your SMA extension cable performs reliably. The two most common choices are brass with gold plating and stainless steel. Both work, but they behave differently once the cable leaves the datasheet and enters the field.

- Brass gold-plated: lightweight, low-cost, excellent conductivity. This is what you’ll find in most SMA patch cable builds for indoor Wi-Fi routers, LTE modules, or bench setups where conditions are mild.

- Stainless steel: tougher, corrosion-resistant, and more tolerant of repeated torque. These connectors are heavier and costlier, but they’ll easily survive over 500 mating cycles without noticeable wear.

Here’s where experience matters. In office environments, brass heads usually hold up fine. But in coastal deployments or outdoor IoT enclosures, corrosion sneaks in quickly. A brass connector that looks shiny on day one may start showing oxidation within months, and that can raise VSWR and add hidden SMA cable loss. Stainless steel, paired with proper O-rings, keeps the interface stable even under salt spray or heavy condensation.

Weight and torque tolerance also play a role. Stainless connectors handle higher tightening forces, making them less likely to strip. If you’ve ever damaged threads during installation, you’ll know how frustrating—and expensive—that mistake can be. In ruggedized builds, especially those running RG316D cable for its wider temperature range, stainless steel is usually the safer long-term bet.

A quick takeaway: brass is fine for light-duty and cost-sensitive setups; stainless is for environments where reliability matters more than saving a few grams. Choosing wisely at this step prevents headaches later when troubleshooting rising VSWR or unexplained RG316 attenuation in the system.

For more details, TEJTE highlights material options in its RF connector assemblies, showing how connector choice aligns with both budget and environment.

How do I avoid SMA vs RP-SMA mix-ups?

It’s surprisingly easy to confuse SMA and RP-SMA connectors, especially when you’re rushing through procurement or field assembly. At a glance they look nearly identical, but the reversed polarity means they will not mate properly. Get it wrong and your brand-new SMA extension cable may never even connect to the device.

The basics are simple enough:

- SMA male → outer thread with an inner pin

- SMA female → inner thread with a socket

- RP-SMA male → outer thread but no pin

- RP-SMA female → inner thread with a pin

That tiny change is what creates most headaches. Routers and consumer Wi-Fi gear usually use RP-SMA antenna ports, while lab instruments and RF modules tend to stick with standard SMA. If you’re setting up a network using several SMA patch cables, confirm port type first. A five-second visual check saves hours of frustration and the cost of extra adapters.

discussing the common confusion between SMA and RP-SMA. The diagram clearly shows the center pin and socket configuration of the four connector types (SMA Male/Female, RP-SMA Male/Female), serving as a practical reference for quick polarity identification. The document emphasizes that wrong polarity prevents mating and can be mistaken for cable loss.

Another tip from experience: when engineers mismatch connectors, they sometimes blame rising SMA cable loss or unexpected RG316 attenuation in the test results. In reality, the signal isn’t even flowing correctly because of the wrong gender/polarity combination. Always check polarity before assuming the coax is at fault.

If mistakes do happen, keep adapter cascades to a minimum. While an SMA-to-BNC or SMA-to-N adapter can be useful in moderation, stacking too many links adds real insertion loss. A cleaner path is always preferred. TEJTE’s BNC/N/TNC to SMA adapter guide walks through practical solutions for bridging standards without building a fragile adapter chain.

For quick polarity ID, TEJTE’s SMA connector reference includes visual guides and port examples. Keeping such references handy helps procurement teams avoid common ordering errors.

Do I need an extension or a jumper/patch instead?

Terminology & connection sketches

The words “extension” and “jumper” often get tossed around like they mean the same thing, but in RF cabling they have different jobs.

- Extension cable → usually male–female, meant to increase the distance between an antenna and a device.

- SMA patch cable / jumper cable → often male–male, designed to bridge test equipment, filters, or splitters.

Think of an extension as a distance stretcher, while a jumper is a link between instruments. Both rely on the same coax—often RG316 or RG316D—but getting the ends wrong can force you into adding adapters. That, in turn, adds extra SMA cable loss that could have been avoided.

From experience, many engineers use the term SMA patch cable casually during testing and forget to specify connector genders in their orders. This is how unnecessary returns or “wrong cable” complaints pile up. Spending an extra minute on drawings or spec sheets saves both budget and project time.

When to use a bulkhead feed-through

in the "When to use a bulkhead feed-through" section. The document explains that when passing a cable through an enclosure wall, using a bulkhead feed-through (rather than a simple extension or jumper) is the proper choice. It provides secure mounting, environmental protection (dust/water resistance), and avoids stress on the cable, thereby preventing increased attenuation due to poor installation.

Sometimes neither an extension nor a jumper is ideal. For example, when you need to cross an enclosure wall, the proper choice is a bulkhead SMA feed-through. It comes with a threaded barrel, O-ring, and nut, making the installation secure and weather-resistant.

