SMA Bulkhead Connector: Panel Mount, Flange Types & Waterproof Use

Sep 19,2025

Pick the right SMA bulkhead for your panel

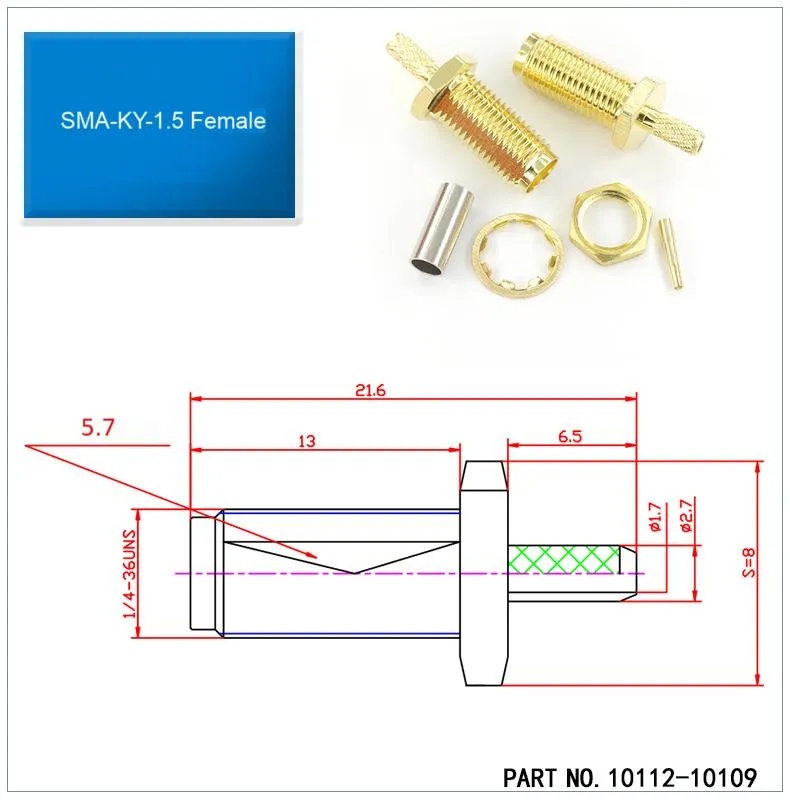

The image illustrates SMA bulkhead connectors designed for panel mounting, comparing nut-mounted and flange-mounted types, and highlighting different thread depths to match housing thickness.

Selecting the right SMA bulkhead connector goes beyond thread size—it’s about ensuring the connector fits your housing securely and keeps signal integrity stable over time. Most models use the standard 1/4-36UNS-2A thread, but not all threads are created equal. A 6.8 mm version may be fine for a thin plastic panel, while thicker or painted housings often call for 13 mm or even 23 mm bulkheads. A simple coating of paint or anodizing, often just 0.1–0.3 mm, can unexpectedly reduce the available thread depth, leaving you short when tightening the nut.

Designers usually compare two mounting methods. A nut-mounted round-hole bulkhead is simple, inexpensive, and widely used in routers or compact IoT devices. By contrast, a 2-hole or 4-hole flange bulkhead distributes torque across the panel, keeps the O-ring evenly compressed, and prevents the connector from twisting loose—an upgrade you’ll appreciate once you’ve had to replace a loose port in the field.

Connector gender matters too. The SMA female bulkhead connector is the workhorse in Wi-Fi access points, gateways, and CPE devices, while the SMA male bulkhead connector is often specified in RF testing setups or specialized modules. If your design requires a pass-through, a jack-to-jack bulkhead coupler makes life easier by linking an inside pigtail to an outside antenna cable, sparing the PCB-mounted jack from mechanical stress.

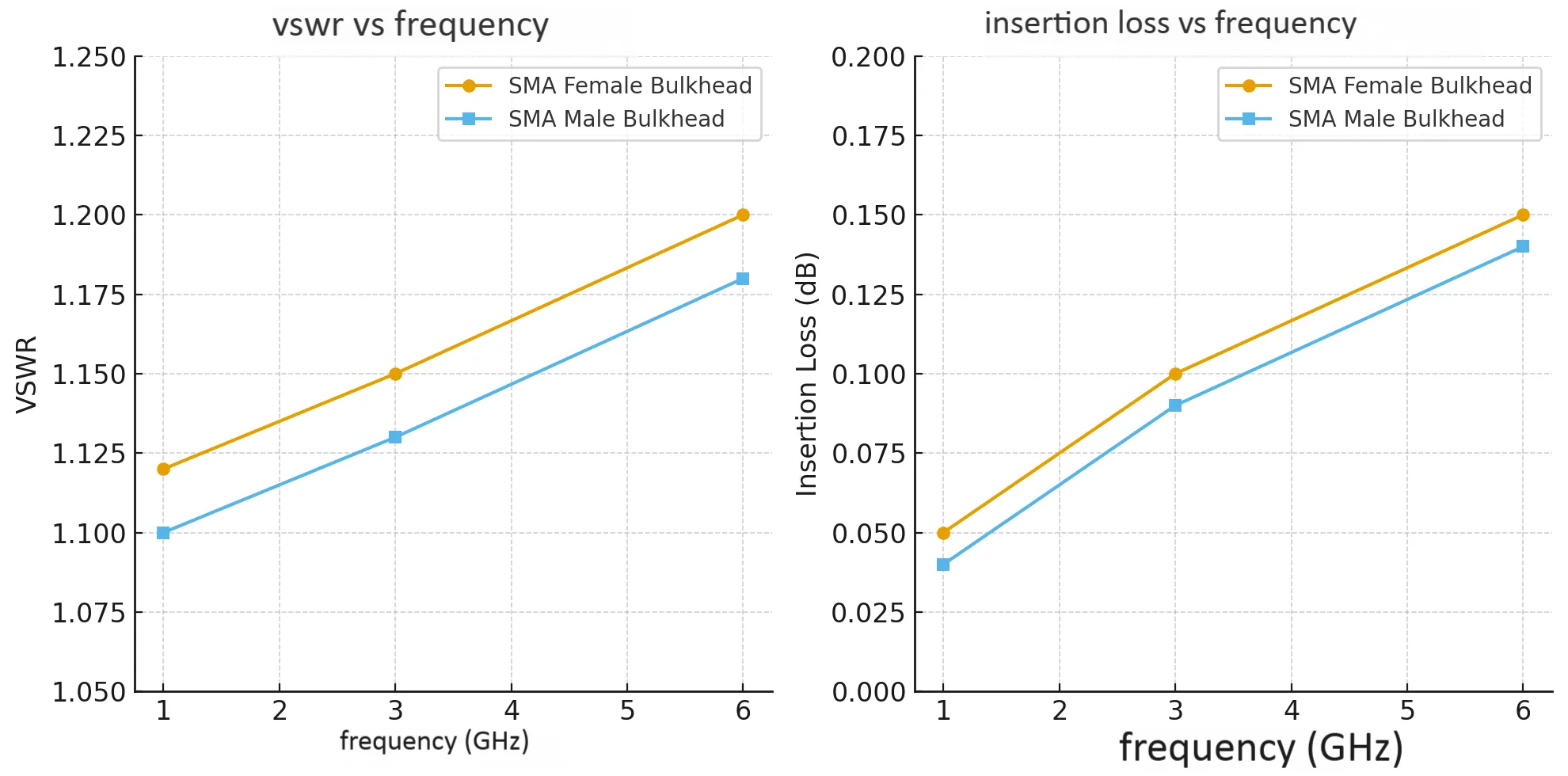

Performance specs reinforce these choices. Many TEJTE bulkhead models operate from DC–6 GHz, with higher-grade versions extending to 18 GHz. Typical results show VSWR ≤1.20 and insertion loss around ≤0.15 dB at 6 GHz, more than sufficient for networking gear. On the mechanical side, brass-gold versions usually last ≥500 cycles, while stainless steel bulkheads handle ≥1000 cycles. From experience, overspecifying a little here pays off—passing compliance testing is good, but a connector that survives years of real-world use is even better.