This approach is common in outdoor IoT gateways or ruggedized industrial controllers. Instead of bending a delicate RG316 cable through a hole and stressing its braid, the bulkhead connector provides a stable mounting point. It not only prevents water ingress but also avoids hidden stress that could increase RG316 attenuation over time.

A quick tip: if you ever find yourself tightening down a cable gland just to pass a jumper through, that’s the moment to consider a bulkhead connector instead. TEJTE offers bulkhead SMA assemblies that pair neatly with RG316 and RG316D to keep both mechanical stability and RF performance intact.

What specs must I submit before ordering?

Length tolerance, ends, torque, O-rings, IP rating

Placing an order for a SMA extension cable is not just about quoting the length. Vendors need precise details to avoid misbuilds, and skipping them often leads to costly delays. A good purchase order should include:

- Length and tolerance — for example, 1.0 m ± 10 mm. Without tolerance, manufacturers may deliver cables slightly short or long.

- Connector ends — SMA male to female for extensions, SMA male to male for SMA patch cable builds, or RP-SMA versions if your device requires them.

- Torque requirements — whether installers will use torque wrenches or rely on hand-tightening.

- Sealing options — O-rings, IP67/68 dust caps, or waterproof boots for outdoor systems.

- Special notes — color-coded jackets, serial tags, or specific routing labels for test harnesses.

Skipping even one of these can cause back-and-forth emails or, worse, a batch of cables that doesn’t fit. I’ve seen teams lose a week in lab schedules simply because they forgot to specify polarity. If you’re not sure which spec to include, TEJTE’s ordering reference for SMA assemblies outlines the most common configurations.

Compliance & lot traceability

For industries where reliability is non-negotiable, the specs don’t stop at dimensions. A proper RF cable supplier should also document and track every batch:

- Incoming material control — each roll of RG316 or RG316D coax logged with a lot ID.

- Factory acceptance tests — insertion loss and VSWR checks at 2.4 GHz and 5.8 GHz.

- Batch records — lot number engraved or printed on the cable jacket.

- Documentation — crimp height, pull test, and torque values stored for each production run.

These steps make it possible to trace back anomalies. For instance, if a set of cables starts showing abnormal RG316 attenuation, the supplier can isolate which batch is responsible. It’s far more efficient than blaming general SMA cable loss after deployment.

Tip from practice: when rolling out a new wireless product line, always request sample reports first. A few extra pages of QC data can prevent expensive downtime in the field. TEJTE covers these traceability measures in their RF connector QC process, giving procurement teams confidence before committing to volume orders.

How do I accept a compliant 50-ohm extension?

When a shipment of SMA extension cables arrives, don’t just rely on the paperwork. A quick acceptance check is the only way to confirm the lot truly meets spec. Here’s a practical checklist used by many RF engineers:

- Impedance: 50 ± 2 Ω

- Frequency rating: up to 6 GHz for RG316 / RG316D

- VSWR: ≤1.25 @ 6 GHz (≤1.10 typical at 2.4 GHz)

- Insertion loss: ≤1.5 dB/m @ 2.4 GHz (compare against the expected run length)

- Mechanical pull test: ≥0.28 N retention force on the contacts

- Crimp height check: measure with micrometer; avoid under- or over-crimping

- Labeling: cable marked with lot or batch ID for traceability

- Visual inspection: no jacket cracks, no exposed braid, plating consistent

One overlooked detail is labeling. If your lab racks are full of SMA patch cables, unlabeled lengths can easily get swapped. A two-second check of markings on delivery saves hours of troubleshooting later.

Red-flag symptoms and fixes

Certain failure signs should never be ignored. Unexpected peaks in return loss curves often point to poor crimps or connectors not seated properly. If a cable fails a pull test, don’t shrug it off—reject it right away. Similarly, cracks in the jacket or slight braid exposure might look minor, but they usually lead to premature failure once the cable is bent a few times.

I’ve seen engineers blame “mysterious SMA cable loss” or rising RG316 attenuation during testing, only to find out the culprit was a bad crimp from the supplier. That’s why aligning your acceptance steps with the vendor is crucial. TEJTE’s RF extension cable QA process outlines these measures in detail, helping procurement teams prevent avoidable issues before cables go into service.

What should I watch for in Wi-Fi/LTE/GNSS/IoT?

Practical loss ceilings by band

Different wireless systems tolerate loss very differently. A 50 ohm SMA cable might look universal, but the acceptable ceiling depends heavily on frequency and application.

- Wi-Fi (2.4 GHz / 5.8 GHz): try to keep total extension loss under 2 dB. More than that and your SNR margin drops quickly, especially in long-range links.

- LTE / 5G sub-6 GHz: telecom gear is stricter, often requiring ≤1.5 dB loss at the band of interest. That’s not easy with RG316 if you run more than 1 m.