Should you ground an (RP-)SMA bulkhead connector?

Whether an SMA bulkhead connector should be grounded directly to the chassis or left isolated is a question every RF engineer faces sooner or later. For most metallic housings, the default is grounding. Tightening the nut and washer against bare metal provides a low-impedance path, helping suppress EMI and stabilize the signal return. That’s why you’ll often find grounded bulkheads in network gateways, outdoor CPE units, and industrial routers.

But real-world enclosures aren’t always bare metal. A powder-coated panel or anodized finish may look neat but can create an insulating layer—sometimes just 0.1 mm thick—that breaks electrical contact. In those cases, installers often rely on a serrated star washer or a dedicated grounding ring to bite through the coating. It’s a small detail, yet skipping it can leave the connector “floating” and cause unpredictable EMI issues.

There are times when isolation is not only acceptable but preferred. In multi-board systems or when multiple antennas share the same housing, isolating the RP-SMA bulkhead connector with an insulating washer prevents ground loops. This keeps signals cleaner and reduces the risk of coupling noise between circuits. From field experience, it’s often safer to start isolated if you’re unsure, then intentionally ground only where needed.

For a broader perspective on grounding practices across connector types, TEJTE’s RF connector guide breaks down how plating, hardware, and mounting methods can influence both mechanical fit and electrical behavior.

What is an SMA bulkhead connector?

The image shows an SMA bulkhead connector assembled through a panel, secured with nut and washer, and sealed with an O-ring for waterproofing, making it both an electrical feed-through and mechanical anchor.

An SMA bulkhead connector is essentially an SMA interface extended with mounting hardware so it can pass through a panel or enclosure wall. Instead of being soldered directly onto a PCB, the connector slides into a drilled opening and locks into place with a nut, washer, and often a silicone O-ring for sealing. This design turns the connector into both an electrical feed-through and a mechanical anchor.

They are available in multiple forms, including the SMA female bulkhead connector and the SMA male bulkhead connector, as well as jack-to-jack couplers for pass-through applications. The female type is widely used in networking gear such as routers or CPEs, while male versions are common in test instruments and RF modules. Bulkhead couplers, on the other hand, make it easy to connect an internal pigtail to an external antenna cable without putting stress on fragile PCB-mounted jacks.

Waterproof versions add another layer of reliability. With an O-ring compressed by 10–25%, they can achieve IP67 protection, keeping dust and water out of the enclosure. When combined with brass-gold or stainless-steel housings, these connectors can withstand ≥500 to 1000 mating cycles, making them suitable for outdoor or long-term industrial use.

From experience, the “bulkhead” detail that engineers sometimes overlook is thread length. A 6.8 mm thread might work fine on a thin aluminum plate, but painted or multi-layered panels often require 13 mm or 23 mm bulkheads to ensure the nut fully engages while still compressing the O-ring. Skipping that check can lead to leaks or loose fittings that only show up once the unit is deployed in the field.

When do you need a waterproof SMA bulkhead outdoors?

Once your device leaves the lab and faces rain, dust, or condensation, a waterproof SMA bulkhead is no longer optional—it’s essential. Unsealed connectors can quickly corrode, raising VSWR, degrading insertion loss, and shortening service life. Even a tiny amount of moisture creeping into the interface is enough to disrupt performance.

The most reliable outdoor bulkheads use a silicone O-ring compressed by 10–25% to seal against the panel surface. TEJTE’s extended-thread designs—ranging from 14 mm to 23 mm—are built to accommodate thicker housings and stacked gaskets while still maintaining proper sealing. When installed correctly, they achieve IP67 protection, keeping out both water and dust during years of field use.

It’s worth noting that not every connector marketed as “outdoor-ready” truly meets the requirement. A simple nut-and-flat washer may resist splashes in the short term, but won’t hold up on a pole-mounted 5 GHz CPE, outdoor camera, or wireless bridge exposed to heavy rain. For these applications, choosing a connector rated for ≥500–1000 mating cycles with brass-gold or stainless housings makes the difference between reliable operation and recurring failures.

From hands-on experience, one small but important habit is to check O-ring compression after tightening. If it looks uneven or loose, it’s better to adjust immediately than discover the problem after the first storm. For additional outdoor design practices, the WiFi antenna extension cable guide offers useful insights into sealing and connector selection in weather-exposed networks.

Compare panel-mount vs 2-/4-hole flange for enclosure design

When integrating an SMA panel mount connector into an enclosure, you’ll often have to choose between the standard nut-and-washer design or a sturdier SMA flange connector. This choice isn’t trivial—it directly impacts sealing performance, torque resistance, and how easy it will be to service the device later.

The classic round-hole panel-mount bulkhead requires only a drilled opening (typically Ø6.2–6.5 mm) and secures with a hex nut. It’s cost-effective, fast to assemble, and widely used in consumer devices like routers or IoT hubs. But under vibration, the nut may loosen, and once that happens, both the O-ring compression and RF stability can degrade. A quick field fix is adding a star washer, but it’s not always foolproof.

In contrast, the 2-hole and 4-hole flange SMA bulkhead connectors spread torque across a flat mounting base. This prevents twisting, ensures consistent O-ring compression, and keeps alignment even under stress. The 4-hole flange offers another benefit: servicing is straightforward. Instead of disturbing the entire housing, you can simply unscrew the flange and replace the connector. That’s why outdoor telecom gear and pole-mounted CPEs often rely on flange types despite the slightly higher cost.

In practice, engineers frequently use both. A nut-mounted panel-mount connector works well for lightweight enclosures, while 4-hole flange connectors dominate in rugged outdoor installations. If you’re comparing connector families more broadly, TEJTE’s RF connector overview gives additional context on how flange vs panel-mount styles fit into the bigger picture of RF design.

Do male vs female bulkhead choices change RF performance?

At first glance, choosing between an SMA female bulkhead connector and an SMA male bulkhead connector seems like a matter of fit rather than performance. Electrically, both are designed for a 50-ohm impedance and can be specified across wide frequency ranges—DC–6 GHz, 18 GHz, and up to 26.5 GHz depending on construction. Still, subtle material and plating differences can influence long-term stability.

- Brass with gold plating is the most common option. It combines good conductivity with corrosion resistance, keeping insertion loss around ≤0.15 dB at 6 GHz.

- Stainless steel housings are stronger and ideal for rugged environments. They handle ≥1000 mating cycles but may introduce slightly higher insertion loss compared to brass-gold connectors.

- VSWR performance tends to be similar, but high-grade female jacks often hold VSWR ≤1.20 up to 6 GHz, while precision male types are favored in lab instruments where even minor mismatches matter.

For everyday applications such as routers, CPEs, or smart gateways, the difference between male and female bulkhead connectors is minimal. What matters more is ensuring the right thread length for your panel and a proper O-ring seal for outdoor use. Engineers often note that mistakes happen less from connector gender and more from mixing SMA vs RP-SMA polarity, which can stop a project cold.

If you’d like a broader view on how connector types affect system behavior, TEJTE’s SMA vs BNC vs N-Type guide explains how gender, plating, and frequency ratings all tie into VSWR stability and real-world RF performance.

Can a bulkhead coupler serve as an in-panel adapter?