- GNSS (1.5 GHz): GPS and BeiDou signals already arrive near the noise floor. Here, <1 dB is the practical ceiling, even on short SMA patch cables.

- IoT bands (433 / 868 / 915 MHz): more forgiving, but low-cost modules often lack strong front ends. Keeping insertion loss <2 dB is still smart practice.

A quick reminder from field setups: ignoring RG316 attenuation at higher frequencies is one of the most common mistakes in IoT gateways. Teams order 3 m cables because “it doesn’t look that long,” only to discover the extra length eats half the link margin.

Enclosure pass-through & grounding

Performance isn’t just about the coax. The way you bring the line into an enclosure or rack can change the results more than you’d expect. Passing through a metal housing without proper grounding creates mismatch and sometimes even EMI leakage.

The correct approach is a bulkhead SMA feed-through with an O-ring seal. This keeps impedance stable, blocks water ingress, and avoids stress points that would otherwise accelerate jacket wear. Even a perfect cable can show unexpected SMA cable loss if mounted poorly.

Practical tip: always torque the bulkhead nut correctly and clean the panel surface. A loose fit may create ripple in your return loss that looks like “mystery interference.” TEJTE’s SMA bulkhead options are designed to maintain stability both indoors and in harsh outdoor housings.

Order now: how to configure and submit at TEJTE

5-step flow + links

When it’s time to move from planning to purchase, clarity is everything. A messy order slows production and risks errors. A clean five-step flow works well:

- Select the cable type — RG316 for flexible routing, RG316D when you need stronger shielding or higher temperature tolerance. Don’t forget that RG316 attenuation rises quickly above 2.4 GHz, so pick carefully.

- Define the length — include tolerance (e.g., 2 m ± 1 cm). Even small variations can affect rack layouts.

- Choose connector ends — SMA male-to-female is standard for extensions, SMA male-to-male for SMA patch cable test links, and RP-SMA when your device ports require it.

- Add sealing options — O-rings, IP67/68 gaskets, or weather caps for outdoor builds.

- Submit inspection notes — specify acceptable VSWR, insertion loss, and labeling requirements.

All of these can be configured directly through TEJTE’s SMA extension cable ordering page, so your build matches both performance and environmental needs without unnecessary back-and-forth.

Lead time, QC sampling, after-sales

Most assemblies are ready within 7–10 business days, depending on customization. For large orders, suppliers typically apply an AQL sampling plan—for example, 5% of units tested for insertion loss, VSWR, and pull strength before shipping. This helps catch problems early, instead of letting them appear during deployment.

On delivery, TEJTE supports customer acceptance checks based on the same QC data. If any batch shows abnormal SMA cable loss or unexpected spikes in RG316 attenuation, replacements are arranged with full traceability back to the lot number. That transparency is particularly useful for integrators managing nationwide rollouts.

A quick note from practice: procurement teams often overlook after-sales terms until an issue arises. Clarifying warranty, replacement conditions, and documentation needs upfront saves stress later. For additional guidance, TEJTE’s SMA connector selection blog links to related assemblies such as right-angle and adapter types, so you can keep your system planning consistent.

FAQ

Q1: At 2.4 GHz, what’s the longest RG316 extension before loss exceeds 1 dB?

A 1 m run of RG316 already shows ~1.46 dB loss at 2.4 GHz. To keep under 1 dB, limit the length to about 70 cm. If you need longer, consider RG316D or a lower-loss coax such as LMR-200.

Q2: Is RG316D a better pick when my layout has several 90° turns?

Yes. Its dual shielding and slightly smaller bend radius (13 mm vs 15 mm for RG316) make it more forgiving in tight layouts. That said, every sharp turn still adds stress and potential SMA cable loss, so avoid excessive bends.

Q3: How can I tell SMA vs RP-SMA quickly when kitting extensions?

Look for the pin. SMA male has a center pin, while RP-SMA male does not. Many Wi-Fi routers use RP-SMA, while test instruments stick to standard SMA. A quick visual check saves you from mismatched SMA patch cables.

Q4: Will a right-angle plug noticeably worsen VSWR on an extension run?

A single 90° head generally has minimal impact, keeping VSWR within spec. Problems arise when multiple angled connectors or adapters are cascaded, which increases reflections and ripple.

Q5: Do stainless-steel SMA heads change electrical performance compared with brass?

Electrically, both materials perform nearly the same. The real difference is in durability, torque tolerance, and corrosion resistance. Stainless is recommended in outdoor or high-cycle use.

Q6: When should I switch from an extension cable to a bulkhead feed-through?

If you’re passing through an enclosure wall or chassis, a bulkhead feed-through is always the cleaner solution. It maintains shielding and prevents stress on the coax that could increase RG316 attenuation over time.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.