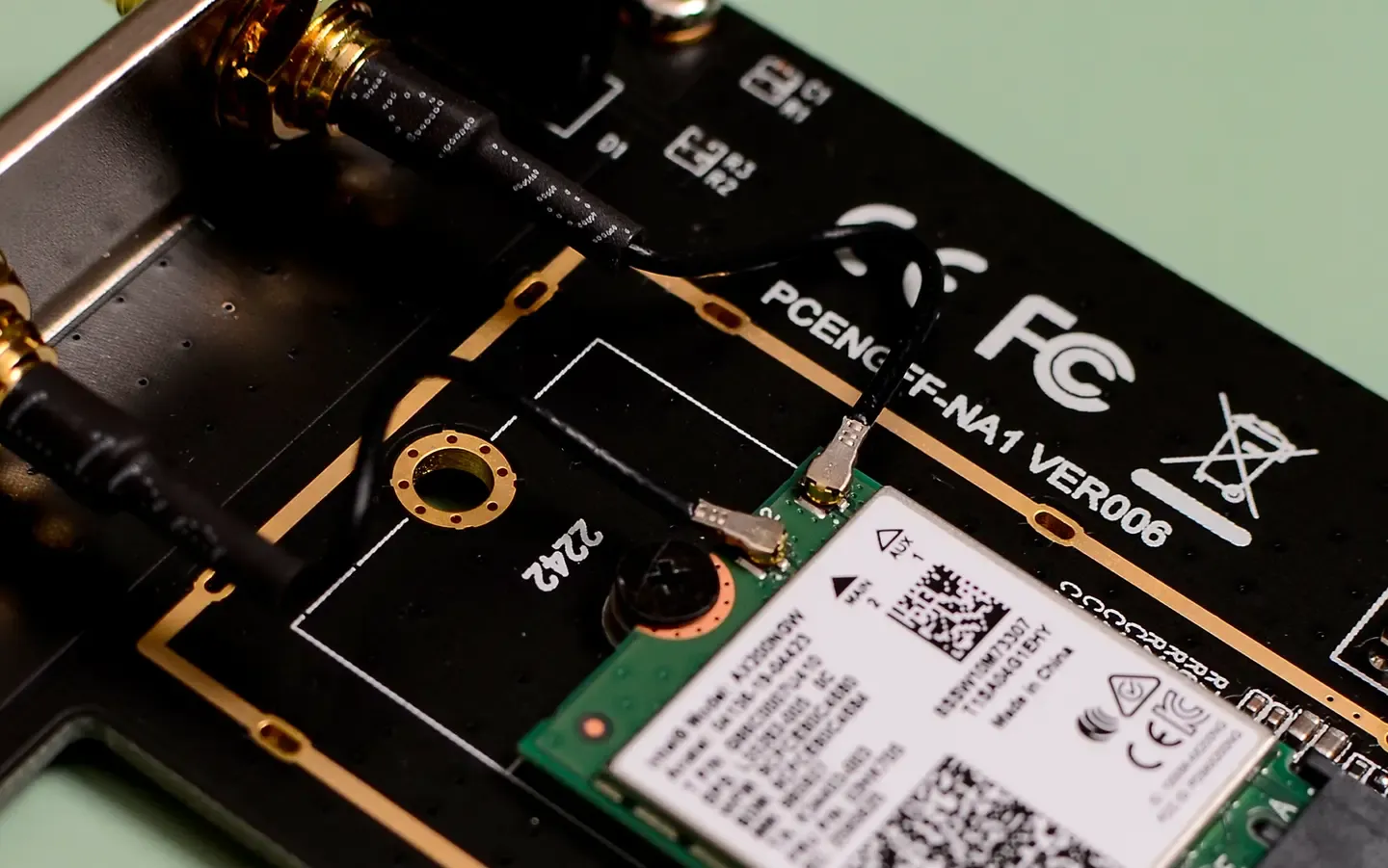

The image presents an SMA bulkhead coupler adapter, allowing short internal pigtails to connect with external antenna cables. It reduces PCB stress and enables easy servicing.

Yes. In many designs, an SMA bulkhead adapter is the simplest way to bridge internal and external RF connections. Instead of routing a long coax across the enclosure, you mount a jack-to-jack bulkhead coupler through the panel. Inside, a short pigtail connects to the module; outside, an antenna cable attaches. This setup reduces stress on the PCB-mounted SMA bulkhead jack, prevents sharp bends, and makes future servicing easier.

Take Wi-Fi modules as an example. An internal U.FL-to-SMA pigtail often links to the inside of a female-to-female bulkhead coupler, while the outer side connects to the antenna. For test systems, engineers sometimes use F-M (jack-to-plug) bulkhead couplers so instruments can tap directly into the RF chain without altering the internal cabling.

Performance is usually excellent. High-quality couplers maintain insertion loss ≤0.15 dB at 6 GHz and VSWR ≤1.20. At higher frequencies, such as 18 or 26.5 GHz, the added loss becomes more noticeable but still small compared to long cable runs. For outdoor equipment, waterproof couplers with silicone O-rings achieve IP67 sealing, making them suitable for routers, outdoor CPEs, or security cameras.

A practical note: bulkhead couplers also act as mechanical relief points. By anchoring the connection at the panel, they protect delicate board-mounted connectors from torque and pull. TEJTE often integrates this approach in its custom RF adapter cable solutions, pairing couplers with RG316 or RG174 jumpers for flexible routing. Done right, the coupler becomes both a signal bridge and a safeguard, improving durability without complicating the design.

Size thread length to panel thickness and gaskets

Before ordering an SMA bulkhead connector, it’s critical to check whether the thread length matches the total thickness of your panel and sealing hardware. A thread that’s too short won’t allow the nut to fully engage, while one that’s too long reduces O-ring compression and may leave the seal ineffective. Both issues can lead to poor grounding, loose fittings, or water ingress.

Here’s a practical Panel Stack & Grounding Calculator that engineers often use to avoid mismatches:

| Field | Description | Example Value |

|---|---|---|

| Panel Thickness (mm) | Raw wall thickness | 2.0 mm (aluminum) |

| Finish Thickness (mm) | Paint / anodizing | 0.2 mm |

| Washer Total (mm) | Flat + spring + insulating washers | 1.0 mm |

| Nut Engagement (mm) | Minimum secure thread engagement | ≥2.0 mm |

| O-ring Compression (mm) | Targeted 10–25 % of gasket thickness | 0.5 mm |

| Product Thread Length (mm) | Spec from datasheet | 6.8 mm |

| Required Thread Length | Sum of above | 5.7 mm |

| Pass/Fail | If Required ≤ Product Thread Length → Pass | Pass ✔ |

As a quick guideline, 6.8 mm bulkheads usually work for thin enclosures, while 13 mm or 23 mm versions are safer choices for thicker housings or panels with layered finishes. If you’ve ever had to re-drill or replace a connector because the nut barely caught the thread, you know how frustrating it can be. Spending a few minutes on this calculation saves hours of rework later.

For more on how bulkhead dimensions interact with enclosure design, you can refer to TEJTE’s RF connector families overview. It shows how panel mounting, flange options, and sealing techniques all tie back to long-term RF performance.

Install an SMA bulkhead correctly: tighten, seal, and verify

Even a high-quality SMA bulkhead connector can fail in the field if it’s installed poorly. Proper installation isn’t about speed—it’s about consistency and care. Both the SMA male bulkhead connector and the SMA female bulkhead connector require the same basic steps, but the details matter more than many engineers expect.

Here’s a proven sequence that balances mechanical security with electrical reliability:

- Prepare the hole – deburr the panel edges. Sharp edges can slice into the O-ring or plating, reducing sealing and lifespan.

- Position the seal – place the silicone O-ring (for waterproof types) or insulating washer (for isolated installs). Aim for 10–25% compression for IP67-rated sealing.

- Hand-tighten first – align threads carefully and finger-tighten the nut. This prevents cross-threading, which is one of the most common field mistakes.

- Torque to spec – apply the recommended 0.45–0.56 N·m torque. Too little leaves the assembly loose; too much can strip threads or crush the dielectric.

- Add anti-rotation – use star washers or choose a flange version if vibration is expected. This stops the connector from backing off over time.

- Final checks – confirm O-ring compression, inspect grounding or isolation, and run a quick VSWR test to ensure return loss is within spec.

Skipping any of these steps can lead to intermittent failures—leakage in outdoor setups, or higher VSWR in lab conditions. A good habit is to retighten and recheck after the first 48 hours of operation, especially for outdoor equipment that faces temperature swings.

For a broader perspective on connector reliability, the SMA vs BNC vs N-Type guide explains how different connector families hold up under repeated mating and environmental stress.

Reduce VSWR and leakage with proper materials and plating

The chart illustrates how SMA bulkhead connectors maintain low insertion loss (≤0.15 dB) and stable VSWR (≤1.20) across operating frequencies from DC up to 6 GHz or higher, ensuring reliable RF performance.

The choice of material and plating in an SMA bulkhead connector can make or break long-term performance. Two parts may share the same drawings and thread size, but their behavior under stress, moisture, or repeated use can differ dramatically.

- Brass with gold plating – the industry standard. It provides excellent conductivity, stable impedance, and insertion loss values typically ≤0.15 dB at 6 GHz. For indoor networking equipment, this balance of cost and performance is hard to beat.

- Stainless steel housings – ideal when durability and corrosion resistance are critical. These versions withstand ≥1000 mating cycles without thread wear, making them a favorite for outdoor CPEs and telecom gear. The trade-off is slightly higher insertion loss compared to brass-gold versions.

- Nickel-plated shells – affordable and robust in dry environments, but less reliable in salt spray or high-humidity conditions. They are better suited for indoor devices or low-cost applications.

Insulator choice also matters. PTFE supports impedance stability over wide temperature ranges, while silicone O-rings block moisture without altering RF behavior. When specified correctly, a bulkhead can maintain VSWR ≤1.20 across wide bands, ensuring clean signal reflections and consistent throughput.

From experience, failures rarely occur in the lab—they happen months later in the field, when humidity or corrosion sets in. That’s why engineers often request connectors tested under salt fog or high-humidity cycles, not just GHz sweeps. TEJTE emphasizes this durability factor in its custom RF adapter cable solutions, where connector plating and materials are matched to real-world deployment needs.

The bottom line: plating and material selection isn’t cosmetic. It directly impacts how well your SMA bulkhead performs in harsh environments and how long it maintains spec without drifting.

Avoid RP-SMA vs SMA mix-ups before checkout

The image explains how SMA and RP-SMA bulkhead connectors look similar but differ in polarity: SMA female has a socket, RP-SMA female has a pin. Misidentification leads to installation errors.

Few mistakes cause as much frustration as confusing an SMA bulkhead connector with an RP-SMA bulkhead connector. Both share the same 1/4-36UNS-2A thread and look nearly identical from the outside, yet their center contacts are reversed.

- A standard SMA female bulkhead connector has a socket that mates with a male pin.

- An RP-SMA female bulkhead instead carries a center pin, flipping the usual gender rule.

That tiny difference can halt an installation. It’s not uncommon for a technician to discover, halfway through mounting an antenna, that the connector doesn’t fit—even though the threads match perfectly. The result? Project delays, unnecessary returns, and frustrated customers.

Here’s a quick checklist before you place an order:

- Verify gender (male pin vs. female socket).

- Confirm polarity (SMA vs. RP-SMA).

- Check thread length matches the panel stack (6.8 / 13 / 23 mm as needed).

- Ensure the kit includes nut, washer, and O-ring if waterproofing is required.

- Match the frequency rating (DC–6 / 18 / 26.5 GHz depending on the application).

From field experience, most mix-ups happen not at the design stage but during procurement. A mislabeled line item can result in dozens of unusable connectors. The easiest safeguard is to double-check datasheet drawings or use product listings like TEJTE’s shop SMA bulkhead connectors, which clearly show polarity and gender.

If you’d like to see how polarity errors impact real deployments, the WiFi antenna extension cable guide highlights why SMA vs. RP-SMA mismatches are among the top installation issues in wireless networks.

Frequently Asked Questions (FAQ)

Can an RP-SMA bulkhead be chassis-grounded, or should it be isolated?

Both methods are used. Grounding the RP-SMA bulkhead connector directly to a metal chassis suppresses EMI and stabilizes return paths. Isolation with washers, on the other hand, prevents ground loops in multi-board systems. The right choice depends on your overall grounding plan.

How do I choose thread length for a painted or thick aluminum panel?

Add up the raw panel thickness, any coating (often 0.1–0.3 mm), and the washer stack. A 6.8 mm thread works for thin walls, but thicker housings usually require 13 mm or even 23 mm bulkheads. To avoid trial and error, try the panel stack calculator shown above.

When is a 2-hole or 4-hole flange better than a nut-tightened panel mount?

A 2-hole or 4-hole SMA flange connector distributes torque, maintains O-ring compression, and holds alignment under stress. A nut-tightened panel mount connector is cheaper but may loosen in vibration-prone or outdoor environments.

Will a bulkhead coupler add noticeable insertion loss at 6/18/26.5 GHz?

Not much. A quality SMA bulkhead adapter has ≤0.15 dB insertion loss at 6 GHz. At higher frequencies, the loss increases slightly but remains small compared to long coax runs.

Do stainless-steel bulkheads impact VSWR compared with brass-gold parts?

Yes. Stainless steel bulkheads are stronger and last ≥1000 cycles, but insertion loss is marginally higher. Brass with gold plating balances conductivity and durability, making it common in indoor gear.

What IP rating and O-ring compression should I target for outdoor installs?

Look for IP67-rated waterproof SMA bulkheads. O-rings should compress by 10–25% to seal correctly without being damaged.

How can I avoid RP-SMA vs SMA polarity mix-ups before purchase?

Double-check datasheet drawings. A quick glance at TEJTE’s shop SMA bulkhead connectors makes it easy to confirm gender and polarity before ordering.

Final Thoughts

An SMA bulkhead connector might look small, but it plays a big role in the reliability of an RF system. The right choice balances thread length, O-ring sealing, grounding method, and plating material. Specs like VSWR ≤1.20, insertion loss ≤0.15 dB at 6 GHz, and ≥500–1000 mating cycles aren’t just numbers on a datasheet—they’re the difference between passing compliance tests and surviving years in the field.

For indoor devices, a brass-gold bulkhead with a 6.8 mm thread may be enough. For outdoor or industrial equipment, a stainless-steel waterproof SMA bulkhead with a 13–23 mm thread and IP67 sealing provides extra security. The key is matching the connector not just to the circuit, but to the environment it will live in.

From experience, paying attention to the details upfront—like checking O-ring compression, verifying polarity, and using the right flange style—avoids costly rework later. To dive deeper into related topics, see the RF connector overview or explore how bulkheads integrate with custom RF adapter cables.

The takeaway: don’t underestimate the SMA bulkhead connector. With the right choice and correct installation, it becomes a rock-solid link that maintains RF integrity through thousands of cycles and years of service.

Bonfon Office Building, Longgang District, Shenzhen City, Guangdong Province, China

A China-based OEM/ODM RF communications supplier

Table of Contents

Owning your OEM/ODM/Private Label for Electronic Devices andComponents is now easier than ever.